EMTEST CWS 500D User manual

Manual

for Operation

Continuous Wave Simulator

Type CWS 500D

Compact RF simulator for BCI, Stripline and TEM cell

applications. 10kHz – 400MHz ( 1000MHz)

The CWS500D is the state of the art solution in a

compact one-box design to test immunity to

conducted disturbances induced by radio frequency

fields. The CWS500D includes signal generator, RF

amplifier directional coupler, 3 channel power meter,

software and GPIB interface.

The integrated amplifier can also be controlled by an

external signal generators. ICD software supports the

test routines and controls external measuring

devices.

C

•ISO 11452 part 4

•ISO 11452 part 5

•RTCA DO 160D

•Mil 461 CS 114

•EN/IEC 61000-4-6

•various automotive

manufacturer’s

specifications

Version: 1.07 / 18.01.2007

emc test equipment Replaces: 1.06 / 28.06.2006

Filename: manual CWS500D V107.doc

Printdate: 18.01.07

EM Test CWS500 D

User manual V 1.07 2 / 34

Contents

1. Safety Aspects ..........................................................................................................................................3

2. Setup the CWS 500D ................................................................................................................................3

2.1. Connections CWS 500D ...........................................................................................................................3

2.2. Test Setup CWS 500D..............................................................................................................................3

2.3. Part Identifications and Functions.............................................................................................................4

2.3.1. Clamp Applications for Automotive standards ..........................................................................................4

2.3.2. CDN Applications as per IEC 61000-4-6 ..................................................................................................5

3. Operating Functions.................................................................................................................................6

3.1. Front View .................................................................................................................................................6

3.2. Rear view CWS 500D 400MHz model......................................................................................................7

3.3. Rear view CWS 500D 1GHz model ..........................................................................................................8

4. Front Panel Operation ..............................................................................................................................9

4.1. Basic Operations.......................................................................................................................................9

4.2. Quickstart ................................................................................................................................................10

4.2.1. Quickstart during instrument calibration..................................................................................................11

4.3. Display during Remote control ................................................................................................................12

4.3.1. Modulation...............................................................................................................................................13

4.4. Service ....................................................................................................................................................14

4.4.1. Adresses .................................................................................................................................................14

4.4.2. Setup .......................................................................................................................................................15

4.4.3. Amplifier Switch.......................................................................................................................................15

5. Starting Operation ..................................................................................................................................16

5.1. Safety Aspects ........................................................................................................................................16

5.2. Generator Function Check ......................................................................................................................17

5.3. Function Check internal Powermeter......................................................................................................18

5.4. Function Check amplifier switch ( 1GHz model only) .............................................................................19

5.5. Calibration ...............................................................................................................................................20

5.5.1. Calibration Setup for Bulk Current Injection Clamp (BCI) as per ISO / DO / MIL ...................................20

5.5.2. Calibration Setup EM TEST and IEC 61000-4-6 ....................................................................................21

5.5.3. Calibration Setup with CDN ....................................................................................................................22

5.5.4. Calibration Setup with EM Clamp ...........................................................................................................23

5.6. Failure Input ............................................................................................................................................23

6. Test Equipment CWS 500D....................................................................................................................24

6.1. Control Unit .............................................................................................................................................25

6.2. Generator Unit.........................................................................................................................................25

6.3. High frequency Power Unit .....................................................................................................................25

6.4. 3dB Attenuator ........................................................................................................................................25

6.5. CDN Coupling/ Decoupling Network.......................................................................................................26

6.6. Test Setup with CDN’s ............................................................................................................................27

6.7. Test Setup with the Current Monitor .......................................................................................................28

6.8. Test Level and Modulation ......................................................................................................................28

7. Technical Data.........................................................................................................................................29

8. Maintenance ............................................................................................................................................31

8.1. General....................................................................................................................................................31

8.2. Calibration and verification......................................................................................................................31

8.2.1. Factory calibration ...................................................................................................................................31

8.2.2. Guideline to determine the calibration period of EM Test instrumentation .............................................31

8.2.3. Calibration of Accessories made by passive components only: .............................................................31

8.2.4. Periodically In-house verification.............................................................................................................31

9. Delivery Groups ......................................................................................................................................32

9.1. Basic equipment......................................................................................................................................32

9.2. Options and Accessories ........................................................................................................................32

10. Appendix..................................................................................................................................................33

10.1. Blockdiagram ..........................................................................................................................................33

10.2. Declaration CE- Conformity ....................................................................................................................34

EM Test CWS500 D

User manual V 1.07 3 / 34

1. Safety Aspects

+

Before using the CWS 500 D read the following manuals carefully :

