Encoder BEPC Product manual

PROFINET® Interface

For BEPC/EPC's Absolute Bus Encoders

REV 05/5/2021

TECHNICAL REFERENCE MANUAL

+44(0)1978 262100 | encoder.co.uk

Sagle, Idaho, USA - Worldwide Headquarters / Wales, UK , European Division

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Contents

1.Introduction ...................................... 5

1.1 AboutThis Manual ....................................5

1.1.1 Explanation of Symbols Used in this Manual ..........5

1.1.2 What Is Not in this Manual .........................6

1.2 Products Supported ...................................6

1.3 Specications ........................................7

1.4 Scope of Delivery .....................................7

2.Safety Information................................. 7

2.1 General .............................................7

2.2 Intended Use.........................................8

2.3 Safe Working.........................................8

2.4 Disposal .............................................8

3.Device Description ................................. 9

3.1 General .............................................9

3.2 PROFINET...........................................10

3.3 Principles of EPC'S A58E Series Encoders.................10

3.3.1 SingleTurn – ST .................................11

3.3.2 Multi-Turn – MT .................................11

3.3.3 Direction of Rotation .............................11

3.3.4 Preset ..........................................11

3.3.5 Scaling .........................................11

3.4 Connection Assignments for PROFINET Encoders..........13

3.4.1 Bus Cover with 3 x M12x1 .........................13

3.5 LEDs and Signalling ..................................13

3.6 MAC Address and IP Address...........................14

4.PROFINET ........................................ 15

4.1 Summary of Functions................................15

4.2 GSDML Modules .....................................15

4.3 Signals .............................................16

4.4 Structure of the signals ...............................16

4.5 Telegrams ..........................................24

4.6 Parameters .........................................25

4.6.1 Description of the most important parameters .......26

4.7 Warnings and errors..................................30

4.7.1 Errors ..........................................30

4.7.2 Warnings .......................................31

4.7.3 G1_XIST2 error codes.............................31

5.Web Server....................................... 31

5.1 General ............................................31

5.2 Information.........................................33

5.2.1 Overview .......................................33

5.2.2 Diagnosis .......................................34

5.2.3 Versions ........................................35

5.3 Conguration .......................................36

5.3.1 Network ........................................36

5.3.2 Encoder ........................................37

5.3.3 Firmware Update ................................38

5.4 License information ..................................42

5.5 Contact.............................................42

6.Commissioning ................................... 43

6.1 General information..................................43

