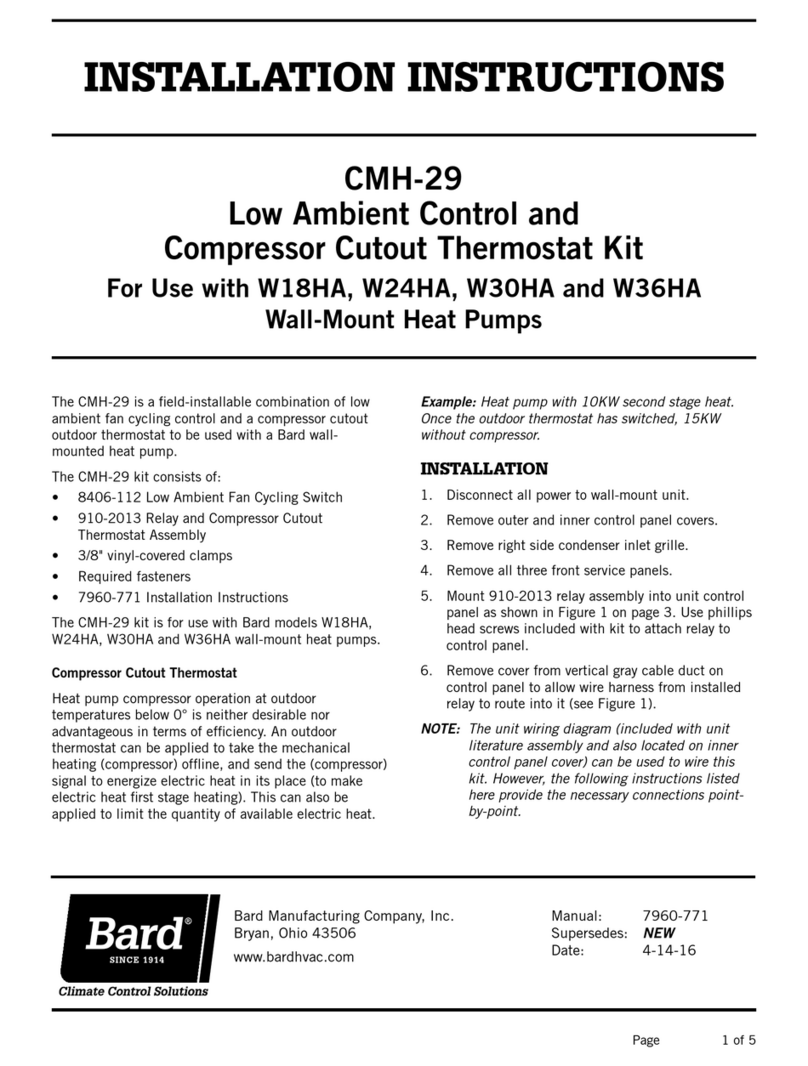

ENDA EDT3423A User manual

D.INP

14 15 16

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT3423A-230-R-RS

DIGITAL DEFROST

THERMOSTAT

11 12 13

COM

B

A

8 680407 726561

DEF.NTC

1 2 3 4 5 6 7

230V AC +10% -20%

50/60Hz 5VA

DEFROST

250V 8A~

FAN

250V 8A~

8 9 10

THER.NTC

GND

Made in Turkey

COMP

250V 8A~

DEF.NTC

1 2 3 4 5 6 7

EDT3423A-230-R

DIGITAL DEFROST

THERMOSTAT

230V AC +10% -20%

50/60Hz 5VA

DEFROST

250V 8A~

FAN

250V 8A~

8 9 10

THER.NTC

GND

11 12

D.INP

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

8 680407 726554

Made in Turkey

COMP

250V 8A~

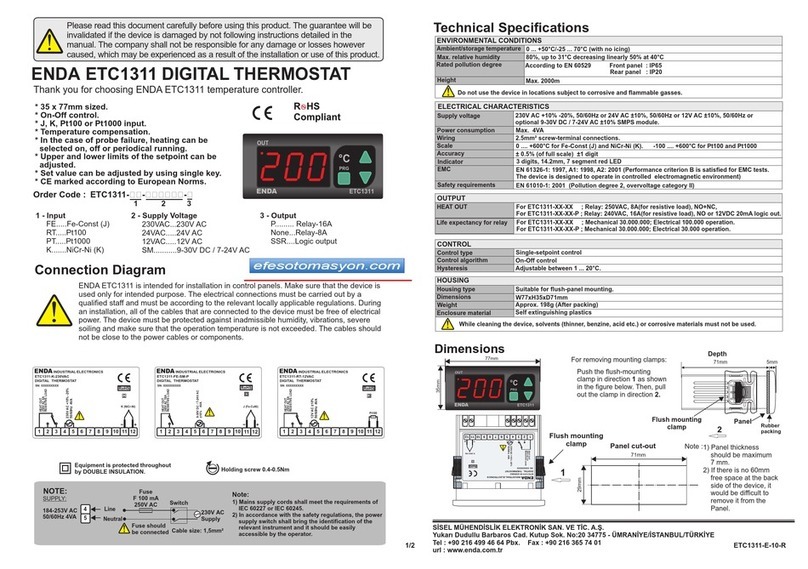

ENDA EDT3423A is intended for installation in control panels. Make sure that the device is used

only for intended purpose. The electrical connections must be carried out by a qualified staff

and must be according to the relevant locally applicable regulations. During an installation, all of the cables

that are connected to the device must be free of electrical power.

Thank you for choosing ENDA EDT3423A temperature controller.

1/4

ENDA EDT3423A DIGITAL THERMOSTAT

CONNECTION DIAGRAM

ENVIRONMENTAL CONDITIONS

Height Max. 2000m

Ambient/storage temperature

Relative humidity

0 ... +50°C/-25 ... 70°C (without icing)

Protection class According to EN60529; Front panel : IP65

Rear Panel : IP20

Supply voltage

Power consumption Max. 5VA

2.5mm² screw-terminal connections

±1%

4 digits, 12.5mm, 7 segment LED

Connection

Scale

Sensitivity

Accuracy

Time accuracy

Display

EMC

Safety requirements

EN 61326-1: 2013

EN 61010-1: 2010 (Pollution degree 2, overvoltage category II)

ELECTRICAL CHARACTERISTICS

-60.0 ... +150.0°C (-76.0 ... +302.0°F)

0.1°C (Can be selected as 0.1ºC or 1ºC.)

±1°C

CONTROL

Control type Single set-point control

On-Off control

Control algorithm

Hysteresis Adjustable between 1 ... 20.0 °C.

OUTPUTS

HOUSING

Housing type Suitable for flush -panel mounting

Dimensions W77xH35xD61mm

