D84-P06-01 GB R3 21/04/2021 www.photowatt.com

6

5.0

MODULE INSTALLATION

PRECAUTIONARY MEASURES AND

GENERAL SAFETY

• Prior to installing modules please obtain information

about any requirements and necessary approvals for

the site, installation and inspection from the relevant

authorities.

• Check applicable building codes to ensure that the

construction or structure (roof, facade, support, etc.)

can bear the module system load.

• EDF ENR PWT bifacial double glass solar modules

have been qualiied for Application Class A (equiva-

lent to Safety Class II requirements). Modules rated

under this class should be used in systems operating

at voltage above 50V or power above 240W, where

general contact access is anticipated.

• EDF ENR PWT bifacial double glass modules have

been certiied as Type 3 or Type 13 according to UL

1703, Type29 according to UL 61730 and as Class A or

Class C for ire performance according to IEC 61730-

2 for ire class performance, please refer to the data-

sheet or the product nameplate for the detailed types.

• Consult your local authority for guidelines and re-

quirements for building or structural ire safety.

UL 1703 SYSTEM FIRE RATING REQUIREMENTS

• The ire rating of this module is only valid when the

product is installed as speciied in the mechanical

mounting instructions.

• When installing the modules, ensure the assembly is

mounted over a ire-resistant roof covering rated for

the application.

• Photovoltaic systems composed of UL1703 or UL

61730 certiied modules mounted on a UL2703 certi-

ied mounting system should be evaluated in combi-

nation with roof coverings in accordance with UL1703

or UL 61730 standard, with respect to meeting the

same ire classiication as the roof assembly.

• Mounting systems with a System Fire Class Rating

(Class A, B or C), tested in conjunction with ire rat-

ed “Type 2” or “Type 13” or “Type 29” rated modules,

are considered acceptable for use with EDF ENR PWT

modules, provides the mounting system does not vi-

olate any other requirement of this manual.

• Any mounting system limitations on inclination or

accessory required to maintain a speciic System

Fire Class Rating should be clearly speciied in the

installation instructions and UL2703 certiication of

the mounting system supplier.

ENVIRONMENTAL CONDITIONS

• The module is intended for use in general open-air cli-

mates, as deined in IEC 6072121: Classiication of en-

vironmental conditions Part 21: Environmental condi-

tions appearing in nature. Temperature and humidity.

• Please consult the EDF ENR PWT technical support

department for more information on the use of mod-

ules in special climates, such as an altitude greater

than 2000 m, heavy snow, severe hail storm, hurri-

cane etc.

• Do not install modules near open lames or lamma-

ble materials.

• Do not immerse modules in water or constantly ex-

pose modules to water (either fresh or salt) (i.e. from

fountains, sea spray).

• Exposing modules to salt (i.e. marine environments)

or sulfur (i.e. sulfur sources, volcanoes) incurs the

risk of module corrosion.

• Do not expose modules and their connectors to any

unauthorized chemical substances (e.g. oil, lubricant,

pesticide, etc.), as modules may incur damages.

• Failure to comply with these instructions will void

EDF ENR PWT warranty.

• EDF ENR PWT modules have passed salt mist cor-

rosion resistance test according to IEC 61701, but

the corrosion may still occur on where the mod-

ules frame is connected to the bracket or where the

grounding is connected. Should the installation loca-

tion be near the ocean, EDF ENR PWT recommends

stainless steel or aluminum materials be used in the

areas with direct contact with the PV modules, and

the connection point should be protected with anti-

corrosion measures. For more information, please

contact EDF ENR PWT technical support team.

INSTALLATION REQUIREMENTS

• Ensure that the module meets the general technical

system requirements.

• Ensure that other systems components do not dam-

age modules mechanically or electrically.

