ENDEVCO 133 User manual

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

1

®

INSTRUCTION MANUAL

For Model 133

PS/ISOTRON®

SIGNAL CONDITIONER

IM133, Revision H2

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

2

®

TABLE OF CONTENTS

SECTION 1: GENERAL DESCRIPTION PAGE

1.1 INTRODUCTION ........................................................................................................3

1.2 DESCRIPTION ........................................................................................................... 4

1.3 FUNCTIONAL CHARACTERISTICS..........................................................................4

1.4 KEY FEATURES ........................................................................................................ 4

SECTION 2: INSTALLATION, FRONT AND REAR PANEL DESCRIPTION AND OPERATION

2.1 INSTALLATION ..........................................................................................................5

2.2 FRONT PANEL DESCRIPTION .................................................................................6

2.3 REAR PANEL DESCRIPTION ................................................................................... 7

2.4 OPERATION............................................................................................................... 11

2.4.1 Channel Selection.......................................................................................................11

2.4.2 Normal Mode .............................................................................................................. 11

2.4.3 Query/Programming Mode ......................................................................................... 12

2.4.4 Function Selection ...................................................................................................... 12

2.4.5 Special Modes ............................................................................................................ 15

2.4.6 Fault Indication ........................................................................................................... 18

2.4.7 RS-232 Operation.......................................................................................................19

2.4.8 Filter Options and Installation .....................................................................................20

2.4.9 Sample Set Up............................................................................................................21

2.5 RACK MOUNTING KIT............................................................................................... 22

SECTION 3: ROUTINE MAINTENANCE AND HANDLING

3.1 INTRODUCTION ........................................................................................................22

3.2 FACTORY SERVICE..................................................................................................23

3.3 ACCESSORIES..........................................................................................................24

SECTION 4: APPENDIX

1. Model 31875-XXXX-O Filter Data Sheet.................................................................24

2. Serial Communication..............................................................................................25

LIST OF FIGURES

FIGURES

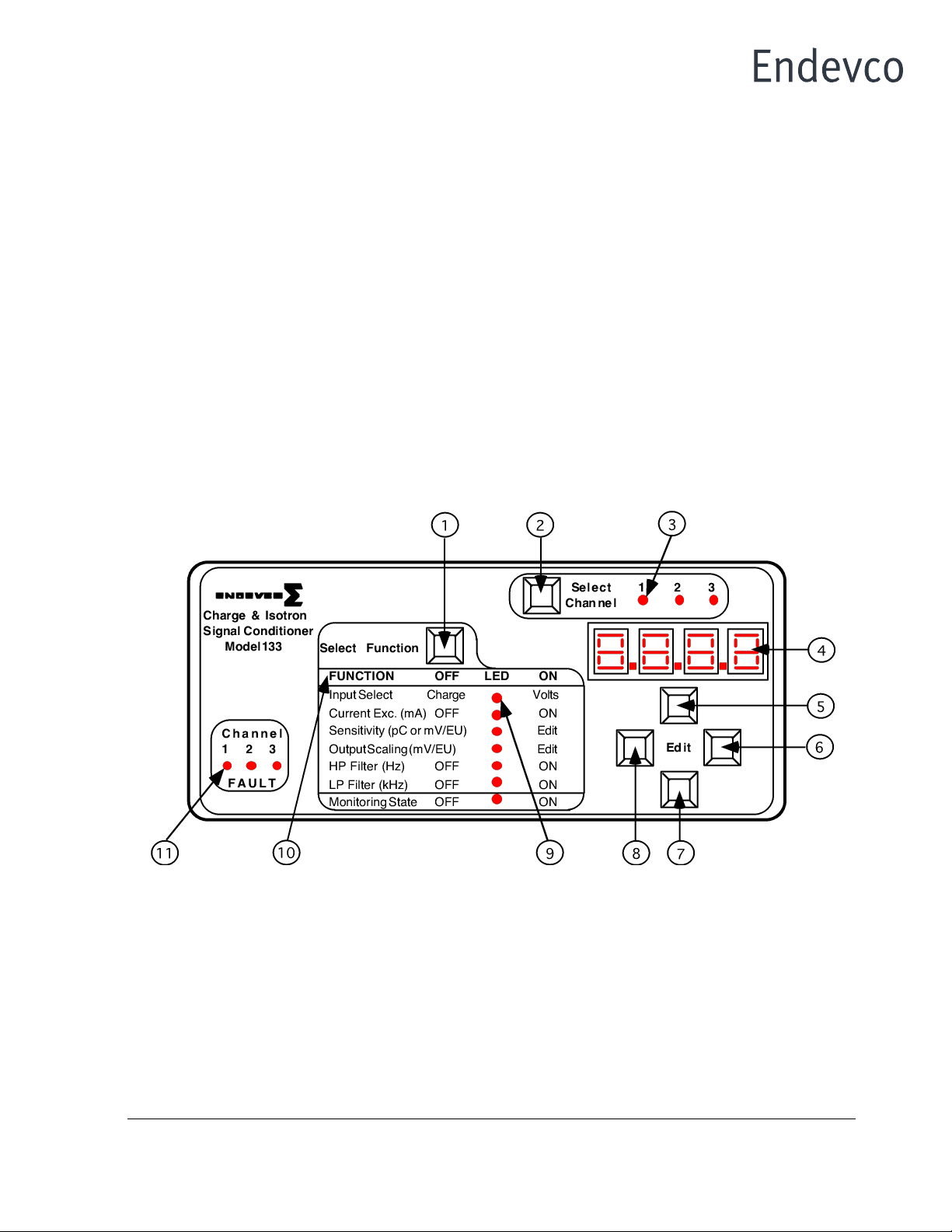

1. Front Panel ................................................................................................................. 7