- Safety requirements manual

- Manual for operation CWS 500D

2. Setup the CWS 500D

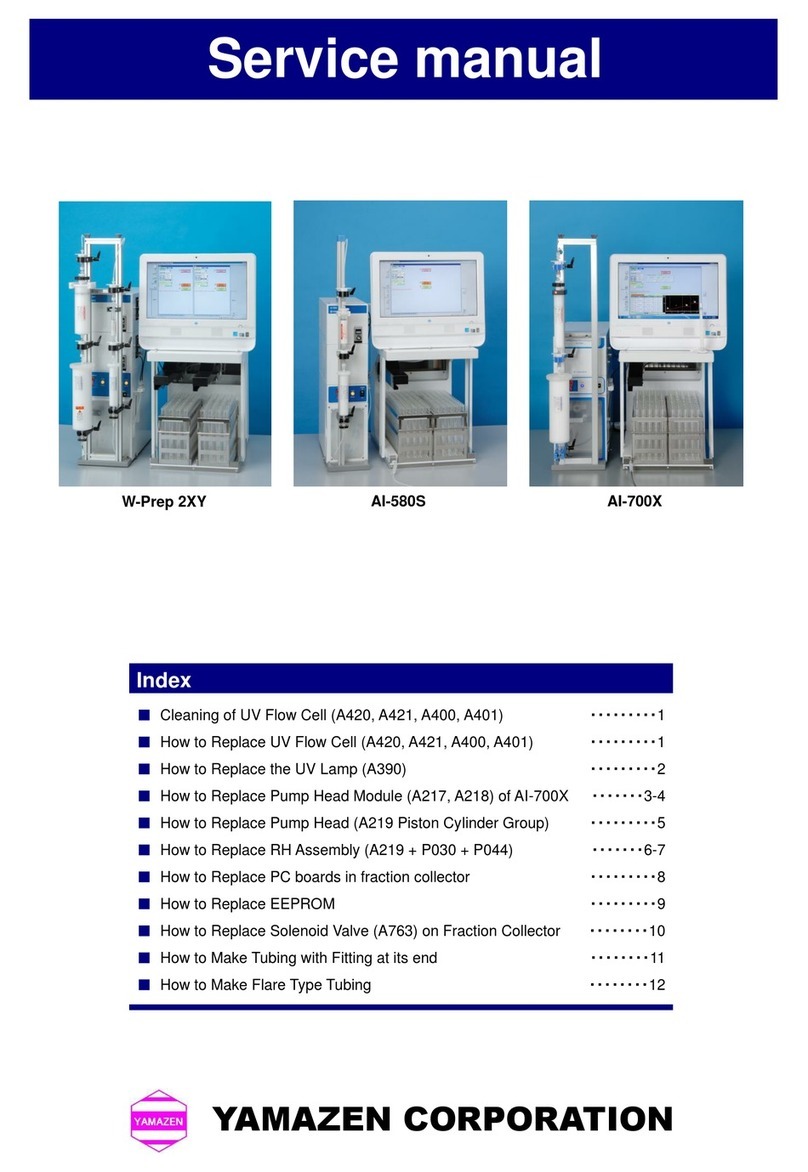

2.1. Connections CWS 500D

Below are all possible connections to the CWS 500D

400MHz model figure 2.1

1000MHz model figure 2.2

Fig 2.1 : CWS 500D (400MHz) connection rear view Fig 2.2 : CWS 500D ( 1 GHz) connection rear view