Weight Approx. 190g (After packing)

Enclosure material Self extinguishing plastics.

Relative humidity 80% for temperatures up to 31°C decreasing linearly to 50% relative humidity at 40°C.

Fan Relay

Defrosting Relay

Compressor Relay

Life expectancy Without load 30.000.000 switching, 250V AC, 8A (resistive load) 100.000 switching.

Device must be protected against inadmissible humidity, vibrations, severe soiling and make sure that the operation

temperature is not exceeded. The cables should not be close to the power cables or components.

Holding screw

0.4-0.5Nm.

Equipment is protected throughout by

DOUBLE INSULATION

SUPPLY:

NOTE:

184-253V AC

50/60Hz 4VA

Line

Neutral

230V AC

Supply

Switch

Note:

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Fuse should

be connected

1) Mains supply cords shall meet the requirements of

IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power

supply switch shall bring the identification of the

relevant instrument and it should be easily

accessible by the operator.

1

2

71,5mm

28,5mm

Please read this document carefully before using this product. The guarantee will be invalidated if the device is

damaged by not following instructions detailed in the manual. The company shall not be responsible for any

damage or losses however caused, which may be experienced as a result of the installation or use of this

product.

Order Code : EDT3423A - - -

123

1 - Supply Voltage

230........230V AC

110........110V AC

024........24V AC

SM.........10-30V DC / 8-24V AC

3 - ModBus Selection

RS.........ModBus (Optional)

Blank.....N/A

2 - Output

R.......8A Relay Output

230V AC +%10 -%20 or 24V AC or 110V AC ±%10, 50/60Hz or 10-30V DC / 8-24V AC ±%10 SMPS

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

- 35x77mm size.

- On-Off control.

- Three relay outputs for cooling, defrost and fan control.

- Two NTC probe input for cooling and defrost control.

- Offset point can be entered for NTC input.

- Compressor protection parameters can be entered.

