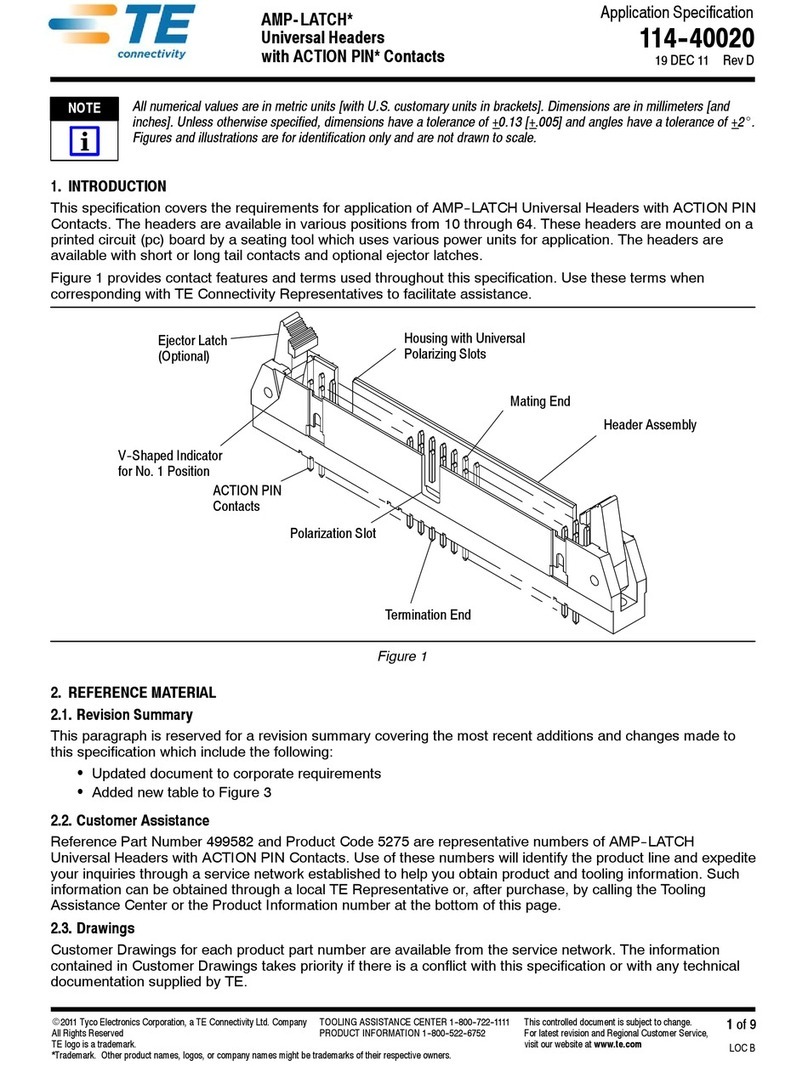

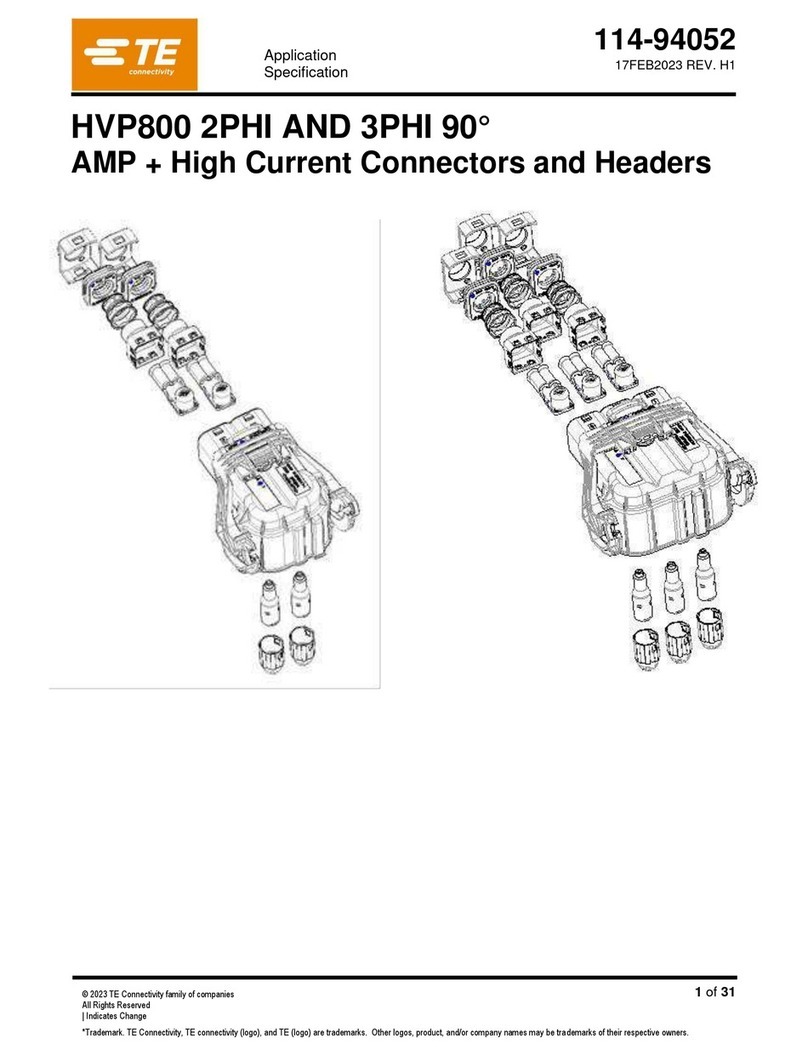

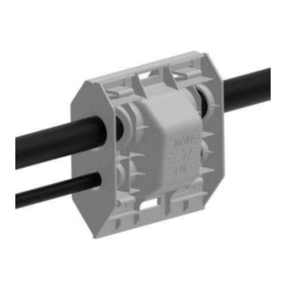

Mounting Nut

Lockwasher

Gasket

Housing

Dielectric

Center Contact

O-Ring Rear Housing

TE CONNECTIVITY

PART NUMBER PREVIOUS PART

NUMBER DESCRIPTION CABLE TYPE

1057160-1 3004-7941-01 Type N Bulkhead Feedthrough Cable Jack - .141 Semi-Rigid Coaxial Cable

- .141 Semi-Rigid Microporous Cable

1057159-1 3004-7941-00

©2011 Tyco Electronics Corporation, a TE Connectivity Ltd. Company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 2

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-4911

Type N

Bulkhead Feedthrough

Cable Jack Connectors 03 NOV 11 Rev C

Figure 1

1. INTRODUCTION

These instructions cover the application of the Type N

Bulkhead Feedthrough Cable Jack Connectors listed

in the table in Figure 1. These connectors are used in

direct solder attachment type applications.

Dimensions in these instructions are in metric units

[with U.S. customary units in brackets], unless

otherwise indicated. Figures are for identification

only and are not drawn to scale.