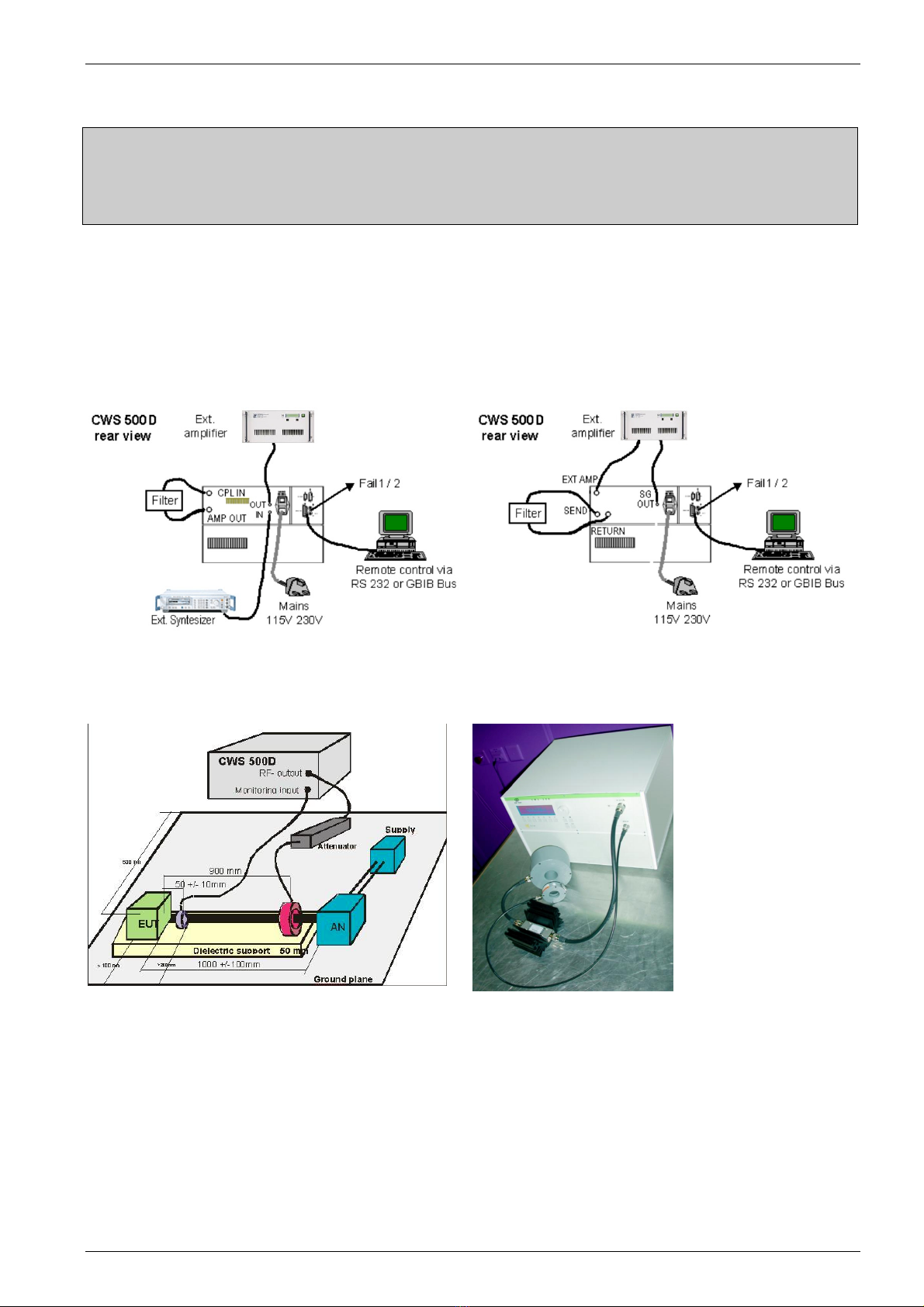

2.2. Test Setup CWS 500D

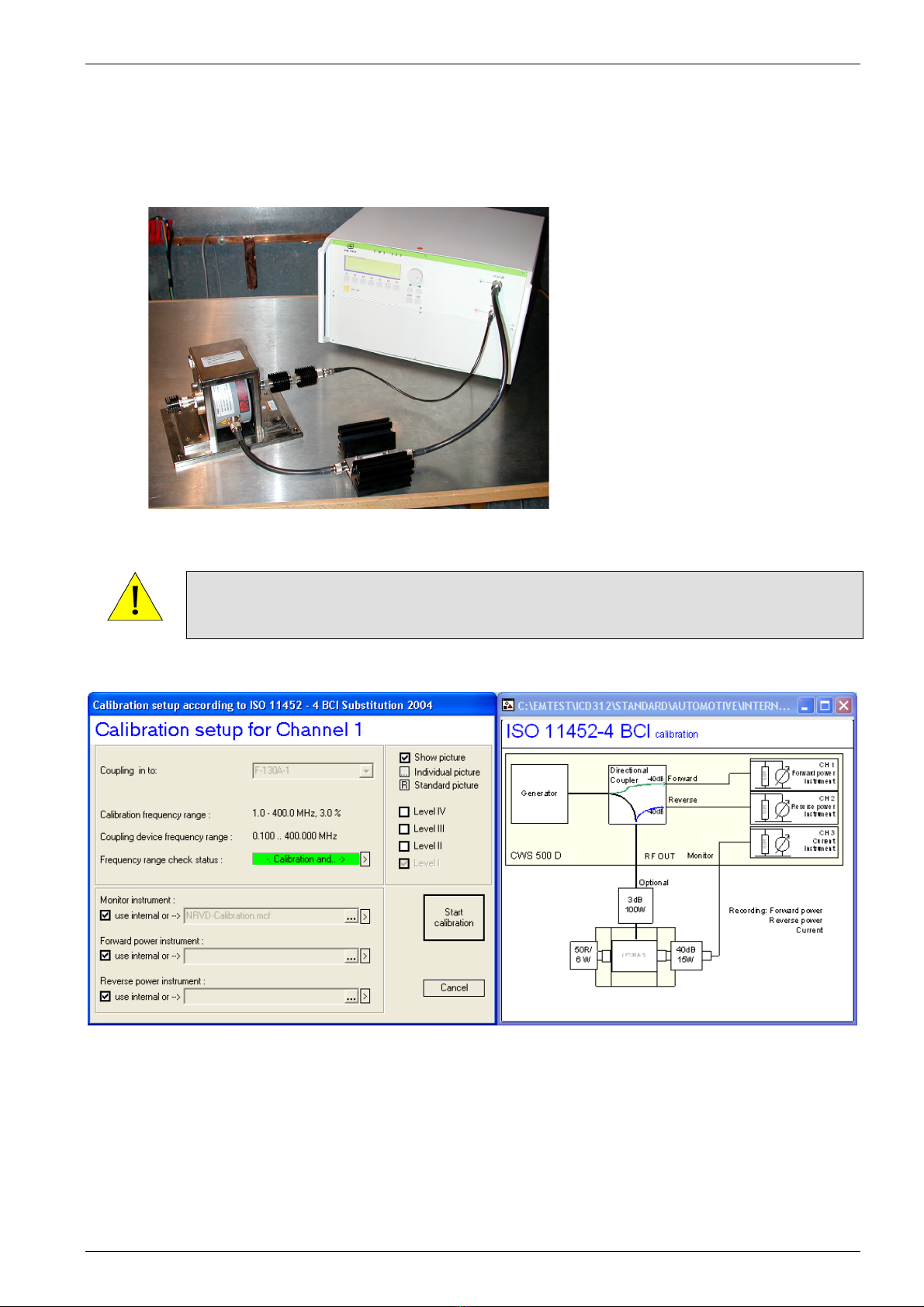

Figure 2.3a / 2.3b :

Typical test setup with

required parts for BCI

application with CWS

500D

EM Test CWS500 D

User manual V 1.07 4 / 34

2.3. Part Identifications and Functions

Continuous Wave Simulator CWS 500D 400MHz

CWS 500D 1GHz

Fig 2.4

2.3.1. Clamp Applications for Automotive standards

Fig 2.5

Bulk Current Injection Clamp BCI type ( selection of clamps)

F-130-A1 10kHz – 400MHz

F-120- 6A 10kHz – 400MHz

FCC-BCICF-1 Calibration Fixture for BCI clamp (jig)

F-140A 100kHz - 1000 MHz

FCC-BCICF-2 Calibration Fixture for BCI clamp (jig)

Fig 2.6

Current Monitor Probe

F-33-2 1kHz – 250MHz

F- 55 10kHz – 500MHz

F- 65 100kHz - 1GHz

Fig 2.7

Attenuator 3dB optional

Type ATT3/100

3dB 100W

Fig 2.8

Attenuator 20dB ( for DO and MIL application )

Type ATT20/100

20dB 100W

Fig 2.9

Attenuator 20dB

20dB 15W

Fig 2.10

Terminating resistor 50 Ohm optional

50 Ω6W

EM Test CWS500 D

User manual V 1.07 5 / 34

2.3.2. CDN Applications as per IEC 61000-4-6

Fig 2.11

Bulk Current Injection Clamp BCI type

F-120-9A 10kHz – 230MHz

FCC-BCICF-4 Calibration Fixture for BCI clamp (jig)

Fig 2.12

Attenuator 6 dB / 75W

Fig 2.13

Coupling / Decoupling Network

Types:

CDN-M 1; M 2; M 3; M4; M 5;

CDN-S1-50/75Ω; S 2; S 4; S 9; S 15; S 25; S68

CDN-T 2; T 4; T 2-RJ11; T8-RJ45;

CDN-AF 2; AF 3; AF 4; AF 8

Fig 2.14

EM Clamp

Type EM 101

Fig 2.15

Calibration

CWS-Cal Basic Calibration Kit

Transport Case

150Ωto 50ΩAdapter

BNC cable 0.5m

Cal adapter according to CDN ,

Fig 2.16

Adapter

R100 150Ωto 50ΩAdapter

R100A 150Ωto 50ΩAdapter for Current Clamp CAL Fixture

EM Test CWS500 D

User manual V 1.07 6 / 34

3. Operating Functions

3.1. Front View

Fig 3.1

1. Display

2. Function keys "F1..F7"

3. "Test On"

4. Knob (Inc / Dec)

5. Cursor keys "←" and "→"

6. Exit

7. Escape

8. RF Output

9. LED RF Output Monitor

10. Current Probe Input (Monitor)

11 LED Current Probe Input

1Display

All functions and parameters are displayed (8 lines with max. 40 characters).

2 Function Keys "F1 .. F7"

Parameters and functions displayed in the lowest line and functions displayed with ” F “, can be selected

with the related function key.

3 Test On

By pressing the key "TEST ON", the RF signal will be released and the test procedure can be started.

4 Knob (Inc / Dec)

This knob increments or decrements parameters with a numeric value or selects parameters from a list.

5CursorKey

Parameters and functions can be changed during the test. The selection of these parameters is done with

the cursor, moving it to the left or to the right.

6 EXIT

The EXIT button resets the firmware to the main menu. This is only possible, if no test routine is running.

7 ESC

The ESC button returns back to the previous level in the menu.

8 RF-Output

At this output the RF power is available. The 3dB-attenuator is connected, if available, via coaxial cable.

For conducted tests together with CDN’s, EM clamps or current injection clamps, it may be suggested to

load the simulator with a matched 50 ohm load. In case the above mentioned coupling device may not

represent such matched load, then it is recommended to add a 3dB attenuator in between.

9 LED RF Output Monitor

When the RF output is active this LED on the front panel is illuminated to indicate that a test signal is

generated.

10 Current Probe Input

For tests with a current injection clamp where the EUT current has to be measured and/or monitored, the

current probe can be connected to this input.

ATTENTION: Do not connect the RF output directly to this input otherwise it will be damaged.

11 LED Current Probe Input

EM Test CWS500 D

User manual V 1.07 7 / 34

When current monitoring is active this LED on the front panel is illuminated.

