Emtron EIC10 User manual

Z

EIC10/ EIC16M

USER

MANUAL

Rev 1.0

Emtron Input

Expansion to CAN

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

1

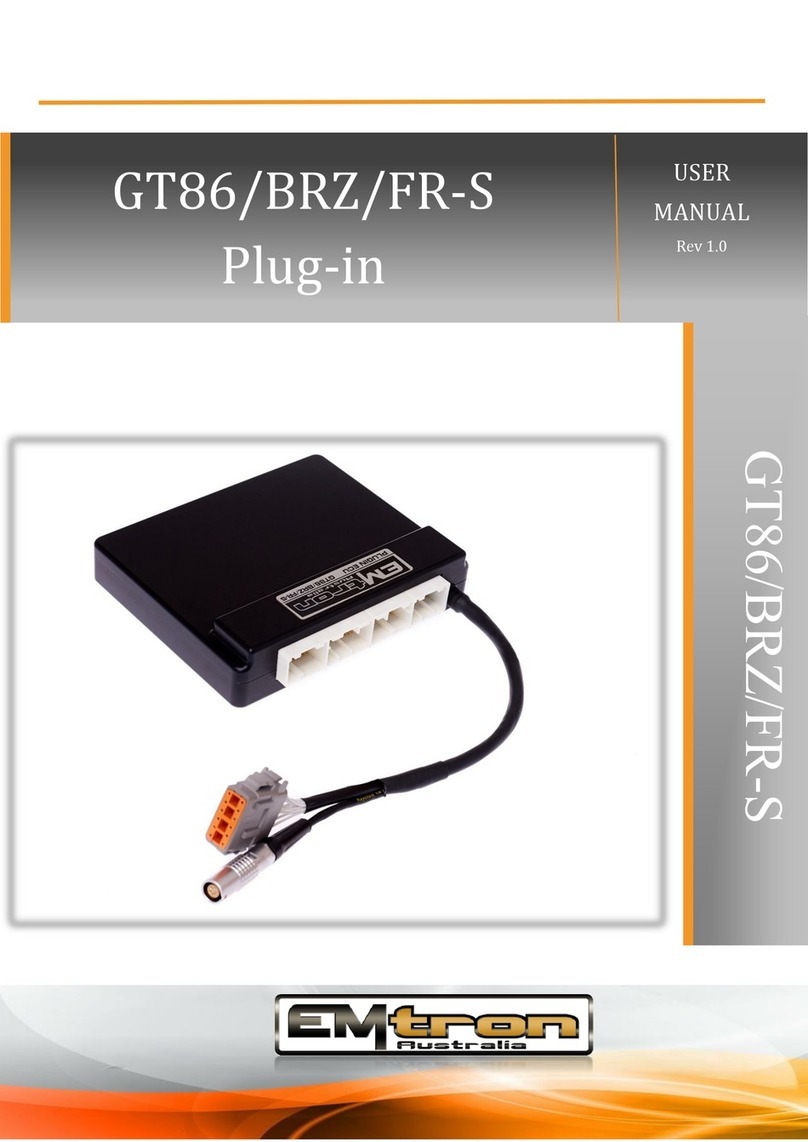

Kit Contents

When purchasing an EIC10 the following items are included:

▪EIC10 Device with Flying Harness

▪Deustch DTM 4-way connector and female pins (DTM06-4S)

▪Deustch DTM 12-way connector and male pins (DTM04-12PA)

EIC10 kit pictured.

When purchasing an EIC16M the loom side mating Autosport connector is not included but

can be purchased separately.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

2

Contents

1.0 Description ...........................................................................................................................3

2.0 Specification.........................................................................................................................4

3.0 Installation ...........................................................................................................................6

3.1 EIC10 Pinout.....................................................................................................................6

3.2 EIC16M Pinout .................................................................................................................7

3.3 CAN Bus............................................................................................................................8

3.4 Pullup Resistors................................................................................................................9

3.5 Frequency Inputs ...........................................................................................................10

3.6 Noise Immunity..............................................................................................................11

3.7 Sensor Wiring.................................................................................................................11

