ENDA EDT2411A User manual

1 / 4. EDT2411A-EN-10052019

COM

B

A

ENDAINDUSTRIALELECTRONICS

EDT2411A-230-P-RS

DIGITAL THERMOSTAT

COMPRESSOR

277V 20A~

Made in TURKEY

1 2 3 4 5 6 7 8 9 10

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT2411A-230-R

DIGITAL THERMOSTAT

11 12

COMPRESSOR

250V 8A~

8 680407 705597

Made in TURKEY

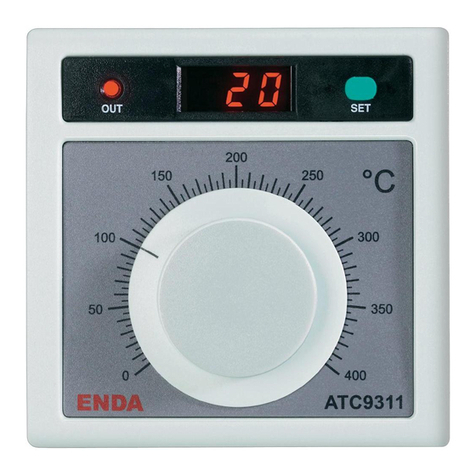

EDT2411A

Thank you for choosing temperature controllerENDA EDT2411A .

ENDA 2 A DIGITAL THERMOSTATEDT 411

35x77mm.

On-Off control.

Relay output for cooling or heating control.

Single NTC probe input.

Offset value can be entered for NTC input.

Compressor protection parameters can be entered.

In case of probe failure, output status can be set to

ON, OFF or periodic.

Upper and Lower setpoint value limits can be ed.adjust

Selectable “Smart Defrost” feature.

Defrosting duration and intervals can be adjusted.

6 Different warning tone selections.

Lower and upper alarm limit can be adjusted to depending

on set value.

Temperature unit can be selected C or F.° °

Digital input ;

E-xternal alarm

I-nitiate defrost

Transfer device parameter settings with ENDAKEY

N- o power-up required.

RS485 ModBus protocol communication feature (optional).

CE marked according to European Norms.

Pleasereadthisdocumentcarefullybeforeusingthisproduct.Theguaranteewill be in

validatedifthe

device is damaged by not following instructions detailed in the manual. The company shall not be

responsiblefor anydamageor losses howevercaused,whichmay be experiencedasaresultof the

installationor useofthisproduct.

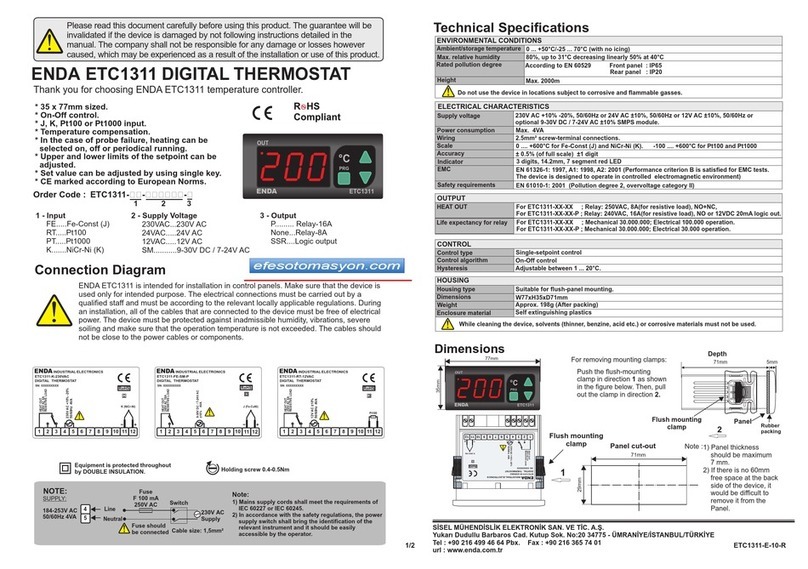

CONNECTION DIAGRAM

ENDA EDT2411A is intended for installation in control panels. Make sure that the device is used

only for intended purpose. The electrical connections must be carried out by a qualified staff

and must be according to the relevant locally applicable regulations. During an installation, all of the cables

that are connected to the device must be free of electrical power. The device must be protected against

inadmissible humidity, vibrations, severe soiling and make sure that the operation temperature is not

exceeded. The cables should not be close to the power cables or components.