2. Rear Panel (AC Input power)...................................................................................... 8

3. Rear Panel (DC Input power) ..................................................................................... 8

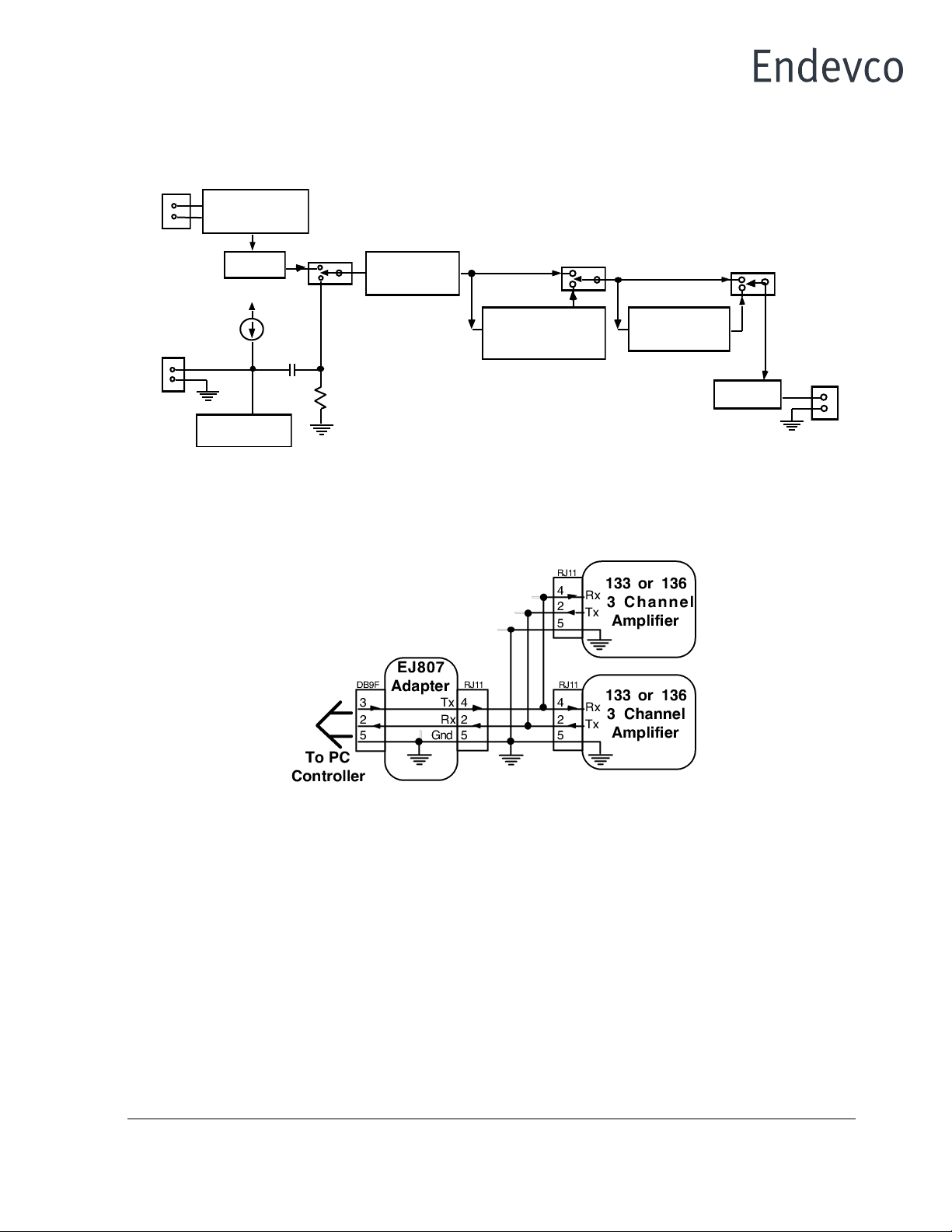

4. Block Diagram, Model 133.......................................................................................... 9

5. RS-232 Serial Communication Block Diagram ...........................................................9

6. RJ-11 Mod Jack, Front view .......................................................................................10

7. Filter Module Location ................................................................................................ 20

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

3

®

SECTION 1: GENERAL DESCRIPTION

1.1 INTRODUCTION

ENDEVCO has remained a leader in the vibration measurement field since 1951, and has

contributed many firsts in vibration sensor design. These include: the first piezoelectric

accelerometer capable of continuous operation from cryogenic temperatures up to +750°F, the

first shear design accelerometer and the world's smallest piezoelectric accelerometer. To support

a broad family of vibration transducers, ENDEVCO has provided a wide variety of signal

conditioners, including the first transistorized charge amplifier, the first computer-programmable

charge amplifier and the first airborne vibration monitoring system that is based on a true digital

tracking filter.

SIGNAL CONDITIONERS

To support the use of its sensors in large scale testing, ENDEVCO has developed several

generations of signal conditioner systems. Until recently, a state-of-the-art vibration laboratory set

up consisted of a rack of manually controlled signal conditioners. These signal conditioners have

manually controlled switches and knobs, to set full scale ranges, sensitivity and filter corners and

the set up information is recorded by hand.