3.2. Rear view CWS 500D 400MHz model

Fig 3.2

1 Connection Amplifier OUT to Coupling IN

2 Bi-directional coupler

3 Connection Signal Generator to Amplifier

4 Power On Switch

5 Power selector 115V – 230V

6Serial Interface RS 232

7IEEE Interface

8 Remote Control Connector

9 Fail 1 Detection "Stop"

10 Fail 2 Detection "Pause"

1 Connection Amplifier OUT to Coupling IN

This connection link is between the amplifier and the power measurement device to the RF Output at the

front side. The user has the possibility to connect the amplifier to another device like a TEM cell.

2 Bi- directional coupler

3 Amp In / SG Out

The internal amplifier can be controlled by an external signal generator. For this operation, the short circuit

link must be disconnected. The external signal generator must be plugged into the connector “Amp In”.

4 Power On Switch

The switch and the main fuses are part of this box. (230V / 3.15AT or 115V / 6.3AT)

5 Power selector

Input power selector for input voltage 115V – 230V.

6 Serial Interface

RS 232 interface with 9-pin connector.

7 Parallel Interface IEEE

IEEE 488 interface with IEEE connector.

8 Remote Control Connector

not used.

9 Fail Detection FAIL 1 (TEST STOP)

The BNC input FAIL 1 can be used for failure detection on the EUT. If the input is set to ground (chassis),

the CWS 500D generator will be stopped and finish the test routine. It is not possible to continue the test.

A complete restart of the routine will be necessary. The message "FAIL 1" is indicated in the ICD software.

10 Fail Detection FAIL 2

The BNC input FAIL 2 can be used for failure detection on the EUT. If the input is set to ground (chassis),

the failure will be detected and the test continues normally. After a FAIL 2 events the test routine will stop

and the message ”FAIL 2“ will appear in the host screen ( ICD software).

EM Test CWS500 D

User manual V 1.07 8 / 34

3.3. Rear view CWS 500D 1GHz model

Fig 3.3

1 Connection Ext. Amplifier RETURN

2 Pre coupler insert loop

3 SG out

4 Power On Switch

5 Power selector 115V – 230V

6 Serial Interface RS 232

7 IEEE Interface

8 Remote Control Connector

9 Fail 1 Detection "Stop"

10 Fail 2 Detection "Pause"

1 Connector External Amplifier (EXT AMP Return )

Input signal from an external amplifier. ( max. power 200W)

2 Pre Coupler insert loop

Output and return connection for the external device like a filter or TEM cell

3 SG Out

Output to an external amplifier for control an amplifier >100W .

4 Power On Switch

The switch and the main fuses are part of this box. (230V / 3.15AT or 115V / 6.3AT)

5 Power selector

Input power selector for input voltage 115V – 230V.

6 Serial Interface

RS 232 interface with 9-pin connector.

7 Parallel Interface IEEE

IEEE 488 interface with IEEE connector.

8 Remote Control Connector

not used.

9 Fail Detection FAIL 1 (TEST STOP)

The BNC input FAIL 1 can be used for failure detection on the EUT. If the input is set to ground (chassis),

the CWS 500D generator will be stopped and finish the test routine. It is not possible to continue the test.

A complete restart of the routine will be necessary. The message "FAIL 1" is indicated in the ICD software.

10 Fail Detection FAIL 2

The BNC input FAIL 2 can be used for failure detection on the EUT. If the input is set to ground (chassis),

the failure will be detected and the test continues normally. After a FAIL 2 events the test routine will stop

and the message ”FAIL 2“ will appear in the host screen ( ICD software).

EM Test CWS500 D

User manual V 1.07 9 / 34

4. Front Panel Operation

4.1. Basic Operations

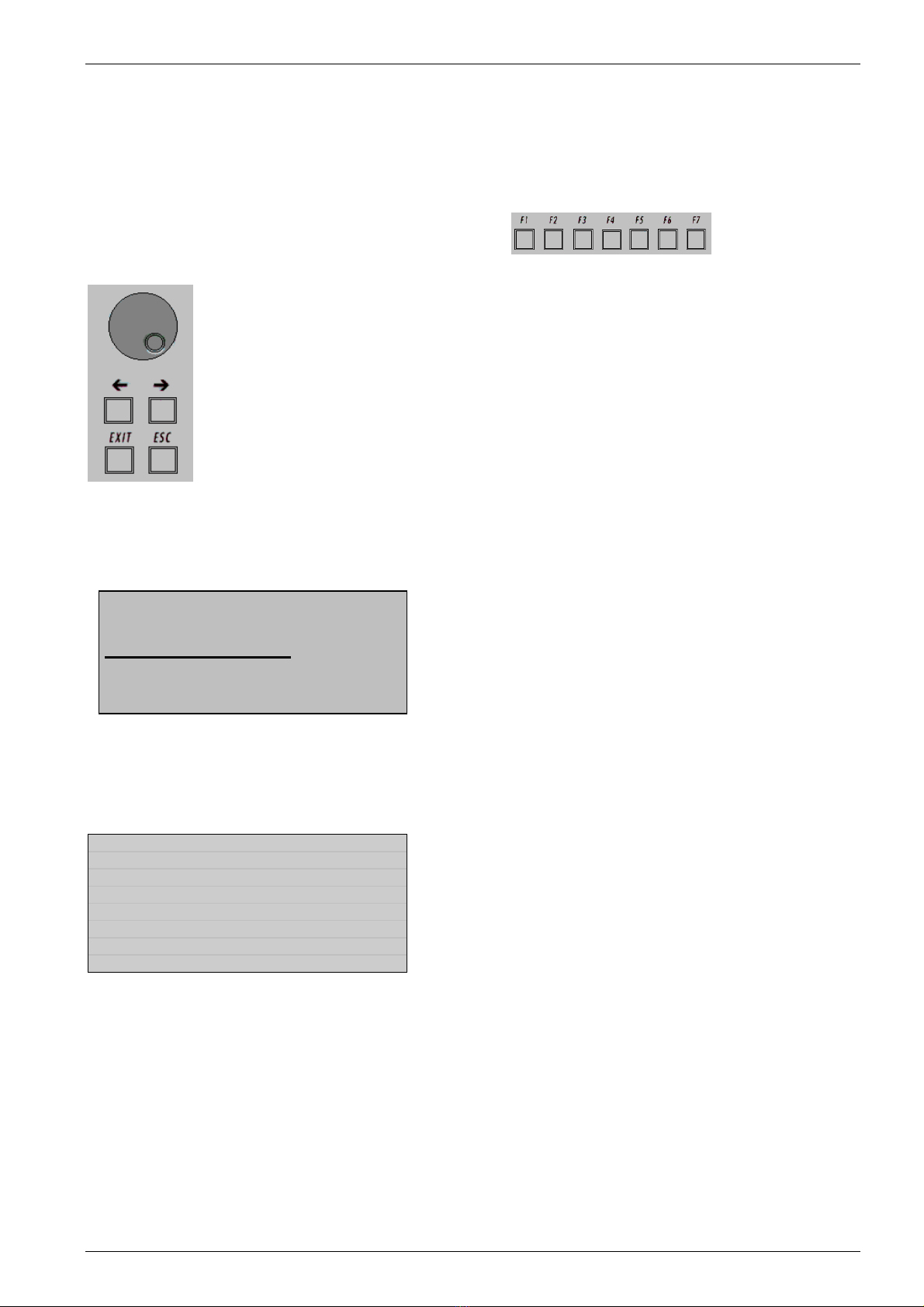

The simulator is operated by an easy menu control system.