SUPPLY:

NOTE:

184-253V AC

50/60Hz 4VA

Line

Neutral 230V AC

Supply

Switch Note:

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Fuse should

be connected

1) Mains supply cords shall meet the requirements of

IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power

supply switch shall bring the identification of the

relevant instrument and it should be easily

accessible by the operator.

1

2

Order Code : EDT2411A - - -

1 2 3

1 - Supply Voltage

230..... 230V AC...

24........24V AC/DC

12........12V AC/DC

SM........9-30VDC / 7-24V AC

24V.......12V / 24V DC

2-Output

R......... 8A Relay output

P......... 20A Relay output

3 b- Mod us

RS..... RS-485 Modb... us Available

(Optional / Specify at order)

....Blank N/A

Holding screw

0.4-0.5Nm

Equipment is protected throughout

by DOUBLE INSULATION.

ENVIRONMENTAL CONDITIONS

Height Max. 2000m

Ambient / torage emperatureS T

Relative umidityH 0 ... +50°C/-40 ... 85°C (without icing)

Protection Class According to EN60529; Front panel : IP65, Rear panel : IP20

Do not use the device in locations subject to corrosive and flammable gasses.

Supply oltageV 230V AC +%10 -%20, 50/60Hz ; 12V AC/DC ± %10 or 24V AC/DC ±%10

Power onsumptionC Max. 5VA

2.5mm² screw-terminal connections

±1%

4 digits, 12.5mm, 7 segment LED (V2 Code : Blue Display)

Connection

Scale

Sensitivity

Accuracy

Time ccuracyA

Display

EMC

Safety Requirements EN 61326-1: 2013

EN 61010-1: 2010 (Pollution degree 2, overvoltage category II)

ELECTRICAL CHARACTERISTICS

-60.0 ... +150.0°C (-76.0 ... +302.0°F)

0.1°C (Can be selected as 0.1 or .)ºC 1ºC

±1°C

CONTROL

Control ypeT Single set-point control

On-Off control

Control lgorithmA

Hysteresis Adjustable between 1 ... 20.0°C.

Life xpectancy for elayE R

OUTPUTS

HOUSING

Housing ypeT Suitable for flush -panel mounting

Dimensions W77xH35xD61mm

Weight Approx. 190g (After packing)

Enclosure aterialM Self extinguishing plastics.

While cleaning the device,solvents (thinner,benzine,acid etc.) or corrosive materials must not be used.

Relay Output

For EDT2411A-X-R ; Without load 30.000.000 mechanical;

250V AC, 8A resistive load 100.000 electrical operation.

For EDT2411A-X-P ; Without load 10.000.000 switching;

277V AC,20A (for resistive load) 100.000 electrical operation.

For EDT2411A-X-R ; Relay : NO+NC 250V AC,8A (resistive load),

1/2HP, 240V AC (inductive load)0.37KW

For EDT2411A-X-P ; Relay : NO 277V AC,20A (resistive load),

1/2HP, 250V AC (inductive load)0.37KW

Max. humidity 80% for temperatures up to 31°C decreasing linearly to

50% relative humidity at 40°C.

DIMENSIONS

Note:

1) Panel thickness should

be maximum 7mm.

2) If there is no 60mm free

space at the back side of

the device,it would be

difficult to remove it from

the panel.

Flush mounting

clamp

For removing mounting clamps:

-Push the flush-mounting

clamp in direction as shown1

in the figure below.Then,pull

out the clamp in direction .2

71,5mm

Panel cut-out

61mm 5mm

Flush mounting

clamp PanelRubber

packing

2

Depth

77mm

1

1 2 3 4 5 6 78910

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT24 1-230-R1

DIGITAL THERMOSTAT

11 12

COMPRESSOR

250V AC 8A

RESISTIVE LOAD

8 680407 702220

EDT2411A

SURAN Industrieelektronik

Dettinger Str. 9

D-72160 Horb a.N. Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de

Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de

english

uPL

Hy5 C.Fos

C.FosC.Fo5

uPL

6. The Hidden Menu

While in “User Menu”, if key is pressed for 7 seconds the message is displayed and hidden

menu is enterd and then parameter is displayed. Selected the parameter’s value can beupl

displayed by pressing key and can be changed with keys. Parameter accessing and saving

functions can be performed like a "User Menu". All parameters can be accessed from this menu.