COMPUTER CONTROLLED SIGNAL CONDITIONERS

To eliminate the risk of incorrect amplifier settings, ENDEVCO has pioneered the concept of

computer controlled signal conditioners. The first generation was the Multi-channel Amplifier

Control system (MAC). The second generation was the Computer Controlled Amplifier Systems

(CCAS). The CCAS family consists of five different systems that use the same rack and digital

interface assemblies with different analog boards. These units receive their setup commands over

an IEEE-488 interface bus from a computer/controller, so that tests can be pre-programmed. In

addition, these units provide comprehensive self-test and self-calibration capabilities, which greatly

improves the reliability of the test data. User feedback is indicated that these units pay for

themselves quickly by shortening test cycles, preventing retests and eliminating over-testing.

MANUAL/COMPUTER CONTROLLED SIGNAL CONDITIONERS

The experience gained in the first two generations of computer controlled amplifiers has now been

applied to a third generation product line: the programmable bridge conditioner and the

programmable laboratory signal conditioner. These units are independently controlled and each

unit contains its own power supplies for single channel integrity.

The Model 133, has both manual and computer programmable features. This PE/ISOTRON®

Signal Conditioner is an example of Endevco's commitment to improving the state-of-the-art in

sensory measurements. The new generation is smaller with more features and will continue to be

expanded to meet an ever widening range of application requirements.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

4

®

1.2 DESCRIPTION

The ENDEVCO®Model 133 ISOTRON/Charge Amplifier is a three-channel signal conditioner

designed for use with piezoelectric accelerometers, ISOTRON® (voltage type) accelerometers,

and remote charge converters. The unit provides an AC output voltage proportional to the charge

or AC voltage input, and it is designed to be powered by 90-240 VAC (9-18 VDC option also

available).

The Endevco Model 133 Signal Conditioner has a fixed 10 Hz 4-pole Butterworth high-pass filter

that can be selected or bypassed. It has a plug-in 4-pole low pass filter whose corner can be set

by an internal header module, which offers optional filter types and multiple corner frequencies.

{See Section 2.4.8 Filter Options and Installation and Appendix 1, (Endevco Model 31875-XXXX-

Y)}. Filter options are available to meet the filter corner requirements for J211 and ISO6487. The

specific filter corners available are: 300 Hz and 1,650 Hz (see Section 2.4.8 Filter Options and

Appendix 1.)

Up to three (3) Model 133 units can be installed in a 19” rack using ENDEVCO Model 31979 Rack

Mounting Kit.

Figure 4 shows a detailed circuit block diagram for the unit.

1.3 FUNCTIONAL CHARACTERISTICS

The Endevco Model 133 can be manually programmed from the front panel (Figure 1) by means

of a “Select Channel” push-button, three (3) “Channel LEDs”, a “Select Function” push-button,

seven (7) “Function LEDs” indicating which function has been selected by the “Select Function”

push-button (referred to in this document as the “function LEDs”), a four (4) character LED display

to show the state of each function, four (4) “EDIT” push-buttons to change the entries in the LED

display, and three (3) LEDs indicating if there are any faults in any of the channels (referred to in

this document as the “Fault LEDs”).

The unit has two modes of operation: (1) Normal and (2) Query/Programming. In the Normal mode

of operation, the unit can be in (a) Monitoring State, or (b) No-Monitoring State. While in the Normal

mode of operation, the selected state will apply to all three channels simultaneously.

The unit will store the settings for all of the function in its internal memory and at power-up it will

automatically restore the settings from the last session.

1.4 KEY FEATURES

The following are some of the highlight features:

• Three-channel piezoelectric/ISOTRON signal conditioner

• 200 kHz Bandwidth (-3dB corner)

• 10 Volt Full Scale Output

• Built-in 10 Hz 4-pole Butterworth High Pass Filter

• Fault indicator for open/short at the ISOTRON input

• Gain range from 0 to 1000

• RS-232 Serial Interface

• Optional Low Pass filter corners available (Butterworth - the standard default filter is a 10

kHz Butterworth)

• Meets filter requirements of J211 and ISO6487.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

5

®

SECTION 2:

INSTALLATION, FRONT AND REAR PANEL DESCRIPTION AND OPERATION

2.1 INSTALLATION

2.1.1 UNPACKING

The Endevco Model 133 PE/ISOTRON signal conditioner is shipped along with its instruction

manual in one package. Carefully unpack and check all items for shipping damage. Report

any obvious damage to the carrier immediately. If the shipping container or cushioning

material is damaged, it should be kept until the contents of the shipment have been checked

mechanically and electrically. In any case, save the original packing materials for future

shipments of the hardware. Check each item of the shipment against the packing list. Notify

Endevco of any discrepancy.

The equipment has been inspected and tested at the factory and is ready for operation when

received.

Unpack the Model 133 and set it on a level, firmly supported surface. Verify that all standard

and ordered optional accessories are included.

2.1.2 FILTER MODULE INSTALLATION OR REPLACEMENT

For filter module installation or replacement, see Section 2.4.8 of this manual.

2.1.3 POWERING ON THE UNIT

For AC input power, install the EW599 power cord into the rear power connection of the Model

133. (See Figure 2, Rear Panel, AC input power.)

For optional DC input power (Model 133-1), install the +9-18 VDC input power source into the

DC input power connector, located on the rear of the Model 133-1. (See Figure 3, Rear Panel,

DC input power.)