Seven function keys are available to select parameters and

functions. Fig 4.1

The selected parameter is blinking and can be changed by turning the knob (incr./decr.).

ÍÎ : The digit to be changed can be selected with the cursor (ÍÎ ).

- Setted values are direct indicated on the screen.

- Status on the bottom lines shows the desired status after pressing the function

key.

ESC : ESC will take you back to the previous level in the menu and set the displayed

values. The latest settings are stored automatically and will be recalled when the

menu is selected again.

EXIT : The firmware will reset to the main screen.

Fig 4.2

Start-up display

EM TEST

C W S 5 0 0D

RF 9kHz – 1 GHz

V 2.11a03 SWN: 002234

←Generator Model

←Frequency Range

The version number and the software number SWN are used for tracing purposes. These numbers are listed in

the test reports and calibration certificates. These numbers are also listed within the test reports generated by

the software report generator.

Page 1 (Main Menu)

MAIN MENU

F1 : Quickstart

F7 : Service

F1 F2 F3 F4 F5 F6 F7

F1 Quickstart

Manual operation by entering the attenuation, frequency and modulation

F7 Service

Setup can be selected and displayed

EM Test CWS500 D

User manual V 1.07 10 / 34

4.2. Quickstart

Easy and very fast operation for functions check and verification of the CWS 500D.

Page 2 (Show Parameters) Page 3 (Change)

Quickstart Quickstart

Att = 63,0 dB f = 109.500 MHz

Mod = AM 1kHz 80% Att : 0.0 dB - 63.5 dB

f : 0.009 MHz - 400.0 MHz

Mod : OFF, AM 80%, AM 90%, Pulse

Att f Mod

START CHANGE 57.0 109.5 ON

F1 F2 F3 F4 F5 F6 F7 F1 F2 F3 F4 F5 F6 F7

Press START to begin testing.

Press CHANGE and the actual parameters can be changed. Selecting a parameter to change will display the

range.

The test begins by pressing START. The blinking parameter can be changed with the knob inc./dec.

Use the cursor keys (ÍÎ ) to select other parameters. By pressing STOP the test will be stopped and on the

last line of the display it will be indicated that the test has been stopped.

Page 3 (Operating)

Quickstart

Att = 33,0 dB f = 109.500 MHz

Mod = AM 1kHz 80%

FPow = - 9.7 dBm Mon = -56.9 dBm

Rpow = - 16.5 dBm

STOP

F1 F2 F3 F4 F5 F6 F7

Error messages:

Quickstart

Att = 40,0 dB f = 109.500 MHz

Mod = off

FPow = + 6.6 dBm Mon = -57.3 dBm

Rpow = + 6.8 dBm

Fpow to low !

Message : Fpow to low !

What happens : The amplifier does not supply the expected gain. The firmware checks the ratio between the

signal generator output and the Forward power. The reason can be an amplifier defect or an

internal error in the CWS 500D. This message appears only when using internal amplifier.

EM Test CWS500 D

User manual V 1.07 11 / 34

4.2.1. Quickstart during instrument calibration

This function needs Firmware 2.11 or higher.

In case of a calibration of the measuring instrument it is necessary to use external signal generators. The CWS

instrument has frequency matched calibration curfes for each instrument channel. When using the internal

signal generator CWS 500 knows the actual frequency and select automatically the correct reference. When

using an external signal Generator, the instrument does not know the actual frequency. Therefore it is very

important to adjust the frequency in the display to the actual applied frequency. otherwise the displayed

measuring value can be wrong.

Page 3 (Operating)

Quickstart AMP :2

Att = 63,0 dB f = 100.000 MHz

Mod = AM 1kHz 80%

FPow = - 3.0 dBm Mon = -56.9 dBm

Rpow = - 56.5 dBm

-----------------------∆f---------------------

STOP 1k 10k 100k 1M 10M

F1 F2 F3 F4 F5 F6 F7

Adjust the frequency when using an external signal generator during instrument calibration

