EMTEST compact NX5 Series User manual

M a n u a l

F o r O p e r a t i o n

compact NX5

The ultra-compact simulator

and its system modules

compact NX5

Sys App 3.1.0.0 or higher

The compact NX5, whereby well understood NG says Next

Generation, is the most versatile tester to cover transient and

power fail requirements according to international standards

(basic and generic standards) and product family standards.

With the intuitive touch panel, the NX5 is the most economical

solution for tests during development as well as for full-

compliant immunity tests and CE Marking for single phase DUT

with the ability to be extended for testing three-phase DUTs by

means of an automatically controlled external coupling network

up to 200A.

EM TEST supplies a large range of accessories for the various

applications such as magnetic field tests and more.

EN/IEC 61000-4-4

EN/IEC 61000-4-5

EN/IEC 61000-4-8

EN/IEC 61000-4-9

EN/IEC 61000-4-11

EN/IEC 61000-4-12

EN/IEC 61000-4-29

EN 61000-6-1

EN 61000-6-2

Version:

1.06 / 10.01.2017

the benchmark for emc

Replaces:

1.05 / 30.09.2016

Filename:

UserManual-compact-NX 5-E-V1.06.doc

Printdate:

10.01.17

EM TEST Compact NX5

Operating Manual V 1.06 2 / 143

Exclusion for Documentation

Unless specifically agreed to in writing, AMETEK Compliance Test Solutions (AMETEK CTS):

(a) Makes no warranty as to the accuracy, sufficiency or suitability of any technical or other information provided

in its manuals or other documentation.

(b) Assumes no responsibility or liability for losses, damages, cost or expenses, whether special, direct, indirect,

consequential or incidental, which might arise out of the use of such information. The use of any such

information will be entirely at the user’s risk, and

(c) Reminds you that if this manual is in any language other than English, although steps have been taken to

maintain the accuracy of the translation, the accuracy cannot be guaranteed. Approved AMETEK content is

contained with English language version.

The present manual shows suggestions of test setups according to the standards IEC 61000-4-x using

equipment manufactured by EM TEST.

The suggestions do certainly not replace the standards! Variations due to different interpretations of the standard

are possible. The circuits shown in the figures supposed to illustrate the functional principles only and do not

show every single detail of the components.

Manual information

Version / date:

1.06 / 10.01.2017

Replaces:

1.05 / 30.09.2016

Filename:

UserManual-compact-NX 5-E-V1.06.doc

Printdate:

10.01.17

Contact Information

EM Test (Switzerland) GmbH

Sternenhofstrasse 15

4153 Reinach BL1

Switzerland

Phone : +41 61 717 91 91

Fax : +41 61 717 91 99

URL : http://www.emtest.com

Copyright © 2017 EM Test (Switzerland) GmbH

All right reserved.

Information in earlier versions. Specifications subject to change

EM TEST Compact NX5

Operating Manual V 1.06 3 / 143

Contents

1. General.............................................................................................................................6

1.1. Purpose ..............................................................................................................................................7

1.2. Warranty Terms..................................................................................................................................7

1.3. Product return procedure....................................................................................................................8

1.4. Recycling and Disposal ......................................................................................................................8

1.4.1. RoHS directive 2011/65/EU (RoHS 2) ...............................................................................................8

1.4.2. WEEE directive 2012/19/EU...............................................................................................................8

1.4.3. Dismantling information......................................................................................................................8

1.4.4. Parts which can be recycled...............................................................................................................8

1.4.5. Parts which cannot be recycled..........................................................................................................8

2. Safety information...........................................................................................................9

2.1. Intended use.......................................................................................................................................9

2.2. Responsibility of the operator.............................................................................................................9

2.3. General hazard...................................................................................................................................9

2.4. Qualification of personnel.................................................................................................................10

2.5. Safety label on the device ................................................................................................................10

2.6. Prohibition of unauthorized conversions and modifications .............................................................10

3. Installation put in service .............................................................................................11

3.1. Safety instructions for installation and initial installation ..................................................................11

3.1.1. Qualifications of the staff ..................................................................................................................11

3.1.2. Installation.........................................................................................................................................11

3.2. Installation of the compact NX5 system ...........................................................................................12

3.2.1. Unpacking.........................................................................................................................................12

3.2.2. Accessories ......................................................................................................................................13

3.2.3. Options .............................................................................................................................................13

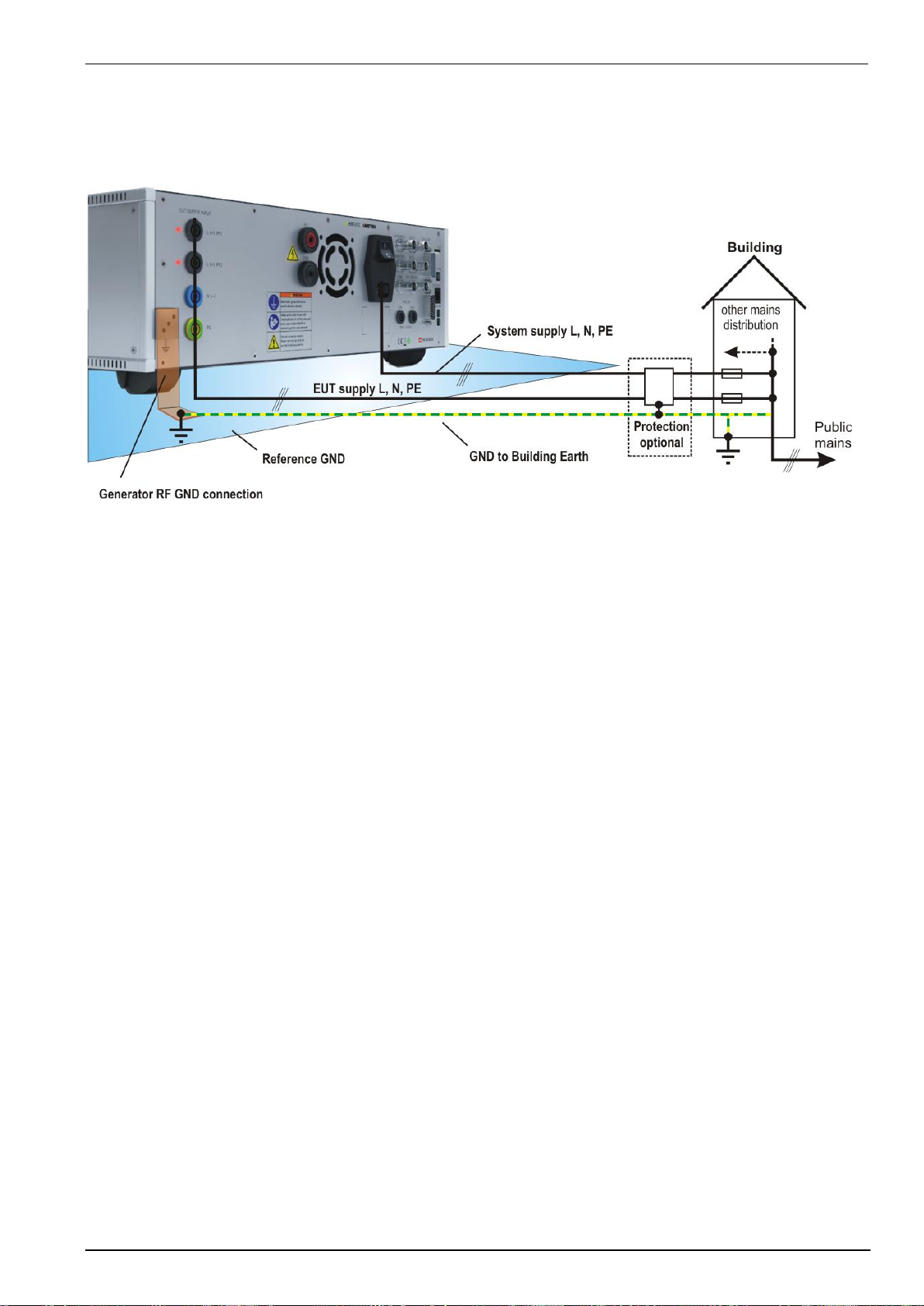

3.2.4. Grounding and power connection.....................................................................................................14