2.1.4 KEY PARAMETERS

The standard unit has an AC input voltage requirement from 90 to 264 VAC, 50 to 60 Hz

(Universal Input). No jumpers or changes to the unit's power supply is required for input power

meeting this requirement.

The "-1" option is a DC powered version that accepts an input voltage range from +9 to 18

VDC.

Power dissipation for either the standard or -1 version is 9 Watts typical.

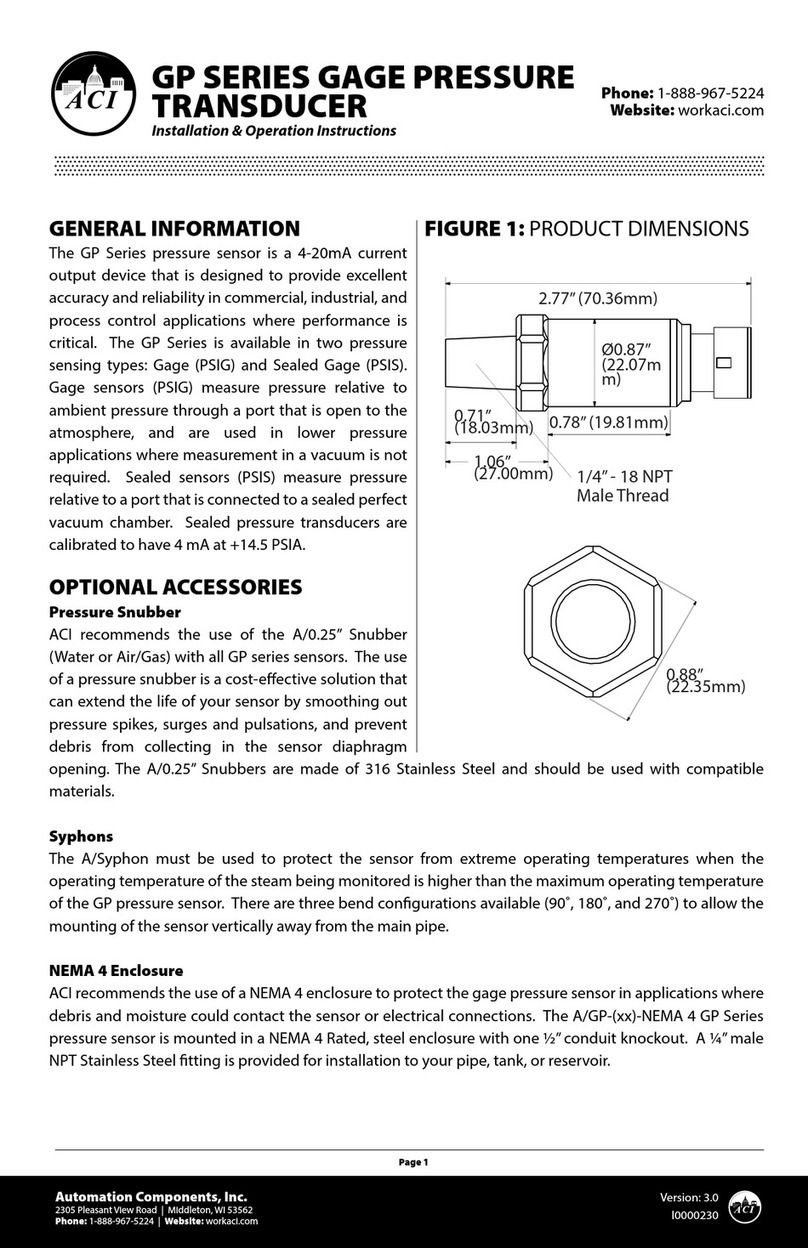

2.1.4.1 Physical Characteristics

Dimensions 5.57" x 2.52" x 12"

Weight 4 lbs typical

Case Material Black Aluminum Cover, Medium Gray Plastic Bezel

Current 1 Amp maximum

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

6

®

2.2 FRONT PANEL DESCRIPTION

Shown in Figure 1 is the Model 133 front panel. The front panel is a mylar overlay, adhesively

attached to the front panel aluminum plate. The mylar overlay has cutouts for the six push

buttons, and clear windows for 13 LED's and the 4-digit panel meter. Each push button and

LED are described as follows:

Figure 1 Item 1, is the "Select Function" push button that controls the functions listed below it.

Pressing the Select Function push button scrolls through the LED's. The function selected

can be modified while the LED is flashing, located to the right of the associated function.

Figure 1 Item 2, is the "Select Channel" push button. Pressing this push button sequentially

selects channels one to three, which is used for set up and display of data on the digital panel

meter. The appropriate channel's LED remains illuminated until a different channel is selected.

Figure 1 Item 3, is the LED for channel one of the three channel unit. The LED illuminated

corresponds to the channel that is actively being set up or data displayed on the DPM.

Figure 1 Item 4, is the digital panel meter (DPM). The DPM displays alpha-numerics for the

appropriate "Select Channel" selected and is used to display the channel set up and for actual

data display. The DPM has an accuracy of ±10%. (See Section 2.4, Operation and sub-

sections contained, for specific push button abilities.)

Figure 1

Figure 1 Items 5, 6, 7, and 8 correspond, respectively to the "Up", "Right", "Down" and "Left"

Edit push buttons. These push buttons are used to change the entries on the digital panel

meter and are used in conjunction with the appropriate "Select Function" parameter to be

programmed. (See Section 2.4, Operation and sub-sections contained, for specific push

button abilities.)