EM Test CWS500 D

User manual V 1.07 12 / 34

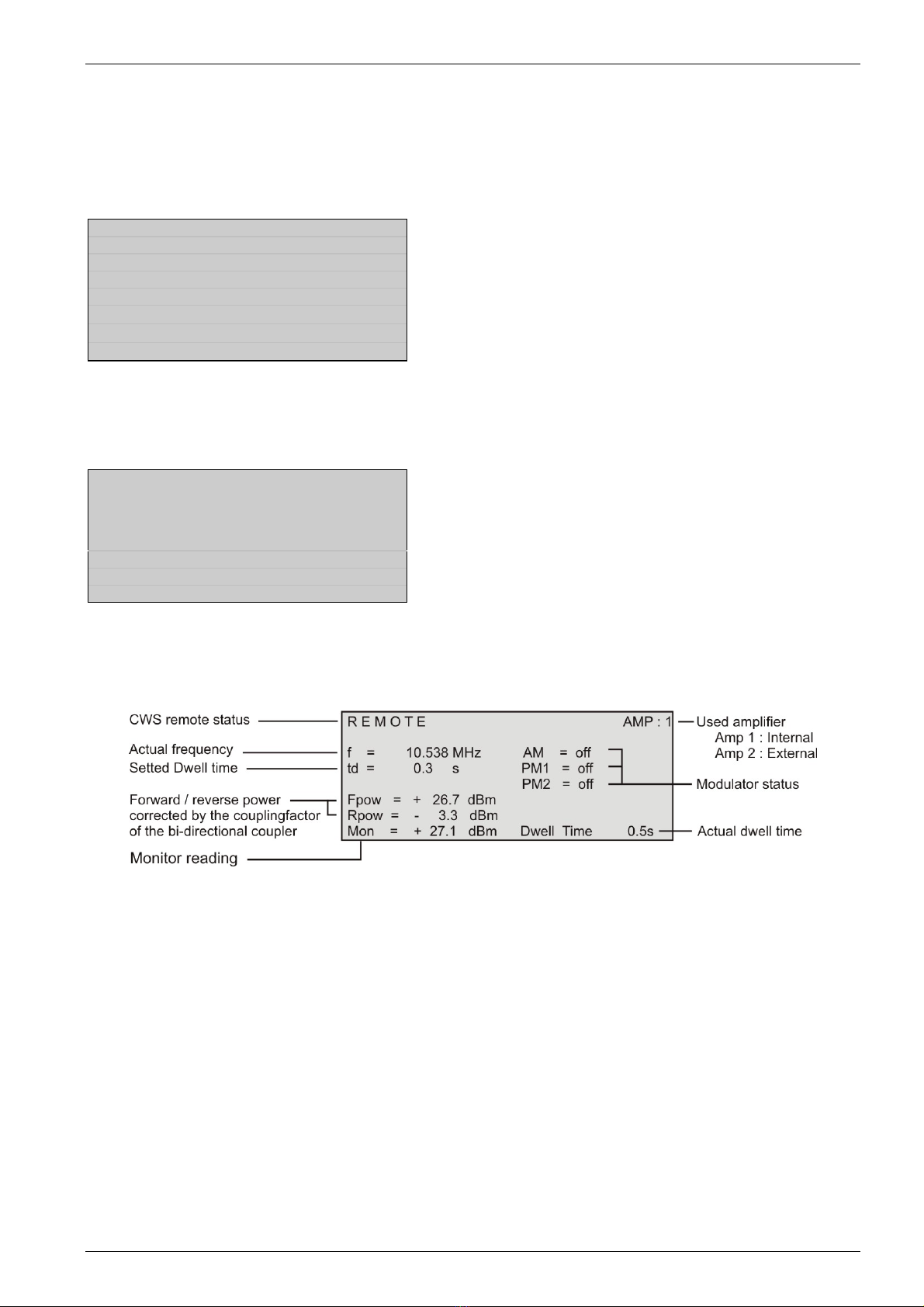

4.3. Display during Remote control

The CWS 500 can only work with remote control from the ICD software Version 3.00 or higher. During the

operation the following information appears on the display:

Remote control

R E M O T E ProgRemote

f = 5.420MHz Mod = OFF

FPow = -17.6 dBm

FPow = ----- dBm

Mon = -30.4 dBm Dwell Time 0.3s

During Remote operation the display shows different screens depend the actual software procedure

Waiting

R E M O T E AMP : 1

f = 10.538 MHz AM = off

td = 0.3 s PM1 = off

PM 2 = off

Display during a test

EM Test CWS500 D

User manual V 1.07 13 / 34

4.3.1. Modulation

Modulation as per IEC

Figure 4.3 shows the modulation for IEC

application.

Fig 4.3 : Unmodulated 80% AM Pulse modulation

Modulation as per ISO

Modulation signal as per ISO, peak

conservation ( pulse) standard. These

standards recommends the modulation signal

with the same amplitude as the non modulated

signal.

Fig 4.4 : AM modulation with peak conservation

EM Test CWS500 D

User manual V 1.07 14 / 34

4.4. Service

All service functions are indicated in the display.

Page 2 (Overview service)

SERVICE

F1 : Addresses

F3 : Setup

F4 : Amplifier Switch

F5 : Function check powermeter

F6 : Function check amplifier switch

F1 F2 F3 F4 F5 F6 F7

F1 Addresses

The addresses of EM TEST AG Switzerland and EM Test GmbH Germany will be displayed.

A list of the world-wide sales partners is awailable on the internet under www.emtest.com.

F3 Setup

The software will clearly explain the setup procedure.

F4 Amplifier Switch

Set the amplifier to internal / external.

Default setting after power on or go to local setting : internal

F5 Function check Powermeter

Function check routine for the built in powermeter (PM). With this check function the correct working of the PM

can be verified.

F6 Function check amplifier switch

Check function for verification of the correct working of the built in amplifier switch, and the built in Amplifier

( gain >50dB ).

4.4.1. Addresses

The addresses of the EM TEST AG and the

EM TEST GmbH are shown. The addresses of all EM

TEST sales agencies are listed on the web site of EM

Test under :

www.emtest.com

Page 3 (Addresses)

EM TEST AG Switzerland

Sternenhofstr. 15

CH – 4153 Reinach BL1

Tel : +041 61 717 91 91

Fax : +041 61 717 91 99

For further sales offices

CH D refer to www.emtest.com

F1 F2 F3 F4 F5 F6 F7

EM Test CWS500 D

User manual V 1.07 15 / 34

4.4.2. Setup

This menu helps the user to define the configuration of the CWS 500D.

Page 3 (Setup Overview)

Setup

F1 : Change language / Sprache ändern

F2 : LCD Back Lighting

F3 : Interfaces

F4 : Keyboard Beeper

F5 : Timer

F1 F2 F3 F4 F5 F6 F7

F1 Change language / Sprache ändern

The user can choose between two languages, German and English.

F2 LCD Back Lighting

With the use of F2 the back lighting can be switched ON or OFF. The Auto-Off Function can be programmed to

switch the back lighting off after a predetermined time following the last manual operation (1 - 30 minutes).

Due to the limited lifetime of the LCD back lighting (approx. 10,000 hours), this function should always be

activated.

The Auto ON/OFF function does not switch on during remote operating

F3 Interfaces

With this menu the user can define the status of the integrated serial and parallel interfaces, e.g. the baud rate

of the RS232- or the address of the IEEE-interface.

F4 Keyboard Beeper

F4 selects the beeper ON/OFF mode.

F5 Timer

By pressing F5 will display the total operating time of the CWS 500D will be displayed.

4.4.3. Amplifier Switch

Change of the used amplifier internal or external

Page 3 (Amplifier Switch)

Amplifier Switch

F1 : Amplifier Int / Ext

Int / Ext

Int

F1 F2 F3 F4 F5 F6 F7

The CWS display shows the actual setting for the used amplifier

Int : Internal = Amp 1

Ext : External = Amp 2

After power on the default amplifier is set to internal

EM Test CWS500 D

User manual V 1.07 16 / 34

5. Starting Operation

5.1. Safety Aspects

Tests performed with RF-disturbances, induced by radio-frequency fields, are immunity tests on electronic

equipment. Therefore it is the responsibility of the user to avoid critical failures and risks to the environment and

the operators.

Long power supply lines to the EUT may radiate energy. It is the responsibility of the user to determine whether

it is allowed to conduct immunity tests in a given location.