- In case of probe failure, compressor operation can be

set to ON, OFF or periodic.

- Selectable smart defrost feature.

- Defrost operation can be performed to evaporator

temperature, time-dependent or manual.

- Lower and upper limits of the set point can be set.

- Defrost time and intervals can be adjusted.

- Lower and upper alarm limit can be set to dependent

on set point.

- Temperature unit can be displayed in ° C or ° F.

- Digital input.

- Transfer device parameter settings with

ENDAKEY-RF .

- RS485 communication features with Modbus RTU

protocol (optional).

- CE Marked according to European standards.

2

B

A

2

3

4

3

1

Panel cut-out

1) Panel thickness should

be maximum 7mm.

2) If there is no 60mm free

space at the back side of

the device, it would be

difficult to remove it from

the panel.

1

To mounting device ;

- Push the device in

direction .

Note :

A2

B - Push the clamps in the direction .

Remove the device from the panel by

pulling in direction .

A - Remove the side covers by lifting

them with a flat screwdriver in direction

To removing the device from panel :

2

3

4

DIMENSIONS

Specify at order.

Please see page 2 for Modbus

Connection Diagram.

KEEP AWAY device from exposed to corrosive, volatile and flammable gases or liquids and

DO NOT USE the device in similar hazardous locations.

Avoid any liquid contact while the device is switched on.

DO NOT clean the device with solvent (thinner, gasoline, acid etc.) and / or abrasive cleaning agents.

NO 250V AC, 8A, 1/2hp 240V AC

NO+NC 250V AC, 8A, 1/2hp 240V AC

NO 250V AC,8A , 1/2hp 240V AC

EDT3423A-EN-01-201214

ENDA

TM

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

2/4

FRONT PANEL COMMANDS

1. Viewing and Changing The set point

Measurement

value

-30.0 -29.9 -30.0

1000-24.0

If key is pressed for 3 seconds in "Running Mode", setpoint value is displayed and it can be changed by using navigation keys.

-9.0

Measurement

value

-24.0

By pressing and keys together for 3 seconds in "Running Mode",

defrosting sensor (probe) measurement value will be displayed.

2. Viewing Defrost Measurement Value

3. Locking / Unlocking the Keys

Loc

unl

1000-24.0

Measurement

value

Locked.

Unlocked

4.Manual Defrost Process

By pressing to key for 2 seconds in "Running Mode", the defrost process will start or stop manually.

The defrosting process will be disabled if the d3 parameter ( d.dur ) is set to 0 .

5.Manually Switching On or Off

If key is pressed for 2 seconds during the "Running Mode", the display indicator switched off, temperature measurement and controls are not performed and outputs

are disabled. While in this status, by pressing to key for 2 seconds again, the current operation can be resumed.

6. Changing Parameter Values

If keys are pressed together for 2 seconds, message appears and the user menu is entered, and the first parameter of the user

menu is displayed. The parameter value can be displayed by pressing key and can be changed by using navigation keys.

If no operation is performed for 3 seconds while a parameter value displayed or by pressing to key, the parameter name will be re-displayed.

If keys are pressed together while the parameter name displayed, "Running Mode" is entered immediately.

Programming Mode

7. The Hidden Menu

If is pressed for 7 seconds, message appears and the hidden menu is entered, and R2

parameter is displayed.

The parameter value can be displayed by pressing key and can be changed by using navigation

keys.

R2

8. Transferring Parameters Between Menus

R2

By pressing to keys together for 2 seconds, the parameter can be transferred to user menu. Up

to 8 parameters can be transferred.

If keys are pressed for 2 seconds, parameter will be removed from user menu.

If no parameter is stored in the user menu, nP message will be displayed.

R0 C2

ERROR MESSAGES

P5C

Pfa

No communication with thermostat sensor.

(Sensor and/or cable broken or not connected) Thermostat probe or connection

line short-circuited.

Temperature value is

higher than the scale.

Temperature value is

lower than the scale.

ALARM SITUATION

Measurement value flashes

in case of an alarm.

-24.0 EA

External alarm is active but

the outputs are not affected.

5A

External alarm is active and the

relay outputs are in OFF situation.

FACTORY DEFAULTS

Power-up the device by pressing and holding down the key for factory defaults. d.Pr message will be displayed if the operation success.