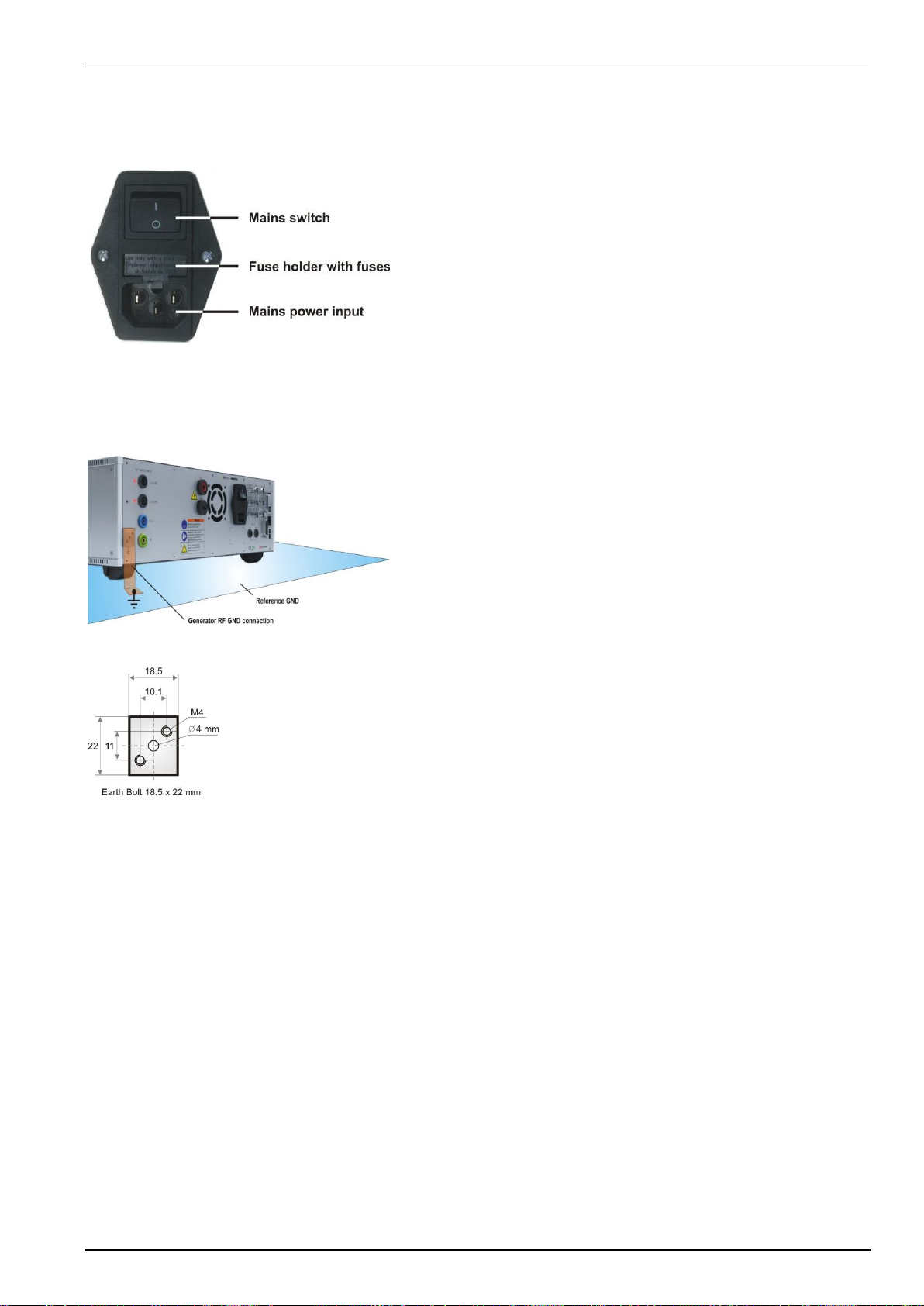

3.2.5. Mains Switch and fuse......................................................................................................................15

3.2.6. Connecting the compact NX5 system to the ground reference........................................................15

