Emtron KV Series User manual

Z

KV8 / KV12 / KV16 / KV16M

KV Series Hardware Manual

Rev 1.0

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

1

Contents

1.0 Analog Inputs .......................................................................................................................3

1.1 Analog Input Channels 1- 16/24 ......................................................................................3

1.2 Analog Temperature Input Channels 7- 12......................................................................4

1.3 Digital Inputs 1-14 used as analog input(s)......................................................................4

1.4 Sensor 0V Reference Pin(s) ..............................................................................................5

1.5 Analog Input configuration example ...............................................................................6

2.0 Digital Inputs ........................................................................................................................7

2.1 Digital Input Channels 1- 8 –Frequency ..........................................................................7

2.11 Arming Threshold Control –Magnetic Sensors .........................................................8

2.2 Digital Input Channels 1- 14 –Switched Input.................................................................9

2.3 Digital Input Channels 1- 14 –Analog Input ..................................................................10

2.4 Digital Input configuration example ..............................................................................10

3.0 Auxiliary Outputs ...............................................................................................................11

3.1 Auxiliary Output 1-8 –Low side or High side.................................................................11

3.2 Auxiliary Output 9-12 –Half Bridge ...............................................................................12

3.3 Auxiliary Output 13-16 –Half Bridge .............................................................................12

3.4 Auxiliary Outputs –Full Bridge Configuration (DBW)....................................................13

3.5 Auxiliary Output –Flywheel diodes ...............................................................................14

3.51 VVT and Idle Solenoids –why we need flywheel diodes.........................................14

3.52 Boost Control Solenoid ............................................................................................14

3.53 Transmission Brake Solenoid ...................................................................................15

3.6 Permanently Powered Loads .........................................................................................15

3.7 Auxiliary Output configuration example........................................................................16

4.0 Injector Outputs.................................................................................................................17

4.1 Injector Control..............................................................................................................17

4.1 Peak and Hold Injector Control......................................................................................17

4.2 Saturated Injector Control .............................................................................................18

4.3 Auxiliary Load Switching on Injector Outputs................................................................18

4.4 Protection ......................................................................................................................18

5.0 Ignition Outputs .................................................................................................................19

5.1 Ignition Control ..............................................................................................................19

5.2 Auxiliary Load Switching on Ignition Outputs................................................................19

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

2

5.3 Protection ......................................................................................................................20

6.0 Crank Index and Sync Sensor Inputs ..................................................................................21

7.0 Knock Control.....................................................................................................................22

8.0 Lambda Control..................................................................................................................22

9.0 Supply Voltage Inputs ........................................................................................................23

9.1 ECU Supply .....................................................................................................................23

9.2 Aux 9-12 Supply .............................................................................................................23

9.3 Aux 13-16 Supply ...........................................................................................................24

10.0 Regulated Voltage Outputs..............................................................................................24

11.0 EFI Relay Control..............................................................................................................25

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

3

1.0 Analog Inputs

The KV series supports up to 24, 12-bit high resolution analog input channels.

KV ECU

Analog Inputs

KV8

16

KV12

16

KV16

16

KV16M

24

1.1 Analog Input Channels 1- 16/24

All analog input channels are sampled using high

resolution 12-bit analog to digital converters with a

0.0 - 5.000V input range. The ECU uses a high

precision internal voltage reference giving high-

performance signal conversion. Analog channels 7-12

have configurable 1k ohm pullups so temperature

sensors can be connected to these channels when

required. All analog inputs can also be used as switched inputs with arming levels

programmable from 0.0 –5.0V.

Analog Voltage Input 1 -24 Summary

▪16x/24x Analog Inputs with 6 channels available for temperature measurement with

switchable pullup resistors

▪Fully configurable including custom calibrations

▪Switchable 1k ohm pull-up resistors on ANV 7-12 making these inputs suitable for

temperature measurement. Pullup supply is to 5.0V Vref1.

▪Every input accepts a 0.0 - 5.000V analog input range. Resolution is 1.22mV using a

12-bit analog to digital converter.

▪Input Impedance 100k Ohms to ground

▪1st order 160Hz Low pass filter

▪All inputs support ratiometric and absolute 3-wire based sensors such as MAP,

Throttle position(s) and pressures etc

▪AN7-12. Support thermistor 2-wire sensors such as engine temperature, inlet air

temperature with the pullup resistor switched ON when required.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

4

1.2 Analog Temperature Input Channels 7- 12

As mentioned on 1.1 these channels have switchable 1k

pullup resistors. This allows these channels to support

ratiometric and absolute sensors (Pullup switch OFF) or

thermistors 2-wire sensors with the pullup(s) switched ON.

When the pullup is enabled the ECU applies a ratiometric

correction which maintains a very stable output independent

of pullup supply variations.

Analog Voltage Input 7 -12 Summary

▪Switchable 1k ohm pull-up resistors, pullup supply to 5.0V Vref1.

▪Every input accepts a 0.0 - 5.000V analog input range. Resolution is 1.22mV using a

12-bit analog to digital converter.

▪Input Impedance 100k Ohms to ground

▪1st order 160Hz Low pass filter

▪Supports either ratiometric and absolute 3-wire based sensors (pullup Off) or

thermistor 2-wire sensors with pullup ON when required.

1.3 Digital Inputs 1-14 used as analog input(s)

Digital Input channels 1- 14 are primarily used to measure frequency based signal and as

switched inputs. However, the analog voltage on each digital input is also measured so all

digital inputs can support ratiometric and absolute 3-wire based sensors. The input range is

extended to 0 -20V, which means the effective resolution is 4 times less than Analog Inputs

1- 16. For this reason, don’t connect engine critical sensors to these channels e.g. Manifold

Pressure, Throttle Position, Pedal Position etc. Digital Input channels 1-14 should be used to

measure an analog signal once all the dedicated Analog Inputs 1-16/24 have been allocated.