3.8 CAN Bus Wiring ..............................................................................................................12

4.0 EIC Device Configuration....................................................................................................14

4.1 EIC Single Device Setup..................................................................................................14

4.11 EIC Device Detection................................................................................................14

4.12 ECU CAN Configuration for Single Device................................................................15

4.13 EIC Data Monitoring for Single Device.....................................................................16

4.2 EIC Multiple Device Setup..............................................................................................16

4.21 EIC Multiple Device Detection .................................................................................17

4.22 EIC CAN Base Address ID Reprogramming ..............................................................18

4.23 ECU CAN Configuration for Multiple Devices ..........................................................19

4.24 EIC Data Monitoring for Multiple Devices ...............................................................19

5.0 ECU Channel Configuration................................................................................................20

6.0 EIC Custom Settings ...........................................................................................................21

7.0 Ordering Information.........................................................................................................24

Appendices...............................................................................................................................25

Appendix 1. CAN Bus Data Packaging..................................................................................25

Appendix B. Magneto-Resistive Sensors .............................................................................32

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

3

1.0 Description

EIC16M

The EIC16M is a Mil Spec device designed to increase the

Input channel capability of all Emtron ECUs with 16 high

resolution analog and/or 4 frequency based inputs. The

device is connected via CAN bus and will be automatically

detected which will significantly minimalize configuration

time. The enclosure is made from billet 6061 aluminium

and is waterproof, allowing for use in extreme

environments. Installation is made simple through use of

a Motorsport proven Deutsch Autosport connector

system.

EIC10

The EIC10 is designed to increase the Input

channel capability of all Emtron ECUs with

10 high resolution analog inputs and/or 4

frequency based inputs. The device is

connected via CAN bus and will be

automatically detected which will

significantly minimalize configuration time.

The waterproof enclosure is extremely

compact and made from billet 6061

aluminium. The device implements a flying

loom system, terminated with the reliable

and environmentally sealed Deutsch DTM

connectors.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

4

2.0 Specification

Power Supply

▪Operating Voltage: 7.0 to 22.0 Volts DC

▪Operating Current: 30mA at 14.0V

▪Reverse Battery Protection: 0mA current draw

▪Battery Transient/Over Current Protection

Internal

▪64MHz 16-bit Automotive Processor

▪Analog Channel Sampling Rate 500 Hz

Inputs - General

•Analog Inputs

oRange 0.0V to 5.0V, Resolution. 1.22mV 12 Bit

•Frequency Inputs

oRange 0.5Hz up to 6500.0Hz, Resolution. 0.1Hz

oMagnetic and Hall effect sensor compatible

oRising Edge Threshold = 1.8V, Falling Edge Threshold = 1.0V

EIC10 –10 Analog Inputs

▪ANV1-6: Analog Inputs 0.0V - 5.0V Range, Resolution. 1.22mV 12 Bit

▪ANV7-10 / Frequency Input 1-4

oAnalog Inputs 0.0 –5.0V range. Resolution. 1.22mV 12 Bit

oSwitchable 1k Pullup with blocking diodes to 8V Supply

oRange 0.5Hz up to 6500.0Hz, Resolution. 0.1Hz

EIC16M –16 Analog Inputs

▪ANV1-12: Analog Inputs 0.0V - 5.0V Range, Resolution. 1.22mV 12 Bit

oSwitchable 1k Pullup Resistor to 5V Sensor Supply (ANV 9-12).

▪ANV13-16 / Frequency Input 1-4

oAnalog Inputs 0.0 –16.0V range. Resolution. 4.02mV 12 Bit

oSwitchable 1k Pullups with blocking diode to 8V Supply

oRange 0.5Hz up to 6500.0Hz, Resolution. 0.1Hz

Outputs

▪5V Sensor Supply. Output current 250mA. Short circuit to ground protected.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

5

Communications

▪CAN 2.0B Baud Rate: 250kBaud, 500kBaud or 1Mbaud Auto Detect

▪CAN Transmit Rate Adjustable: 50Hz/100Hz/200Hz/500 Hz

Operating Temperature

▪Operating Temperature Range: -30 to 100°C (-22 to 212°F)

Physical

EIC16M

▪Enclosure Size 52 mm x 74 mm x 18 mm

▪125g

EIC10

▪Enclosure Size 63mm x 54 mm x 20mm

▪160g

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

6

3.0 Installation

Each device has a M4 x 1.5 thread tapped into the base of the enclosure and can be used for

mounting. In high vibration applications rubber mounting is recommended.