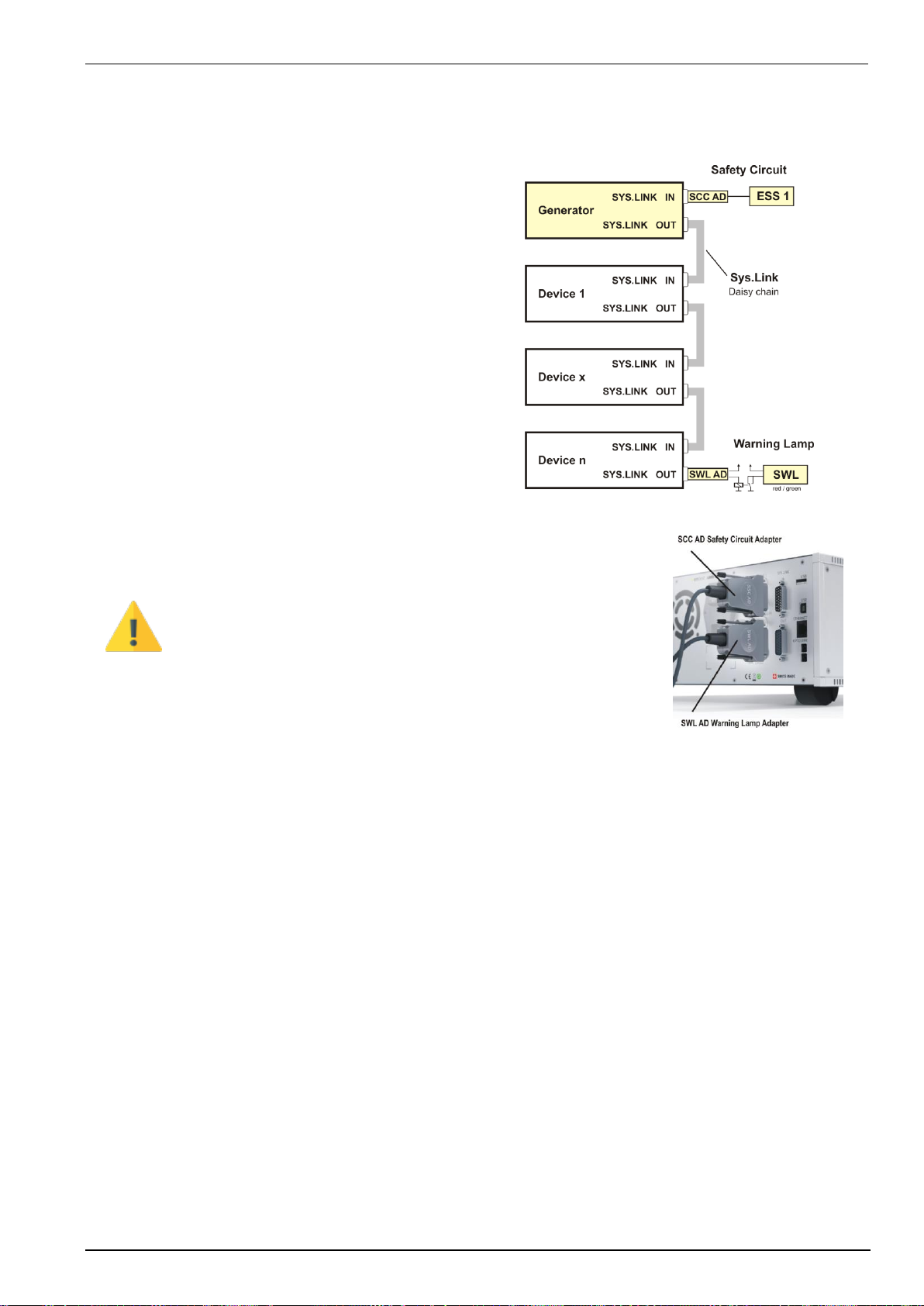

3.3. Safety circuit, Warning lamps...........................................................................................................16

3.3.1. Safety circuit.....................................................................................................................................17

3.3.2. Warning Lamp ..................................................................................................................................17

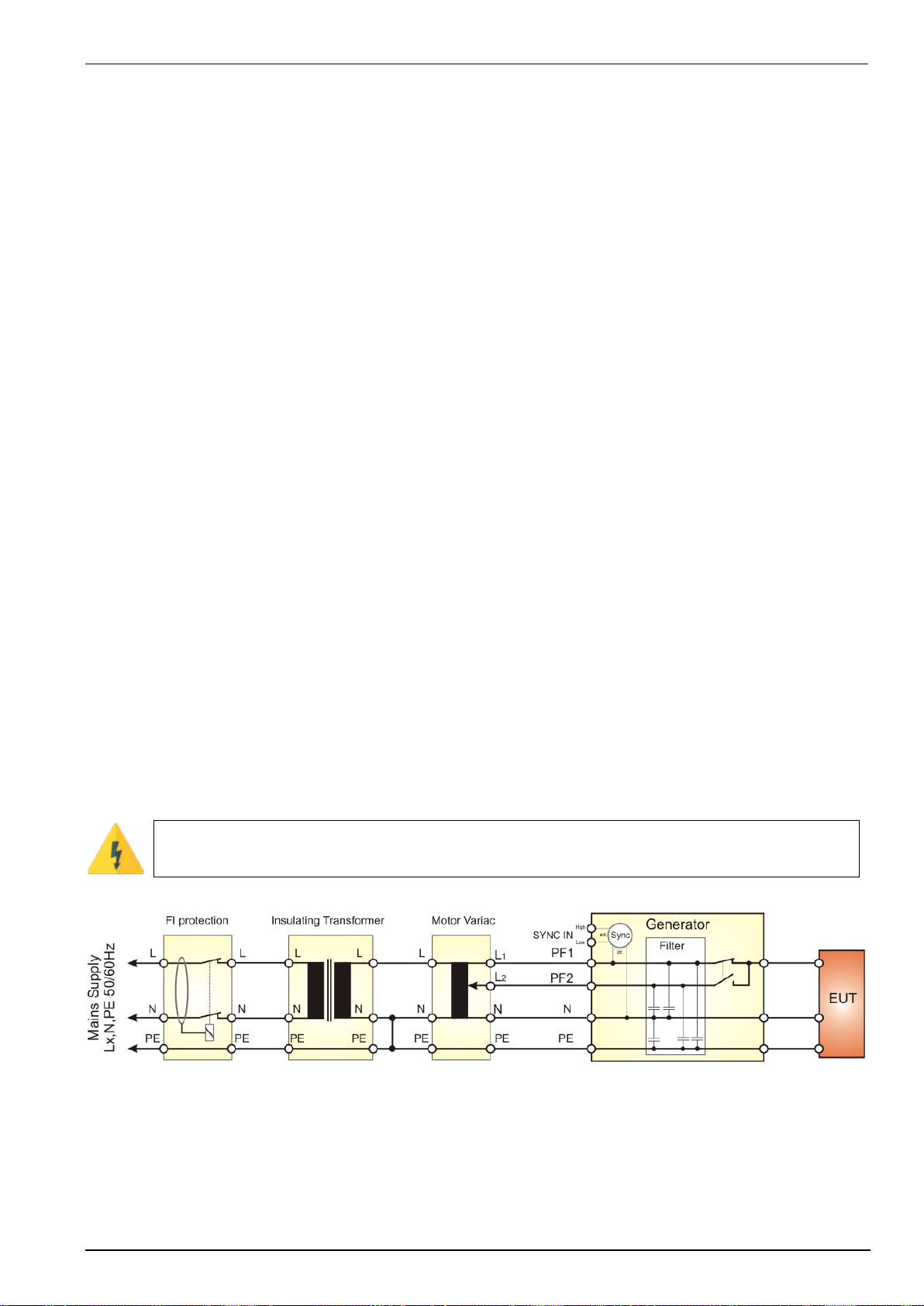

3.4. EUT Power supply and power switch...............................................................................................18

3.4.1. Notes on protective devices which need to install the operator .......................................................18

3.5. System configuration........................................................................................................................21

3.5.1. Power ON the compact NX5 generator............................................................................................21

3.5.2. Help ..................................................................................................................................................23

3.5.3. Software Number for IEC.control software license...........................................................................24

3.6. Software Update...............................................................................................................................25

3.6.1. Software Update new Version..........................................................................................................25

3.6.2. Software Update Install SysOS........................................................................................................28

3.6.3. Export actual settings .......................................................................................................................30

3.6.4. Import the settings............................................................................................................................32

3.6.5. Manual Firmware Update .................................................................................................................34

4. Design and Functions...................................................................................................36

4.1. Front view.........................................................................................................................................36

4.2. Rear view..........................................................................................................................................38

4.3. Menu description ..............................................................................................................................41

4.3.1. Main Menu........................................................................................................................................41

4.3.2. Menu Setting.....................................................................................................................................42

4.3.3. Test phenomena...............................................................................................................................43

4.3.4. Test and Run Window......................................................................................................................46

4.3.5. EUT Setup........................................................................................................................................49

4.3.6. Setup ................................................................................................................................................53

4.3.7. TEST Link.........................................................................................................................................60

4.3.8. Manager............................................................................................................................................60

4.3.9. Devices & Modules...........................................................................................................................60

4.3.10. Information........................................................................................................................................62

4.4. Service..............................................................................................................................................63

4.5. Variable voltage transformers adjustment procedure ......................................................................64

EM TEST Compact NX5

Operating Manual V 1.06 4 / 143

4.5.1. Adjustment procedure for variable transformers..............................................................................65

4.5.2. Adjustment procedure for tapped transformers with analogue DC control voltage..........................67

5. Test Equipment compact NX5 N ..................................................................................68

5.1. compact NX5....................................................................................................................................68