If keys are pressed together for 2 seconds; parameter is transferred to the user menu. In this way

up to 8 parameters can be transferred to the "User Menu".

7. How can we to transfer parameter between menus?

Program Mode

ERROR MESSAGES

P5C

Pfa

ALARM SITUATION

5. Changing Parameter Values

4. Activating / Inactivating The Control Outputs

C.dI5

CENB

When in the "Running mode", if key is pressed for 2 seconds, message is displayed and control outputs becomes to the inactive position, the deviceC.dI5

works as the indicator. When the control outputs are disabled; if key is pressed for 2 seconds is disabled and the device continues to control function.C.EnB

If keys are pressed together for 2 seconds is displayed and “User Menu” is entered, then first parameter’s name is displayed in the user menu.

While a parameter is selected, by pressing key, parameter value can be displayed. This parameter can be changed with keys. If no operation

performed for 3 seconds or during this time, key is pressed while parameter value displayed, parameter name will be displayed again. While parameter name

displayed, if by pressing together keys, "Running Mode" is entered.

1000-24.0

The control ouput becomes inactive.

The control output becomes active.

EA

SET

SET

SET

SET

In “User Menu” if keys are pressed together for 2 seconds, parameter is removed from “User Menu.

When a parameter is displayed “User Menu”, F LED lights up in hidden menu. If there is no parameter in°

"User Menu", message is displayed.nP

SET

1000-24.0

SA

Means, thermostat probe is broken.

Temperature value is higher than the scale.

Means, thermostat probe is short circuit.

Temperature value is lower than the scale.

1. Measurements shown flashes when the alarm condition occurs and if parameter is not , audible warning is heard.5ND 0

2. External alarm is active but the outputs are unaffected.

3. External alarm is active and in this state, specifies that the relay outputs are turned off (off state).

While warning, by pressing key, audible warning can be temporarily disabled.

FACTORY SETTINGS

If key is held down while the device is powered up, message appears and factory parameters restored.d.PAr

DEFROST LED : With the defrost lights up.

SET

FAHRENHEIT LED : F”In parameter value or the measured temperature value “ unit while this LED°

lights up. In the hidden menu at the same time the user menu parameter is shown the LED lights up.

COMPRESSOR LED : If compressor output is active, this LED lights up. While these compressor

delays expected, this LED flashes.

In "Running Mode", indicates the set value.

In “Programming Mode”, indicates the selected parameter value.

While in "Programming Mode", provides the transition to the next parameter. If parameter is being

adjusted, it increases parameter’s value. Constantly holding this key, the parameter value rapidly

increases.

While in "Programming Mode", provides the transiton to the previous parameter. If parameter is

being adjusted, it decreases parameter’s value. Constantly holding this key,the parameter value

rapidly decreases.

HEATING LED :Heating is being checked; while the output is active, the LED lights.

FRONT PANEL COMMANDS

1. Viewing and Changing The Set Value

Measurement

value

-30.0 -29.9 -30.0

1000-24.0

SET

While in "Running mode", if key is pressed set value is displayed for 3 seconds. While in this case, the set value is changed with keys.

SET

Loc

unl

1000-24.0

SET

Keys are locked.

Keys are unlocked.

SET

SET

SET

SET

While in "Running Mode", if keys are pressed together for 2 seconds, message is displayed and the keys are locked. If the keys are lockedLoc

keys are pressed for 2 seconds again, message is displayed and keys are unlocked. While keys are locked and if key is pressed, set value can beunL

displayed but can not be changed. While the keys are locked and if any key is pressed , message appears.( except key ) Loc

2. Locking and Unlocking Keys

3. Manuel Defrost Process

While in the "Running Mode", if key is pressed for 2 seconds, defrost process starts manually. If parameter is , manual defrost will be inactive.0d.dur

*When in the "Running Mode", if the control outputs

are inactive, message appears periodically.oFF

°F.