6.2 Integration into aTIA project ..........................43

6.3 Scaling function .....................................54

6.3.1 Example scaling function single-turn 16-bit to 12-bit .54

6.3.2 Example scaling function multi-turn ................56

6.3.3 Executing a preset................................59

6.3.4 Resetting a preset (Telegram 81 – 84 + 59000). . . . . . .62

6.3.5 Executing a preset (Telegram 86-89) ................62

6.4 Integration into a Step 7 project........................63

7.Technical Data .................................... 69

7.1 Properties ..........................................69

7.2 Dimensions .........................................69

8.Technical support ................................. 70

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

List of Tables

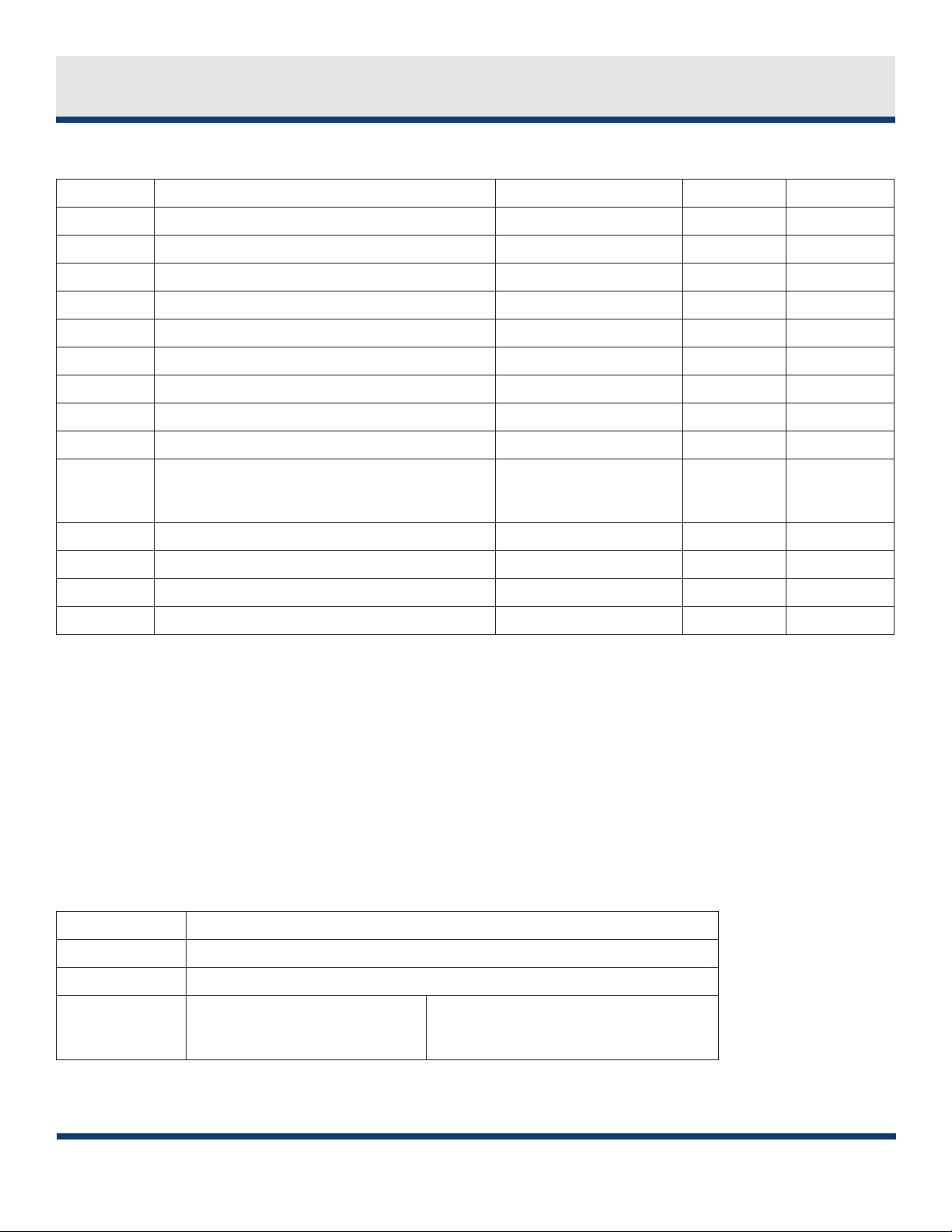

Table 3.1: Pin Connection Assignment ................. 13

Table 4.1: Functions ................................. 15

Table 4.2: GSDML Modules............................ 15

Table 4.3: Signals ................................... 16

Table 4.4: Structure of signal 6 NIST_A ................. 17

Table 4.5: Structure of signal 8 NIST_B ................. 17

Table 4.6: Structure of signal 9 G1_STW ................ 18

Table 4.7: Structure of signal 10 G1_ZSW ............... 19

Table 4.8: Structure of signal 11 G1_XIST1 .............. 19

Table 4.9: Structure of signal 12 G1_XIST2 .............. 20

Table 4.10: Structure of signal 39 G1_XIST3............. 20

Table 4.11: Structure of signal 80 STW2_ENC............ 21

Table 4.12: Structure of signal 81 ZSW2_ENC............ 22

Table 4.13: Structure of signal 238(60000) G1_XIST1_

PRESET_B.......................................... 22

Table 4.14: Structure of signal G1_XIST1_PRESET_B1 .... 23

Table 4.15: Structure of signal G1_XIST1_PRESET_C ..... 23

Table 4.16: Structure of signal 60001 DEBUG_STW ....... 23

Table 4.17: Structure of signal 60002 DEBUG_ZSW ....... 24

Table 4.18: Telegrams ............................... 25

Table 4.19: Supported parameters .................... 26

Table 4.20: Velocity measuring units................... 28

Table 4.21: Hysteresis position........................ 28

Table 4.22: Extrapolation position..................... 29

Table 4.23: Filter max. RPM........................... 29

Table 4.24: Filter position ............................ 30

Table 4.25: Filter speed .............................. 30

Table 4.26: Errors ................................... 30

Table 4.27: Warnings ................................ 31

Table 4.28: G1_XIST2 error codes ...................... 31

Table 6.1: Data content for Example ................... 59

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

List of Figures

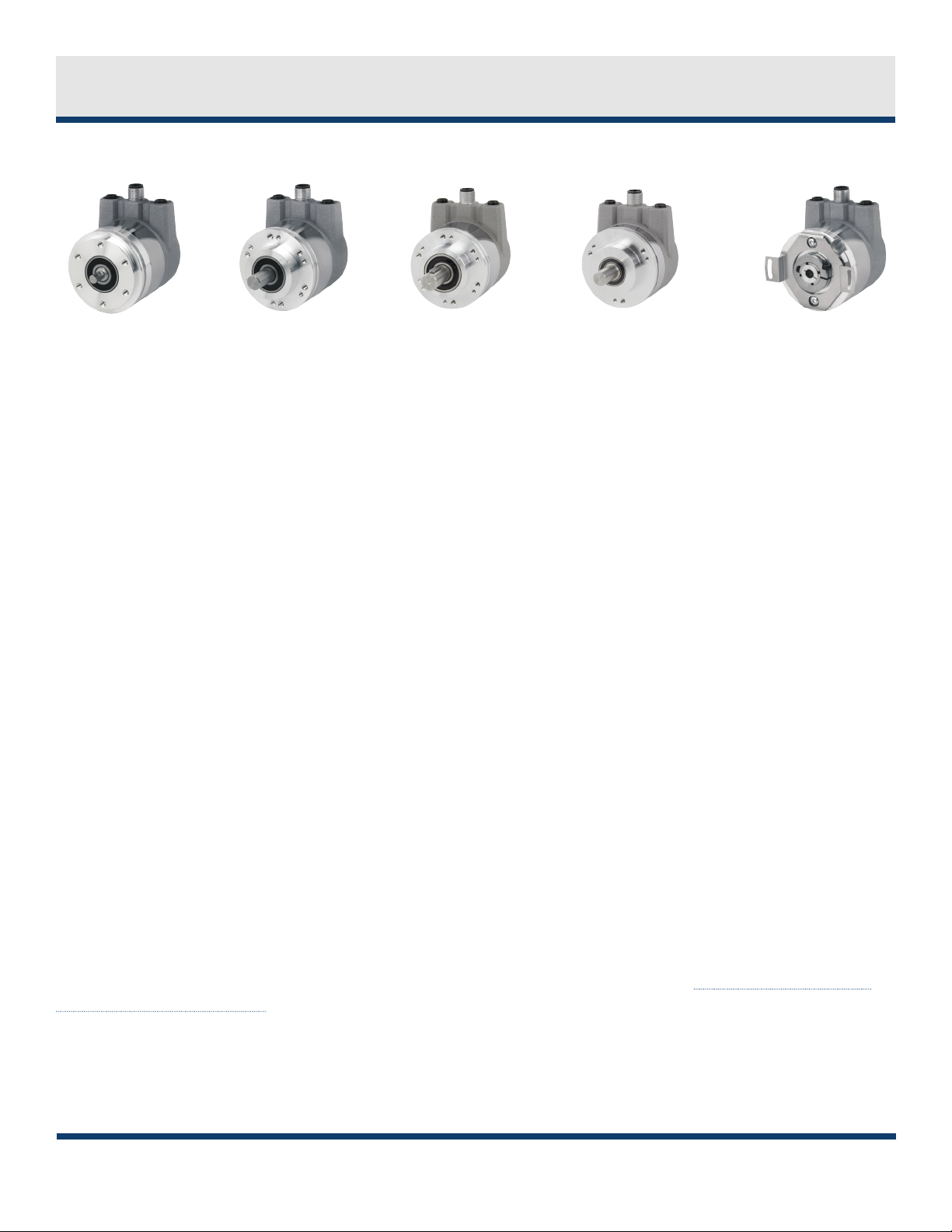

Figure 3.1: EPC EtherCAT-ready encoders with PROFINET-IRT

bus covers. .......................................... 9

Figure 5.1: Web server — overview ................... 33

Figure 5.2: Diagnostic page........................... 35

Figure 5.3: Versions ................................. 35

Figure 5.4: Network settings ......................... 37

Figure 5.5: Encoder information. . . . . . . . . . . . . . . . . . . . . . . 37

Figure 5.6: Firmware update. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 5.7: Firmware update - choose le............... 39