6. Technical data ...............................................................................................................69

6.1. EFT Electrical Fast Transients Burst as per IEC 61000-4-4...............................................................69

6.2. SURGE Immunity requirements as per IEC 61000-4-5 ...................................................................70

6.3. Pulsed magnetic Field as per IEC 61000-4-9...................................................................................71

6.4. Power Fail Generator as per IEC 61000-4-11..................................................................................72

6.5. EUT Supply Specifications ...............................................................................................................73

6.6. General Specifications......................................................................................................................73

6.7. Environmental conditions .................................................................................................................73

7. Maintenance setup and service ...................................................................................74

7.1. General.............................................................................................................................................74

7.2. Maintenance and cleaning................................................................................................................74

7.3. Test set- up.......................................................................................................................................74

7.4. Insulating- or external transformer for EUT power supply................................................................74

7.5. Calibration and verification...............................................................................................................75

7.5.1. Factory calibration ............................................................................................................................75

7.5.2. Guideline to determine the calibration period of EM Test instrumentation ......................................75

7.5.3. Calibration of Accessories made by passive components only: ......................................................75

7.5.4. Periodically In-house verification......................................................................................................75

8. Delivery Groups.............................................................................................................76

8.1. Basic equipment...............................................................................................................................76

8.2. Accessories and options...................................................................................................................76

9. EFT Burst as per IEC 61000-4-4 ...................................................................................78

9.1. Operation..........................................................................................................................................78

9.1.1. Quick Start........................................................................................................................................79

9.1.2. Standard test routines ......................................................................................................................80

9.1.3. Extended Test...................................................................................................................................81

9.1.4. Max Burst impulses / s .....................................................................................................................82

9.2. Burst Menu .......................................................................................................................................83

9.2.1. Configuration ....................................................................................................................................84

9.3. Burst generation ...............................................................................................................................87

9.4. Test level with Burst as per IEC 61000-4-4......................................................................................87

9.5. Coupling/decoupling network ...........................................................................................................88

9.5.1. Coupling/decoupling network for ac/dc power lines.........................................................................88

9.5.2. Capacitive coupling clamp................................................................................................................88

9.6. Burst Test Setup...............................................................................................................................89

9.6.1. Test setup with capacitive coupling clamp.......................................................................................90

10. Surge Immunity as per IEC 61000-4-5 .........................................................................91

10.1. Operation..........................................................................................................................................91

10.1.1. Quick Start........................................................................................................................................92

10.1.2. Standard test Routine.......................................................................................................................92

10.1.3. User Test Routines...........................................................................................................................94

10.2. Surge Menu......................................................................................................................................96

10.3. Surge pulse settings.........................................................................................................................97

10.3.1. Configuration ....................................................................................................................................97

10.3.2. Setup current peak limiter for surge current...................................................................................100

10.3.3. HV-COM output (18 µF capacitor)..................................................................................................101

10.4. Surge pulse application..................................................................................................................102

10.4.1. Phase synchronization in 3-phase system.....................................................................................102

10.4.2. Charging time for surge..................................................................................................................102

10.5. Surge pulse application..................................................................................................................103

10.6. Coupling/decoupling network .........................................................................................................103

10.6.1. Coupling to AC/DC power supply lines ..........................................................................................103

10.6.2. Coupling to I / O lines .....................................................................................................................104

10.7. Test set-up......................................................................................................................................104

EM TEST Compact NX5

Operating Manual V 1.06 5 / 143

11. Magnetic field test as per IEC 61000-4-9 ...................................................................105

11.1. Pulsed Magnetic field as per IEC 61000-4-9..................................................................................106

12. Voltage Dips and Interruptions as per IEC 61000-4-11 ............................................108

12.1. Test setup for DIPS and Interruption tests.....................................................................................108

12.2. Operation........................................................................................................................................110

12.2.1. Quick Start......................................................................................................................................111

12.2.2. Standard Test Routines..................................................................................................................112

12.2.3. Extended Tests...............................................................................................................................113

12.3. Voltage Variation ............................................................................................................................114

12.4. Power Fail Menu.............................................................................................................................115

12.5. The Power Fail Test .......................................................................................................................116

12.5.1. Test routines termination................................................................................................................116

12.5.2. Operating........................................................................................................................................116

12.6. Overcurrent.....................................................................................................................................117

12.7. The Power Fail Test .......................................................................................................................118

12.7.1. Voltage Interruptions ......................................................................................................................118

12.7.2. Voltage dips, voltage variations......................................................................................................119

12.8. DC Power networks........................................................................................................................119

12.9. Test setup and accessories............................................................................................................120

12.9.1. Transformer type V4780.................................................................................................................120

12.9.2. Variable Transformer variac NX1-260-16.......................................................................................122

13. Power frequency Magnetic Field as per IEC 61000-4-8............................................124

13.1. Magnetic field as per IEC 61000-4-8..............................................................................................125

14. Telecom Surge Immunity as per IEC 61000-4-5........................................................128

14.1. Operation........................................................................................................................................128

14.1.1. Quick Start......................................................................................................................................129

14.1.2. Standard test Routine.....................................................................................................................129

14.1.3. Extended Test Routines .................................................................................................................130

14.1.4. Generator Network for Telecom Surge ..........................................................................................131

14.2. Telecom Surge Menu .....................................................................................................................132

14.3. Telecom Surge pulse settings........................................................................................................132

14.3.1. Configuration ..................................................................................................................................132

15. Report...........................................................................................................................135

15.1. Block diagram for report generation...............................................................................................135

15.1.1. Safe a report after the test..............................................................................................................135

15.2. Report setting .................................................................................................................................136

15.3. Report Export..................................................................................................................................137

16. Appendix......................................................................................................................138

16.1. Declaration of CE-Conformity.........................................................................................................138

16.1.1. CE-Conformity compact NX5 .........................................................................................................138

16.1.2. CE-Conformity V4780.....................................................................................................................139

16.1.3. CE-Conformity V4780.....................................................................................................................140

16.2. compact NX5 General Diagram......................................................................................................141

16.3. Main diagram control connection....................................................................................................141

16.4. Main diagram high voltage connection...........................................................................................143

EM TEST Compact NX5

Operating Manual V 1.06 6 / 143

1.

General

The following manual is based on the following or later firmware:

Available Generators

Compact NX Family

Burst

Surge

Power Fail

Telecom Surge

16 A models

compact NX5 bsp-1-300-16

X

X

X

compact NX5 bst-1-300-16

X

X

X

compact NX5 bspt-1-300-16

X

X

X

X

compact NX5 bs-1-300-16

X

X

compact NX5 bp-1-300-16

X

X

compact NX5 sp-1-300-16

X

X

compact NX5 st-1-300-16

X

X

compact NX5 b-1-300-16

X

compact NX5 s-1-300-16

X

32 A models

compact NX5 bspt-1-300-32

X

X

X

X

compact NX5 bsp-1-300-32

X

X

X

compact NX5 bst-1-300-32

X

X

X

compact NX5 bs-1-300-32

X

X

compact NX5 bp-1-300-32

X

X

compact NX5 sp-1-300-32

X

X

compact NX5 st-1-300-32

X

X

compact NX5 b-1-300-32

X

compact NX5 s-1-300-32

X

compact NX5 p-1-300-32

X

EM TEST Compact NX5

Operating Manual V 1.06 7 / 143

1.1.