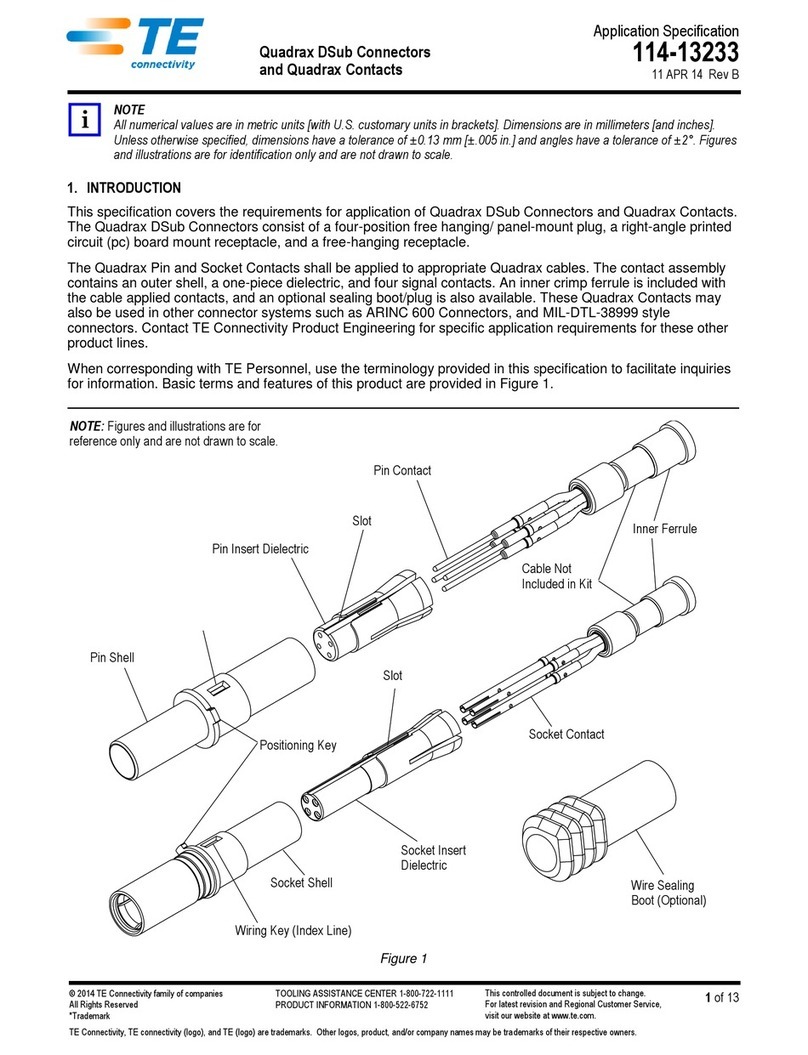

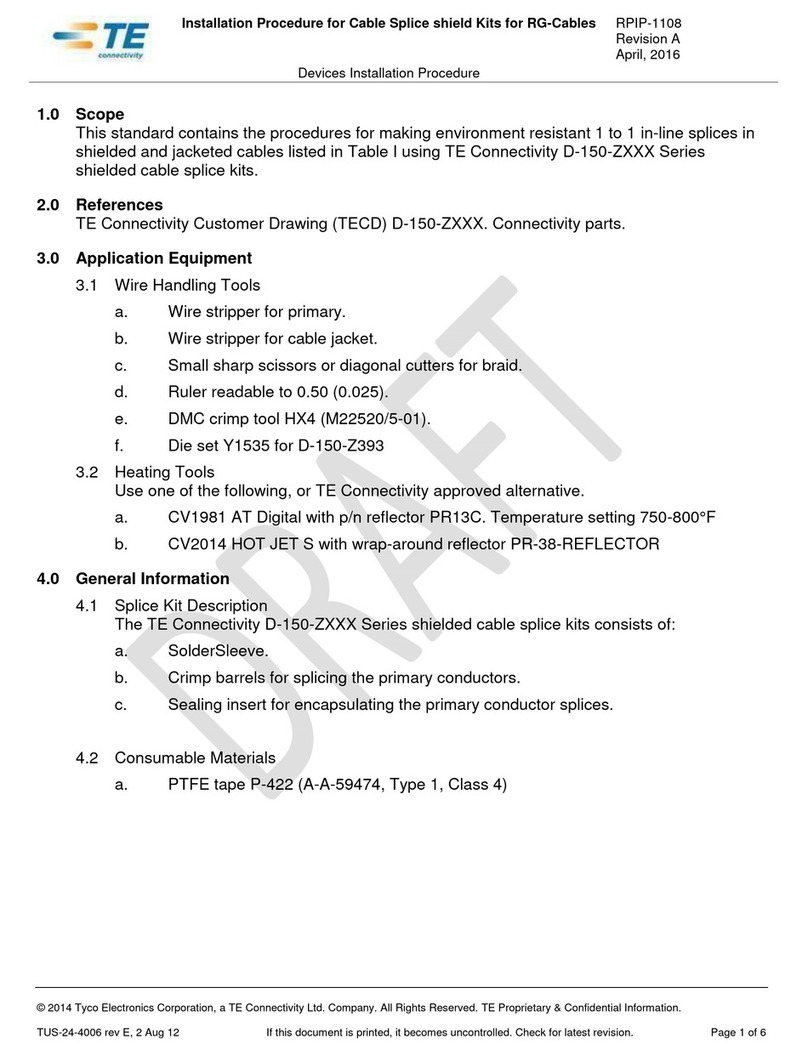

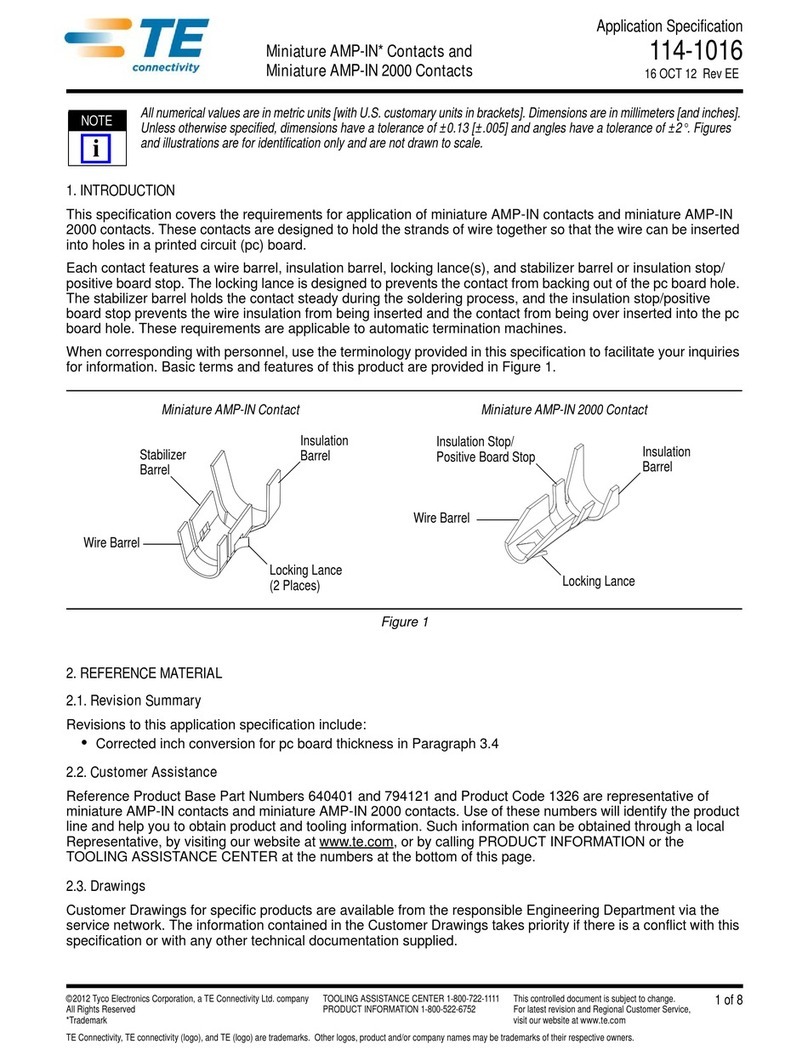

The table in Figure 2 indicates the tooling required for

the application of these connectors. The TE part

numbers are listed, along with the previous part

numbers, and the tooling description.

TE PART

NUMBER PREVIOUS PART

NUMBER DESCRIPTION

1055439-1 2098-5206-54

(T-4567) Cable Fixture

Subassembly

1055440-1 2098-5207-54

(T-4700-1 Clamp Insert Assembly

1055472-1 2098-5277-10

(T-4561) Center Contact Holder

91362-1 - - Solder Gage

1055471-1 2098-5276-02

(T-4572) Locator Tool

Figure 2

Reasons for revision can be found in Section 3,

REVISION SUMMARY.