Figure 5.8: Firmware update - Transferring le .......... 40

Figure 5.9: Firmware update - Successful ............... 40

Figure 5.10: Firmware update - Failed.................. 41

Figure 5.11: License information ...................... 42

Figure 6.1: Switching to project view .................. 44

Figure 6.2: Manage device description le (GSD)......... 45

Figure 6.3: Installing GSDML.......................... 46

Figure 6.4: Switch to Devices & Networks ............... 46

Figure 6.5: Hardware Catalogue....................... 46

Figure 6.6: Network View ............................ 47

Figure 6.7: Change device name....................... 47

Figure 6.8: Select module ............................ 48

Figure 6.9: Select telegrams .......................... 48

Figure 6.10: Change the I/O addresses ................. 49

Figure 6.11: Download to device ...................... 49

Figure 6.12: Assigning device names................... 50

Figure 6.13: Name and PG interface ................... 50

Figure 6.14: Accessible nodes ......................... 51

Figure 6.15: Online status information ................. 52

Figure 6.16: PLC variables ............................ 53

Figure 6.17: Show all ................................ 53

Figure 6.18: Default tag table ........................ 53

Figure 6.19: Example of commissioning ................ 54

Figure 6.21: Assembly parameters..................... 55

Figure 6.23: Conguration of 12-Bit Single-turn with scaling56

Figure 6.24: Example of commissioning ................ 57

Figure 6.25: Device overview - MAP .................... 58

Figure 6.26: Assembly parameters..................... 58

Figure 6.27: Conguration of 360 Steps/revolution and 10

revolutions ........................................ 59

Figure 6.28: set STW2_ENC bit 10 to TRUE .............. 60

Figure 6.29: set G1_STW bit 13 to TRUE................. 60

Figure 6.30: G1_STW Bit 11 default 0 = absolute ........ 61

Figure 6.31: set and reset G1_STW Bit 12 ............... 61

Figure 6.32: SIMATIC Manager ........................ 63

Figure 6.33: Installing the GSDML le .................. 64

Figure 6.34: Hardware catalogue...................... 65

Figure 6.35: Hardware view .......................... 65

Figure 6.36: Select via single mouse click ............... 66

Figure 6.38: Slot 1, highlighted green.................. 66

Figure 6.39: Slot 1.2 with inserted telegram 81 ......... 66

Figure 6.40: Change the I/O addresses ................. 67

Figure 6.41: "Addresses" tab.......................... 67

Figure 6.42: Save and transmit – Download to module ... 67

Figure 6.43: Variable table ........................... 68

Figure 6.44: HEX position value ....................... 68

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk Page 5 of 68

1.Introduction

1.1 About This Manual

This technical manual describes the conguration and mounting possibilities for absolute-value encoders with a PROFINET interface produced by

Encoder Products Company (EPC). It supplements the other publicly available EPC documents, e.g. data sheets, assembly instructions, leaets,

catalogues and yers.

Ensure that you read the manual before provisioning — check beforehand that you have the latest version of the manual.

When reading, pay particular attention to the information, important notices and warnings that are marked with the corresponding symbols (see

1.1.1).

This manual is intended for persons with technical knowledge in the handling of sensors, PROFINET IRT interfaces and automation elements. If you

do not have any experience in this eld, request the assistance of experienced personnel before proceeding.

Keep the information provided with our product in a safe place so that you can refer to it at a later date as necessary.

The contents of this manual are arranged with practical use in mind.

All of the information in the following sections is required to get the best possible use out of the equipment, and should be

read through thoroughly.

1.1.1 Explanation of Symbols Used in this Manual

The INFO symbol is placed next to a section of text that is particularly informative or important for what to do next with

the equipment.

The IMPORTANT symbol is placed next to a section of text in which a process is described to resolve a particular problem.

TheWARNING symbol is placed next to a section of text that should be paid particular attention to in order to ensure the

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk Page 6 of 68

correct use of the equipment and to protect against danger.

1.1.2 What Is Not in this Manual

• Basic information about automation technology

• System planning

• Risks (availability, safety)

• Shielding concepts

• Reections

• Repeaters

• Network conguration

• Bus cycle times

• FMA management services

• Transmission services

• Telegram types

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 7 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

1.2 Products Supported

This manual supports the following types of EPC Absolute Encoders:

• Model A58HE – PROFINET absolute hollow-bore encoder with bus cover

• Model A58SE – PROFINET absolute shaft encoder, synchro or clamping ange, heavy-duty or compact, with bus cover

EPC's PROFINET product range can be found on our website: encoder.com/pronet

1.3 Specications

An encoder is a sensor that is designed to detect angular positions (single-turn) and revolutions (multi-turn).The measured data and variables are

processed by the encoder and provided as electrical output signals for the connected peripherals.

Patented technologies for single-turn and for multi-turn are used in the A58SE and A58HE series encoders. As a result, these encoders from EPC are

maintenance-free and very eco-friendly.

The encoders whose article descriptions are listed in Section 1.2 communicate via the PROFINET IRT interface.

1.4 Scope of Delivery

The scope of delivery depends on the product variants and the details of your order. Before commissioning, check the contents of the delivery for

completeness.

As a rule, the A58HE and A58SE products have a PROFINET IRT interface includes the following items:

• A58HE or A58SE with PROFINET-IRT (with bus cover)

• Assembly instructions

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 8 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

2.Safety Information

2.1 General

• When provisioning the encoder, ensure that you observe the assembly instructions, manual and data sheet.

