Endecotts Sonic Sifter User manual

The Sonic Sifter User Guide

Test Sieve Shaker

________________________________________________

ISSUE 03-03 Contents

Description Page 1

Setting Up: 2 - 6

Unpacking 2

Assembly & Operating Conditions 3

Electrical Connections 4

Sieve Stacking 5 - 6

Operating Instructions 7 - 12

Position of Controls 7

Setting & Functions

Run/Stop 8

Pause/Resume 8

Program 8

Memory 8

TestSequences 9

Adjusting Pulse Amplitude & Tappers 10

Programming-Saving-Recalling-Running 11 - 12

Maintenance 13 - 14

Cleaning 13

Care of Sieves 13

Care of Accessories 14

Fuse Replacement 14

General Advice 15

Specification 16

Description

_________________________________________

The Endecotts Sonic Sifter is a vibrating sifter employing an acoustic method to

carry out sieve tests for particle size analysis of various material samples.

It is based on the principle of pulsating a column of air through a stack of sieves at

a set frequency. This causes the particles of the sample material to vibrate and

move around the mesh of the sieves in order to pass through the apertures. To

assist in this movement of particles there is pulsator that periodically taps the base

of the table to release blocked or blinded apertures with particles that are close to

the aperture size. The Sonic Sifter incorporates

a horizontal pulse which provides an

electromechanical shock wave horizontally.

This assists in sifting samples that are 45µm

and finer where agglomeration occurs due to

electrostatic charges.

The Sonic Sifter has an amplitude control

to vary the vibration amplitude. It also has a

digital timer than can be programmed for process time. It switches of automatically

at the end.

- 1 -

Setting Up

_______________________________________________________

Unpacking

The Sonic Sifter should be set up according to the following procedure and the

diagram on Page 3:

Carefully remove the Sonic Sifter from carton, remove the internal packing

material and check the contents as follows:

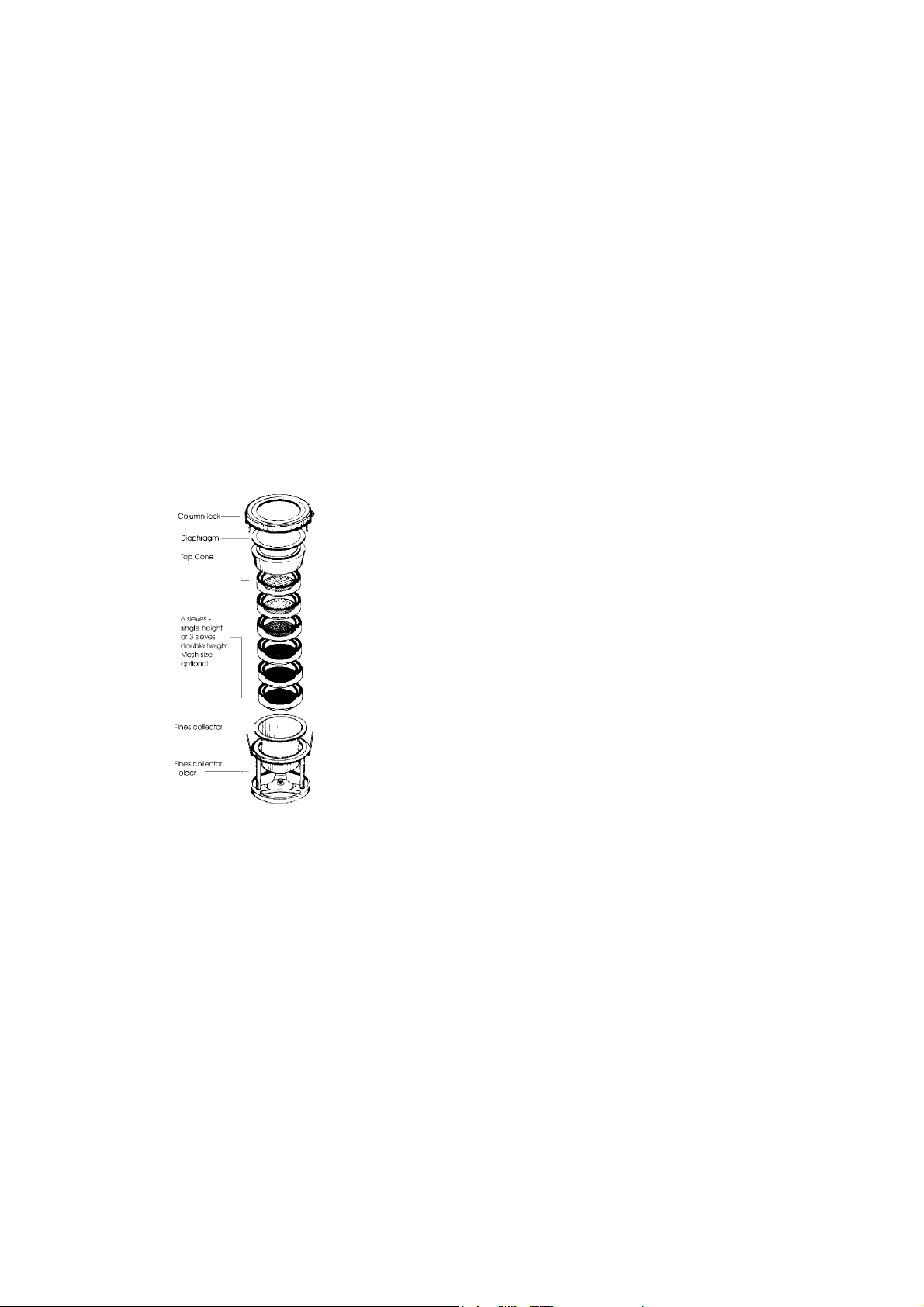

1 off Endecotts Sonic Sifter

1 off Mains Cable

1 off Stack Assembly Comprising:-

1offColumnLock

6 off Spacers, Standard

1 off Fines Collector

1 off Fines Collector Holder

1 off Diaphragm

1 off Top Cone

1 off Instruction Manual

The Sonic Sifter does not need any assembly apart from connecting the mains

cable to the IEC connector at the rear of the instrument. Assembly of the sieve

stack is described in Sieve Stack Assembly.

- 2 -

Setting Up

______________________________________________________

Assembly & Operating Conditions

Operating Conditions

The Sonic Sifter will function correctly at any non-condensing humidity level

within the temperature limits of -18ºCto+49º(OºF to + 120ºF). However, for best

results, it is recommended that the ambient temperature and humidity be

controlled. Sieves should never

be subjected to temperatures above

+49ºC (+ 120ºF) or below

-43ºC (-45ºF). External vibrations

of low amplitude will have little

effect on the accuracy of the

results. To ensure that optimum

results are achieved the instrument

should be placed on a level surface.

This will help ensure an even layer

of particles on each sieve.

- 3 -

Setting Up

_______________________________________________________

Electrical Connections

Ensure that the voltage and frequency on the Rating Label and switchable fused

IEC inlet at the rear of the Sonic Sifter correspond with the local electrical mains

supply. If there is any discrepancy please consult your supplier or a qualified

electrician.

Do Not Connect to any supply other than that stated

on the nameplate

Important – This equipment must be connected to mains earth

The Endecotts Sonic Sifter is provided with a detachable 2 metre long mains cable

with an IEC moulded connector at the shaker end. Certain models may be supplied

with a fused plug. In the event of failure the fuse must be replaced with a fuse of

identical rating.

IF THERE IS ANY DOUBT CONSULT A QUALIFIED ELECTRICIAN

- 4 -

Setting Up

_______________________________________________________

Sieve Stacking

The Sonic Sifter accommodates

upto: 6 Standard Sieves or

1 Precision Sieve

+4Standardsieves

Any combination of Standard and

Precision Sieves can be used in one

stack provided that the stack height

is equivalent to the height of

6 Standard Sieves. When a sieve

stack is smaller in height, the

discrepancy can be made up with

spacers. Extra Spacers may be

purchased separately.