P52

Pf2

To locking or unlocking the keypad, keys are pressed together for 2 seconds. Loc or

unL message will appears for valid status.

During Loc status, just the setpoint value will appear if the key is pressed.

No communication with defrost sensor.

(Sensor and/or cable broken or not connected) Defrost probe or connection

line short-circuited.

120 Ohm

Master Slave - 1 Up to 127 slave devices

can be controlled.

Slave - 2

Slave - 127

-

+

A

B

-

+

A

B

-

+

A

B

-

+

A

B

120 Ohm

* MODBUS CONNECTION DIAGRAM

Termination should be accomplished by

attaching 120 Ohm resistors to the start and at

the end of the communication line. * Applies to devices with Modbus function.

Note :

The warning led on the

device will blink in case of

an error condition.

EDT3423A-EN-01-201214

ENDA

TM

Make sure the keypad is not locked before performing the following operation.

1

TRANSFERRING THE PARAMETERS

Parameter Transfer from Device to ENDAKEY-RF.

Parameter Transfer from ENDAKEY-RF to Device.

By pressing the key for 6 seconds continuously, Hrd message appears and the device waits for reading ENDAKEY-RF.

By touching with the ENDAKEY-RF to top of the left corner of the device and by pressing to button on the ENDAKEY-RF,

parameters will be transferred to the ENDAKEY-RF. If the parameter transfer is successful, 5uc message appears on the

display.

By touching with the ENDAKEY to top of the left corner of the device and by pressing to button on the ENDAKEY,

parameters will be transferred to the device. If the parameters transferred successfully, HYE and 5uc message appears on

display.

Move ENDAKEY-RF towards the

top left of the device in direction 1

CONTROL PARAMETERS

R1

R2 -60.0 150.0 °C 150

-60.0 150.0 °C -60

R0

o1

20.0 °C 2

20.0 °C 0

0.1

-20.0

MIN. MAX. UNIT

DEF. SET

°F °C

C0

C2

C4

99:00 min:sec

99:00 min:sec

0:00 99:00 min:sec

°C

0:00

0:00

0:00

P1

No

YE5

No

CONFIGURATION PARAMETERS

COMPRESSOR PROTECTION PARAMETERS

DEFROST CONTROL PARAMETERS

Delay time required for the compressor to restart following a stop.

i5 Digital input types. nd:Digital input unused. EA: External alarm. EA message flashes in the display. Output unchanged.

5A:Important external alarm.5A message flashes in the display.Relay output is turned off. df:Defrost operation is started.

i3 Digital input delay. The period of the digital inputs to be active. 99:00

nd dF nd

Upper limit for setpoint value.

Lower limit for setpoint value.

Cooling hysteresis.

Offset value for cooling.

Decimal point (no= decimal point not added, ie 22°C, YE5=decimal point added, ie 22.3°C.)

Delay time for the compressor after power is on.

Off time for the compressor output in the case of probe failure

Digital input polarity. cL = While a digital input contact is closed,it is activated.

oP= While a digital input is opened, it is activated. CL oP Cl

1:00

1:00

1:00

0:00 0:00

(Devices with part code suffix ‘F' have deg F as the default 'Unit').

LP While keylock active, the set value is changed. NO: Set value is not changed. YE5: Set value is changed. no yE5 no

i1

- Please specify at order “ENDAKEY-RF” if required.

Defros type selection ( ELC : electric defrost (compressor is switched off), GA5 : hot gas (compressor is ON))

1

1

1

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

3/4

EDT3423A-EN-01-201214

ENDA

TM

P2 Temperature unit

0:00

99:00 min:sec

C5 On time for the compressor output in the case of probe failure.

d4 YE5 No

No

d3 99:00 min:sec

0:00

Defrost duration (If d.dur=0 , automatic and manual defrost will be disabled.)

Defrosting process begins with energy (no = Defrost process doesn’t start when the energy comes.

YE5 = Defrost process starts when the energy comes.)

1:00

d1

ELC

GA5

ELC

d2

-600

150.0

2.0

Defrost stop temperature ( If evaporator temperature is greater than this value, defrost will not work) °C

d9

d5

99:00

99:00 min:sec

d6

rE

Lc. Lc.

0:00 1:00

During defrost,display configuration (rE= Real temperature is displayed during defrost.

(Lc= The temperature which is measured before defrost is displayed during defrost.