Digital Analog Inputs 1 -8 Summary

▪Accepts a 0.0 - 20.0V analog input. Resolution is 4.88mV (10-Bit)

▪Switchable 4k7 pull-up resistor to 8.8V on all 8 channels

▪Input Impedance 39k Ohms to ground

▪Over and under voltage protection

Digital Analog Inputs 9 -14 Summary

▪Accepts a 0.0 -20.0 V analog input. Resolution is 19.61mV (8-Bit)

▪Switchable 4k7 pull-up resistor to 9.4V on all 6 channels

▪Input Impedance 70k Ohms to ground

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

5

1.4 Sensor 0V Reference Pin(s)

These pins are NOT ECU grounds. Although a multi-meter test will show continuity to the

ECU ground, these pins are designed as a low current 0V reference for pressure, position

and temperature sensors. The following rules MUST always be observed:

▪DO NOT connect these pins to the ECU main ground location(s). This is a specialised

ground reference for all analog sensors and should be connected directly to the sensor

0V(ground) pin.

▪DO NOT connect frequency-based sensor grounds to the 0V Reference pin; for example,

an Ethanol content sensor. Use the main ECU ground.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

6

1.5 Analog Input configuration example

Table 1.0 shows a typical analog input assignment on a Drive by Wire (DBW) application.

Channel

Input Pin

Manifold Pressure

Analog Voltage 1

Boost Pressure

Analog Voltage 2

DBW1 Servo Position Main

Analog Voltage 3

DBW1 Servo Position Sub

Analog Voltage 4

Mass Air Flow Meter 1

Analog Voltage 5

Engine Temperature

Analog Voltage 7 (Pull-up Channel)

Inlet Temperature

Analog Voltage 8 (Pull-up Channel)

Engine Oil Temperature

Analog Voltage 9 (Pull-up Channel)

Gearbox Oil Temperature

Analog Voltage 10 (Pull-up Channel)

Fuel Temperature

Analog Voltage 11 (Pull-up Channel)

Engine Oil Pressure

Analog Voltage 12 (Pull-up Channel)

Fuel Pressure

Analog Voltage 13

Gear Detection Voltage

Analog Voltage 14

Pedal Position Sensor 1

Analog Voltage 15

Pedal Position Sensor 2

Analog Voltage 16

Table 1.0. Analog Channel 1-16 assignment example.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

7

2.0 Digital Inputs

Digital Inputs 1- 14 provide frequency and switched based inputs into the ECU. These inputs

have a high level of configurability allowing easy interface to all sensor types. Digital Inputs

1-8 can be used to measure frequency, while all channels can accept a switched input. The

analog voltage on all 14 channels is measured and can be used for diagnostics or ratiometric

sensor interface.

2.1 Digital Input Channels 1- 8 –Frequency

▪Frequency range from 0.0Hz up the 30.0kHz on all 8

channels

▪Magnetic and hall/optical effect sensor compatible with

programable trigger edge(s); rising, falling and both.

▪Independent programable frequency-based arming

threshold control, range 0.0 - 12.0V

▪Wheel speed, output shaft speed, turbo speed and other

frequency-based signals

▪VVT position(s) up to 4 channels available on DI 1- 4.

▪Switchable 4k7 ohm pull-up resistors on all 8 channels to

8.8V

▪Filter time constant = 20us

▪Maximum/Minimum input signal amplitude +/- 80V

▪Input Impedance 39k Ohms to ground.

▪Switch Input: Switch to 0V, Switch to VBatt, logic signal

NOTE

1. ONLY Digital Inputs 1-4 can be used to measure Cam Position(s) for VVT control.

2. The ECU uses “True” zero crossing detection on magnetic based signals. This gives

precise 0V crossing detection, critical on magnetic sensors used in VVT control.

3. Emtron Scope function is available on Digital Inputs 1-4.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

8

2.11 Arming Threshold Control –Magnetic Sensors

Arming threshold control is primarily used in zero crossing detection of magnetic based

signals. The zero crossing circuity cannot be triggered until the input signal has crossed an

"arming" threshold on the positive-going(rising edge) portion of the waveform. Until this

happens the zero crossing circuity is OFF and all zero crossings will be ignored. Once the

input signal has exceeded the arming threshold, the zero crossing circuity is now

ready(armed) and waiting for the zero crossing.

The arming threshold values will need adjusting as the signal frequency increases. i.e. signal

amplitude is proportional to frequency until the sensor reaches saturation. For this reason,

frequency-based signal should use a 2D tables for arming threshold control.

Below is a scope trace showing a signal over one cycle, scaled at 2V/Div. A conventional

oscilloscope or the Emtron scope can be used to view a signal to best determine the correct

arming thresholds. The preferred method is to find the lowest amplitude during one cycle

(highlighted by the red circle below) and make the arming threshold 60% of that value. In

this example the lowest value is 1.9V. Taking 60% gives an arming threshold of 1.1V.

In summary when the positive-going input exceeds 1.1V, the zero crossing circuity becomes

armed and is ready to detect the zero crossing on the next falling edge.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

9

2.2 Digital Input Channels 1- 14 –Switched Input

Digital Input channels 9 -14 are for non-frequency based signal such as switched inputs,

while Digital Inputs 1-8 are available for both. The status of a switched input (On/Off) is

controlled by measuring the analog input voltage and comparing against user defined On

threshold and user defined Off threshold. A switched input can supply either a ground or

voltage into the ECU.

▪Accepts a 0.0 - 20.0V analog input.

▪Effective resolution DI 1-8 is 4.88mV (10-Bit)

▪Effective resolution DI 9-14 is 19.61mV (8-Bit)

▪Switch to 0V, Switch to VBatt, logic signal

▪On/Off switched inputs: AC request, launch enable, cruise

switch, table control switching etc with programable

switch-based arming threshold control, range 0.0 - 20.0V

▪Switchable 4k7 ohm pull-up resistors on all 14 channels.

▪Over and under voltage protection.

▪Input Impedance DI1-8, 39k ohms to ground

▪Input Impedance DI9-14, 70k ohms to ground

Switch to Ground

In the case of a switch supplying a ground, the pullup resistor needs to be turned ON. With

the switch in the OFF position, the ECU input will read the voltage supplied by the pullup

resistor. With the switch in the ON position, the pullup resistor voltage is pulled to ground

and the ECU input will read close to 0V.

NOTE: The current is limited by the 4k7

resistor so pulling the input to ground using

the switch will not damage the ECU.