Purpose

The compact NX5 test system is a multifunction compact generator that simulates conducted electromagnetic

interference effects for immunity testing according to international, national, and manufacturers’standards.

The system is designed for full compliance conducted electromagnetic compatibility (EMC) test requirements.

The application range is for testing of industrial, light industrial, household or commercial equipment, including

many product family and product standards as per following basic standards

- IEC 61000-4-4

EFT / Burst

- IEC 61000-4-5

Surge

- IEC 61000-4-8

50/60Hz Magnetic Field

- IEC 61000-4-9

Pulse Magnetic Field

- IEC 61000-4-11

Voltage Dips, Voltage Interruptions for ac power mains supply

- IEC 61000-4-29

Voltage Interruptions

Voltage Dips for dc power supply systems

1.2.

Warranty Terms

EM TEST provides this written warranty covering the product stated above, and if the buyer discovers and

notifies EM TEST in writing of any defect in material or workmanship within the applicable warranty period stated

above, then EM TEST may, at its option: repair or replace the product; or issue a credit note for the defective

product; or provide the buyer with replacement parts for the product.

The buyer will, at its expense, return the defective product or parts thereof to EM TEST in accordance with the

return procedure specified below. EM TEST will, at its expense, deliver the repaired or replaced product or parts

to the buyer. Any warranty of EM TEST will not apply if the buyer is in default under the purchase order

agreement or where the product or any part thereof:

is damaged by misuse, accident, negligence or failure to maintain the same as specified or required by

EM TEST;

is damaged by modifications, alterations or attachments thereto which are not authorized by EM TEST;

is installed or operated contrary to the instructions of EM TEST;

is opened, modified or disassembled in any way without EM TEST’s consent; or

is used in combination with items, articles or materials not authorized by EM TEST.

The Buyer may not assert any claim that the products are not in conformity with any warranty until the buyer has

made all payments to EM TEST provided for in the purchase order agreement.

EM TEST Compact NX5

Operating Manual V 1.06 8 / 143

1.3.

Product return procedure

1. Request a Return Material Authorization (RMA) number from the local EM TEST representative

2. When requesting an RMA, have the following information ready:

- Model number

- Serial number

- Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by EM TEST, to be in specification is subject to an

evaluation fee and applicable freight charges.

1.4.

Recycling and Disposal

1.4.1.

RoHS directive 2011/65/EU (RoHS 2)

RoHS directive 2011/65/EU (RoHS 2)

The EM TEST compact NX5 series generator complies with the directive 2011/65/EU (RoHS - Restriction of

certain Hazardous Substances).

From December 2005, all EM TEST products either hand soldered or by machine are produced using lead-free

solder.

1.4.2.

WEEE directive 2012/19/EU

The EM TEST compact NX5 serie generator, is dedicated under category 9 in the directive 2012/19/EU (WEEE).

The product should be recycled through a professional organization with appropriate experience for the disposal

and recycling of electronic products. EM TEST is also available to help with questions relating to the recycling of

this equipment.

1.4.3.

Dismantling information

Always remove power cord first. There is no special danger involved in dismantling the compact NX5

1.4.4.

Parts which can be recycled

The NX5 generator contains parts made from steel, aluminum, PVC, two-component sealing compound. The

impulse capacitors are filled with non-poisonous mineral oil. The various parts can be separated and recycled.

1.4.5.

Parts which cannot be recycled

All parts in the compact NX5 series can be recycled.

EM TEST Compact NX5

Operating Manual V 1.06 9 / 143

2.

Safety information

Attention

Before using this equipment, read the operating manual and the

separate delivered safety manual carefully

2.1.

Intended use

The “compact NX5” test system is designed primarily for conducted transient interference tests as specified in the

European generic standards IEC/EN 61000-6-1 to cover equipment for household, office and light industrial use,

and IEC/EN 61000-6-2 for applications in industrial environments. The “compact NX5” generates these tests in

accordance with IEC/EN 61000-4-4, -4-5, -4-11, -4-18 and -4-29, depending of the model configuration.

Accessories are available for generating optional tests to IEC/EN 61000-4-8 and -9.

The EMC Directive 2014/30/EU (for the assignment of the CE mark) refers to these standards and to this type of

equipment.

2.2.

Responsibility of the operator

These operating instructions form an essential part of the equipment and must be available to the operator at all

times. The user must obey all safety instructions and warnings.

WARNING

The purpose of this instrument is the generation of defined interferences signals for EMI

immunity testing. Depending on the arrangement of the test rig, the configuration, the

cabling and the properties of the EUT itself, a significant amount of electromagnetic

radiation may result that could also affect other equipment and systems.

The equipment is designed to operate in industrial environment. For operating in other or

sensitive environment, such as light industry, airport area…, the user may use a shielded

room for operate.

The user himself or herself is ultimately responsible for the correct and controlled operation

of the rig. In case of doubt, the tests should be carried out in a Faraday cage.

2.3.

General hazard

Before applying power to the system, verify that your product is configured properly for your particular application.

WARNING

The Compact NX5 system and its accessories operate at high voltages.

Hazardous voltages may be present when covers are removed. Qualified personnel must

use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above (below) chassis

ground.

Only qualified personnel who deal with attendant hazards in impulse generators, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or chassis.

Similarly, other power ground lines including those to application and maintenance equipment must be grounded

properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any cable.

The user must ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

EM TEST Compact NX5

Operating Manual V 1.06 10 / 143

Guard against risks of electrical shock during open cover checks by not touching any portion of the electrical

circuits. Even when power is off, capacitors may retain an electrical charge. Use safety glasses during open

cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK CTS, or EM TEST (Switzerland) GmbH, nor any of the subsidiary sales organizations can

accept any responsibility for personnel, material or inconsequential injury, loss or damage that results from

improper use of the equipment and accessories.

WARNING Personnel fitted with a heart pacemaker must neither operate

the instrument nor approach the test setup while a test is being

executed.

Only approved accessories, connectors, adapters, etc. are to be used to ensure safe operation.

2.4.

Qualification of personnel

The compact NX5 must be operated only by authorized and trained specialists.

2.5.

Safety label on the device

Please take note of the following explanations of the symbols used in order to achieve the optimum benefit from

this manual and to ensure safety during operation of the equipment.

This symbol warns of a potential risk of shock hazard. The symbol on an instrument

shows that that it can source 1000 volt or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid

personal contact with these voltages.

This symbol indicates where a caution is required. Refer to the operating instructions

located in the manual in order to protect against personal injury or damage the

equipment.

CAUTION

The CAUTION symbol indicates a potential hazard. It calls attention to a procedure,

practice or condition which, if not followed, , could possibly cause damage to

equipment. Such damage may invalidate the warranty. If a CAUTION is indicated, do

not proceed until its conditions are fully understood and met.

WARNING

The WARNING symbol indicates a potential hazard. It calls attention to a procedure,

practice or condition which, if not followed, could possibly cause bodily injured or

death. If a WARNING is indicated, do not proceed until its conditions are fully

understood and met.

2.6.

Prohibition of unauthorized conversions and modifications

The user is not entitled to the device to perform its own modifications and adaptations. Modifying parts on the

generator by unauthorized persons will void the warranty of the device and the correct functioning cannot be

guaranteed.

EM TEST Compact NX5

Operating Manual V 1.06 11 / 143

3.