Delay time for defrosting after power is on.

Delay time for display real temperature after defrost is over.

1:00

min:sec

0:00

d7 99:00

0:00

Dripping (discharge) time 2:00

min:sec

A1

A4

A7

A3

A2

A4 °C -60

A1 150.0 °C 150

0:00 99:00

0.1 20.0 °C

Ab5 rEF Ab5

A6

99:00 min:sec 0:00

-60.0

0:00

Limit for upper alarm level. When A2 is changed, it should be readjusted.

Limit for lower alarm level. When A2 is changed, it should be readjusted.

Hysteresis alarm

Alarm configuration. ( Ab5 = Independent alarm. Alarm values are A1 and A4 .)

(rEF = Relative alarm. Alarm values are SET-A1 and SET+A2.)

NOTE: Upper and Lower alarm level variables are determined according to the “ A.tYP ” parameter.

If A1 = A.b5 , A1 and A4.

If A2 = rEF, R1 = SET-A1 and A4.

Time delay to display alarm message after alarm is on.

Time delay to display alarm message after power is on.

2

0:10

hr:min

150.0 °C/°F 1

no YE5 YE5

99:00 min:sec 3:00

2

no YE5 YE5

99:00 min:sec 1:00

yE5 no

0.1 20.0 °C/°F

-60.0

00:00

00:00

no

Fan control depending on room temperature. (no=If evaporator temperature over f5tp value, fan does not run.

yE5=If difference between room temperature and the temperature of the evaporator temperature is below from f.5tp

value, fan stops. If the room temperature and evaporator temperature differences greater than f5tp + f.hy5 ,

fan runs again.

Fan operates with thermostat .(no=Fan runs independently from thermostat.,yE5=Fan operated with thermostat.

Fan operation during defrost process.(no= , yE5= Fan stops during defrost process.)Fan holds its status

Required delay time for fan to be powered up.

Required delay time for fan to be powered up after defrost.

FAN CONTROL PARAMETERS

Fan stop temperature.

F1

F6

F3

F0

F4

F2

F7

H2

H1

19.20

1

off

Modbus slave device address for device

MODBUS COMMUNICATION PARAMETERS

Modbus communication speed ( Baud rate, 0 : oFF, 1 :1200, 2 : 2400, 3 : 4800, 4 : 9600, 5 :19.20 )

247 1

bps 9600

Please see page 2 for Modbus Connection Diagram.

d8 Smart Defrost selection (no : Defrost counter (between 2 defrost duration) decrease irrespective of status of the compressor.

YE5 : Defrost counter decreases as long as compressor work.).

No

YE5

No

d0 The time between 2 consecutive defrosts. 1:00 99:00 hr:min 1:00

ALARM CONTROL PARAMETERS

Fan differential.

F5 Fan operations when compressor stop. (no= Fan holds its status, yE5= Fan stops with compressor.) no YE5 YE5

Holding Register

Addresses

Data

Type Data Content Parameter

Name Read/Write

Permission

Setpoint value

Setpoint value for upper limit

Upper level alarm

Setpoint value for lower limit

Lower level alarm

Offset cooling value

Cooling differential

Alarm differential

Defrost stopping temperature

Compressor output ON-state time duration in case of probe failure.

The time between 2 consecutive defrosts.

5Et

R2

A4

R1

A1

o1

R0

A3

d2

F1

F4

i5

i3

C0

C2

C5

C4

d3

d0

d9

d7

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Data

Type

Measured ambient, temperature value (°C / °F)

* Holding and Input Register parameters of type integer, those “signed integer” is defined as the decimal port of and associated with these parameters. (So,”14.0” is a

parameter value of “140” will be read in). Relevant parameters for a period of “mm:ss” type ones in seconds, ”hh:mm” while those species defined in minutes.