The current can be worked out using Ohms

Law: V = I x R. Measure the voltage at the pin

with the switch OFF, typically around 9V.

Resistor = 4700 Ohm

Current (I) = 9V / 4700 = 1.9mA

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

10

Switch to Power

In the case of a switch suppling power, the

pullup resistor needs to be turned OFF. With

the switch in the OFF position, the ECU input

will read the 0V through the internal pull-

down resistor network. With the switch in the

ON position, the switch voltage is fed into the

ECU input.

NOTE: The ECU input is protected against high

voltage up to +80V. Feeding the battery

voltage into an input will not damage the ECU

2.3 Digital Input Channels 1- 14 –Analog Input

When not used as frequency or switched inputs these channels can be used to measure analog

signals for ratiometric and absolute 3-wire based sensors. Refer back to Section 1.3.

2.4 Digital Input configuration example

Table 2.0 shows a Digital Input engine configuration example for both Non-VVT and VVT

applications.

DI Input Pin

Channel (non VVT)

Channel (VVT)

Digital Input 1

Speed Rear LH

Intake LH Cam Position

Digital Input 2

Speed Rear RH

Intake RH Cam Position

Digital Input 3

Power Steer switch

Exhaust LH Cam Position

Digital Input 4

Start Switch

Exhaust RH Cam Position

Digital Input 5

Clutch Switch

Speed Front LH

Digital Input 6

Turbo Speed

Speed Front RH

Digital Input 7

Launch Enable Switch

Speed Rear LH

Digital Input 8

Fuel Used Reset Switch

Speed Rear RH

Digital Input 9

Rotary Switch

Clutch Switch

Digital Input 10

AC switch

Start Switch

Digital Input 11

Launch Enable Switch

Digital Input 12

Fuel Used Reset Switch

Digital Input 13

AC switch

Digital Input 14

Rotary Switch

Table 2.0. Digital Input engine configuration example

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

11

3.0 Auxiliary Outputs

The ECU has 16 Auxiliary Outputs with a wide variety of driver types to suit all applications.

These drives are suitable for controlling relays, resistive and inductive loads, stepper

motors, DC servo motors and electronic throttles. All outputs are short circuit and over

current protected.

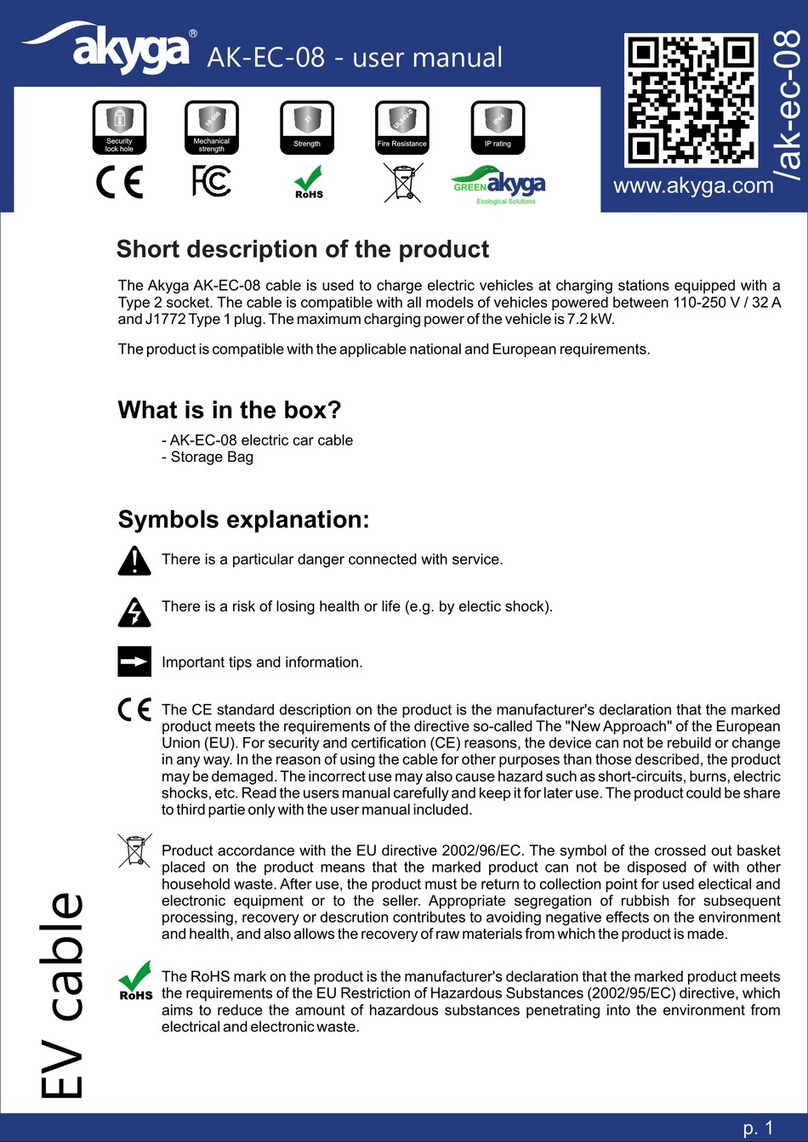

3.1 Auxiliary Output 1-8 –Low side or High side

Auxiliary 1-8 drivers can be configured as Off, Low side

or High side driving. Low side refers to an open

collector output that switches to ground. A High side

driver refers to an output that switches to the ECU

Supply voltage.