CAUTION: When mounting the device inside the engine compartment, it should be

positioned in cooler areas and away from heat sources such as exhaust manifolds. Any

unnecessary radiated heat may affect device performance.

3.1 EIC10 Pinout

The pinouts are shown below in Table 3.0 and Table 3.1.

Power and CAN Flying Loom Connector: DTM 4 pin

(M).

Pin

Function

Wire Colour

1

Ground

BLACK

2

CAN Lo

GREEN

3

CAN Hi

YELLOW

4

12V Supply

RED

Table3.0. EIC10 Power and CAN Deustch Connector

Pinout

Analog Input Flying Loom Connector: DTM 12 pin (F).

Pin

Function

Voltage

Range

Pullup

Wire

Colour

1

Analog Voltage 1

0 - 5.0V

No

BRN

2

Analog Voltage 2

0 - 5.0V

No

BLUE

3

Analog Voltage 3

0 - 5.0V

No

GREY

4

Analog Voltage 4

0 - 5.0V

No

W/GREY

5

Analog Voltage 5

0 - 5.0V

No

W/BLUE

6

5V Sensor Supply

W/BRN

7

Analog Sensor 0V Reference

W/RED

8

Analog Voltage 6

0 - 5.0V

No

W/BLACK

9

Analog Voltage 7/ Freq 1

0 - 5.0V

Yes

W/OR

10

Analog Voltage 8/ Freq 2

0 - 5.0V

Yes

OR

11

Analog Voltage 9/ Freq 3

0 - 5.0V

Yes

WHITE

12

Analog Voltage 10/Freq 4

0 - 5.0V

Yes

PUR

Table3.1. EIC10 Input Deustch Connector Pinout (DTM06-12SA)

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

7

3.2 EIC16M Pinout

Mating Connector Loom Side

(Deutsch Autosport AS Series)

AS612-35SA (Yellow)

Pin

Function

Voltage Range

Pull-Up

1

14 V Supply

2

Ground

3

CAN Hi

4

CAN Lo

5

Analog Voltage 1

0.0 –5.0V

No

6

Analog Voltage 2

0.0 –5.0V

No

7

Analog Voltage 3

0.0 –5.0V

No

8

Analog Voltage 4

0.0 –5.0V

No

9

Analog Voltage 5

0.0 –5.0V

No

10

Analog Voltage 6

0.0 –5.0V

No

11

Analog Voltage 7

0.0 –5.0V

No

12

Analog Voltage 8

0.0 –5.0V

No

13

Analog Voltage 9

0.0 –5.0V

Yes

14

Analog Voltage 10

0.0 –5.0V

Yes

15

Analog Voltage 11

0.0 –5.0V

Yes

16

Analog Voltage 12

0.0 –5.0V

Yes

17

Analog Voltage 13/Frequency 1

0.0 –16.5V

Yes

18

Analog Voltage 14/Frequency 2

0.0 –16.5V

Yes

19

Analog Voltage 15/Frequency 3

0.0 –16.5V

Yes

20

Analog Voltage 16/Frequency 4

0.0 –16.5V

Yes

21

5.0V Sensor Supply

22

0V Analog Sensor Reference

Table 3.2. EIC16M Pinout

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

8

3.3 CAN Bus

The EIC10 or EIC16M can be connected to the ECUs CAN Bus 1 or 2.

All devices on the CAN Bus must be configured to use the same baud rate. For this reason,

all Emtron CAN devices will Auto-scan the CAN bus until a successful baud rate has been

detected. Once detected this rate will be stored and used at the next power up.

The device will scan 3 different Baud rates at 500ms intervals moving from 1Mbaud ->

500kBaud -> 250k Baud -> 1Mbaud and so on.