Figure 1 Item 9, is one of seven Function parameters LED's that is selectable/programmable.

The flashing LED identifies the function that is actively capable of being set up or modified at

that time.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

7

®

Figure 1 Item 10, is a list of "Functions" that are programmable for each channel, which are

selected by the "Select Function" push button and are set up or modified with the four "Edit"

push buttons.

Figure 1 Item 11, are the "Fault" LED's. The illuminated LED indicates that particular channel

is in the ISOTRON mode, the current excitation is on and there exists a short or open circuit

for the input.

2.3 REAR PANEL DESCRIPTION

Shown in Figure 2 is the rear view of the Model 133.

Figure 2 Item 1, is the standard AC input power connector. The supplied Endevco power cable,

PN EW599, is connected to this connector. (Note: The acceptable input power is 90 to 264 VAC,

50/60 Hz. No jumpers or adjustment is required for input voltages within this range. There is no

on/off power switch for the unit. )

Figure 2 Item 2, is the Single-Ended Piezoelectric (SEPE) input connector. This is a standard 10-

32 connector, mating to Endevco's 3090 and 3060 series cables.

Figure 2 Item 3, is a blocked-off area for a single channel, depicted is channel 3. The channels

correspond to the front panel channels 1, 2, and 3.

Figure 2 Item 4, is a standard BNC cable connection that is used to connect the input of ISOTRON

or voltage type accelerometers. (10-32 connector style input cables can easily be used with the

Endevco EJ21, a 10-32 to BNC adapter. The EJ21 mounts directly onto the BNC connector.)

Figure 2 Item 5, is a standard BNC connector used for the output from each channel.

Figure 2 Item 6, is the RJ-11 Modular Jack, Front View. (Please see Figures 5, 6 and Section

2.4.7. for the RS-232 information.)

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

8

®

Figure 2

Figure 3 is the optional Model 133-1 Rear panel view. Item 1, is the DC input power connector.

The input power requirements are: 9 to 18 volts DC and a maximum current of 1 amp. The input

connector is a 760 Plug style.

Figure 3

RS-232

Isotron INOUTPUT

I N

Charge

CHANNEL 3

Isotron INOUTPUT

IN

Charge

CHANNEL 2

Isotron INOUTPUT

I N

Charge

CHANNEL 1

9-18 VDC

Charge &Isotron Signal Conditioner

1

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

9

®

Figure 4

Figure 4 is the Model 133 block diagram.

Figure 5

Figure 5 is the block diagram for the RJ-11 RS-232 computer control connector.

0, 4, or

10 mA

24 VDC

Charge Converter

(0.303 mV/pC)

10-32 Connector

BNC

Programmable

Gain: 0 to 100

Fault Detector

10 Hz 4-pole

High-Pass Filter

4-pole Butterworth

Low-Pass Filter

BNC

Gain = 3

Gain: 1, 10

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

10

®

Figure 6

Figure 6 is the RJ-11, Modular Jack, Front View RS-232

Pin 1: Analog Ground

Pin 2: TX (connects to RX in computer)

Pin 3: Not Used

Pin 4: RX (connects to TX in computer)

Pin 5: Digital Ground

Pin 6: Digital Ground

R X

Digital Ground

Digital Ground

1 2 3 4 5 6

Not Used

TX

Analog Ground

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

11

®

2.4 OPERATION

The Endevco Model 133 can be manually programmed from the front panel (See Figure 1) by

means of a “Select Channel” push-button, three (3) “Channel LEDs”, a “Select Function” push-

button, seven (7) “Function LEDs” indicating which function has been selected by the “Select

Function” push-button (referred in this document as the “function LED's”), a four (4) character LED

display to show the state of each function, four (4) “EDIT” push-buttons to change the entries in

the LED display, and three (3) LEDs indicating if there are any faults in any of the channels

(referred in this document as the “Fault LED's”).

The unit has two modes of operation: (1) Normal and (2) Query/Programming. In the Normal mode

of operation, the unit can be in (a) Monitoring State, or (b) No-Monitoring State. While in the Normal

mode of operation, the selected state will apply to all three channels simultaneously.

The unit will store the settings for all of the function in its internal memory and at power-up it will

automatically restore the settings from the last session.

2.4.1 Channel Selection

The user selects which channel is being programmed by pressing the “Select Channel” push-

button. Each press of the “Select Channel” push-button will sequentially turn-on one of the 3

“Channel LED's” located to the right of the “Select Channel” push-button indicating the channel

number selected for programming.

The unit will remain in the selected mode/state of operation (normal or query/programming) while

pressing the “Select Channel” push-button.

2.4.2 Normal Mode

1. Monitoring State

In the Monitoring state of operation the unit takes an RMS reading of the signal present at the

output of the selected channel every 500 mSec and displays the value on the LED display in

Engineering Units (EU: the physical variable in RMS being measured by the transducer) or V out

in RMS. This state is activated by selecting either the "EU" or “V out” entry in the "Monitor" Function

selection.

Pressing the “Select Channel” push-button while in the Monitoring state allows the user to quickly

view (sequentially) the signal levels at the output of each channel.