Installation put in service

This chapter includes a checklist with steps that should be taken before the compact NX5 generator is switched

on and put into operation.

3.1.

Safety instructions for installation and initial installation

National regulations in installation and operation of electrical equipment must be respected.

WARNING The compact NX5 test system is not suitable for use in an explosive atmosphere.

WARNING Connect the EUT only after the initial system setup has finished.

3.1.1.

Qualifications of the staff

Basic knowledge of electrical engineering and electromagnetic compatibility is required to service the unit. The

national regulations for installation of electrical equipment as well as the safety at work of electrical equipment

must be known to the user.

3.1.2.

Installation

The Compact NX5 system conforms to protection class 1. Local installation regulations must be respected to

ensure the safe flow of leakage currents.

WARNING Operation without a ground connection is forbidden!

Two independent ground connections are necessary - one for the test system and one for the EUT. These must

be connected back to the local permanent installation or to a fixed, permanent ground conductor.

Operate the equipment only in dry surroundings. Any condensation that occurs must be allowed to evaporate

before putting the equipment into operation. Do not exceed the permissible ambient temperature or humidity

levels. Use only officially approved connectors and accessory items.

Ensure that a reliable return path for the interference current is provided between the EUT and the generator.

The ground reference plane and the ground connections to the instruments, as described in the relevant test

standards, serve this purpose well.

The test system may only be opened by a qualified specialist upon specific instruction given by the manufacturer.

The equipment works, on principle, with two independent power supplies, one for the generator and one for the

EUT. The compact NX5 must be disconnected from both sources before any modifications to the test setup are

undertaken. Besides the mains connections themselves, certain components also operate at high voltages, and

are not provided with any form of extra protection against accidental contact.

The system complies with the safety requirements of IEC/EN 61010-1 (Safety requirements for electrical

equipment for measurement, control and laboratory use).

It is the user’s responsibility to ensure that the test rig does not emit excessive electromagnetic interference (EMI)

that might affect other equipment. The test system itself does not produce any excessive radiation; however, the

injection of interference pulses into the EUT can result in the device and/or its associated cables radiating EMI.

To avoid radiating unwanted interference the standards organizations recommend that the test setup be located

in a Faraday cage.

Since the purpose of the test system is to produce interference signals for interference immunity testing, the

requirements in the IEC/EN 61000 series concerning limiting the radiated EMI can only be complied with by

operating the test system inside a Faraday cage.

EM TEST Compact NX5

Operating Manual V 1.06 12 / 143

3.2.

Installation of the compact NX5 system

3.2.1.

Unpacking

Check the packaging for signs of damage in transit. Any damage should be reported immediately to the

transportation company and the local representative.

Lift the compact NX5 test system out of its packaging. Place the test system so that there is sufficient free space

around the cooling air inlets on both sides and behind the fan outlet on the rear panel.

NOTE Do not dispose of packaging materials. All packaging should be retained in the event that the instrument or any

of its accessories should need to be returned to a EM TEST service center for repair or calibration.

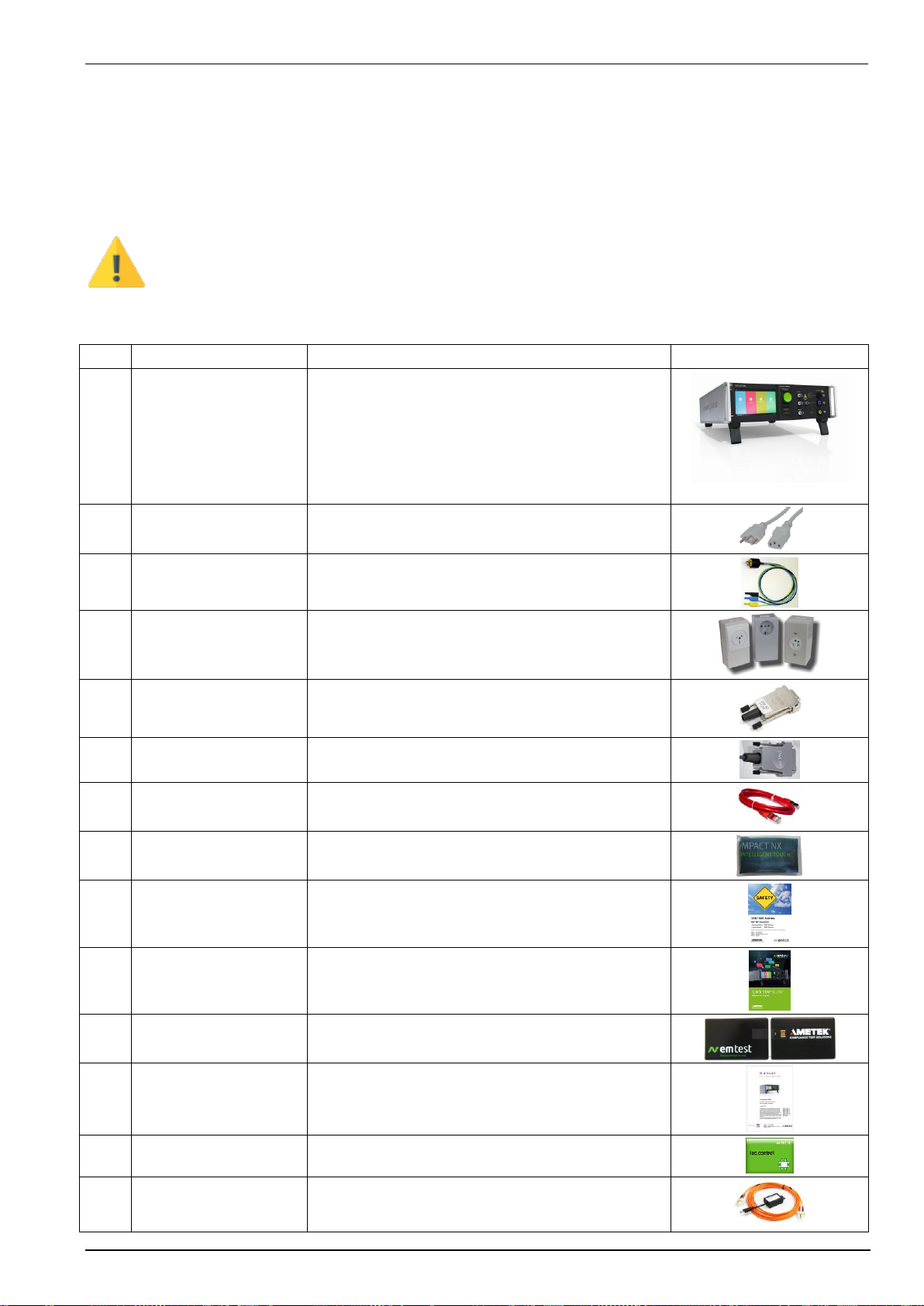

Using the following list, check that all the items ordered have been delivered:

Item

Name

Remark

Picture

1

Compaxt NX5

Compact NX5 generator including

- Single phase coupling network 300 V / 16 A

Including ordered Modules

- Burst Module

- Surge Module

- Power Fail Module

- Telecom Surge Module

2

Power Mains cable

Power Mains cable

- Connectors country coded

3

ESC

EUT Supply Cable

- Connectors country coded

4

ESA1

EUT Supply Adapter

- Connectors country coded

5

SCC AD

Safety Circuit Adapter (Sys. Link)