Measurement

value

Measurement

value

While warning, by pressing any key, audible warning can be temporarily disabled.

2 / 4. EDT2411A-EN-10052019

EDT2411A

LoL

uPL -60.0 °C 150uPL

LoL 150.0 °C -60

HY5

oFF °C20.0 2

20.0 °C 0

0.1

-20.0

Min. Max. UNIT DEFAULT

VALUE

A.LoL

A.uPL

A.dFL

A.HY5

A.typ

°CA.uPL -60

A.LoL 150.0 °C 150

0:00 99:00

0.1 20.0 °C

Ab5 rEF Ab5

A.dPo

min:sec99:00 0:00

-60.0

0:00

D.drE

D.Pon

D.dPo

99:00

YE5 No

No

min:sec99:00

Unit °F °C

C.pon

C.Fo5

C.PPn

C.PPF

D.dur

D.int

D.dSP

99:00

RE

Lc. Lc.

99:00 min:sec

99:00 min:sec

99:00 min:sec

99:00 min:sec

0:00 99:00 min:sec

5nd 6 0

°C

0

0:00

0:00

0:00

0:00

0:00

Dpnt No

YE5

No

CONFIGURATION PARAMETERS

COMPRESSOR PROTECTION PARAMETERS

DEFROST CONTROL PARAMETERS

ALARM CONTROL PARAMETERS

1:00

Delay time required for the compressor to restart following a stop.

d.inp

ddi

Display configuration in defrosting process ( Real temperature is displayed during defrost.rE :

( During a defrosting process, last measured temperature valueLc :

is displayed before the defrosting process. This value remains constant until the end of defrosting.

Delay time for defrosting after power-up.

99:00

nd Lght

Upper limit for setpoint

Differential cooling (hysteresis)

Offset value for cooling

Delay time for the compressor after power is on.

On time for the compressor output in the case of probe failure.

Off time for the compressor output in the case of probe failure

Defrost duration ( If selected, automatic and manual defrost is disabled ).d.dur 0=

Time between 2 consecutive defrosts.

Delay time for display real temperature after defrost is over.

Defrost process with power. ( = Defrost process is not started when power-up.no

= Defrost process starts when power-up ).YE5

Limit for upper alarm level. When is changed, should be readjusted.A.tYP AuPL

Limit for lower alarm level. When is changed, should be readjusted.A.tYP ALoL

Hysteresis alarm

Alarm configuration. ( = Independent alarm. Alarm values are and .)Ab5 A.LoL A.uPL

( = Relative alarm. Alarm values are and .)rEF SET-A.LoL SET+A.uPL

NOTE: Upper and Lower alarm level variables are determined according to the “ ” parameter.A.tYP

If = , and .A.tYP A.b5 A.LoL A.uPL

If = , = and .A.tYP rEF LoL SET-A.LoL A.uPL

Time delay to display alarm message after alarm is on.

Time delay to display alarm message after power is on.

dpo CL oP Cl

1:00

0:00

2

1:00

1:00

1:00

1:00

1:00

hr:min

min:sec

0:00

0:00

0:10

hr:min

0:00

ENDAKEY PARAMETER TRANSFER

NOTE 1 : No power-up required for transfering the by using "ENDAKEY". For long

battery life, "ENDAKEY" must be disconnected from device after the transferring process.

NOTE 2 : Please specify at order “ENDAKEY” if required.

parameter

nd

d.5mt Smart Defrost selection (no : Defrost counter (between 2 defrost duration) decrease irrespective of d.int

status of the compressor. YE5 : Defrost counter decreases as long as compressor work)..

No

YE5

No

baud

Adr5

19.20

1

off

Modbus slave device address for device

MODBUS COMMUNICATION PARAMETERS

Modbus communication speed ( Baud rate, 0 : , 1 : , 2 : , 3 : , 4 : , 5 :oFF 1200 2400 4800 9600 19.200 )

247 1

bps 9600

C.typ Co

Co

HE

Control type selection ( = (*) heating control is selected, = Cooling control is selected.)HE Co

C.tYp HEparameter as is selected, the defrost function of the device is disabled.