▪Auxiliary 1-8 drivers can be configured for Low side

or High side driving

▪Maximum frequency 15kHz

▪Flywheel diode integrated into all outputs with

recirculation current to the ECU Supply pin D1

▪Pin voltage monitored for diagnostics

▪Over current / Short to Battery/Thermal overload protection

▪Electrostatic discharge (ESD) protection

▪Reverse battery protection

Low Side Drivers

▪Auxiliary 1-4: Low side 4A continuous, 8A limit

▪Auxiliary 5-8: Low side 2.5A continuous, 5A limit

High Side Drivers

▪Power soured from the ECU Supply pin

▪Auxiliary 1-8: High side 4A continuous, 9A limit

Suitable applications

▪High frequency solenoids used in Variable Valve Timing (VVT), Variable Valve Timing

Electric (VTiE), Idle Speed Control

▪Low frequency solenoids used in boost control, gearshift solenoids, stepper motor and

many more

▪Solenoid and relay switching used in cam switching (VTEC), runner length control and

basic fuel pump, fan and AC relay control.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

12

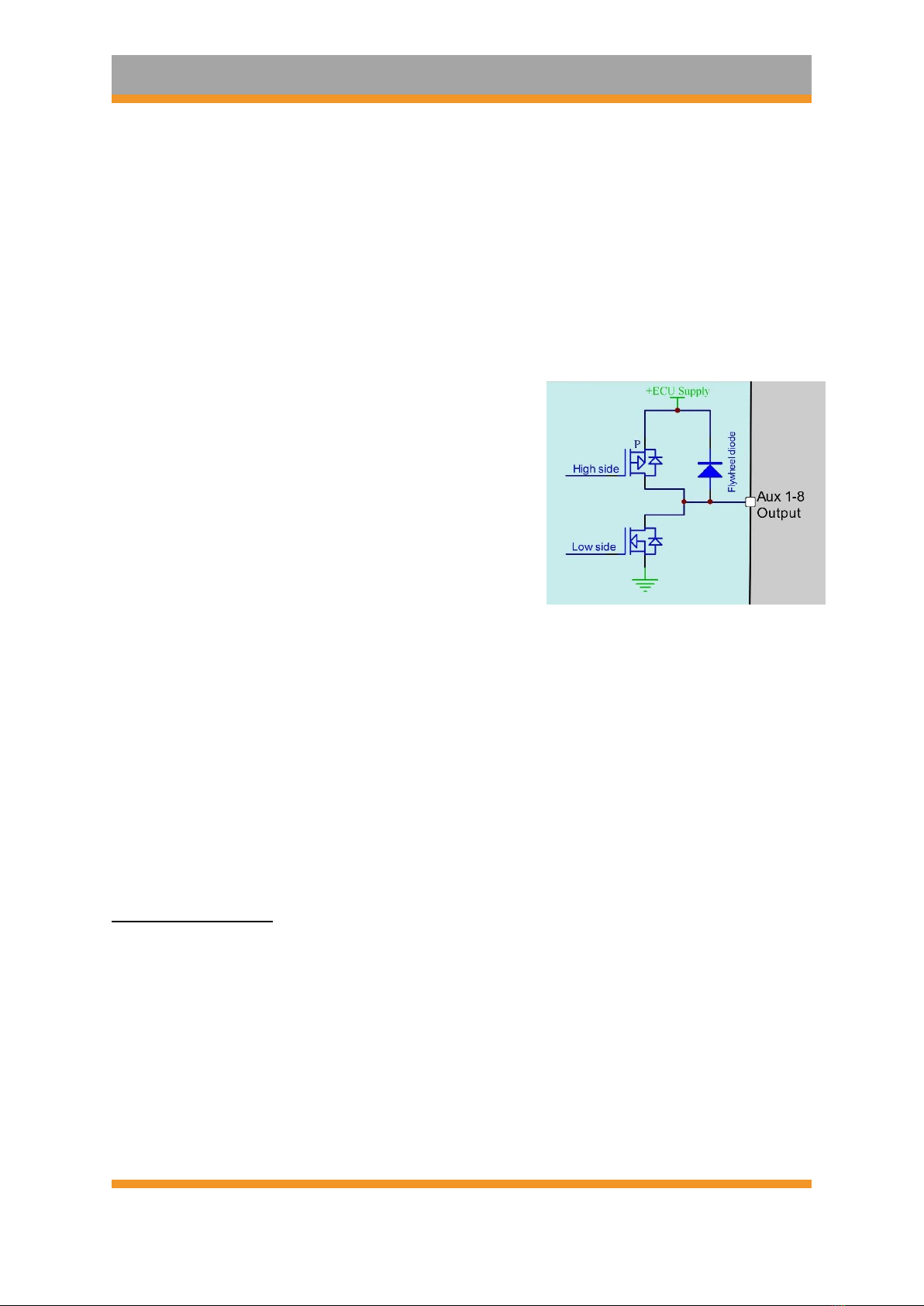

3.2 Auxiliary Output 9-12 –Half Bridge

Half bridge drivers supply either a ground or battery voltage i.e. there is no “off” state.

Auxiliary outputs 9-12 are medium power half bridge drivers, primarily used for DBW

control. Auxiliary 9/10 can be paired into H-bridge configuration for DBW 1 control and

Auxiliary 11/12 can be paired into H-bridge configuration for DBW 2 control.

▪Driver IC for Aux9 -12 needs power using “Aux 9-12

Supply” pin D20. In non-DBW applications the ECU

Supply power source can be used. In DBW

applications power to this pin MUST come from an

ECU controlled DBW Relay.

▪Maximum frequency 15 kHz

▪Flywheel diode integrated into all outputs with

recirculation current to the Aux 9-12 Supply pin D20

▪Over current / Short to Battery/Thermal overload

protection

▪Electrostatic discharge (ESD) protection

▪Reverse battery protection

▪Half Bridge 5A continuous and 8A limit. Can be used

as Low Side, High Side or paired with another channel for DC motor control (DBW)