2. ASSEMBLY

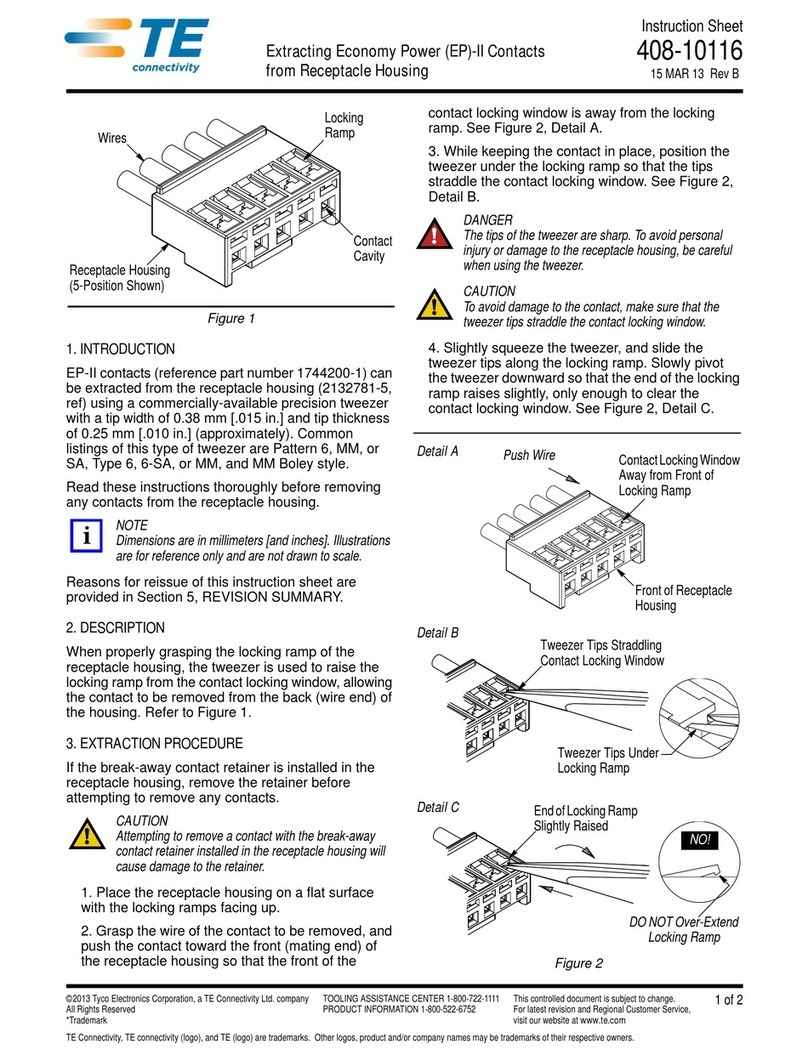

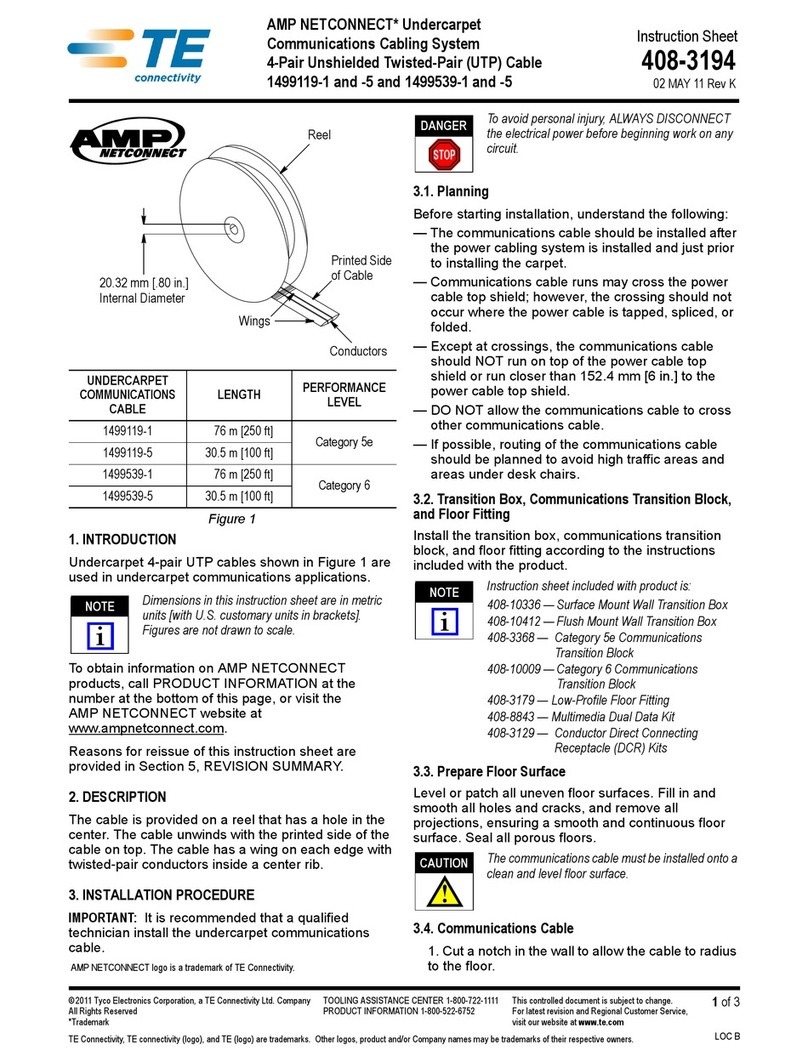

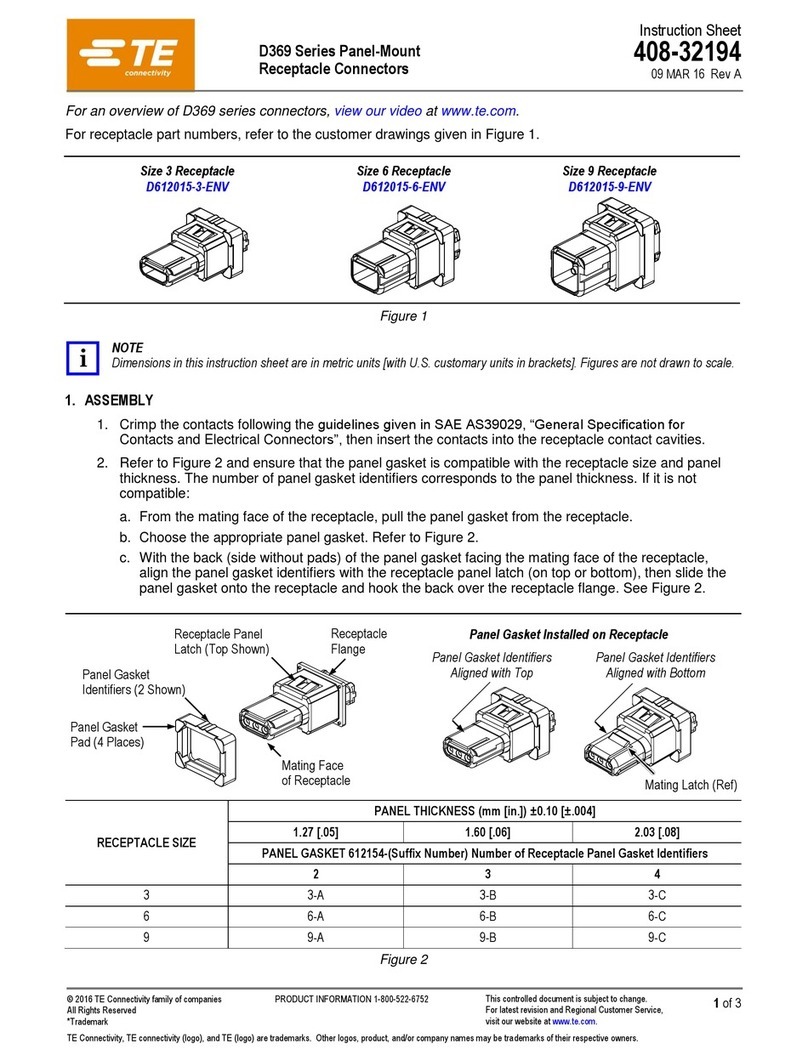

2.1. Cable Preparation (See Figure 3)

1. Insert the squared end of the cable into the fixture

base hole pattern #2.

2. Place the saw in the saw slot and cut through the

outer conductor and into the dielectric while rotating

the cable.

To avoid personal injury, always use caution and

followall localpractices whenusing acutting blade.

3. Remove the cable from the fixture and finish

cutting the cable with a cutting blade.

4. Bare the inner conductor by prying the outer

conductor and dielectric from the cable.