0:00

Read

button

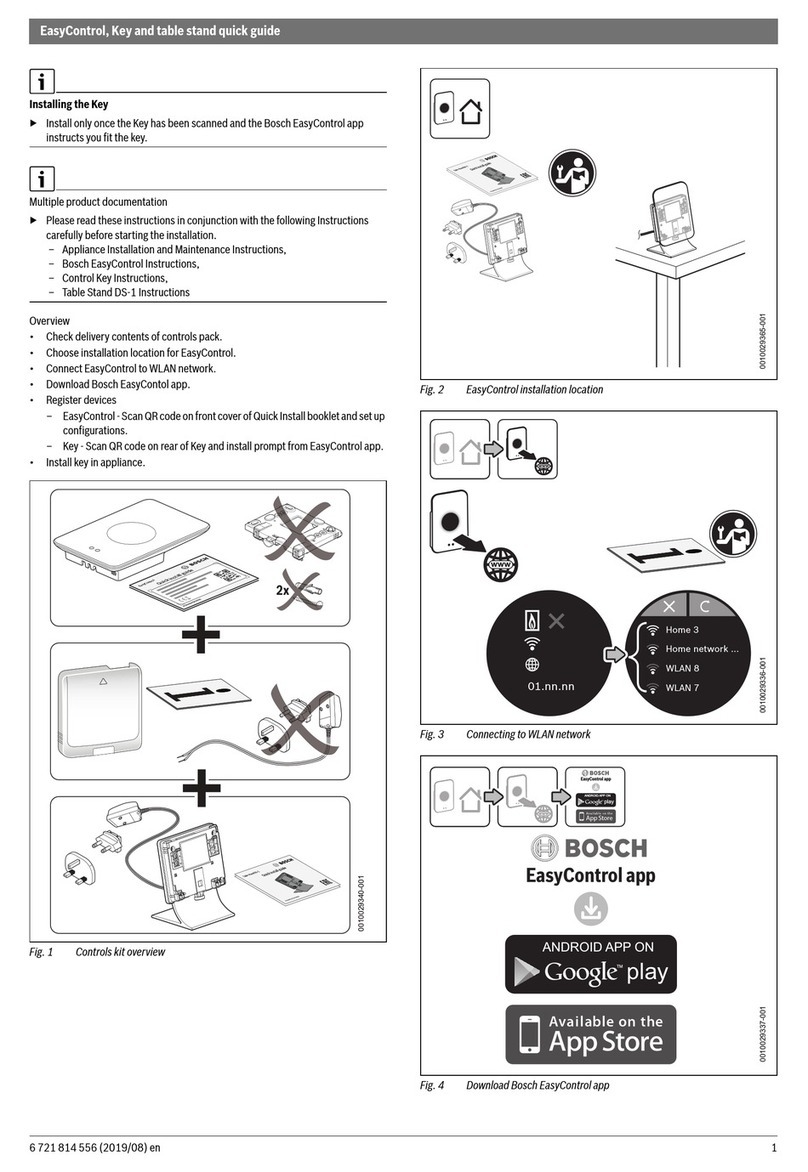

TRANSFERRING THE PARAMETERS FROM ENDAKEY TO DEVICE

While in "Running Mode", if key on device or “Read” button on “ENDAKEY” is pressed, appears on

display and parameters are read and transferred to the device. If the parameter transfer is successful, the " "rEf

message appears and the device begins to work with the loaded parameter values. If the parameters are wrong,

incorrect or " ENDAKEY " is faulty, " " message appears. Parameters will not be changed on device.Err

“ messagedL”

TRANSFERRING THE PARAMETERS FROM DEVICE TO ENDAKEY

While in "Running Mode", if key is pressed on device, appears on display and parameters are read

and transferred to the device. If process success, “ ” message appears. In case of failure, " Err" message5uc

appears.

“ messageuL”

Parameters will not be changed on device.

CONTROL PARAMETERS

Lower limit for setpoint

Digital input types. :Digital input unused. : External alarm. message flashes in the display. Outputnd EA EA

unchanged. : Important external alarm. message flashes in the display. Relay output is turned off.SA A HC5:

Control type. parameter is changed.( If = , If )Ctyp HE Co Co HE df = :Defrost operation is started .

Digital input delay. The period of the digital inputs to be active.