• Failure to observe the safety instructions may lead to malfunctions, property damage and personal injury!

• Observe the operating instructions provided by the machine's manufacturer.

2.2 Intended Use

Rotary encoders are components that are intended for installation in machines. Before commissioning (operation in accordance with the intended

use), it must be determined that the machine as a whole corresponds to the EMC and Machine Directive.

A rotary encoder is a sensor that is designed to detect angular positions and revolutions and must only be used for this purpose! EPC Automation

manufactures and distributes encoders for use in non-safety-relevant industrial applications.

The encoder must not be operated outside the specied limit parameters (see product datasheet).

2.3 Safe Working

The installation and mounting of the encoder must only be carried out by a qualied electrician.

For the construction of electrical installations, all relevant national and international regulations must be strictly observed.

Failure to commission the encoder correctly may result in malfunction or failure.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 9 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

• All electrical connections must be tested before commissioning.

• Appropriate safety measures must be taken to ensure that no persons are harmed and no damage to the system or operating equipment

occurs in the event of a failure or malfunction.

2.4 Disposal

Devices that are no longer needed or are defective must be disposed by the user in proper compliance with the country-specic laws. It must be

taken into consideration that this is a special waste of electronics and that disposal is not permitted via normal household waste.

There is no obligation by the manufacturer to take the device back. If you have any questions regarding proper disposal, contact a disposal specialist

in your area.

3.Device Description

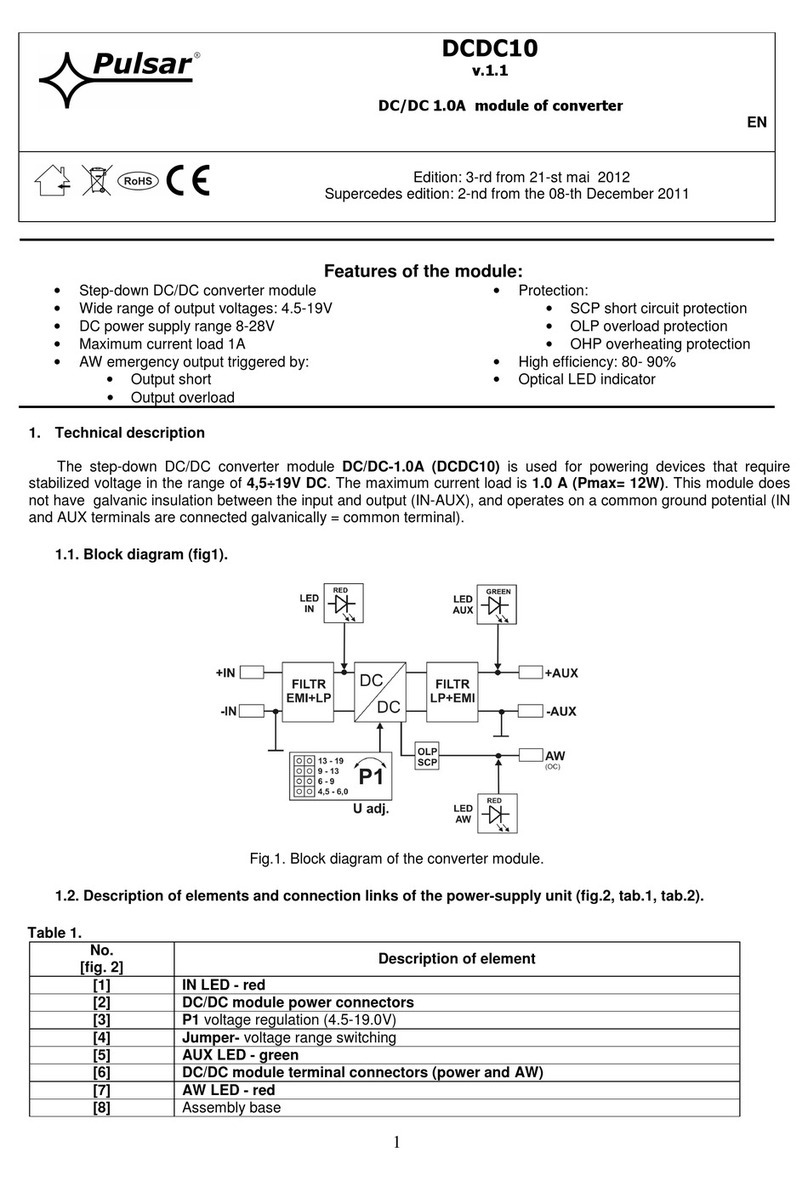

3.1 General

Various mechanical variants of the A58SE and A58HE-series encoders with PROFINET-IRT are available. The required variant is determined by the

need for a bus cover, the ange design and the shaft type (solid or hollow).The size is specied as 58 mm by the diameter at the ange.The follow-

ing gure shows examples of A58SE/HE-series encoders with PROFINET IRT.

The solid or hollow shaft is connected to the rotating component whose angular position or rotational speed is to be measured. Cable or plug

outlets create the interface for connection to the PROFINET network.The status LEDs mounted in the cover signal the various encoder states during

operation.They assist with conguration of the encoder and troubleshooting in the eld.The ange holes or supplied spring sheets are used for

attachment to the machine and during the respective application.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 10 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Figure 3.1: EPC EtherCAT-ready encoders with PROFINET-IRT bus covers.

From left to right: A58SE with clamping ange; A58SE with synchro ange; A58SE heavy-duty; A58SE compant; A58HE (blind hollow bore)

3.2 PROFINET

PROFINET is distributed by the PROFIBUS User Organization (PNO) as a successor to Probus. PROFINET is the standard interface for industrial Ether-

net. PROFINET provides similar functionality to Probus, but extends these by rmware upgrades.

Established IT standards are used for the transfer of information. UDP, IP and XML form the basis for this. XML is used as a description language

in the device prole (abbreviated to "GSDML le"). In order for the devices to exchange their data via IP — process data (cyclic) and parameter data

(acyclic) — a unique name must be assigned to each PROFINET node during conguration.The control can only assign an IP address to the node via

this name.