2. No-Monitoring State

The No-Monitoring state allows for low noise operation. This is accomplished by not taking A/D

readings from the outputs, and by placing the CPU in idle mode in order to minimize power

consumption and digital noise in the unit. The LED display will be turned OFF. This state is

activated by selecting the "OFF" entry in the "Monitor" Function selection.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

12

®

2.4.3 Query/Programming Mode

The Query/Programming Mode allows for manual programmability and querying of the

programmable functions. This Mode is activated by pressing the “Select Function” push-button.

A function is queried by selecting it using the “Select Function” push-button. The current setting for

the selected function will be displayed on the LED display. The entry in the LED display is edited by

using the four EDIT push-buttons (located just below the LED display.)

The new setting will be implemented into the unit hardware as soon as the entry shown on the LED

display is modified. The unit returns to the Normal mode of operation after 20 seconds of inactivity

(no push-buttons pressed) or after pressing the “Select Function” push-button while the “Monitoring

State” function LED is flashing.

2.4.4 Function Selection

The user selects which function is being programmed by pressing the “Select Function” push-button.

Each press of the “Select Function” push-button will sequentially make one of the “Function LEDs”

blink indicating that the function is selected for programming.

The first press of the “Select Function” push-button selects the function LED that was selected the

last time that the unit was in Query/Programming Mode. The selected Function LED will be blinking

and the current setting will be displayed on the LED display. Each additional press of the “Select

Function” push-button selects the next function (corresponding Function LED blinking) and the

corresponding setting is displayed on the LED display. Pressing the “Select Function” push-button

while the “Monitoring State” function LED is flashing puts the unit immediately back into Normal

mode.

The following functions can be selected for programming: (1) Input Select, (2) ISOTRON Current

Excitation, (3) Sensor Sensitivity, (4) Output Scaling, (5) High pass Filter, (6) Low pass Filter, and

(7) Monitoring State.

When the function is selected, the corresponding “Function LED” will stay blinking until the “Select

Function” push-button is pressed again to select the next function. The LED display will show the

current setting for the selected function. The EDIT push-buttons can then be used to change the

setting. If no buttons are pressed after 20 seconds, then the “Function LED” will stop blinking and

the unit will return to the normal mode of operation (monitoring or non-monitoring state).

Each “Function LED” will remain OFF or ON during the normal mode of operation (and also

immediately after selecting the next function) depending on the setting selected by the user for the

corresponding function.

The user can select a function, and then use the “Select Channel” push-button to view/edit the current

setting for the selected function for each channel.

1. Input Select

This function is used for selecting the type of input to be enabled. The up-down EDIT push buttons

are used to select the input type. The following messages will be shown sequentially on the LED

display each time the up-down EDIT push buttons are pressed: (1) “Chrg”, and (2) “Volt”.

1. "Chrg": Piezoelectric (PE) input is enabled.

2. "Volt": ISOTRON input is enabled.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

13

®

The “Function LED” corresponding to the Input Select function will remain OFF or ON during the

normal mode of operation if the user selected the “Chrg” or “Volt” setting respectively.

2. Current Excitation

This function is used for setting the excitation current connected at the ISOTRON (Voltage) input.

This setting is applied to all three (3) channels simultaneously (each channel can not have

its own setting). The up-down EDIT push buttons are used to select the excitation current level

in mA. The following messages will be shown sequentially on the LED display each time the up-

down EDIT push buttons are pressed: (1) “0.0”, (2) “4.0” and (2) “10.0”.

1. "0.0": Excitation current disabled.

2. "4.0": Excitation current set to 4.0 mA.

3. "10.0": Excitation current set to 10.0 mA.

The “Function LED” corresponding to the Current Excitation function will remain OFF during the

normal mode of operation if the user selected the “0.0” setting (excitation current disabled). The

function LED will remain ON if the excitation current was enabled by selecting any of the other

settings listed in the table above.

3. Sensor Sensitivity

This function selection provides for programming the sensitivity of the transducer (in mV/EU for

Voltage input, or pC/EU for Charge input). The Endevco Model 133 uses this information to

determine the gain needed to achieve the required output scaling. The left-right EDIT push buttons

select the number position in the LED display, and the up-down EDIT push buttons increment or

decrement the selected number.

The user can enter four significant digits ranging from 0.001 to 9999.

4. Output Scaling

This function selection provides for programming the desired scaling of the amplifier’s output (in

mV/EU). The left-right EDIT push-buttons select the number position in the LED display, and the

up-down EDIT push-buttons increment or decrement the selected number. The Endevco Model

133 determines the gain needed to achieve the required output scaling by using the following

equation:

Amplifier’s Gain = Output Scaling / Sensor Sensitivity

The gain of the amplifier will be set to within the resolution specified in the Performance

Specification. The entry in Output Scaling depends on the Sensor Sensitivity setting and it will

automatically change to the lowest or highest limit if the current entry violates the following

constraint:

0 <Output Scaling / Sensor Sensitivity < 1000

The user can enter four significant digits ranging from 0.001 to 9999 limited by the above constraint.

The “Function LED” corresponding to the Output Scaling function will be set to OFF when the unit

returns to the normal mode of operation.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

14

®

5. High Pass Filter

This function selection provides for enabling or disabling the built-in 10 Hz 4-pole Butterworth High-

Pass filter. The following messages will be shown sequentially on the LED display each time the up-

down EDIT push buttons are pressed: (1) “OFF”, and (2) “10.0”.

1. "OFF": High-pass filter disabled.

2. "10.0": 10 Hz high-pass filter enabled.