The RF voltages on the center pin of the RF output connector can be hazardous. The RF output connector must

be connected to a load before AC power is applied to the CWS 500D. Do not touch the center pin of the RF

output connector or accessories which are connected to it. Switch the equipment to the “Test OFF” position

before disconnecting or connecting the load to the RF output connector.

During this test RF interference is generated at a power of 100W or more. Therefore, the test should be

performed in a shielded room to prevent interference with other equipment in the vicinity. Also see the

information included in the declaration of conformity for the CE mark.

For the test setup, national and international safety regulations must be observed.

Persons beings with pacemakers must not be allowed to perform such tests.

Special Information For Operating the CWS 500D :

1. The intake and outlet for the cooling system must not be covered. Free air circulation of is required for

proper function of the CWS 500D. Blockage of the cooling air system may result in damage to the RF

amplifier or intermittent shut down of the equipment.

2. All panels must be installed. They are important components of the cooling system. Never perform tests

with a partially or completely open generator.

3. Before a test or a calibration may be performed, the CWS 500D must be operating for at least 15 minutes

warm up time. After this time the CWS 500D output becomes stable

4. High voltage components will only be exposed when the 3 cover panels are removed (unscrewed). To

service the inside the generator, the power supply must be turned off and the power cord must be removed

before opening the equipment.

5. CDN’s are coupling/decoupling networks as specified in IEC 61000-4-6 . Due to this specification, higher

ground current exists as a result of increased value of the Y-capacitors. Therefore, the general use of fault

current protection relays is not possible. The use of isolating transformers for the power supply may be

required.

6. Some CDN’s are designed for higher and hazardous voltages. It is necessary to remove the power cord

from the input connection of the CDN’s before opening the housing.

7. Only trained and qualified service technicians are allowed to perform service and repair the instruments.

Please contact an EM TEST service center or your local sales partner for repairing or servicing the units.

8. The calibration of the test setup has to be done on the output of the CDN’s. To connect the 150-to-50Ω

matching resistor, special adapters are required (e.g. power supply connector to single pole plugs).

9. Make sure to read carefully and completely all the manuals.

EM Test CWS500 D

User manual V 1.07 17 / 34

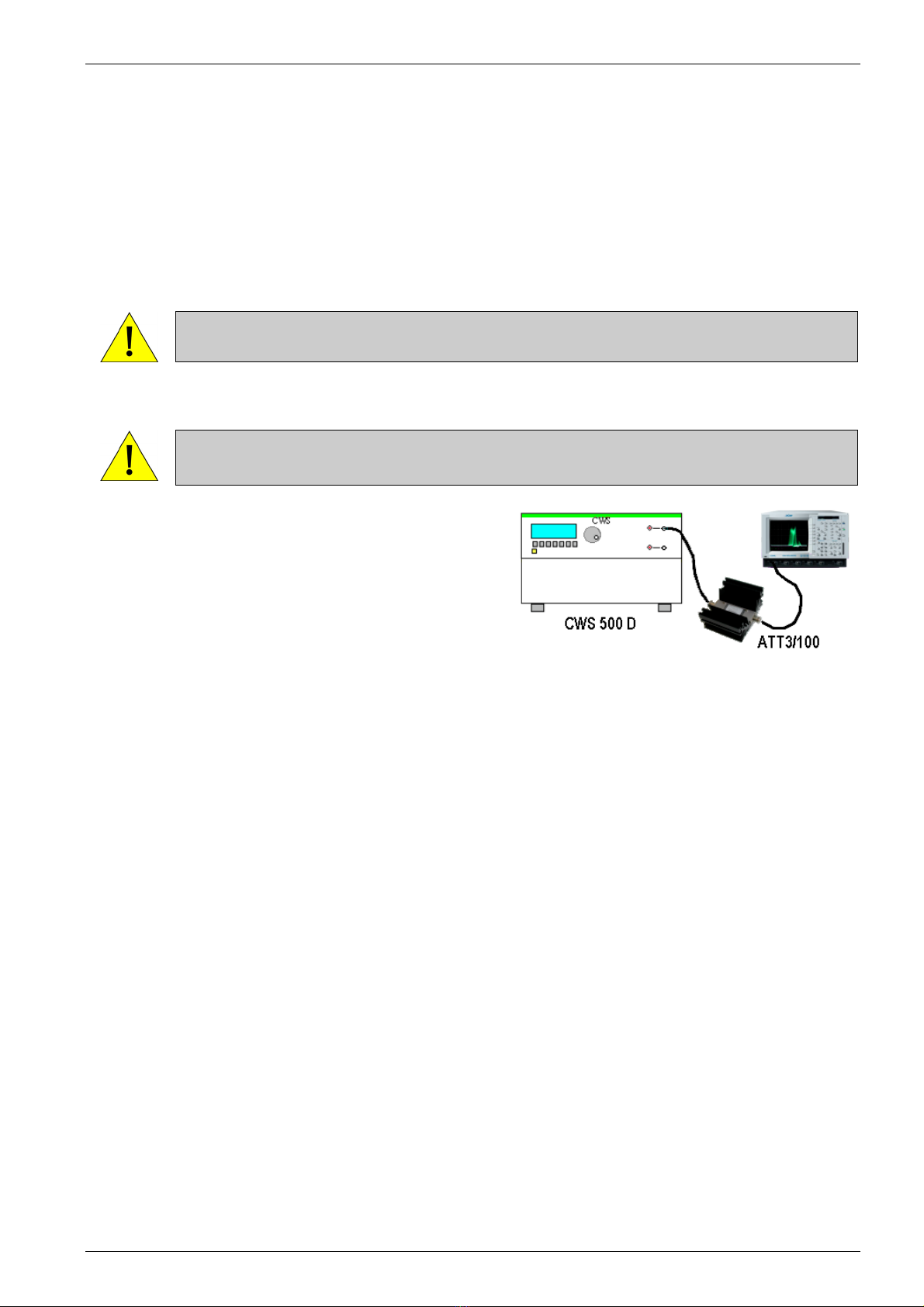

5.2. Generator Function Check

As with all testing equipment, the continuous wave simulator type CWS 500D should be checked for

performance and accuracy from time to time. The check should be completed as listed below.

- Connect the RF-output of the CWS 500D to the 3dB-attenuator or an adequate attenuator.

- Switch on the power supply.

- Select the in Quickstart with the following parameters:

voltage : 30dB

frequency : 23MHz

modulation : OFF, 2Hz, 400Hz or 1kHz

- Connect the output of the 3dB-attenuator with the 50Ωinput channel of the oscilloscope.

ATTENTION Take attention to the maximum input power capability and the bandwidth of the

test input.

- Push "TEST ON" and start the test.

ATTENTION DO NOT connect the output of the ATT3/100 nor the output of the CWS 500D

to the monitor input, otherwise the monitor input will be destroyed.