NOTE: For this process to function effectively, when new devices are introduced to the CAN

bus, they should initially be connected one at a time. This allows each device to sync up to

the CAN Bus baud rate and store that setting. This typically takes 3-5 seconds.

The EIC10 and EIC16M leave the factory programmed with individual serial numbers, but all

have the same Base CAN Address ID used to transmit data over the Bus. The CAN Base

address can be adjusted from the factory setting using the ID Reprogramming Tool. This is

required when 2 or more of the same devices are connected to the CAN Bus (See section

4.2)

EIC10.

▪Factory CAN Base Address of 718. Transmits data sequentially on the next 3 IDs.

Total CAN ID Range is therefore 718 –721.

▪Up to 2x EIC10 devices can be used on the CAN Bus giving a total of 20 available

Input Channels.

EIC16M.

▪Factory CAN Base Address of 705. Transmits data sequentially on the next 5 IDs.

Total CAN ID Range is therefore 705 –710.

▪Only 1 EIC16M device permitted on the CAN Bus.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

9

3.4 Pullup Resistors

EIC10

The EIC10 has no switchable pullups to 5V, so an external 1k resistor will need to be fitted

when connecting to a temperature sensor. The 5V Analog Sensor Supply pin can be used as

the pullup supply.

Table 3.1 shows the inputs with software controlled 8V 1k Ohm pullup resistors plus

blocking diode.

Pin

Function

Pull-Up

Pin 9

Analog Voltage 7 or Frequency Input 1

Yes –8.0V

Pin 10

Analog Voltage 8 or Frequency Input 2

Yes –8.0V

Pin 11

Analog Voltage 9 or Frequency Input 3

Yes –8.0V

Pin 12

Analog Voltage 10 or Frequency Input 4

Yes –8.0V

Table 3.1. EIC10 Inputs pullup resistor summary

EIC16M

Analog Voltage Channels 9 -12 have independent software controlled 5V 1k ohm pullup

resistors. These are suitable for temperature measurement or as ON/OFF inputs by pulling

the input to ground through a switch.

Analog Voltage Channels 13 -16/ Frequency Inputs 1-4 have software controlled 8V 1k Ohm

pullup resistors plus blocking diode. A summary is shown in Table 3.2.

Pin

Function

Voltage Range

Pull-Up

13

Analog Voltage 9

0.0 –5.0V

Yes –5.0V

14

Analog Voltage 10

0.0 –5.0V

Yes –5.0V

15

Analog Voltage 11

0.0 –5.0V

Yes –5.0V

16

Analog Voltage 12

0.0 –5.0V

Yes –5.0V

17

Analog Voltage 13/Frequency 1

0.0 –16.5V

Yes –8.0V

18

Analog Voltage 14/Frequency 2

0.0 –16.5V

Yes –8.0V

19

Analog Voltage 15/Frequency 3

0.0 –16.5V

Yes –8.0V

20

Analog Voltage 16/Frequency 4

0.0 –16.5V

Yes –8.0V

Table 3.2. EIC16M Inputs pullup resistor summary

NOTE: The blocking diode on the 8V pullup prevents large frequency based signals back-

feeding into the supply. If these channels are to be used for temperature measurement this

pullup is not suitable. An external 1k resistor will need to be fitted and pulled up to the 5V

Sensor Supply.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

10

3.5 Frequency Inputs

The EIC10 and EIC16M have 4x Frequency Inputs which get shared with Analog Input pins as

shown with Tables 3.3 and 3.4.

oRange 0.2Hz up to 6500.0Hz

oResolution. 0.1Hz

oRising Edge Threshold = 1.7V

oFalling Edge Threshold = 0.9V

o8V independent software selectable 1k Ohm pullup resistors

oBoth Falling or Rising Edges are software selectable.

EIC10

Pin 9

Analog Voltage 7 or Frequency Input 1

Pin 10

Analog Voltage 8 or Frequency Input 2

Pin 11

Analog Voltage 9 or Frequency Input 3

Pin 12

Analog Voltage 10 or Frequency Input 4

Table 3.3. EIC10 Frequency Input Summary.