PROFINET supports the following three transmission types:

• PROFINET NRT (not real time), non-time-critical applications in automation, clock rates of around 100 milliseconds.

• PROFINET RT (real time), cyclic data trac is used to achieve clock rates of 10 milliseconds.

• PROFINET IRT (isochronous real time), clock rates of 1 millisecond and jitter of less than 1 microsecond.This is suitable for use in motion-

control applications (for example).

Further information about PROFINET is available via the homepage of the PROFIBUS User Organization (PNO) at: https://www.probus.

com/technology/pronet/

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 11 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

3.3 Principles of EPC'S A58E Series Encoders

The following sections describe the basic functions of an absolute encoder.

Unlike incremental encoders, absolute-value encoders output their position value as a digital number via a eldbus. A distinction is made here

between single-turn and multi-turn encoders.

In addition to simply outputting the position value, most encoders permit a certain degree of parameterization, such as selecting the positive direc-

tion of rotation, setting the position value to a reference value at a xed physical position, and scaling the position value to an arbitrary resolution

and a limited measuring range.This reduces the required complexity of the control program as well as the computational burden on the controller.

3.3.1 Single Turn – ST

Measurement of the angle from 0° to 360° by means of a shaft represents the minimum functionality of a rotary encoder. The sensor system is

based on optical or magnetic sampling of a measuring graduation on the encoder shaft.

The A58SE/HE encoders from EPC feature new magnetic technology, which provides maximum precision and resolution for a single-turn encoder.

3.3.2 Multi-Turn – MT

A multi-turn encoder allows the number of revolutions to be recorded.This is achieved via a rotation counter. The A58SE and A58HE encoders

include technology, which ensures that the corresponding information is retained, even in a voltage-free state.This means that buer batteries and

gearboxes, which require a comparatively large installation space and a correspondingly high degree of maintenance, are no longer needed.

3.3.3 Direction of Rotation

The positive direction of rotation can be reversed by a simple two's complement of the position value (invert every bit and add "1").

3.3.4 Preset

The desired position value can be assigned to the encoder at a specic physical position.This must be within the measuring range so that the posi-

tion value is correlated with a physical reference position. For this purpose, the dierence between the current position value and the desired value

is calculated.The result is stored in non-volatile memory and added to the position value as an oset.

3.3.5 Scaling

For the precise matching of the position value with the parameter to be measured in physical terms, adjustments can be carried out using the scal-

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 12 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

ing parameters. The scalable parameters are "Measuring units per revolution (MUPR)" and "Total measuring range in measuring units (TMR)".

The scaling parameters "Measuring units per revolution (MUPR)" – increments per revolution – indicates the resolution of the position value per

revolution (also: ST resolution). The value equates to 360°. This means that, if a value of 3600 Cts is parametrized, the encoder outputs the position

in 0.1° increments (see Equation #2).

Equation #1 MUPR = ST = 3600 Cts

Equation #2 Angular steps = Angle of one revolution = 360° = 0.1° / Cts

MUPR 36000 Cts

The scaling parameter "Total measuring range in measuring units (TMR)" – the maximum total measuring range of the position value (single-turn

and multi-turn multiplied) – indicates the total resolution of the encoder. When the position value reachesTMR -1, it jumps back to 0 and vice

versa.

As a rule, the selectedTMR parameter should be an integer multiple of the "Measuring units per revolution (MUPR)" (see equation #4), so that the

zero point is always at the same position of the encoder shaft.

Equation #3 TMR = 36000 Cts

Equation #4 MT = TMR = 36000 Cts = 10

MUPR 3600 Cts

In exceptional cases, it is suitable thatTMR is not an integer multiple of MUPR – for example, in a system in which a gear ratio ensures that the

desired measured variable is moving 10% faster relative to the encoder shaft.

In this case, a setting of MUPR = 3960 Cts andTMR = 36000 Cts would ensure that the faster (but not directly measurable) shaft can be measured

with a resolution of 0.1° and over a range of 10 revolutions. Normally, the number of revolutions would be calculated by dividing the position value

by MUPR. In this case, however, it must be divided by 3600 Cts, since the result would otherwise be the number of revolutions of the encoder shaft

and not the faster shaft of the system.

It should be noted that measurement errors occur if the result of this formula is a decimal.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 13 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