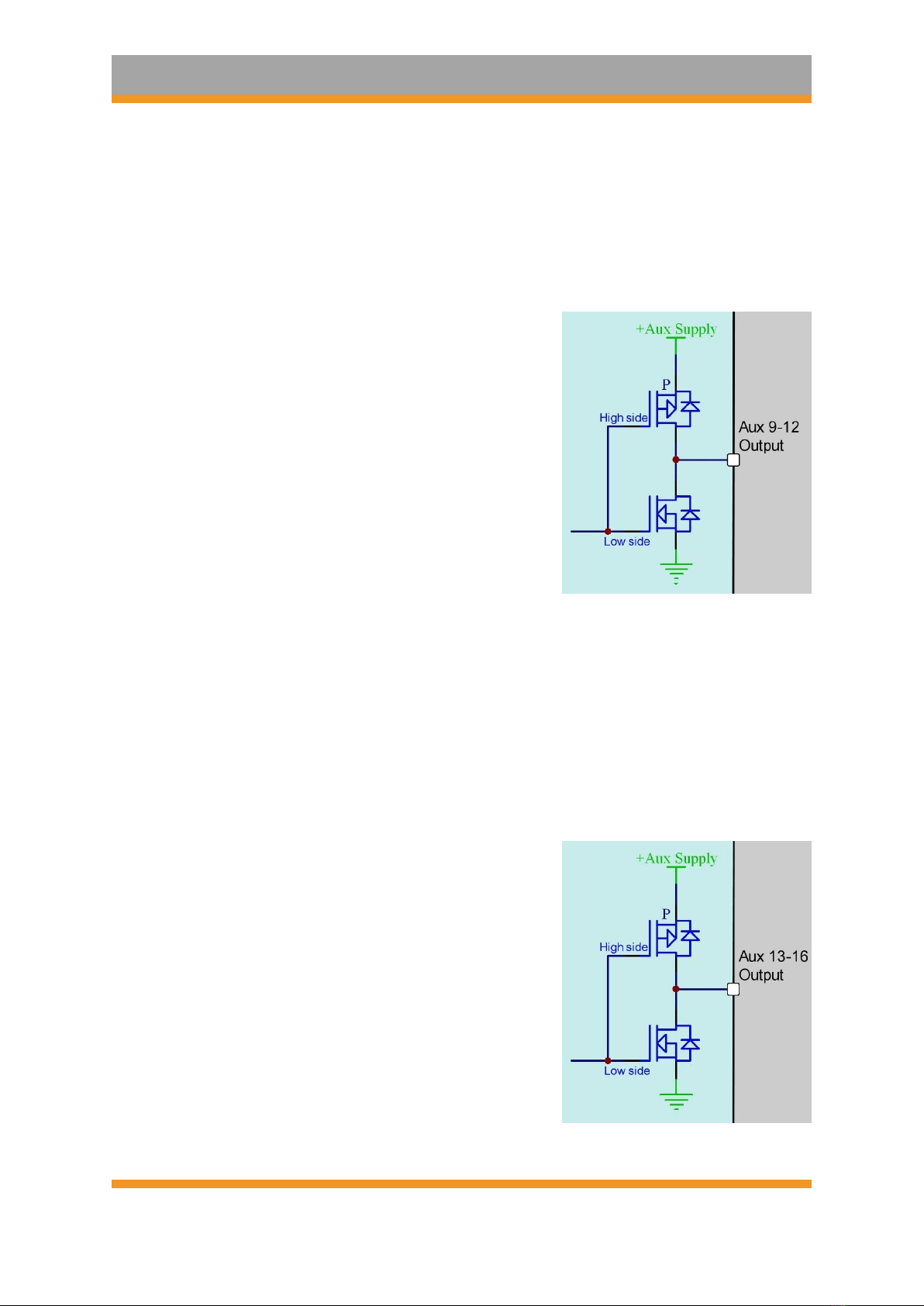

3.3 Auxiliary Output 13-16 –Half Bridge

Half bridge drivers supply either a ground or battery voltage i.e. there is no “off” state.

These are high power half bridge drivers used to switch high current inductive loads. In a

KV12 and KV16 they can also be paired for DBW control giving a total of 4 DBW channels.

▪Driver ICs for Aux13 -16 needs power using “Aux 13-

16 Supply” pin D2. In non-DBW applications the ECU

Supply power source can be used. In DBW

applications power to this pin MUST come from an

ECU controlled DBW Relay.

▪Maximum frequency 15 kHz

▪Flywheel diode integrated into all outputs with

recirculation current to the Aux 13-16 Supply pin D2

▪Over current / Short to Battery/Thermal overload

protection

▪Electrostatic discharge (ESD) protection

▪Reverse battery protection

▪Half Bridge 15.0A continuous (pin limited). Can be

used as Low Side, High Side or paired with another channel for DC motor control (DBW)

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

13

3.4 Auxiliary Outputs –Full Bridge Configuration (DBW)

By connecting 2x half bridge outputs together a full bridge can be configured. This is used

for DC motor direction and braking control required for applications like DBW control. The

below schematic shows Aux 9 and 10 paired to form a full bridge configuration for DBW

control.

The following table 3.0 explains the operation for the full bridge.

Transistor

Q1 State

Transistor

Q2 State

Transistor

Q3 State

Transistor

Q4 State

DBW/Motor

Direction

Aux 9

Output

Aux 10

Output

ON

OFF

OFF

ON

Forward

H

L

OFF

ON

ON

OFF

Reverse

L

H

ON

OFF

ON

OFF

High side

Freewheeling

H

H

OFF

ON

ON

OFF

Low Side

Freewheeling

L

L

Table 3.0. Full Bridge operation

For 1 or 2 channels DBW applications the following output pairing is required:

▪DBW1, it is recommended to pair Auxiliary 9 and Auxiliary 10 outputs.

▪DBW2, it is recommended to pair Auxiliary 11 and Auxiliary 12 outputs.

For KV12 and KV16, 4 channel DBW applications the following output pairing is required:

▪DBW3, it is recommended to pair Auxiliary 13 and Auxiliary 14 outputs.