EIC16M

Pin

Function

17

Analog Voltage 13/Frequency 1

18

Analog Voltage 14/Frequency 2

19

Analog Voltage 15/Frequency 3

20

Analog Voltage 16/Frequency 4

Table 3.4. EIC16M Frequency Inputs Input Summary.

NOTE: Any EIC configuration changes made from Emtune are immediately sent to the EIC10

or EIC16M device over the CAN Bus and stored automatically by the device.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

11

3.6 Noise Immunity

To minimise signal contamination and maximise noise immunity, the wire pairs shown in

Table 3.2 must be twisted. It is recommended to twist the wire pairs at a minimum one twist

per 40mm of cable. This is very important and should always be implemented.

Pair 1

Pair 2

CAN High

<------->

CAN Low

Table 3.3. CAN Hi and Lo wire pairing for twisting

3.7 Sensor Wiring

5V Sensor Supply Pin

This is a 250mA 5V output designed to supply automotive sensors.

Analog Sensor 0V Reference Pin

This pin should be connected directly to the 0V (Ground) pin on any low current analog

sensor, for example Pressure or Temperature.

•DO NOT connect the EIC 0V Reference pin directly to the Engine Block or ECU Ground.

This is a dedicated and specialised 0V/ground output for analog sensors.

•DO NOT connect a sensor 0V/ground pin directly to the Engine Block or Device Ground.

Instead this pin should be directly connected to the dedicated EIC 0V Reference pin. See

Figure 3.1/3.2.

•DO NOT connect frequency based sensor grounds to the EIC 0V Reference pin; for

example, an Ethanol content sensor. Use the main device ground.

Figure 3.1. Correct MAP Sensor 0V Wiring

Figure 3.2. Incorrect MAP Sensor 0V Wiring

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

12

3.8 CAN Bus Wiring

▪CAN Bus High and Low are differential signals, so twisted pair MUST be used. Failing to

do so will compromise the entire CAN Bus System.

▪In some extreme environments, shielded twisted pair may be required to help with

reliability and data integrity.

▪The less connectors in any transmission system the better. Unnecessary connectors are

almost guaranteed to present an impedance discontinuity and hence may cause

reflections and data loss.

▪CAN Bus termination must be done correctly by using a 120 ohm 0.25W resistor at each

END of the bus system.

▪Maximum Stub length to a device from the main Bus is recommended at 0.3m, in

accordance with High-Speed ISO 11898 Standard specification. See Figure 3.3.

The EIC16M and EIC10 devices do not include an on-board CAN termination resistor,

allowing the device to be wired at any position on the Bus. CAN Bus termination must be

done correctly by using a 120 ohm 0.25W resistor at each end of the bus system as

mentioned above. Figures 3.1 and 3.2 show possible CAN Bus Implementation examples.

Figure 3.1. CAN Bus Wiring Example. ECU and Dash at each end with 120 Ohm Termination

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

13

Figure 3.2. CAN Bus Wiring Example. ECU and EIC10 at each end with 120 Ohm Termination

Figure 3.3. CAN Bus Wiring Example. Stub Length less than 0.3m

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

14

4.0 EIC Device Configuration

Once the EIC10 or EIC16M is powered and connected to the ECU’s CAN bus, the following

steps should be taken to complete the setup. All setup and device monitoring is done using

Emtune, so this software needs to be installed and connected to the ECU.

4.1 EIC Single Device Setup

This section outlines the setup procedure for a single device and involves 3 steps:

1. Device Detection by the ECU

2. ECU CAN Bus configuration

3. EIC Live Data Monitoring

4.11 EIC Device Detection

To confirm the EIC device has been detected, connect to the ECU using Emtune. Open the

ECU Runtime menu (F3) and select the Communications Tab. Within this tab there will be a

list of Emtron CAN devices that the ECU has detected. It will list:

1. CAN Device Model

2. Device Serial Number

3. Device Firmware Version

4. Device Hardware Version

5. CAN Base Address ID

With a single EIC10 device connected, the data should look as shown in Figure 4.0. With a

single EIC16M device connected, the data should look as shown in Figure 4.1.