3.4 Connection Assignments for PROFINET Encoders

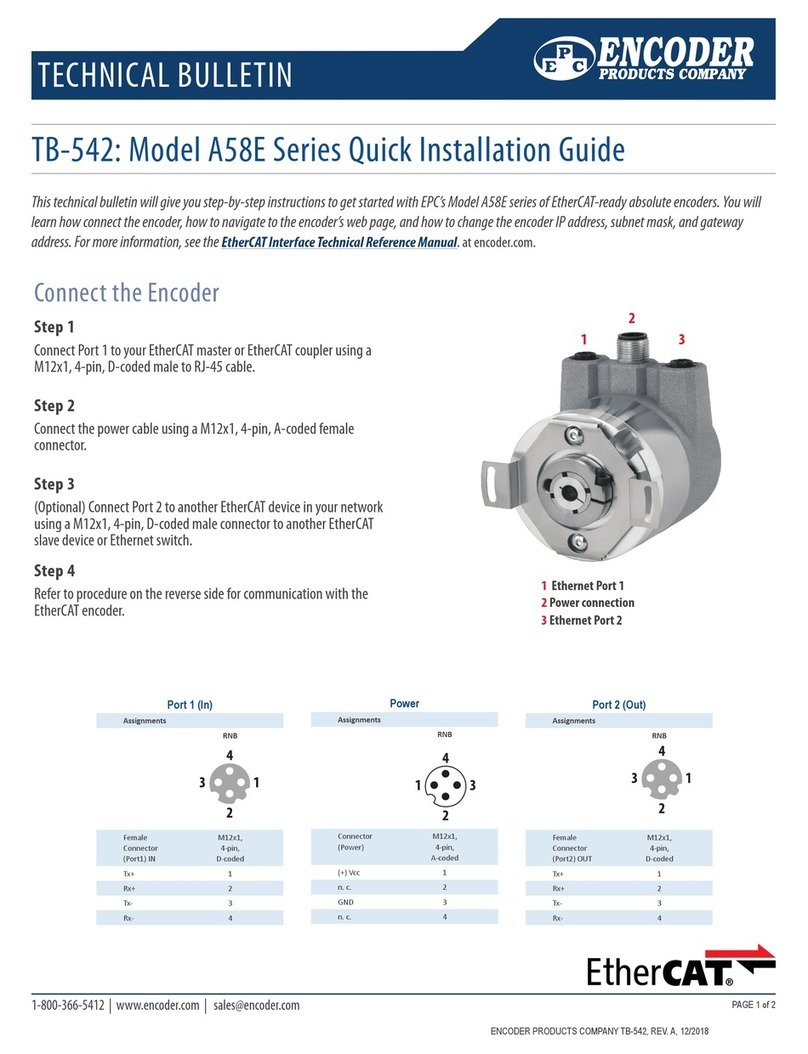

3.4.1 Bus Cover with 3 x M12x1

The "RNB" code in the order key refers to an encoder with a bus cover. The electrical connection is made at the bus cover via the 2 x M12 plugs and 1

x M12 socket. The connection assignment of the plugs and sockets can be found in Table 3.1.

Port 1 (In)

Assignments

RNB

Female

Connector

(Port1) IN

M12x1,

4-pin,

D-coded

Tx+ 1

Rx+ 2

Tx- 3

Rx- 4

Power

Assignments

RNB

Connector

(Power)

M12x1,

4-pin,

A-coded

(+) Vcc 1

n. c. 2

GND 3

n. c. 4

Port 2 (Out)

Assignments

RNB

Female

Connector

(Port2) OUT

M12x1,

4-pin,

D-coded

Tx+ 1

Rx+ 2

Tx- 3

Rx- 4

This chart is for:

A58SE datasheet

A58HE datasheet

TB-541

TB-542

PROFINET manual

EtherCAT manual

Tx+ 1

Rx+ 2

Tx- 3

Rx- 4

Female Connector

Port1 (IN)

M12x1,

4-pin,

D-coded

Function

(+) Vcc 1

n. c. 2

GND 3

n. c. 4

Power

M12x1,

4-pin,

A-coded

Function

Tx+ 1

Rx+ 2

Tx- 3

Rx- 4

Female Connector

Port2 (OUT)

M12x1,

4-pin,

D-coded

Function

Below is version from Daniel Konoff. Above version contains

same information, approved format from Cody Swisher and

Sarah Walter 9/19/19

PLACE AS A PDF

in the documents. Otherwise BECO can’t

open the les.

Table 3.1: Pin Connection Assignment

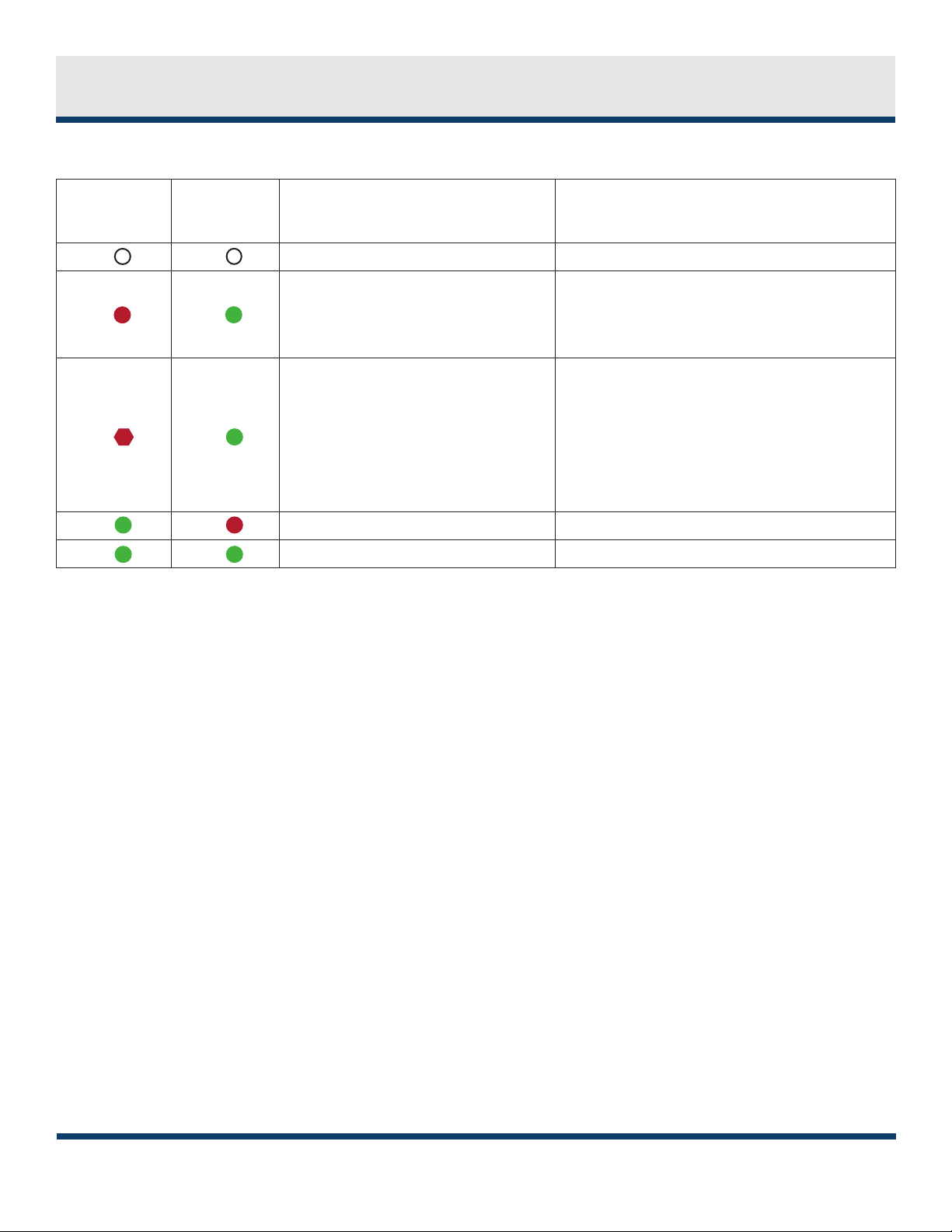

3.5 LEDs and Signalling

Four status LEDs on the bus cover signal the various encoder states and thus support error diagnosis and troubleshooting in the eld (seeTable

