2

1.0 GENERAL DESCRIPTION

Model C100 100 litre chamber capacity

Model C157 157 litre chamber capacity

Model C330 330 litre chamber capacity

1.1 CONSTRUCTION, HEATING AND INSULATION

Even heating throughout the entire chamber is ensured by the LEEC designed heating

element. The low wattage element is bonded to the outer surface of the chamber walls

ensuring quick heat conduction and low heating element temperature, only a few

degrees above the incubator operating temperature.

New profiled resistive wire heating elements and high performance insulation ensure

optimum temperature control. All models have gentle fan assisted air circulation. This

ensures even temperature distribution throughout the chamber. Fast temperature

recovery keeps heat loss to a minimum after door opening.

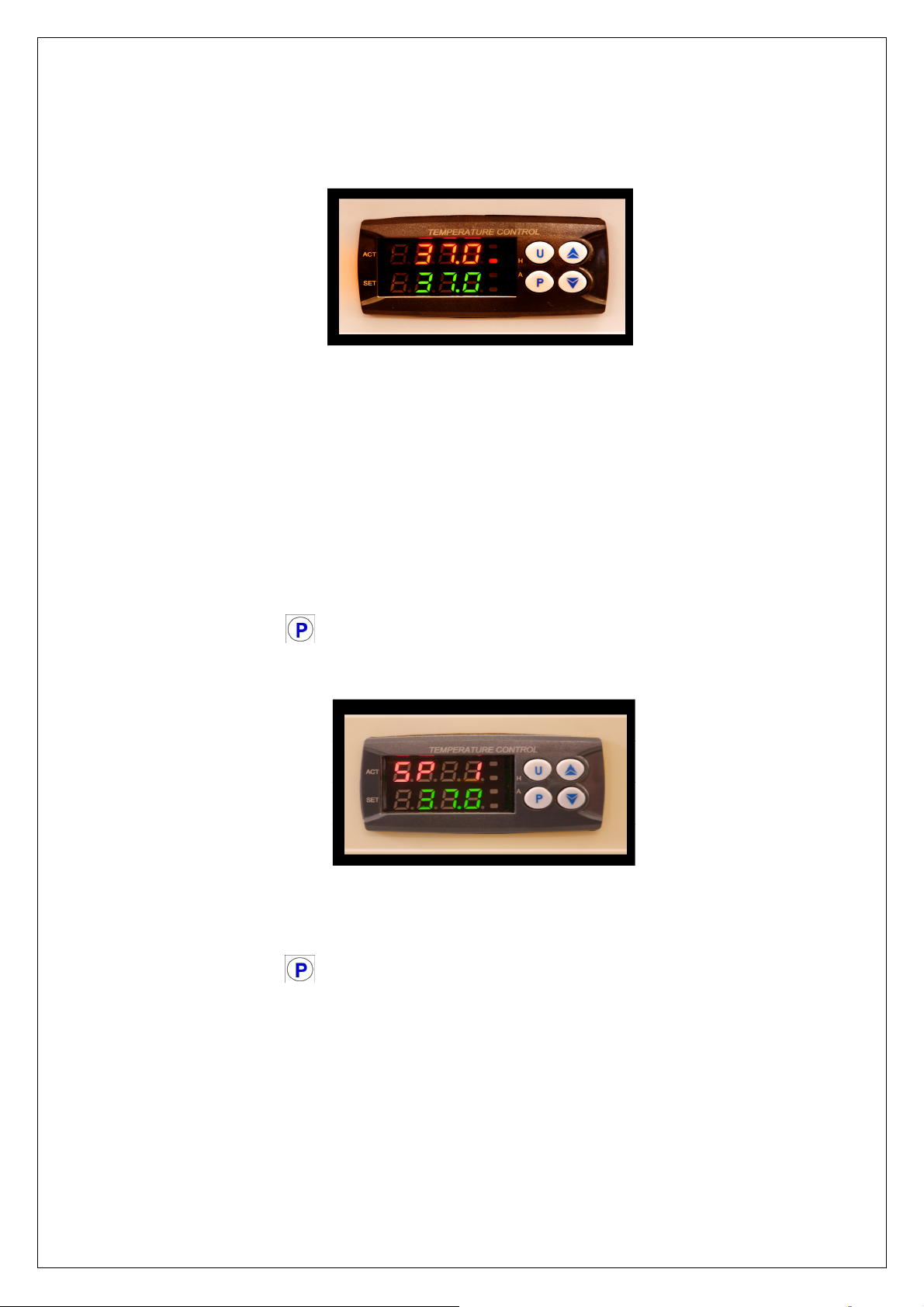

1.2 TEMPERATURE CONTROLLER

A very easy to program electronic PID temperature controller is fitted to the LEEC

Classic Incubator range.

This controller is easy to use and enables quick programming of the incubator chamber

temperature.

In addition, this temperature controller has built in under temperature (low) level alarm

and over temperature (high) level alarm functions. The low and high level alarm limits

are factory set to +/- 2.0 °C above/below programmed temperature respectively after a

delay of 2 minutes.

1.3 INDEPENDENT OVER TEMPERATURE SAFETY CUT OUT

An independent fail safe over temperature safety cut out is fitted to this incubator. The

over temperature cut out is factory set to 40°C, but can be adjusted by the customer,

refer to section 4.3. In the extremely unlikely event of the incubator temperature

controller failing on, the over temperature safety cut out will disconnect the heaters.

This device, once tripped, has to be manually reset. Refer to section 3.6 for instructions

to reset.

1.4 CIRCULATION FAN

The internal fan helps to achieve accurate temperature uniformity throughout the inner

chamber. It also helps to enhance temperature recovery when the chamber is heavily

loaded. The fan is located at the top of the chamber. Air is drawn up through the

chamber, circulated around the full width ducting, and returned to the chamber floor.

The fan also improves temperature recovery after inner glass door opening. A micro

switch disconnects the fan upon door opening to minimise temperature loss to the

chamber environment during door opening.