Using an oscilloscope or powermeter for checking the

operation of the generator very easy. Fig 5.1.

Take notice that this procedure is only a functional check of

the generator. Differences in the test level may be caused

by a limited bandwidth or mismatching within the testing

system.

Exact and accurate measurements can only be guaranteed

with the specified test setup according to standard. Fig 5.1

expected values >22 dBm

-30dBµA 53dB = 23dBm ±4dB

EM Test CWS500 D

User manual V 1.07 18 / 34

5.3. Function Check internal Powermeter

This function is for checking the built in 3-channel powermeter e.g. Forward Power and Rev Power and current

monitor. Within this measuring procedure the measured values are compared with some nominal values, this in

order to verify the correct function of the three measuring inputs. In addition also the accuracy of the measuring

is checked in a larger range. In order to avoid any damage, it may be self explaying that only a low voltage

signal may be released by the amplifier and occur at these inputs.

The MONITOR input is tested with the following signals:

- Measuring with a 50Ωterminal connection at the input.

- Measuring with the maximum attenuation ( -60dB ) to the RF output via a 3dB attenuator.

- Measuring with a reduced attenuation (-45dB ) to the RF output via a 3dB attenuator.

The function check has the following procedure:

Page 3 (Service )

Function check Powermeter step 1/ 2

- Press TEST ON

- Disconnect the HF OUT

- Connect a 50 Ohm matching resistor

to the MONITOR input

continue break Fig 5.2

F1 F2 F3 F4 F5 F6 F7

50 Ωmatching resistor

connected at the monitor

input.

Page 3 (Service )

Function check Powermeter step 2/ 2

- Connect the MONITOR input to the

HF OUT via a ATT 3 dB attenuator

continue break

Fig 5.3

F1 F2 F3 F4 F5 F6 F7

Page 3 (Service )

Function check Powermeter result

Pass / Fail

end

F1 F2 F3 F4 F5 F6 F7

Finally the result of the check appears in the display. With the measured results the user is able to check the

correct function of the measuring inputs.

EM Test CWS500 D

User manual V 1.07 19 / 34

5.4. Function Check amplifier switch ( 1GHz model only)

This function is for checking the correct operation of the built in amplifier switch. During this test the output

connector at the frontside should be left open.

The function check has the following procedure:

Page 3 (Service )

Function check amplifier switch

- Press TEST ON

- Disconnect the HF OUT

- Connect the SG OUT directly

to the CPL IN ( on the backside )

continue break Fig 5.4

F1 F2 F3 F4 F5 F6 F7

Page 3 (Service )

Function check amplifier switch

result

Pass / Fail

end

F1 F2 F3 F4 F5 F6 F7

EM Test CWS500 D

User manual V 1.07 20 / 34

5.5. Calibration

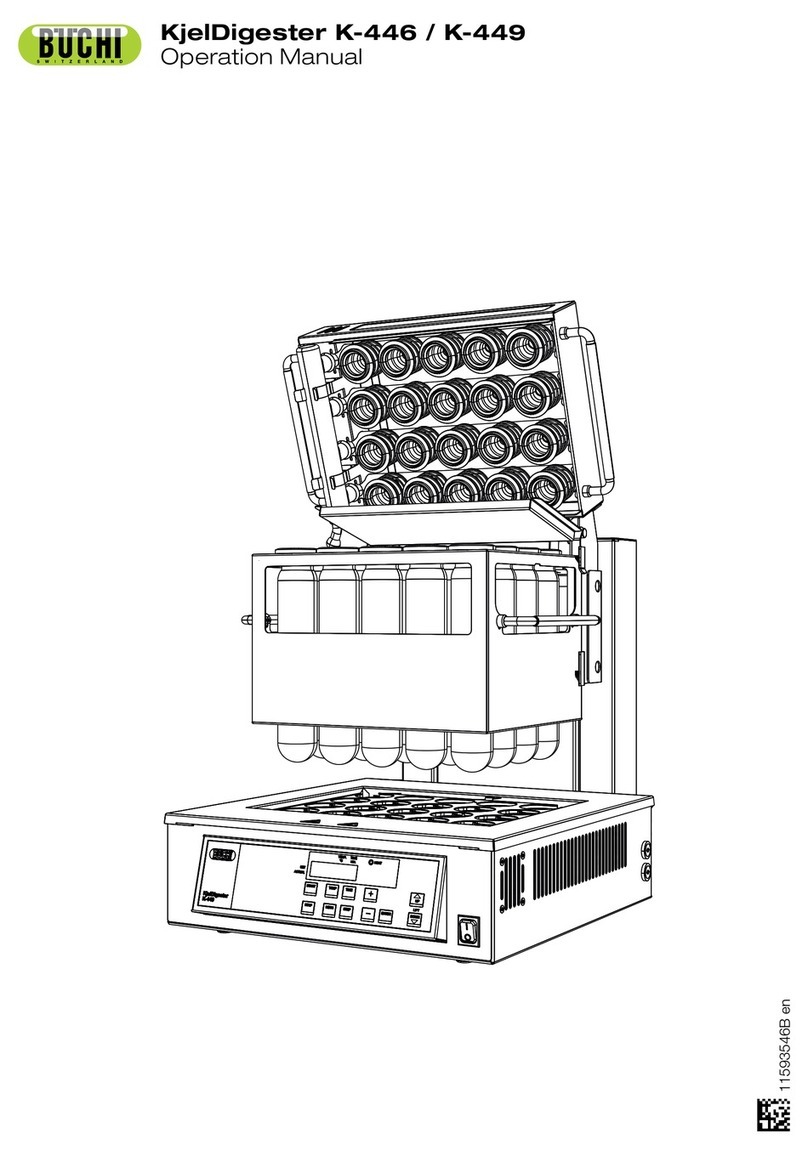

5.5.1. Calibration Setup for Bulk Current Injection Clamp (BCI) as per ISO / DO / MIL

Fig 5.5 : Calibration setup with BCI

ATTENTION

During calibration of the test setup on a ground reference plane at very low levels (very low

currents) is important. The test results may be influenced by the cable layout on the ground

plane. High grade coaxial cables are essential.

Fig 5.6 : Calibration setup with BCI

Table of contents

Other EMTEST Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Medic Therapeutics

Medic Therapeutics MT-UVWA-001 manual

Endress+Hauser

Endress+Hauser Liquistation CSF48 operating instructions

Monmouth Scientific

Monmouth Scientific Circulaire HLFT1000 operating & maintenance manual

Buchi

Buchi KjelDigester K-446 Operation manual

Millipore

Millipore Labscale user guide

Gilson

Gilson MyPIPETMAN Select manual