3.2).The two Link Activity LEDs (L/A) light up or ash green when the encoder is connected to another PROFINET node (PLC, switch, additional eld

device...) and data is being exchanged.The STAT LED indicates the status of the eldbus, the MOD LED the status of the encoder.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 14 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

STAT LED

dual color

MOD LED

dual color

Meaning Cause

No voltage

No connection;

no data exchange Bus disconnection or master not accessible or switched o

Parametrization error, no data exchange

Criterion:

Data exchange correct.

However, the slave does not switch to the

data-exchange mode

Slave is not congured yet.

Incorrect station address, but not out of range.

The actual conguration of the slave diers from the

nominal conguration.

System error Diagnosis exists, slave is in data-exchange mode

Data exchange, slave and operation OK

3.6 MAC Address and IP Address

EPC PROFINET encoders have three MAC addresses. These always start with D4-90-E0-xx-xx-xx.The number depends on the number of ports on the

integrated three-port switch.There is one MAC address each for Port1 and Port2, as well as one MAC address for the "internal port" to which the

encoder itself is connected.

In the delivered state, the PROFINET encoder has no IP address and no name. These are dened during conguration (e.g.,TIA Portal).

4.PROFINET

4.1 Summary of Functions

Our PROFINET encoders support the functions shown inTable 4.1, below.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 15 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Functions Meaning

Conformance class CC-C

Prole Encoder ProleV4.1

Prole class Encoder Prole Class 4,

as well as compatibility with Class 3

Performance Cycle time 250 μs (with clock synchronisation) and fast

start-up of 1 s

Redundancy MPR and MRPD

Web server Display and conguration of parameters,

rmware updates

Clock synchronisation RT, IRT and IRT isochronous

Table 4.1: Functions

4.2 GSDML Modules

The modules from the current GSDML le are listed inTable 4.2, below

Designation Meaning

ST0016 No multi-turn, single-turn 16 bit

MT4316 Multi-turn 43 bit + single-turn 16 bit = 59 bits in total

Table 4.2: GSDML Modules

4.3 Signals

Table 4.3, below, shows the signals that are supported by EPC PROFINET encoders.

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 16 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Signal Description Name Length (bits) Signed

