ColorSave 1000ST-INJ user manual

LIAD Weighing and Control Systems Ltd 2

TABLE OF CONTENTS

Equipment Handling And Safety ............................................................................................4

1.0 Introduction........................................................................................................................5

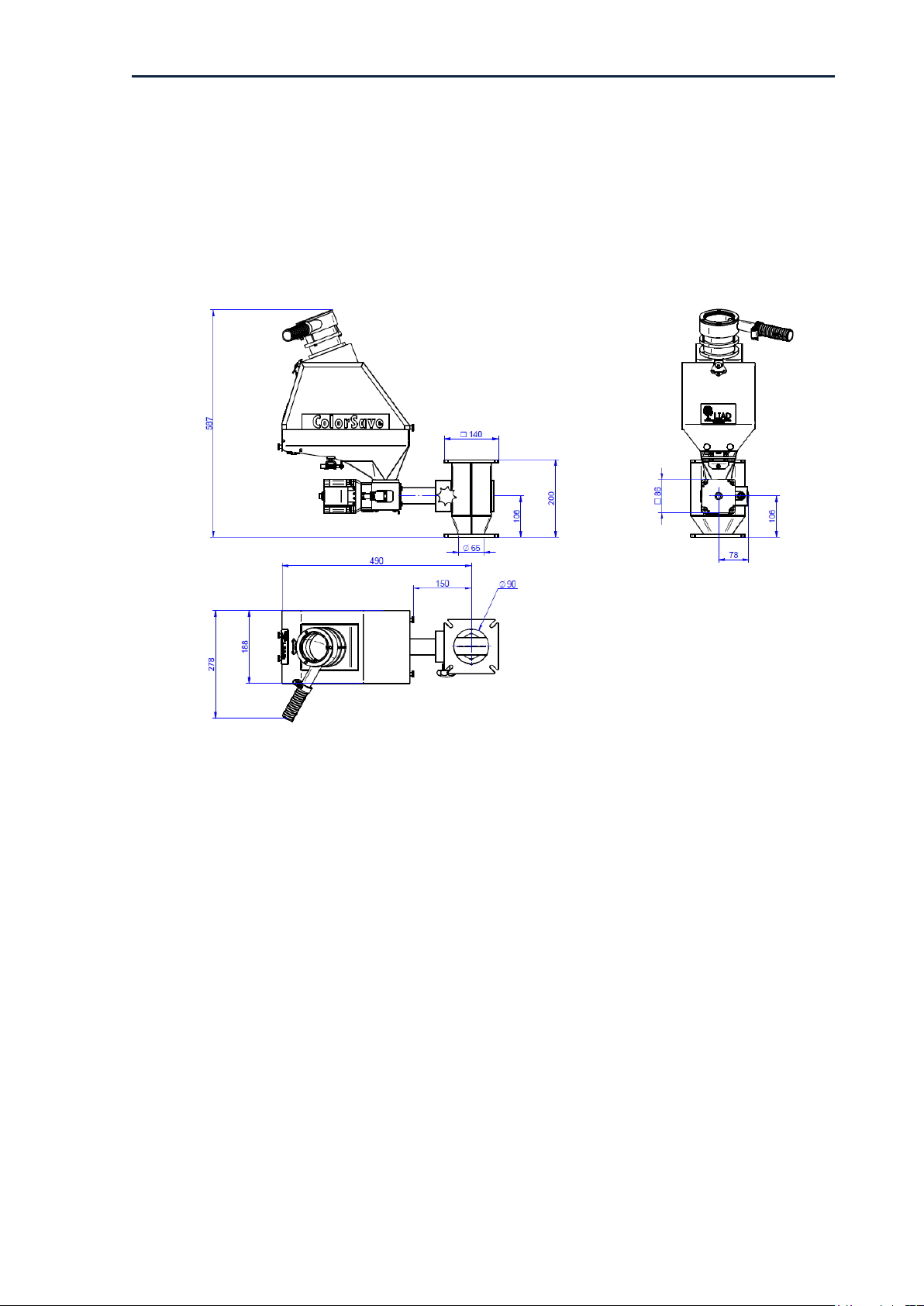

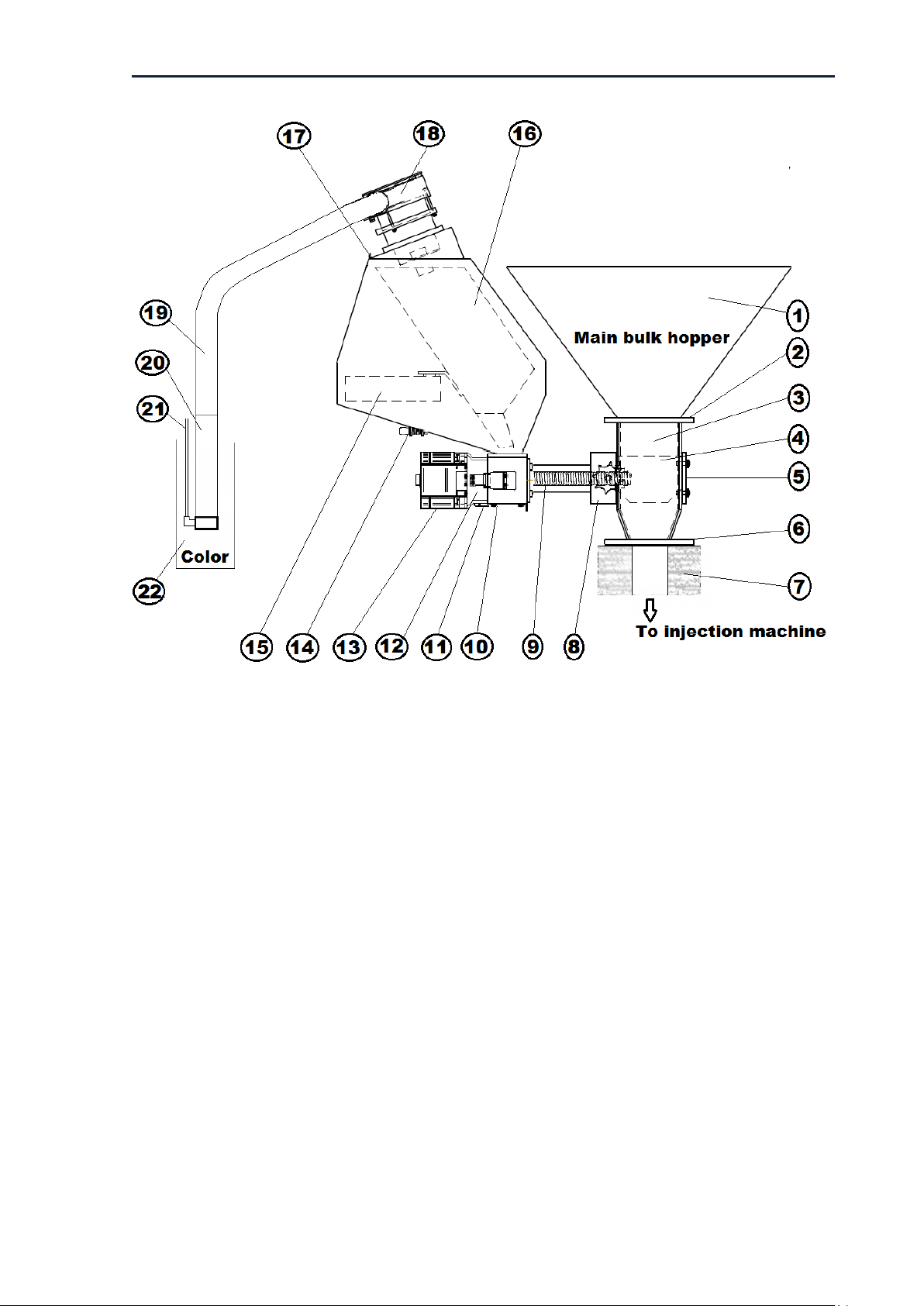

2.0 Product Overview ..............................................................................................................6

2.1 Feeding System .............................................................................................................6