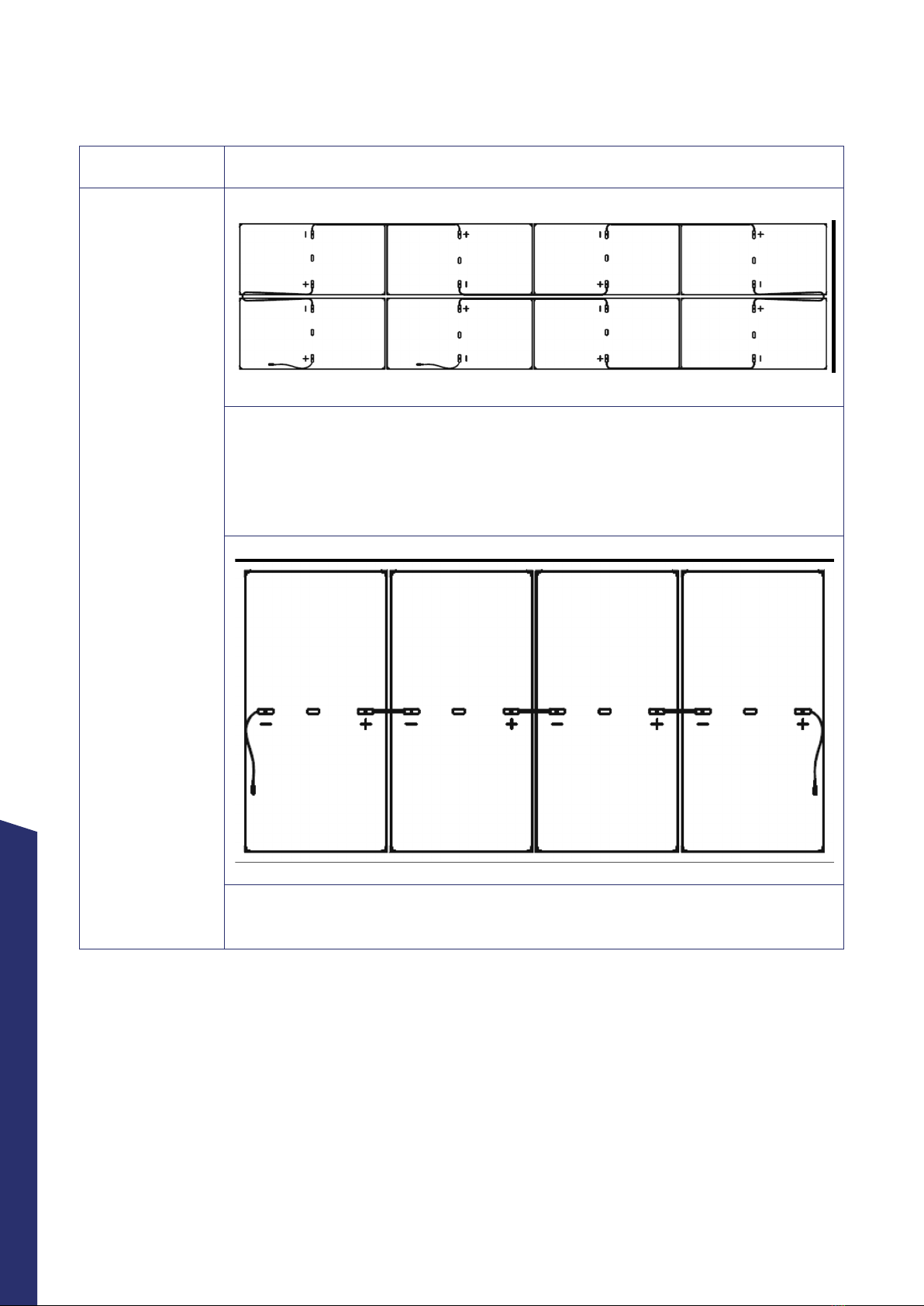

• Modules can be wired in series to increase voltage or

in parallel to increase current. To connect modules in

series, connect the positive terminal of one module

to the negative terminal of the next module. To con-

nect in parallel, connect the positive terminal of one

module to the positive terminal of the next module.

• The quantity of bypass diodes in the module’s junc-

tion box provided may vary depending on the model

series.

• Only connect the quantity of modules that corre-

sponds to the voltage speciications of the inverters