The “Function LED” corresponding to the High-Pass Filter function will remain OFF during the normal

mode of operation if the user selected the “OFF” setting (filter disabled). The function LED will remain

ON if the high-pass filter was enabled by selecting the “10.0” setting.

6. Low Pass Filter

This function selection provides for enabling or disabling the built-in 4-pole Butterworth Low-Pass

filter (set by header module 31875). The following messages will be shown sequentially on the LED

display each time the up-down EDIT push buttons are pressed: (1) “OFF”, and (2) “XX.XX”.

1. "OFF": Low-pass filter disabled.

2. "XX.XX”: Low-pass filter enabled. XX.XX represents the corner frequency in kHz.

The “Function LED” corresponding to the Low-Pass Filter function will remain OFF during the normal

mode of operation if the user selected the “OFF” setting (filter disabled). The function LED will remain

ON if the low-pass filter was enabled by selecting the “XX.XX” setting. XX.XX could be a value from

0.01 (10 Hz) to 80.00 (80 kHz). The unit displays the actual corner frequency in each channel by

reading an ID Voltage (VID) set by the header module that sets the -3dB corner frequency of the

low-pass filter. VID ranges from 0 to 2 VDC. The unit uses the table shown in section 10.0 to convert

the ID Voltage into the corner frequency (in Hz).

7. Monitoring State

This function selection provides for programming the desired state of the amplifier while in the normal

mode of operation. The following messages will be shown sequentially on the LED display each time

the up-down EDIT push buttons are pressed: (1) “EU”, (2) “V out” and (3) “OFF”.

1. "EU": RMS voltage at V out is monitored and shown on the LED display in EU at the rate of

approximately two (2) times per second. The values displayed on the LED display range

from 0.000 to 9999. The value shown on the LED display is computed as follows:

Display (EU) = VRMS at Output / Output Scaling

2. "V out": RMS voltage at V out is monitored and shown on the LED display in VRMS at the

rate of approximately two (2) times per second. The values displayed on the LED display

range from 0.00 to 9.99. The value shown on the LED display is computed as follows:

Display (VRMS) = VRMS at Output

3. "OFF": The LED display will be turned OFF. This setting provides the lowest noise

performance.

The “Function LED” corresponding to the Monitor function will remain OFF during the normal mode

of operation if the user selected the “OFF” setting. The function LED will remain ON if monitoring

was enabled by selecting any of the other settings listed in the table above.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

15

®

2.4.5 Special Modes

The special modes are not frequently used and they may be selected by pressing the “Select

Function” push button while simultaneously pressing a combination of multiple EDIT push buttons.

The unit must be in the normal mode of operation to enter any of the special modes of operation.

The table below shows the combination of the EDIT push buttons that need to be pressed to obtain

the desired special mode.

Mode

EDIT push-buttons

1. Addressing

RIGHT

2. Error List

LEFT

3. Reset

UP

4. Store Setup in EEPROM

DOWN

5. Test Display

UP & LEFT

6. Recall Default Setup

DOWN & RIGHT

7. Calibration

LEFT & RIGHT

8. Troubleshooting

UP & DOWN

9. Not Assigned

UP & RIGHT

10. Not Assigned

DOWN & LEFT

1. Addressing

This special mode selection provides for programming the address of the unit used for computer

control through the RS-232 serial communication. The unit’s address applies to all 3 channels

(same address regardless of the channel selection).

The unit determines its address at power up by using the following algorithm:

1) VID: Address determined by ID voltage set in hardware

2) MEM: Address stored in non-volatile memory

3) READ VID

4) IF VID = 0 THEN Address = MEM

5) IF VID > 0 THEN Address = VID = MEM

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the RIGHT EDIT push button. The unit returns to the normal mode of operation

(Monitoring or Non-monitoring state) after pressing the “Select Function” push button one more

time.

When this special mode is selected the first "Function LED" will be blinking and the serial

communication baud rate for the unit will be shown on the LED display. The baud rate can be

modified by using the EDIT buttons. An additional Press of the "Select Function" button will make

the second "Function LED" blink and the address of the unit will be shown on the LED display.

The address can be modified by using the EDIT buttons only if VID = 0. The new address will be

set and stored into the internal non-volatile memory when the unit returns to the normal mode of

operation.

2. Error List

This special mode selection allows the user to retrieve a listing of all of the errors that may be

causing the failure LED to be ON.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

16

®

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the LEFT EDIT push button. The unit returns to the normal mode of operation (Monitoring

or Non-monitoring state) after pressing the “Select Function” push buttons one more time.

After the mode is selected, all of the “Function LEDs” will be off and the first error code will be

shown on the LED display. The user may scroll through the list by using the UP and DOWN EDIT

push buttons.

3. Reset

This special mode selection allows the user to reset the unit (equivalent to a power-up initialization).

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the UP EDIT push button. The unit returns to the normal mode of operation (Monitoring

or Non-monitoring state) immediately after initialization.

4. Store Setup in EEPROM

This special mode selection allows the user to force the unit to store all of the function settings into

non-volatile memory.

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the DOWN EDIT push button. The unit returns to the normal mode of operation

(Monitoring or Non-monitoring state) immediately after writing all of the function settings into non-

volatile memory.

5. Test Display

This special mode selection allows the user to test the display board by displaying a different

pattern on the LED indicators and the LED display every time any one of the front panel push

buttons is pressed.

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the UP and LEFT EDIT push buttons. The unit returns to the normal mode of operation

(Monitoring or Non-monitoring state) after pressing the “Select Function” push button one more

time.