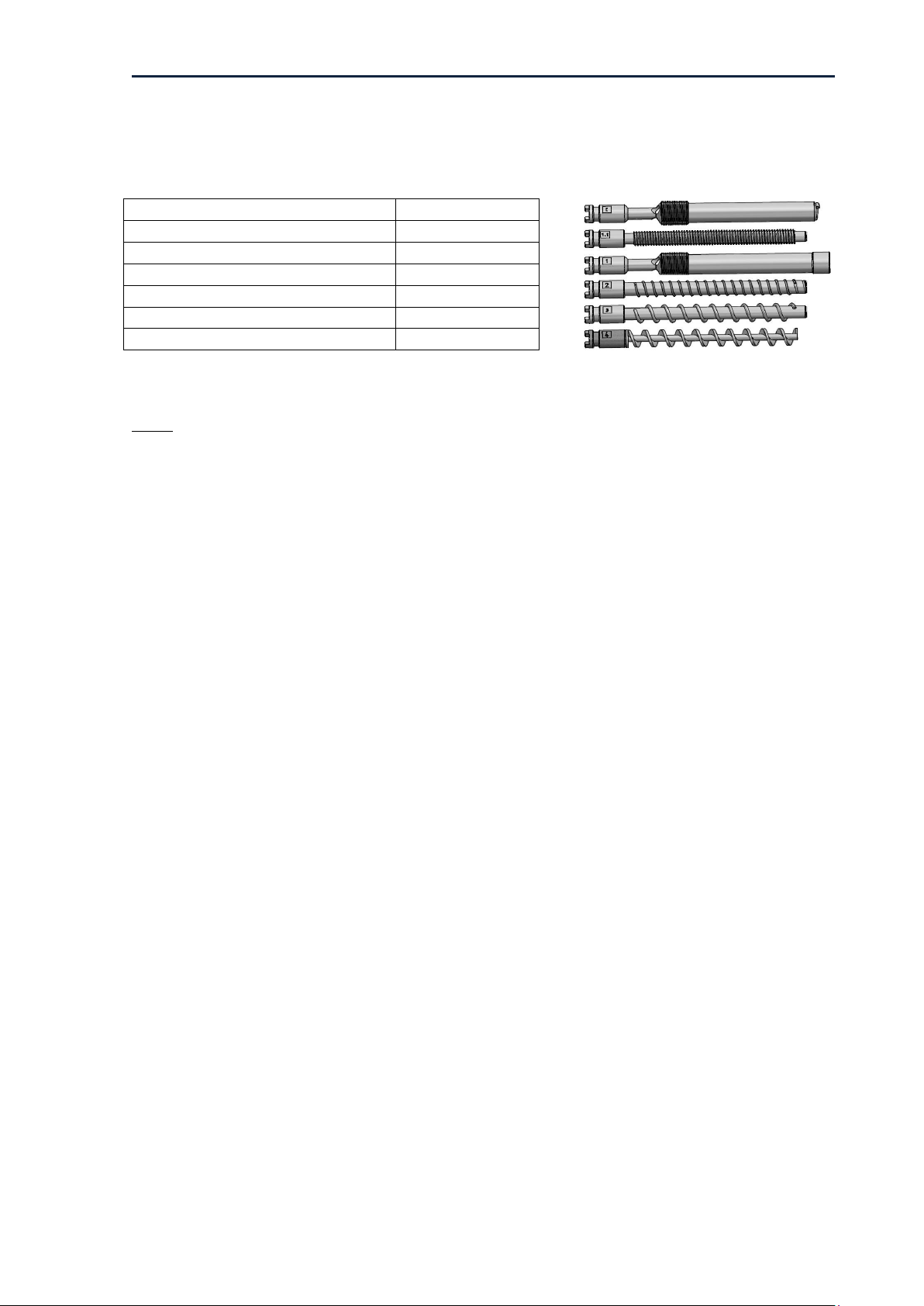

2.2 Feeding (dosing) Screws ..............................................................................................8

2.3 Control Unit ....................................................................................................................9

2.3.1 ColorSave 1000ST-INJ Controller Front View ....................................................9

2.3.2 ColorSave 1000ST-INJ Controller Rear View .....................................................9

3.0 Installation........................................................................................................................10

3.1 General Safety Notes And Warnings ........................................................................10

3.2 Mechanical Installation ...............................................................................................11

3.2.1 Mounting To The Injection-Molding Machine Throat .....................................11

3.2.2 Releasing The Load Cell......................................................................................11

3.2.3 Venturi Loader Installation .................................................................................12

3.2.4 Control Unit Mounting .........................................................................................12

3.3 Electrical Installation...................................................................................................13

3.3.1 Connections...........................................................................................................13

3.3.2 Sensor Cable Wiring Options..............................................................................14

4.0 Operation..........................................................................................................................15

4.1 General..........................................................................................................................15

4.1.1 Operation Modes..................................................................................................15

4.1.2 MB/AD Feeding Modes ........................................................................................16

4.1.3. Speeds Displayed On Main Screen...................................................................16

4.1.4 Gram Per Rotation ...............................................................................................17

4.2 Starting Sequence .......................................................................................................18

4.2.1 Main Screen For Mode "0" (Gravimetric mode, with machine dosing time)

..........................................................................................................................................18

4.2.2 Main Screen For Mode "1" (Gravimetric mode, with constant dosing time)

..........................................................................................................................................18

4.2.2.1 Changing Screw Feeding Time In Mode "1".................................................19

4.2.3 Main Screen For Mode "2" (Volumetric mode, with machine dosing time) 19

4.2.3.1 Changing Screw Speed In Mode "2"..............................................................19

4.2.4 Main Screen For Mode "3" (Volumetric mode, with constant dosing time) 20

4.2.4.1 Changing Screw Speed And Feeding Time In Mode "3" ............................20

4.2.4.2 Changing Screw Revolutions And Speed In Micro Mode "3" .....................21

4.3 Configuration Parameters Setup ...............................................................................22

4.3.1 Setting Parameter Values ...................................................................................22

4.3.2 Setting Installed Screw Number ........................................................................22

4.3.3 Setting Desired Operation Mode........................................................................23

4.3.4 Setting Max/Min Hopper Weight Parameters ..................................................23

4.3.5 Setting Recipe Mode............................................................................................23

4.3.6 Setting Cavity Mode.............................................................................................24

4.3.7 Setting Permitted Tolerance...............................................................................24

4.3.8 Setting Alarm Output Type.................................................................................24

4.3.9 Gravimetric/Volumetric Switch...........................................................................25

4.4 Accumulated Data Display .........................................................................................26