▪DBW4, it is recommended to pair Auxiliary 15 and Auxiliary 16 outputs.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

14

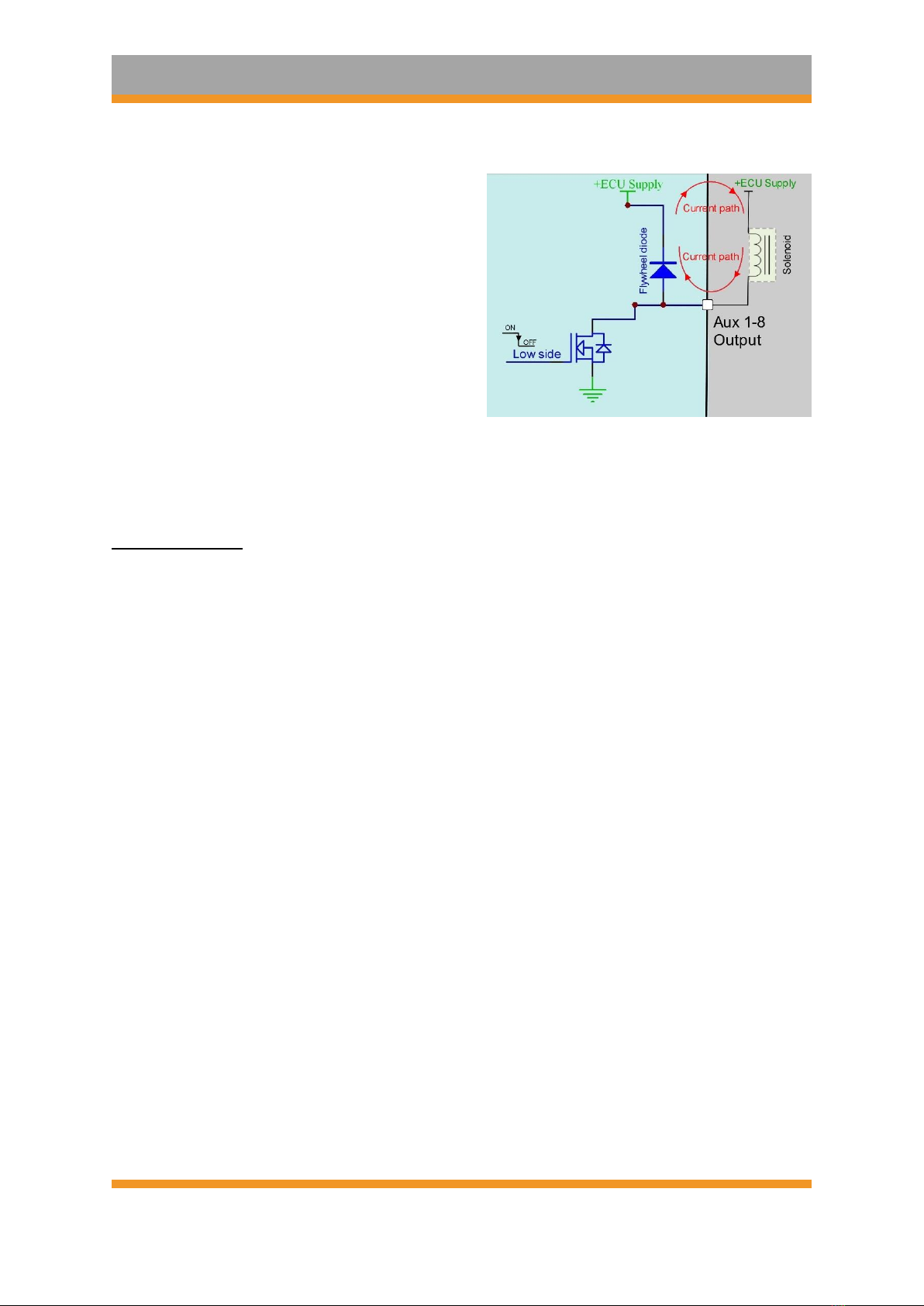

3.5 Auxiliary Output –Flywheel diodes

Flywheel diodes are used to eliminate the

voltage spike or flyback voltage when an

inductive load is switched off. The diode

recirculates the inductive energy at switch off,

so it can be dissipated by the internal

resistance of the load. This schematic on the

right shows the Low side driver switching off,

the red arrows indicate how the current

recirculates through the flywheel diode and

back through the load. The current will decay

until its insufficient to keep to load On or

solenoid open, at which point the load will turn Off.

Note: The ECU and load share the same power supply allowing the flywheeling to operate.

Important points

▪Flywheel diodes allow inductive energy to be dissipated back into the load

▪Flywheel diodes will increase the time it takes for the load to switch off

▪Flywheel diodes minimize EMI by removing the inductive voltage spike and forcing

the current to recirculate. The higher the frequency to more important this is.

3.51 VVT and Idle Solenoids –why we need flywheel diodes

When controlling VVT solenoids flywheel diodes are required for the solenoid to operate

correctly. At frequencies between 200Hz - 300Hz, the flywheel diode prevents the solenoid

switching fully On or fully Off. The flywheel diode allows the current to recirculate and find

an “average” value during the switch On and switch Off times (duty cycle). Instead of the

solenoid switching fully On or fully Off we can control its position between these 2 points.

By controlling the duty cycle, the solenoid average position can be controlled.

For this reason, Auxiliary channel 1-16 are recommended for VVT/Idle solenoid control. If

however a Fuel or Ignition channel is used an external flywheel MUST be fitted.

3.52 Boost Control Solenoid

These solenoids require a fast reduction in current when switched off. As all Auxiliary

channels have integrated flywheel diodes this recirculation circuity slows the switch off time

at higher frequencies and will cause solenoid control issues. For this reason, the boost

control modulation frequency should be kept below 30Hz. Typical values are 15 –20Hz.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

15

3.53 Transmission Brake Solenoid

Some Transmission Brake solenoids produce a large amount of energy when released.

Auxiliary channels 13-16 are the only outputs with enough current to power such solenoids.

It is strongly recommended to run an external flywheel diode to prevent long term ECU

damage. If the output is modulated a flywheel diode MUST be installed (See Emtron www

for details).

NOTE: Maximum Trans-brake frequency is 100Hz

3.6 Permanently Powered Loads

Auxiliary outputs 1-8 are not suitable for

permanently powered loads. The integrated

flywheel diode will cause back-feeding onto

the flywheel recirculation pin (ECU Power pin)

and keep the ECU powered up. This can be

viewed using the schematic on the right. With

the Low and Hide side drivers off, current will

flow through the solenoid, through the

flywheel diode and back onto the ECU supply.

To avoid this issue, move the load to a non-

flywheel output such as an unused Fuel or

Ignition channel or re-configure the solenoid

supply feed.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

16

3.7 Auxiliary Output configuration example

Table 3.1 shows an Auxiliary output engine configuration example for both Non-VVT and

VVT applications.