Important:

▪At this stage the ECU has only detected the device. It has not been configured to an ECU

CAN Channel so the EIC data is not yet available.

▪Note the CAN Base Address ID. This is required in the ECU CAN setup. The factory setting

is ID 718 for the EIC10, and ID 705 for the EIC16M

Figure 4.0. EIC10 connected to the CAN Bus

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

15

Figure 4.1. EIC16M connected to the CAN Bus

4.12 ECU CAN Configuration for Single Device

Next step is to configure an ECU CAN channel, allowing the ECU to decode the EIC CAN

packets.

For this example, CAN 1- Channel 4 has been selected.

1. Set “Enable" to 1(ON)”

2. Set "CAN Base Address" to the Base Address shown in Figure 4.0 / 4.1. In this

example select 718 for EIC10 or 705 for EIC16M.

3. EIC10. Set "DATA Set" to 73 (EIC10 1x Device). See Figure 4.2

EIC16M. Set "DATA Set" to 69 (EIC16M 1x Device). See Figure 4.3

Figure 4.2. EIC10 CAN Configuration

Figure 4.3. EIC16M CAN Configuration

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

16

4.13 EIC Data Monitoring for Single Device

To confirm the EIC data is being decoded by the ECU, open the ECU runtime menu (F3) ->

Emtron CAN Device Tab. The EIC10/EIC16M live data can be viewed. See Figure 4.4 and 4.5.

Figure 4.4. EIC10 CAN Live Data –x1 Device

Figure 4.5. EIC16M CAN Live Data–x1 Device

4.2 EIC Multiple Device Setup

As mentioned in section 3.4, the Base CAN Address ID used to transmit Data over the Bus by

default is the same for each device type. The EIC10 has a factory CAN Base Address of 718

and EIC16M has a CAN Base Address of 705. When multiple EIC10/EIC16M devices are

installed on the same CAN Bus, each device MUST have a unique CAN Base Address to avoid

Bus conflicts. This means the CAN Base Address ID will need to be reprogrammed which is a

simple task using the ID Reprogramming Tool as outlined in section 4.22.

REMEMBER: For this process to function effectively, when multiple new devices are

introduced to the CAN bus, they should be initially connected one at a time. This allows

each device to sync up to the CAN Bus baud rate and store that setting. This usually takes 3-

5 seconds.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

17

4.21 EIC Multiple Device Detection

The following example uses the EIC10. Connect to the ECU using Emtune. Open the ECU

Runtime menu (F3) and select the Communications Tab. Within this tab will be a list of

Emtron CAN devices that the ECU has detected. It will list:

1. CAN Device Model

2. Device Serial Number

3. Device Firmware Version

4. Device Hardware Version

5. CAN Base Address

With 2x EIC10 devices connected to the CAN bus, the CAN Summary List should look similar

to that shown in Figure 4.6. In this example the following devices have been detected:

▪Device 1 - SN 1230

▪Device 2 - SN 1225

Figure 4.6 Example showing two EIC10 devices detected by the ECU

Note: ALL devices have the same Base Address of ID 718, which is the factory setting for a

single device. To avoid Bus conflicts, the factory base address needs to be changed when

multiple devices are used, to ensure each device has its own unique ID. When re-

programming the Base Address for each device the IDs MUST be:

1) Sequential in order.

2) Have a gap of 4 numbers between each EIC10 device.

(Doesn’t apply to EIC16M as only one device permitted on the Bus)

The Base Address ID can be any number but Emtron recommends the following:

•EIC10 Device 1: ID Base Address 718. (CAN ID Range 718-721)

•EIC10 Device 2: ID Base Address 722. (CAN ID Range 722-725)

The following Base Address is recommended for the EIC16M devices:

•EIC16M Device 1: ID Base Address 705 (CAN ID Range 705-710)

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

18

4.22 EIC CAN Base Address ID Reprogramming

To ensure each EIC device has a unique ID from the example in Figure 4.6, EIC10 Device 2

needs a new Base Address of 722.