Temperature unit

Decimal point ( = decimal point isn’t shown C, =decimal point is shown C.)no 22 YE5 22.3° °

Type of buzzer sound (6 different voice types can be selected. Alarm during is chosen, the voice warning is0

canceled.) For Relay-8A is valid.

Digital input polarity. While a digital input contact is closed,it is activated.cL =

While a digital input is opened, it is activated.oP=

3. / 4 EDT2411A-EN-10052019

Holding Register

Addresses

Decimal Hex

Data

Type Data Content Parameter

Name Read/Write

Permission Status

Value

0000d

0001d

0002d

0003d

0004d

0005d

0006d

0007d

0008d

0009d

0010d

0011d

0012d

0013d

0014d

0015d

0016d

0017d

0018d

0019d

0020d

0x0000

0x0001

0x0002

0x0003

0x0004

0x0005

0x0006

0x0007

0x0008

0x0009

0x000A

0x000B

0x000C

0x000D

0x000E

0x000F

0x0010

0x0011

0x0012

0x0013

0x0014

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

word

Digital input types .0= ;1= ;2= ;3= ;4=nd EA SA HC dF

Set value

Set point upper limit

Upper level alarm

Set point lower limit

Lower level alarm

The offset value for the cooling

Cooling hysteresis

Switch hysteresis for alarm

Type of buzzer sound

Digital input delay

Delay time for the compressor after power is on.

On time for the compressor output in the case of probe failure

Off time for the compressor output in the case of probe failure

Defrost duration

The time between 2 consecutive defrosts.

Delay time for defrosting after power is on.

After the cooling process of cooling start-up delay

Time delay to display alarm message after alarm is on.

Time delay to display alarm message after power is on.

--

uPL

A.uPL

LoL

A.LoL

oFF

Hy5

A.HY5

5nd

d.inp

ddi

C.Pon

C.Fo5

C.PPn

C.PPf

d.dur

d.int

d.dpo

d.drE

A.dfl

A.dpo

-20

150

150

-60

-60

0

2

2

0

nd

0:00(0 sec)

1:00(60 sec)

0:00(0 sec)

0:00(0 sec)

1:00(60 sec)

1:00(60 sec)

1:00(60 min)

1:00(60 sec)

1:00(60 sec)

0:00(0 sec)

0:10(10 min)

1.1 HOLDING REGISTERS

ENDA EDT2411A DIGITAL THERMOSTAT MODBUS PROTOCOL ADDRESS MAP

Delay time required for the compressor to restart following a stop.

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Input Register

Addresses

Decimal Hex

Data

Type Data Content Read/Write

Permission

0000d 0x0000 word Measured temperature value ( C / F)° ° --

1.2 INPUT REGISTERS

Read

Parameter

Name

*Holding and Input Register parameters of type integer, those “signed integer” is defined as the decimal port of and associated with these

parameters. (So,”14.0” is a parameter value of “140” will be read in). Relevant parameters for a period of “mm:ss” type ones in seconds, ”hh:mm”

while those species defined in minutes.

Discrete Input

Addresses

Decimal Hex

Data

Type Data Content Read/Write

Permission

0000d 0x0000 Bit Control output status (0=OFF; 1=ON) --

1.3 DISCRETE INPUTS

Parameter

Name

Read

Coil

Addresses

Decimal Hex

Data

Type

00d 0x00 Bit Control type selection. OFF = ON =Co , HE C.typ

1.4 COILS

01d 0x01 Bit Temperature unit. OFF = , ON =C F Unit

02d 0x02 Bit Decimal point . OFF= ON=no , YE5 D.PNT

03d 0x03 Bit Digital input polarity. OFF = ON =cL , oP Dpo

04d 0x04 Bit Smart Defrost selection. OFF = , ON=no YE5 D.5mt

Display configuration during defrost. OFF = , ON =Lc rE

D.poN

05d 0x05 Bit

06d 0x06 Bit Defrost process is started by power-up. OFF = , ON =no YE5

A.tYP

07d 0x07 Bit Alarm configuration. OFF = , ON = Relative alarmAb5 rEF

D.d5p

Data Content Read/Write

Permission

Parameter

Name

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

Read / Write

4. / 4 EDT2411A-EN-10052019

This manual suits for next models

2

Table of contents

Other ENDA Thermostat manuals