6 Velocity A NIST_A 16 Y

8 Velocity B NIST_B 32 Y

9 Sensor 1 control word G1_STW 16 –

10 Sensor 1 status word G1_ZSW 16 –

11 Sensor 1 position 1 G1_XIST1 32 N

12 Sensor 1 position 2 G1_XIST2 32 N

39 Sensor 1 position 3 G1_XIST3 64 N

80 Encoder control word 2 STW2_ENC 16 –

81 Encoder status word 2 ZSW2_ENC 16 –

238

(60000) Sensor position preset control word G1_XIST_PRESET_A 32 N

TBD Sensor position preset control word G1_XIST_PRESET_B1 32 N

TBD Sensor position preset control word G1_XIST_PRESET_C 64 N

60001 Debug control word DEBUG_STW 16 N

60002 Debug status word DEBUG_ZSW 16 N

Table 4.3: Signals

4.4 Structure of the signals

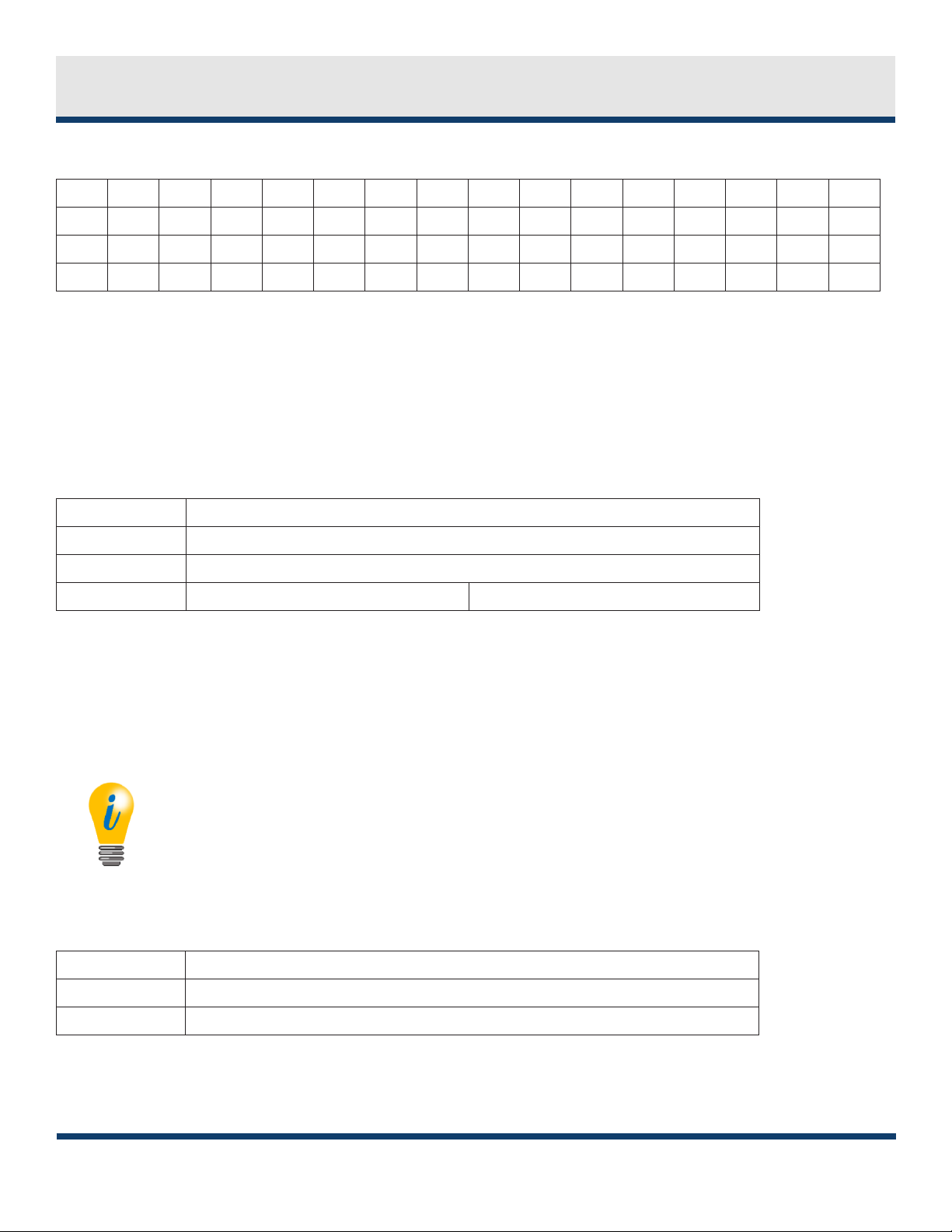

NIST_A: Velocity value A

This value includes the velocity, has a width of 16 bits and is signed.

Signal NIST_A

Bits 15 ... 0

Contents

15 … 0 Velocity value A Right-aligned, output in set unit

(seeTable 4.20, Velocity Measuring Units)

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 17 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Table 4.4: Structure of signal 6 NIST_A

NIST_B: Velocity value B

This value includes the velocity, has a width of 32 bits and is signed.

Signal NIST_B

Bits 31 ... 0

Contents

31 … 0 Velocity value B Right-aligned, output in set unit

(seeTable 4.20, Velocity Measuring Units)

Table 4.5: Structure of signal 8 NIST_B

G1_STW: Sensor 1 control word

Signal G1_STW

Bit 15 14 13 12 11 10 ... 0

Contents

15 Conrm sensor error 0 = Sensor error not conrmed by controller

1 = Sensor error conrmed by controller

14 Park mode 0 = Normal operation

1 = Activate park mode

13 Cyclically query absolute position value 0 = Do not interrogate

1 = Master performs query (cyclic output of G1_XIST2)

12 Activate preset 0 = Preset not active

1 = Preset active

11 Preset mode 0 = Set preset to absolute value

1 = Move preset by value (oset)

10 ... 0 Reserved, currently not used

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 18 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Table 4.6: Structure of signal 9 G1_STW

To enable the encoder to respond to the requirements in G1_STW, the controller must set bit 10 to 1 in STW2_ENC.

G1_ZSW: Sensor 1 status word

Signal G1_ZSW

Bit 15 14 13 12 11 10 ... 0

Contents

15 Sensor error Signals a sensor error and outputs a device-specic error code in G1_XIST2

14 Park mode active Conrms "Park mode". No error messages are transmitted

13 Cyclically query absolute position value Conrms "cyclically query absolute position value"

12 Preset activated Conrms "activate preset"

11 Sensor error acknowledgement active Signals processing of the requested sensor error acknowledgement

10 ... 0 Reserved, currently not used

Table 4.7: Structure of signal 10 G1_ZSW

G1_XIST1: Sensor 1 position 1

Signal G1_XIST1

Bits 31 ... 0

Contents

31 ... 0 Absolute position value 1 Right-aligned

Table 4.8: Structure of signal 11 G1_XIST1

Structure of G1_XIST1 using the example of a 16-bit multi-turn and a 16-bit single-turn encoder:

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 19 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

MMMMMMMMMMMMMMMM

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

SSSSSSSSSSSSSSSS

M = multi-turn / S = single turn

This value includes the position, has a width of 32 bits, and is unsigned.The encoder parameter settings inuence this position value if "Class 4

functionality" is activated. The inuence of the preset functionality can be controlled with "G1_XIST1 Preset Control".

G1_XIST2: Sensor 1 position 2

Signal G1_XIST2

Bits 31 ... 0

Contents

31 ... 0 Absolute position value 2 Right-aligned

Table 4.9: Structure of signal 12 G1_XIST2

This value includes the position, has a width of 32 bits and is unsigned.The encoder parameter settings inuence this position value if "Class 4

functionality”is activated.When activated, the preset functionality always has an inuence on G1_XIST2.

If an error occurs, G1_XIST2 contains the error register instead of the position value.

G1_XIST3: Sensor 1 position 3

Signal G1_XIST3

Bits 63 ... 0

Contents

TECHNICAL REFERENCE MANUALPROFINET®Interface

BEPC/EPCTechnical Reference Manual

Absolute Encoders with PROFINET Interface

REV 05/5/2021

Page 20 of 68+44(0)1978 262100 | encoder.co.uk | sales@encoder.co.uk

Signal G1_XIST3

63 ... 0 Absolute position value 3 Right-aligned

Table 4.10: Structure of signal 39 G1_XIST3

This value includes the position, has a width of 64 bits and is unsigned.

It can be used if the measuring range of the encoder is larger than 32 bits.The encoder parameter settings inuence this position value if "Class 4

functionality" is activated.

STW2_ENC: Encoder control word 2

Signal STW2_ENC

Bits 15 ... 12 11 10 9 ... 0

Contents

15 ... 12 Sign-of-life from the PLC Receives a count value from 1 to 15 when isochro-

nous transmission is activated

11 Reserved, currently not used

10 Control by PLC 0 = No control by PLC

1 = Control by PLC

9 ... 1 Reserved, currently not used

0Controls the execution of the preset

1 = Preset executed

Table 4.11: Structure of signal 80 STW2_ENC

ZSW2_ENC: Encoder status word 2

Signal ZSW2_ENC

Bits 15 ... 12 11 .... 10 9 8... 0

This manual suits for next models

5

Table of contents

Other Encoder Media Converter manuals