Aux Output Pin

Channel (non VVT)

Channel (VVT)

Auxiliary 1

Idle Solenoid

VVT Intake LH Solenoid

Auxiliary 2

Boost Solenoid

VVT Intake RH Solenoid

Auxiliary 3

Tacho

VVT Exhaust LH Solenoid

Auxiliary 4

Fuel Pump

VVT Exhaust RH Solenoid

Auxiliary 5

Fuel Pump Speed

Cooling Fan

Auxiliary 6

AC Clutch

Boost Solenoid

Auxiliary 7

Cooling Fan

Tacho

Auxiliary 8

Cam Switch

Fuel Pump

Auxiliary 9

AC Fan

DBW 1+

Auxiliary 10

CEL

DBW 1-

Auxiliary 11

Downshift Solenoid

Auxiliary 12

Upshift Solenoid

Auxiliary 13

AC Fan

Auxiliary 14

CEL

Auxiliary 15

AC Clutch

Auxiliary 16

DBW Relay

Table 3.1. Auxiliary Output engine configuration example

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

17

4.0 Injector Outputs

The KV series supports from 8 up to 16 injector outputs and will control both modes of

injection; Saturated and Peak and Hold.

KV ECU

Injector Outputs

KV8

8

KV12

12

KV16

16

KV16M

16

4.1 Injector Control

Precise and consistent control is also gained with a high 70V flyback voltage, allowing for

rapid current reduction at switch Off time.

▪Flyback Voltage Clamp 70V

▪Total current limited to 10A

▪Outputs can be used for ground switching, 6A Continuous, 10A Limit

▪All outputs are short circuit and over current protected

▪Pin voltage monitored for diagnostics

▪No Flywheel diodes (external diode(s) required for VVT and Idle Speed control)

▪Suitable to connect loads that are permanently powered

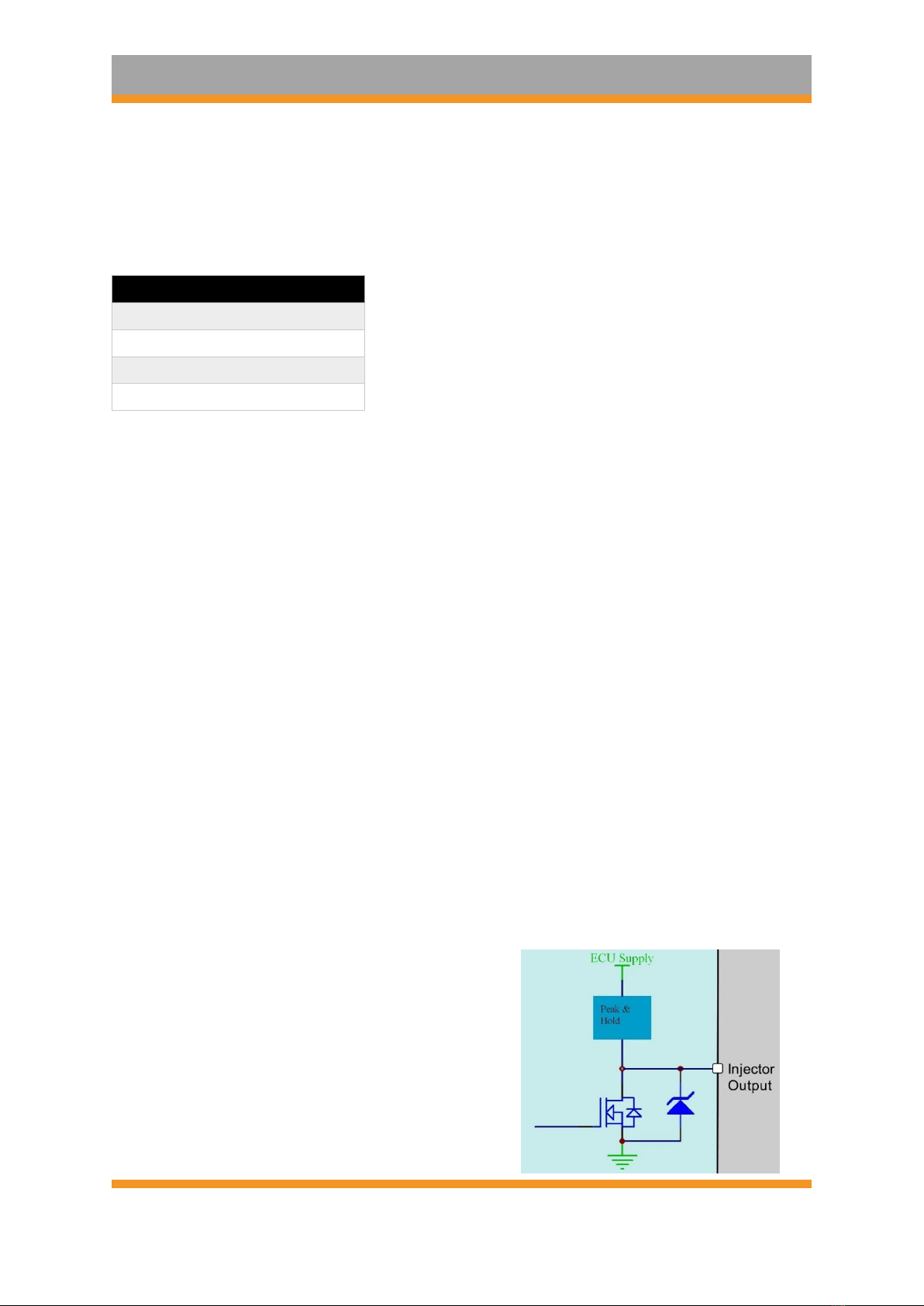

4.1 Peak and Hold Injector Control

When using low impedance injectors (< 5 Ohms) the ECU uses a switch mode current

limiting technique to minimise heat dissipation in the Injector. This gives better injector

control and helps maximize injector life by lowering its operating temperature. Switched

Flywheel circuity is used to recirculate injector current back to the ECU supply during the

“Hold”phase. This is ONLY active in Peak and Hold mode.