1. Assemble the sieve stack with the coarsest sieve at the top and the finest at the

bottom from the sieves that are selected for the test to be carried out. Generally

any spacers used are placed at the top of the stack.

2. Install the Fines Collector in the Fines Collector Holder.

3. Fasten the round metal plate at the bottom of the Fines Collector to the Fines

Collector Holder. This is done by sliding the keyhole slot in the Fines

Collector over the fastener mounted in the Fines Collector Holder base.

- 5 -

Setting Up

_______________________________________________________

Sieve Stacking

4. Place the sieve stack in the Fines Collector Holder with the Fines

Collector in position.

5. Place the Top Cone on the top sieve or spacer if it is used.

6. Sample material for test is then placed in the top sieve.

7. Position the Diaphragm with the metallic ring downwards on the Top one.

8. Place the Column Lock onto the sieve stack and press own until the latch

bars lock onto the Fines Collector Holder. The sieve stack is ready for

placing in the sift chamber.

9. Disassembling the sieve stack is done by sliding the thumb and forefinger

into the openings between the lowest sieve or spacer and the column

locking arms. While steadying the stack with the other hand, spread the

column locking arms. The spring loaded column lock will release.

Remove the column lock carefully and access can be gained to the rest of

the stacking components.

10. Test times vary with size, density, texture, and quantity of samples. Five

minutes is typical, but sieving time can be as little as 30 seconds under

favorable conditions.

When using woven wire sieves, maximum sample quantities are 10g or

4cc for samples smaller than 38µm, and 20g or 7cc for larger particle

samples. A one gram sample is typical for precision sieving with

electroformed sieves.

- 6 -

Operating instructions

_______________________________________________________

Position of Controls

Operators should be familiar with, and fully understand the controls and indicators

before operating the machine. This should be done in conjunction with the diagram

below:-

ON/OFF

Power Switch

Operating Mode

Indicator

Lights

Tapping Action

Control Programmable

Buttons Control Keypad

LEDDigitalDisplay

Test Phase Diagram & Indicator Lights

- 7 -

Operating Instructions

_______________________________________________________

Settings & Functions

The 16-button keypad used for digital entries of amplitude and times is also used to

activate the following functions:

Run / Stop

The Run/Stop function starts and halts the sieving action. The LED light is on

when the Sonic Sifter is running. The digital display counts down from the total

test time to automatically stop when the counter reaches zero. The program

sequence LEDs indicate which phase is active.

Pause / Resume

The Pause/Resume function interrupts the progress of a sieving sequence. The

Pause LED light is lit when this function is activated. Tim remaining and the

position in the A,B,C sequence are indicated on the display and program LEDs.

Press the Pause button a second time to resume operation.

Program

Amplitude and Phase times are programmed in order by entering each via the

keypad. The Program button is used to advance to the next entry or is used without

entries to review an existing program from the memory.

Memory

The Memory function is used to store and retrieve programmed sequence from 10

memory locations coded from 0 to 9. Buttons to Save and Recall the programmed

sieving sequences are activated when operating in the Memory Mode.

- 8 -

Operating Instructions

_________________________________________

Test Sequences

Establish the maximum amplitude for the test. Set the Sonic Sifter in Manual

Mode, vary the amplitude and determine visually the intensity of oscillation needed

to move the largest particles on the largest size sieve. Note the amplitude value of

this point on the 0-99 scale on the Sonic Sifter’s display.

The stepwise test sequence is illustrated on the Sonic Sifter control panel marked

by red signal lights. In Program Mode the maximum amplitude, as determined

above, is entered via the keypad. Three Phase times and Amplitude are entered in

sequence.

Time A is the duration needed for pulsing to build from zero to maximum

amplitude, During this phase, small particles are gently separated from larger ones

and roughly sorted in the sieve stack. This avoids initial exposure to more severe

agitation which often creates electrostatic attraction of fines to larger particles and

hinder proper separation.