Short circuit for Interlock

6

SWL AD

Warning Lamp Adapter

7

Ethernet cable

Ethernet crossover network cable

RJ45, Cat 6, SF/UTP, red

8

Cleaning tissue

9

Safety Manual

Safety Manual

200 / 500 /NX Series

10

Quick Start Guide

Quick Start Guide

Compaxt NX –English or German

11

USB Memory card

Files on USB Memory card

12

User Manual

User manual (pdf on the memory card)

13

Iec.control Software

Software iec.control, (on the memory card)

14

Software license

If ordered on a license sheet

- UOC Optolink Converter USB to LWL

- Optical fiber cable 5m

EM TEST Compact NX5

Operating Manual V 1.06 13 / 143

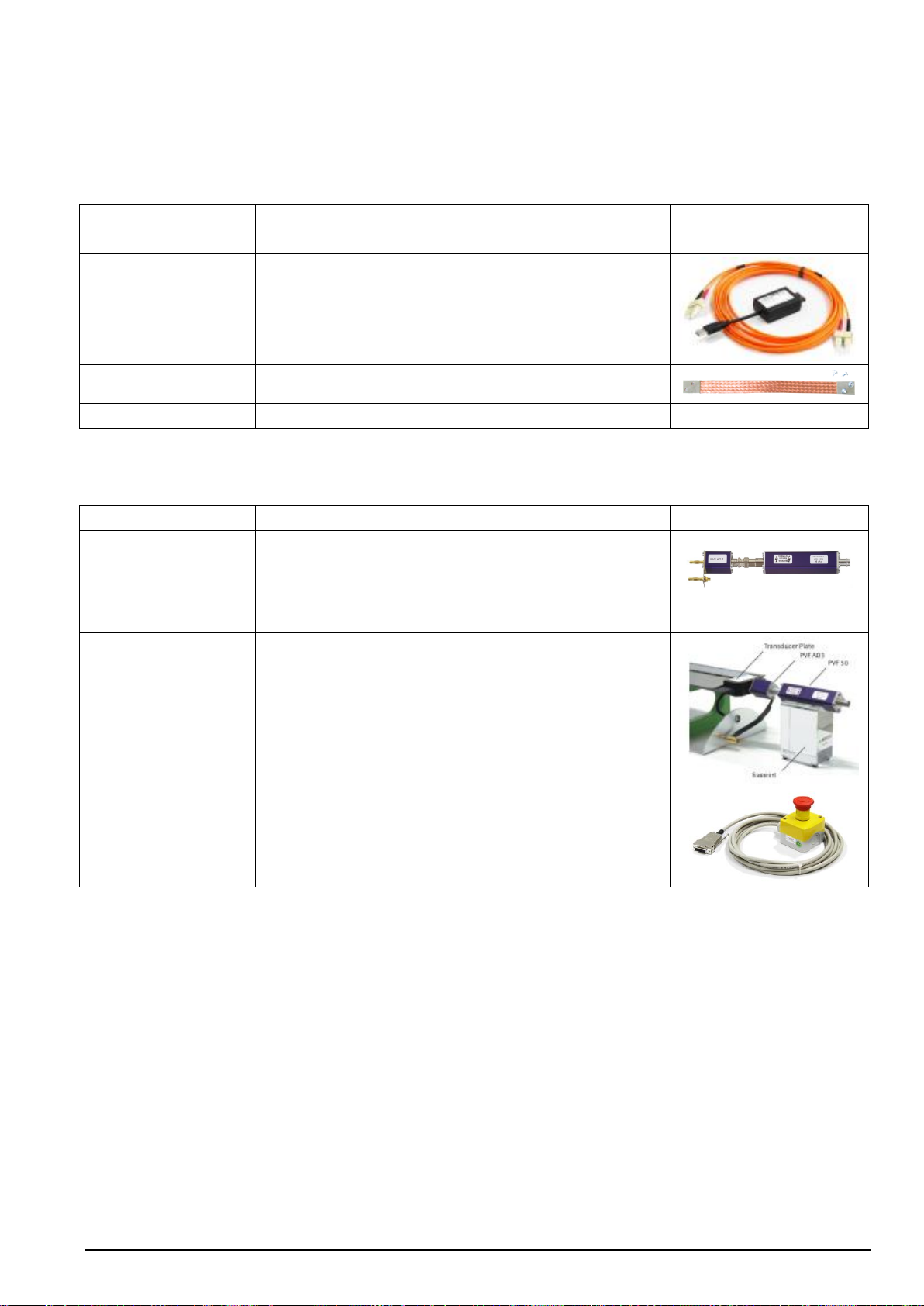

3.2.2.

Accessories

If additional equipment is ordered refer to the user manual of these devices

Name

Remark

Picture

SLC xxx

Sys Link Cable with various cable length

UOC

USB Optolink Converter (USB to LWL)

Optical Fiber cable, 5m

Remark:

The USB Optolink is included in the software license

Copper braid

Earh band connection NX-generator to coupling NX,

Dimension: 300 x 23 mm, 25mm2, 4 x Screws M4 x 10mm

3.2.3.

Options

Name

Remark

Picture

PVF BKIT 1

Pulse Verification Fast Burst Kit 1

PVF 50, Pulse Verification Fast 50 Ohm

PVF 1000, Pulse Verification Fast 1000 Ohm

PVF AD 1 Pulse Verification Fast Adapter 1 –

Multi Contact (MC) to SHV fix

PVF AD1 PVF 50 or

PVF 1000

ICC PVKIT 1

Industrial Capacitive Coupling Clamp

Pulse Verification Kit 1

Transducer plate

Support

PVF AD3 Pulse Verification Fast Adapter 3 –

MC to SHF

ESS 1

ESS 1 Interlock for NX5 system

Switches OFF High voltage and EUT power supply

EM TEST Compact NX5

Operating Manual V 1.06 14 / 143

3.2.4.

Grounding and power connection

Two independent ground connections are necessary- one for the test system and one for the EUT. These must

be connected back to the local permanent installation or to a fixed, permanent ground conductor. To avoid

electric shock the power cord protective grounding conductor must be connected to ground.

System GND

The system is connected to GND via the earth wire of the connected mains power cable for the generator and the

EUT supply. A separate GND wire from the reference GND plane to the building earth point may be useful to

avoid interferences to other areas.

EUT GND

Ensure that a reliable return path for the interference current is provided between the EUT and the generator.

The GND wire from the generator to the reference GND and must be designed as a low inductance connection

suitable for high frequencies. The reference ground plane and the ground connections to the instruments, as

described in the relevant test standards, serve this purpose well.

Protection (optional)

A proposal is to separate protection of the EMC system with filters, insulation transformer or fault current

protection and other measures may be useful for the EMC installation. The advantage is the separation of the

EMC system from all other installation.

A shielded room with adequate filters may be the best solution for avoid unwanted conducted and radiated

interference to other areas.

EM TEST Compact NX5

Operating Manual V 1.06 15 / 143

3.2.5.

Mains Switch and fuse

The mains power voltage indicated on the instrument must correspond with the local supply voltage (mains

voltage: 85–265 Vac, universal power unit, mains frequency: 50–60 Hz).