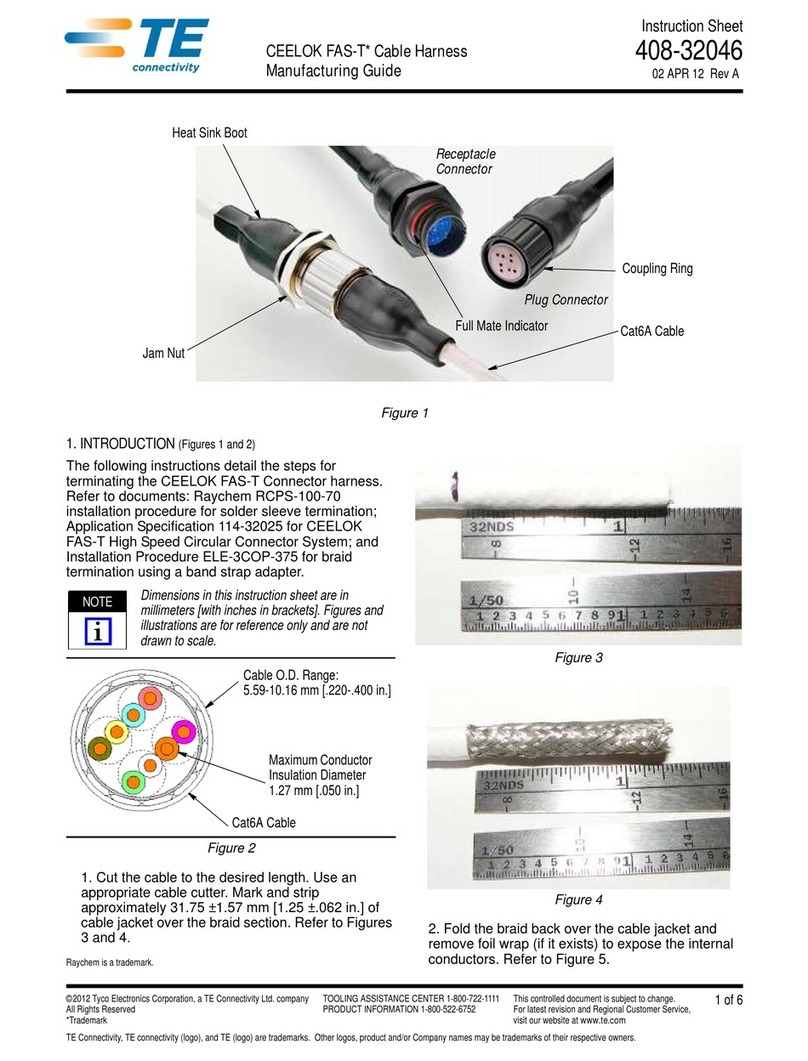

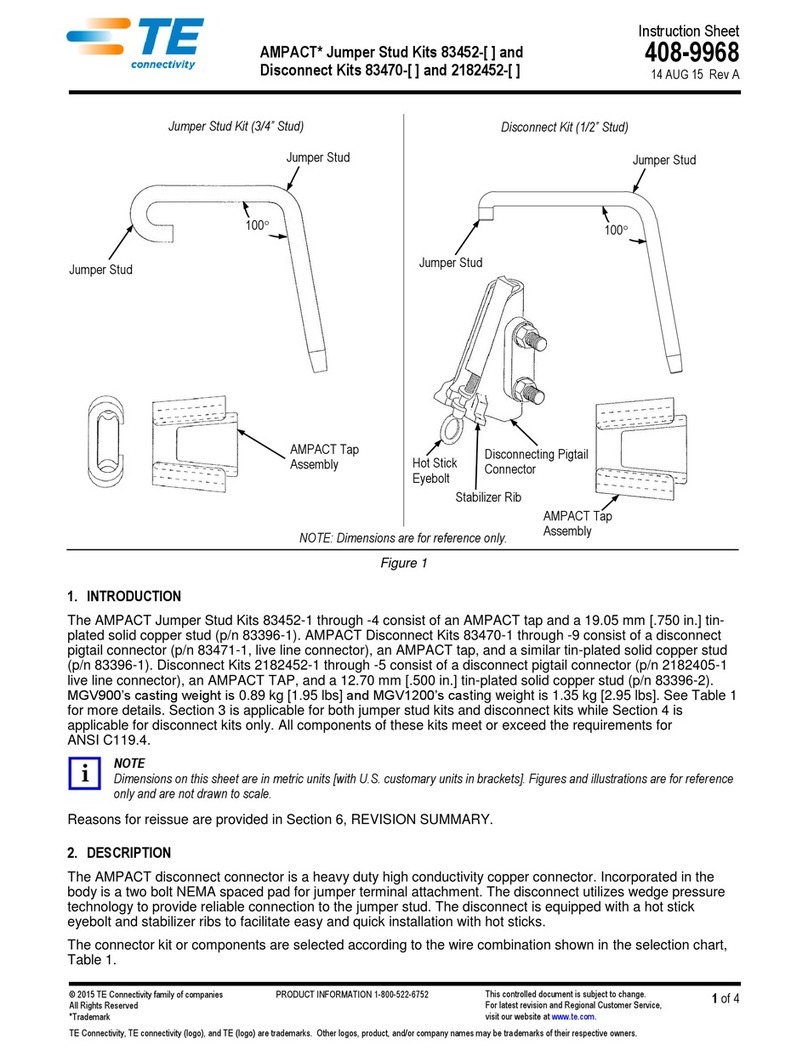

2.2. Soldering the Center Contact to the Cable Inner

Conductor (See Figure 4)

To avoid personal injury, always use caution and

follow all local practices when using soldering

equipment.

1. Tin the inner conductor of the cable.

2. Place the solder gage on the inner conductor

flush with end of the outer conductor.

3. Place the center contact in the holder, heat the

center contact and push it over the inner conductor

of the cable to rest firmly against the solder gage.

4. Remove solder gage and excess solder.