Time B runs constantly at maximum amplitude. Most of the test time occurs in

this phase.

Time C is the duration needed for the pulse amplitude to decline from the

maximum to zero. Each sieve size has an optimum separation amplitude that

decreases with particle size. The gradual decrease at the end of the test serves to

clean up separation of near-sized particles on each sieve.

Note: Total test times (A+B+C) . i.e.9.9 + 99.9 +9.9

up to 119 minutes may be programmed.

- 9 -

Operating Instructions

_________________________________________

Adjusting Pulse Amplitude & Tappers

Load a sample typical of the given type into the sieves to be used with that sample

and place them in the Sonic Sifter.

When the On button is engaged, the unit will be in the Automatic mode. To

determine the proper vibratory level and duration for separating a given sample

type, switch the unit to Manual mode. When the Manual mode indicator light is on,

the amplitude value of pulsing (the power level) must be entered. Generally, start

by setting the value at some low value such as five (5).

To select tappers press arrow keys in the lower left of key pad. The vertical arrow

key activate the vertical tapper located in the bottom plate. The combined

horizontal/vertical arrow key turns on both horizontal and vertical tappers. (Note:

Horizontal tappers cannot be enabled separately).

Press the Run/Stop key. The maximum amplitude indicator light will light, and the

power level can be adjusted upward or downward as indicated by the up and down

arrows on the Record (REC) and Save (SAVE) buttons.

Adjust the amplitude until the sample on the top sieve flows smoothly in a gentle

fluid action. Note the final value on the LED readout for later programming. This

maximum amplitude value should be determined for every sample type, or for

similar sample types with variations in particle topsize.

- 10 -

Operating Instructions

________________________________________

Programming-Saving-Recalling-Running

After you determine the proper amplitude (power level) for sieving a sample, press

the Manual/Auto key and return the unit to automatic operation. The timing is

programmed in 1/10th of a minute intervals. The power level (amplitude) is from 0

to 99% of power.

1) Press the Program key (PGM) until the Time A indicator light starts to blink.

Then enter the duration using the numbered keypad for the power level to rise

from 0 to the maximum power for the run. A minimum default value of 0.1

minutes (6 seconds) is pre-established.

The TIME A, or ramp-up time, is critical with samples containing large

amounts of fines and/or samples of low specific gravity or with tendencies to

acquire electrostatic charge. Gradual power build up allows such particles to

gently separate before the more severe action causes electrostatic charges to

agglomerate the particles. Experimentation may be necessary to determine

whether extended ramp-up times should be used with each sample type.

2) Press the program key until the maximum amplitude light starts blinking, then

enter the percentage of power needed to sift the particles as determined in

Manual mode during Setup Adjustment.

3) Press the Program key again and the TIME B indicator light will start blinking.

Enter the time of the main test duration to be run at a constant maximum

amplitude.

- 11 -

Operating Instructions

_________________________________________

2) Press the Program key again, and the TIME C indicator light will blink. Enter

the desired time for the power to ramp down to 0 value.

3) Press the Program key once more. The total time set for the test (the value of

A+B+C times) will appear.

4) Select tappers as previously advised (see Page 10), these settings will be stored

with the program.

5) If the program is to be stored for future re-execution, press the Save key, and

enter a number from 0 to 9 as the program’s identifying code. Up to ten

programs may be stored in memory for later retrieval by assigned code

number.

6) To operate with a stored program, press the RECALL button, enter the

program’s code number, then press the RUN key.

7) After completing the test, press down on the sieve stack locking bar brace

until the bars latch onto the fines collector holder.

8) Remove the stack assembly and weigh the sieves with the separated material

on them.

9) Subtract the tare weight of the sieve from the loaded sieve weight to obtain the

weight of the separated portion of the test sample.

The following added technique yields an accurate weight without any loss of

test sample from handling and cleaning of the sieves. Weigh the fines on the

tared fines collector, the top diaphragm, the top cone and the spacers. Subtract

the tare of each part of the stack assembly to obtain the total weight of the

fines.