▪Independently configurable Peak and Hold

currents up to 16 cylinders

▪Flyback Voltage Clamp 70V

▪Max Peak current 8A

▪Max Hold current 4A

▪Total current limited to 10A

▪Flywheel recirculation current to the ECU

Supply pin D1 during “Hold” phase.

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

18

4.2 Saturated Injector Control

Required when injector resistance is greater than 5 Ohms

▪Flyback Voltage Clamp 70V

▪Total current limited to 10A

4.3 Auxiliary Load Switching on Injector Outputs

When the Injector output is not configured to drive an injector, it can be used to switch or

modulate a resistive or inductive load. i.e. relay, waterspray solenoid, Boost solenoid etc.

▪Flyback Voltage Clamp 70V

▪Total current limited to 10A

▪Maximum Frequency 5kHz

▪No internal flywheel diodes. VVT and Idle solenoids require external flywheel diodes

4.4 Protection

▪Over current / Short to Battery protection

▪Electrostatic discharge (ESD) protection

▪Flyback Voltage Clamp 70V

KV SERIES HARDWARE MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD JUNE 2018

19

5.0 Ignition Outputs

The KV series supports from 8 up to 12 Ignition channels with logic level outputs.

KV ECU

Ignition Outputs

KV8

8

KV12

12

KV16

12

KV16M

12

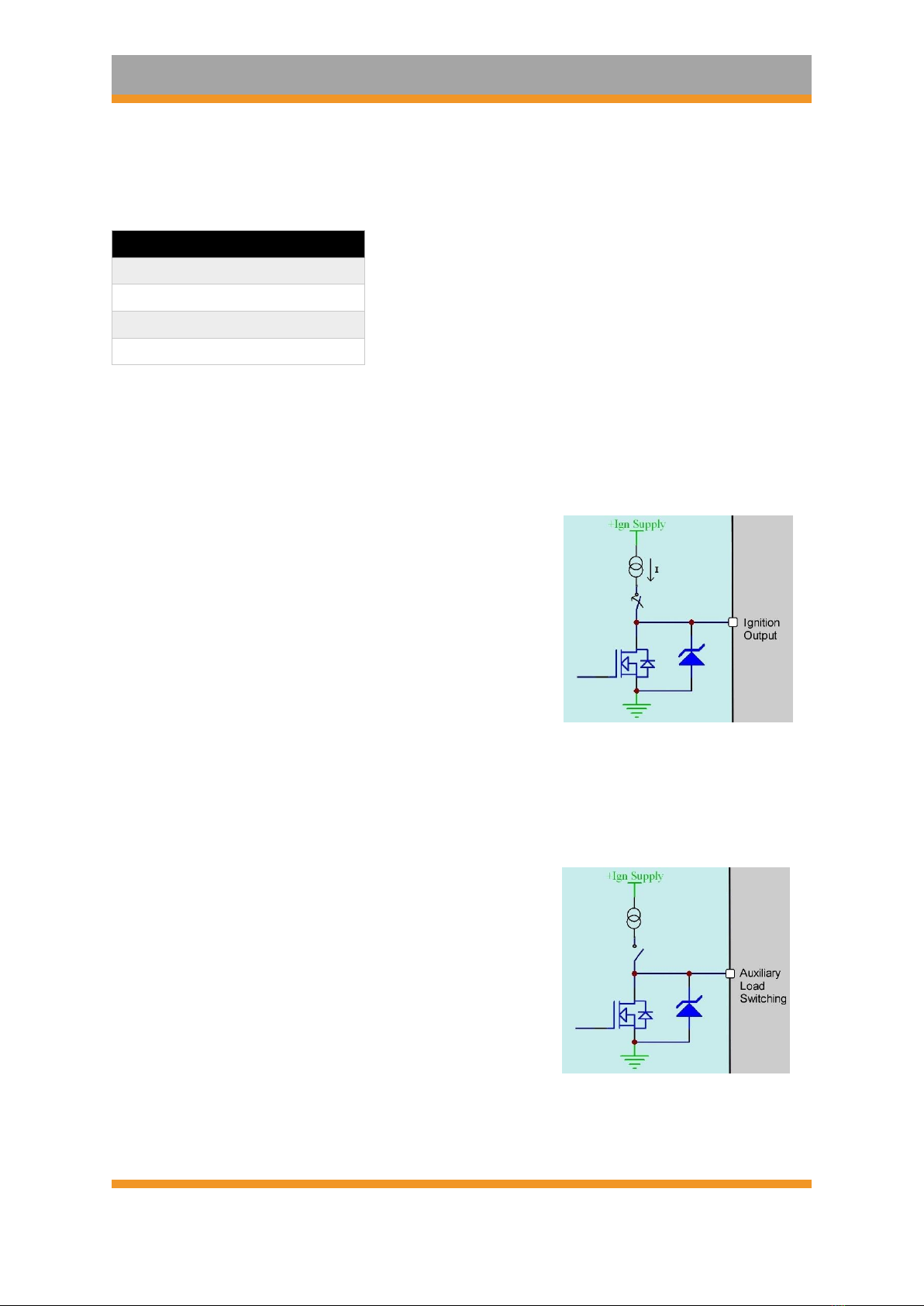

5.1 Ignition Control

When configured for ignition, these outputs are logic level drivers, capable of sourcing

current in the range of 35 - 70mA. DO NOT connect directly to a coil and attempt to drive it.

An ignitor MUST be used between the ECU and coil.

▪Open collector output (low side) with active

current source control to produce a logic level

signal for Ignitor control.

▪Adjustable Ignition drive current (35mA or 70mA

global control). For example, more current is

required when 1 output is driving 2 ignitors.

5.2 Auxiliary Load Switching on Ignition Outputs

When the Ignition output is not configured to drive an ignitor, it can be used to switch or

modulate a resistive or inductive load. i.e. relay, waterspray solenoid, Boost solenoid etc.

▪Open collector outputs (low side) with current

source is OFF.

▪Flyback Voltage Clamp 40V

▪Continuous current limited to 1A

▪Total current limited to 3A

▪Maximum Frequency 5kHz

▪No internal flywheel diodes. VVT and Idle

solenoids require external flywheel diodes

This manual suits for next models

4

Table of contents

Other Emtron Cables And Connectors manuals