Compressor output status (0=OFF; 1=ON)

Coil

Addresses

Decimal Hex

Data

Type

00d 0x00 Bit

1.4 COILS

01d 0x01 Bit

Temperature unit. OFF = °C , ON = °FP2

02d 0x02 Bit

Decimal point . OFF= no , ON= YE5 P1

03d 0x03 Bit

Digital input polarity. OFF = cL , ON = oP i1

04d 0x04 Bit

Smart Defrost selection. OFF = no , ON= YE5 d8

Defrost type selection OFF = ELC , ON = GAS

d6

05d 0x05 Bit

06d 0x06 Bit d4

07d 0x07 Bit

d1

Data Content Read/Write

Permission

Parameter

Name

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Dripping (discharge) time Read / Write

d5

Decimal Hex

0000d

0001d

0002d

0003d

0004d

0005d

0006d

0007d

0008d

0009d

0010d

0011d

0012d

0013d

0014d

0015d

0016d

0017d

0018d

0019d

0021d

0x0000

0x0001

0x0002

0x0003

0x0004

0x0005

0x0006

0x0007

0x0008

0x0009

0x000A

0x000B

0x000C

0x000D

0x000E

0x000F

0x0010

0x0011

0x0012

0x0013

0x0015

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

1.1 HOLDING REGISTERS

Input Register

Addresses

Decimal Hex

1.2 INPUT REGISTERS

0000d 0x0000 word --

Discrate Inputs

Addresses

Decimal Hex

1.3 DISCRATE INPUTS

0000d 0x0000 bit --

word

0x0014

0020d

0001d 0x0001 bit --

ENDA EDT3423A DIGITAL THERMOSTAT MODBUS PROTOCOL ADDRESS MAP

Data Content Parameter

Name

Read/Write

Permission

Read

Data

Type Data Content Parameter

Name

Read/Write

Permission

Read

Read

Defrost output status (0=OFF; 1=ON)

A2

08d 0x08 Bit

Alarm configuration. OFF = Ab5 , ON = Relative alarm rEF

Read / Write

Defrosting process begins with energy. OFF = no , ON = YE5

During defrost, display configuration. OFF = Lc , ON = rE

Time delay to display alarm message after alarm is on. A7

F6

F3

Read / Write

Read / Write

Read / Write

Read / Write

A6

0022d

0023d

0025d

0x0016

0x0017

0x0019

word

word

word

word

0x0018

0024d

Required delay time for fan to be powered up.

Required delay time for fan to be powered up after defrost.

Fan differential.

Measured defrost sensor, temperature value (°C / °F)

0001d 0x0001 word --

Read

0002d 0x0002 bit --

Read

Fan output status (0=OFF; 1=ON)

F0

09d 0x09 Bit f5

10d 0x0A Bit

Read / Write

Read / Write

F2

11d 0x0B Bit Read / Write

F7

Fan operates with thermostat. OFF = no , ON = yE5

Fan starts when compressor stop. OFF = no , ON = yE5

Fan operation during defrost process. OFF = no , ON = yE5

Fan control depending on room temperature. OFF = no , ON = yE5

--

Read

0002d 0x0002 word

All controls output status

* All outputs will be displayed in the word as compressor (0.bit) defrost (1.bit) fan (2.bit).

12d 0x0C Bit Read / Write

LP

13d 0x0D Bit

While the keys are locked , set value is adjustable. OFF = no , ON = ye5

Read / Write

14d 0x0E Bit

15d 0x0F Bit

Read / Write

Read / Write

16d 0x010 Bit Read / Write

The keylock active / inactive. OFF= inactive , ON= active

Starting manual defrost or stopping manual defrost. OFF= stopping , ON= starting

Control outputs active / inactive. OFF= active , ON= inactive

The factory setting is loaded. ON= The factory setting is loaded.

--

--

--

--

* Up to 16 bits can be read and/or written to the coil at one time.

Fan stopping temperature

Fan differential.

Digital input types .0=nd ; 1=EA ; 2=5A ; 3=df

Delay time duration for Digital input.

Delay time duration for the compressor on power-up.

Delay time duration for the compressor restart after the stop.

Compressor output OFF-state time duration in case of probe failure.

Defrost duration.

Defrost start delay time after the defrost end.

Real temperature displaying delay time, after the defrost end.

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

4/4

EDT3423A-EN-01-201214

ENDA

TM

Other ENDA Thermostat manuals

Popular Thermostat manuals by other brands

Cosa

Cosa 9610 Installation, operation and maintenance manual

meitav-tec

meitav-tec ETN-P Series Owner's manual installation and operating instructions

Hitachi

Hitachi Room Unit Operation manual

Aube Technologies

Aube Technologies TH106 user guide

VDH

VDH ALFA 71 MODulation user manual

Lux Products

Lux Products SMART TEMP TX1500Ub Installation and operating instructions