Note: Balance should be accurate to .01 grams

- 12 -

Maintainance

_______________________________________________________

The Endecott’s Sonic Sifter and accessories will perform satisfactorily if the

following basic instructions for care are observed:

Cleaning

The Sonic Sifter cabinet, Sift Chamber and aluminium components may be wiped

clean periodically with a soft damp cloth.

Do not use any solvents for cleaning or harsh detergents

Care of Sieves

1) For best results, sieves should be cleaned in an ultrasonic cleaner of 150 watts

or less. General cleaning is accomplished in a mild detergent. The solution

must be maintained at a temperature of 24ºC to 27ºC (75ºF to 85ºF). If an

ultrasonic cleaner is not available, immerse the items to be cleaned in the same

mild solution. After washing, rinse the parts with water, and allow the parts to

air dry.

2) Precision and Finer (150 microns or less) mesh sieves especially should be

treated carefully as these are very fragile. Please observe the following when

using or cleaning these sieves.

3) Store all sieves in the protective containers supplied after cleaning.

Important

Care of precision and finer sieves

Do not expose the sieves, spacers or top cone to heat sources

Do not brush or use sharp objects to remove particles in the mesh

Do not use compressed air to clean or remove particles in the mesh

- 13 -

Maintainance

_______________________________________________________

Care of Accessories

The Fines Collector and Diaphragm should be cleaned with a mild detergent. Do

not use solvents of any kind as this will cause disintegration and failure of the

Latex parts. After the Fines Collector and Diaphragm have dried, dust lightly with

fine talcum powder and store in a cool, dry place. Avoid heat and direct sunlight

on all the Latex parts.

All spacers and the Top Cone may be cleaned in the ultrasonic bath used for sieves

in the same place as the sieves and accessories. Avoid heat and direct sunlight.

Fuse

Should either of the fuses require replacement they must be of the identical type

and rating as the originals. The rating and the type are marked on the yellow

warning label at the rear of the unit. Switch off the mains supply at the local outlet

and remove the IEC mains connector at the rear. Remove the holder and fuses from

the combined IEC inlet fuseholder with a suitable tool. Test the fuses and replace

any which have blown.

All replacement parts must be ordered by quoting the serial number of the

machine and the correct part number. Part number can be obtained from our

sales or technical department

- 14 -

GENERAL ADVICE

_______________________________________________________

Endecotts shakers are fully tested and factory checked before shipping to

customers. No parts require lubrication or resetting unless disturbed.

The machine has been constructed and factory tested to ensure correct operation

when connected to the specified electricity supply indicated on the machines

rating plate.

Use of unapproved spares or any alteration to the machine would invalidate all

warranties and compliance with European directives for ‘CE’Marking.

Endecotts Ltd does not accept any responsibility if

the operating instructions contained in this manual

are not strictly followed.

The Sonic Sifter is fully EMC and LVD

compliant and complies with all

relevant European directives.

- 15 -

Specification

__________________________________________________________

Model: Sonic Sifter

Voltage: 115 Volts or 230 Volts (selectable)

Frequency: 60 Hz or 50 Hz

Phase: Single

Power Consumption: 90 VA 90 VA

Class: 1 (earthed)

Vibrations Speed: 3,000 per minute at 50 & 60Hz

Tapping: A. No tapping

B. Vertical only. 30/min

C. Vertical and horizontal, alternating 60/min

Process Time: 0 – 119 minutes

Incremental 0.1 minutes (in 6 second increments)

Time Ranges 9.9 + 99.9 + 9.9

Clock: 24 Hour (hours and minutes)

Operating Temp: -18ºC to 49ºC

Humidity: 90 % Non Condensing

Dimensions: 508mm Height x 254mm Width x 254mm Deep

Weight: 16.8 kg

Endecotts policy is one of continuous development and we

reserve the right to modify future models.

- 16 -

Table of contents