Mains Switch, fuse holder and power input

To replace a fuse:

1) Disconnect the mains cable

2) Pull the fuse holder out of the connector

3) Remove the damaged fuse(s)

4) Insert 1 or 2 fuses (4 A / 115V and 2 A / 230 V slow blow)

5) Replace the fuse holder

6) Plug the mains cable into a power outlet with a solid ground

connection

7) Switch the system on and operate as instructed in this manual

3.2.6.

Connecting the compact NX5 system to the ground reference

Connection to reference ground

Connection to reference ground

For burst tests, the generator must be placed on a ground

reference plane which is connected to ground.

A low inductive high frequency ground connection between the

test system and the ground reference plane (GRP) is absolutely

essential for performing burst tests correctly.

Earth bolt dimension

Earth bolt dimensions:

Screws: Metric M4 ,

Distance: 10.1 mm x 11 mm

Plug: Banana plug, 4 mm

EM TEST Compact NX5

Operating Manual V 1.06 16 / 143

3.3.

Safety circuit, Warning lamps

Safety circuit and warning lamps are located at each end of the Sys Link. Each End of the Sys.Link is terminated

with an adapter.

Safety circuit

Plug position: SYS.LINK IN Compact NX generator

Connector: 2 screw contacts IN, OUT

Pin Sys Link: 7, 16

Operating: short circuit closed = operation

short circuit open = no operation

Voltage level: 24 Vdc (internal powered)

Warning Lamp

Plug position: SYS.LINK OUT Last device from daisy chain

Connector: 2 screw contacts IN, OUT

Pin Sys Link: 8, 17

Operating: Potential free contact

open = System is out of operation (green)

closed = System is operating (red)

Voltage level: 60 V, max. 2 A (external powered)

IMPORTANT

Important for operation

Connect the delivered Safety Circuit adapter SCC AD to

the SYSLINK plug.

The compact NX generator does not start any test if the safety

circuit is not connected and closed.

NOTE: The short circuit is already short-circuited at the

delivered Safety circuit adapter SCC AD.

EM TEST Compact NX5

Operating Manual V 1.06 17 / 143

3.3.1.

Safety circuit

The safety circuit locks the system and enables the

generation of the high voltage impulses in the

generators.

Design

Each device that has internal relevant high voltage

unit, includes a safety circuit. The safety circuit works

like an “open collector circuit”, where the external

safety loop must be closed for switch on the high

voltage.

Safety circuit closed

The device will generate high voltage pulses after start

Safety circuit open

The device will switch off the high voltage and

discharges the high voltage circuit

3.3.2.

Warning Lamp

The warning lamp offers a voltage free contact that

indicates the status of the generator system.

Design

Each device with warning lamp function can short

thewarning lamp contact. An external powered relays

max. 60 V / 2 A controls the lamp. The user is

responsible for the warning lamp power supply

Warning Lamp switch closed (red):

- Safety circuit is closed and

- TEST ON is on

Status:RED Lamp, Power on EUT output,

High voltage can be “ switched ON”

Warning Lamp switch opened (green):

- Safety circuit is open and / or

- TEST ON is off

- Generator is switched off

Status:GREEN Lamp, no danger, High voltage is off

EM TEST Compact NX5

Operating Manual V 1.06 18 / 143

3.4.

EUT Power supply and power switch

The EUT input should be connected through a properly rated power switch device, which should be located close

to the test setup. In order to ensure easy and quick access to the EUT power, the switch should be clearly and

visibly labeled as “EUT power ON/OFF”.

The in-house power distribution must be equipped with a proper circuit breaker and an emergency off button as

per IEC 61010-1:2001.

Dimensioning of the mains supply and rating of fuse protection of the AC or DC power supply must conform with

local electrical codes and EUT requirements. Inappropriate arrangement, mounting, cabling or handling of the

EUT or ground can reduce or negate the effectiveness of the compact NX5’s safety features.

3.4.1.

Notes on protective devices which need to install the operator

There are two different protective devices in a mains distribution system for safe operation.

A Fault current protection: A residual-current device (RCD), or residual-current circuit breaker (RCCB)

is an electrical wiring device that disconnects a circuit whenever it detects that

the electric current is not balanced between line and the return neutral. In

normal circumstances, these two wires are balanced, and any difference

current usually indicates a short circuit or other electrical anomaly like a surge

impulse is present.

B Circuit breaker protection: A circuit breaker is an electrical switch designed to protect an electrical

circuit by overload or short circuit. Its basic function is to detect a fault

condition and interrupt current flow.

3.4.1.1.

Fault current protection

The standards recommend decoupling and filter capacitors to PE for decoupling surge pulses. This is the reason

for tripping fault current protection relays that interrupt the mains to the EUT supply. For eliminate the

circumstance use one of the following options:

Remove the fault current protection

This solution does not limit the current to PE. The surge test as other EMC tests with higher currents to PE are

possible. The user must take care to the circuit with no fault current protection. Only trained professional people

are allowed to perform such tests. Some countries do not allow to operate without fault current protection.

Using of insulating transformers

An insulating transformer separates the circuit from the test circuit. The Fault current detector (FI protection)

cannot detect the earth current in the EUT circuit.

The fault current safety detection function in the generator circuit is disabled. The user must respect

this circumstance. For a safe operation he must follow the electrical rulers.

Behind the insulating transformer the neutral and PE must be connected for a proper phase synchronization of

the generator. In case of a 3-phase system the user must perform similar.

EM TEST Compact NX5

Operating Manual V 1.06 19 / 143

3.4.1.2.

Fuses for EUT with smaller nominal currents

The EM Test pulse generators have no built in fuse for the EUT power supply. It is in the scope of responsibility

of the user to protect the EUT external for the rated current.

The design of the external fuse must be match the following rules:

- fuse dimension must be equal or smaller than the rated EUT current of the connected test

generator

- fuse must be designed for protect the connected EUT device under test in malfunction

Example of external circuit breaker

Circuit breakers in the building are designed for 32 A. A circuit breaker box with 16 A protection is

installed between the building supply and the test generator.

Test generator and EUT are now fused for 16 A rated current

EM TEST Compact NX5

Operating Manual V 1.06 20 / 143

3.4.1.3.

Phase indicator

The phase indication shows the correct connection of the supply to Phase and Neutral input of the compact

NX5. For the generator hardware both, L and N paths are potential free and a reverse connection is not relevant

for the generator operation.

For EUT where it is important that phase and neutral are correct, the LED indication shows the correct phase

connection.

Phase indication

1 compact NX5 generator

2 EUT supply may be a

- direct supply from building or via a

- tapped or variac transformer

3 Phase indication LED illuminated

4 Phase indication LED inactive

Remark: The phase synchronization signal taken

from the L path.

The table below shows all combinations with correct (OK) and incorrect (Fail) supply connections

Type A

Supply to PF1, L, PE

Type B

Supply to PF1, PF2, L, PE

Type C

Supply to PF2, L, PE

This manual suits for next models

7

Table of contents

Other EMTEST Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

VWR

VWR Powerpette Pro instruction manual

Owen Mumford

Owen Mumford Autoject 2 Instructions for use

vitro

vitro MD STAINER QUICK GUIDE TO TECHNICAL INSTRUCTIONS FOR USE AND CLEANING

Agilent Technologies

Agilent Technologies N2727A installation guide

Agilent Technologies

Agilent Technologies Intuvo 900 Safety manual

WEPA

WEPA TopiTec Automatic operating manual