This is easily done using Emtune from the Config view -> Communications Menu -> Emtron

CAN Devices -> Emtron CAN Device Programming menu.

Device 2 ID Reprogramming

Enter in Serial Number = 1235

Enter in Custom Address = 722

Make sure the “Program

Address” checkbox is ticked.

Select the “Program” button and the new Custom Address ID will be programmed into the

device.

To check the device(s) have been programmed correctly with the new Base Address IDs,

open the ECU Runtime menu (F3)-> Communications Tab. Each device now has a unique

Base Address ID. See Figure 4.8.

Figure 4.8. 2x EIC10 Devices detected by the ECU with reprogrammed IDs

Each device now as a unique CAN Base Address ID and will be transmitting valid data on the

Bus.

EMTRON EIC USER MANUAL

WWW.EMTRON.WORLD

© EMTRON AUSTRALIA PTY LTD APRIL 2018

19

4.23 ECU CAN Configuration for Multiple Devices

The next step is to configure an ECU CAN channel, allowing the ECU to decode the EIC CAN

packets.

Only 1 CAN Channel is required for multiple devices. CAN 1 - Channel 4 has been selected.

Config as follows:

1. Set “Enable" to 1(ON)”

2. Set "CAN Base Address" to

the Lowest Base Address ID

shown in Figure 4.8. In this

example its 718.

3. Set "DATA Set" to 74 -

Emtron EIC10 2x Devices

(CAN PID 718/722).

The ECU is now configured and will receive data from all devices on IDs 718-721, 722-725.

NOTE: You only need to program in the lowest Base Address. The ECU automatically

configures the remaining IDs based on the assumption that the IDs are sequential in order.

4.24 EIC Data Monitoring for Multiple Devices

To confirm the EIC10 data from multiple devices is

being decoded by the ECU, open the Runtime menu

(F3) -> Emtron CAN Device Tab to view the live data.

This manual suits for next models

1

Table of contents

Other Emtron Cables And Connectors manuals

Popular Cables And Connectors manuals by other brands

PCB Piezotronics

PCB Piezotronics IMI SENSORS 009M205/100 Installation and operating manual

NEUTRIK

NEUTRIK FIBERFOX EBC25 Handling instruction

Emerson

Emerson Rosemount 356 Reference manual

Meltric

Meltric DSDC Series operating instructions

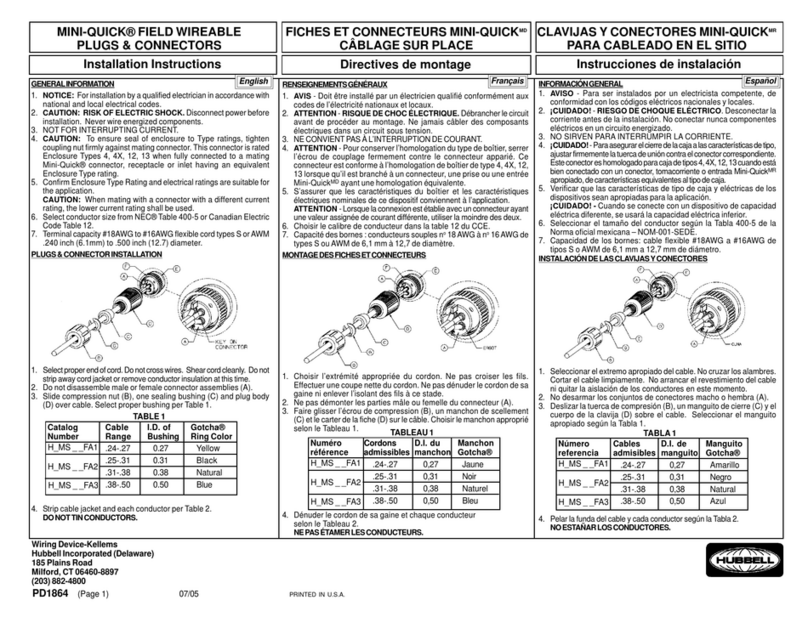

Hubbell

Hubbell MINI-QUICK H MS FA1 Series installation instructions

cable matters

cable matters Easy Transfer Cable user manual