6. Recall Default Setup

This special mode selection allows the user to recall the default function settings.

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the DOWN and RIGHT EDIT push buttons. The unit returns to the normal mode of

operation (Monitoring or Non-monitoring state) immediately after restoring all of the default function

settings.

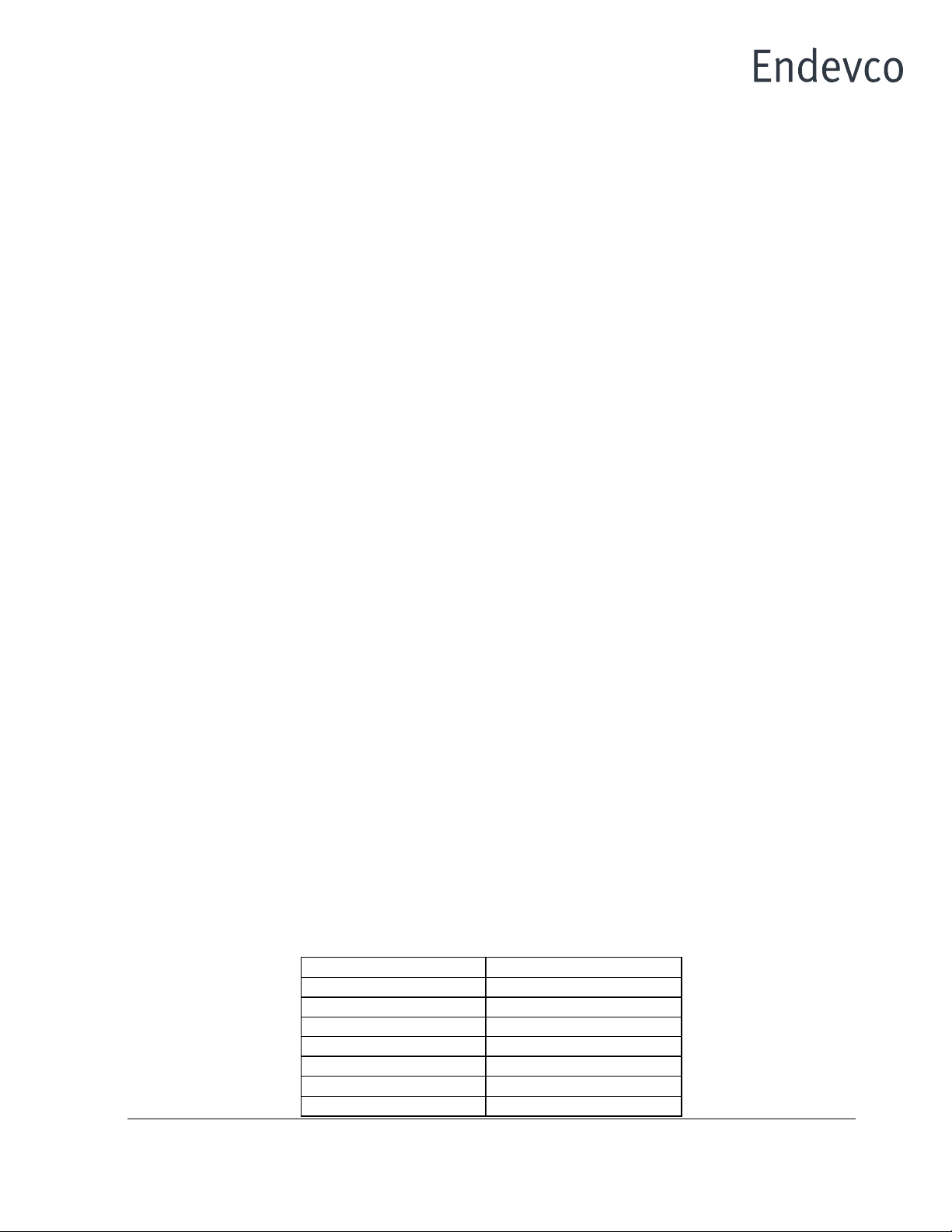

Function

Factory Default Setting

1. Input Select

Volt (ISOTRON)

2. Current Exc. (mA)

0.0 (off)

3. Sensitivity

1.000

4. Output Scaling

1.000

5. HP Filter

10.0 (on)

6. LP Filter

XX.XX (on)

7. Monitoring State

V out

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

17

®

7. Calibration

This special mode selection allows the user to manually calibrate the unit.

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the LEFT and RIGHT EDIT push buttons. When this special mode is selected the first

“Function LED” will be blinking and the first calibration constant for the selected channel will be shown

on the LED display. The settings of all of the functions will be saved in non-volatile memory when

entering this mode.

The user selects which calibration constant is being set by subsequently pressing the “Select

Function” push button. Each press of the “Select Function” push button will sequentially make one

of the “Function LEDs” blink indicating that the calibration constant is selected for programming and

the corresponding calibration constant will be shown on the LED display.

Pressing the “Select Function” push-button while the “Monitoring State” function LED is flashing

places the unit back into Normal mode. The calibration constants will be stored into the internal non-

volatile memory when the unit returns to the normal mode of operation. The settings for all of the

functions will be restored using the new calibration constants when the unit returns to the normal

mode of operation.

A checksum for the calibration constants is also stored in non-volatile memory. The unit will use this

checksum at power up to verify that all calibration constants are good. The unit will declare an error

if the checksum test for the calibration constants fails.

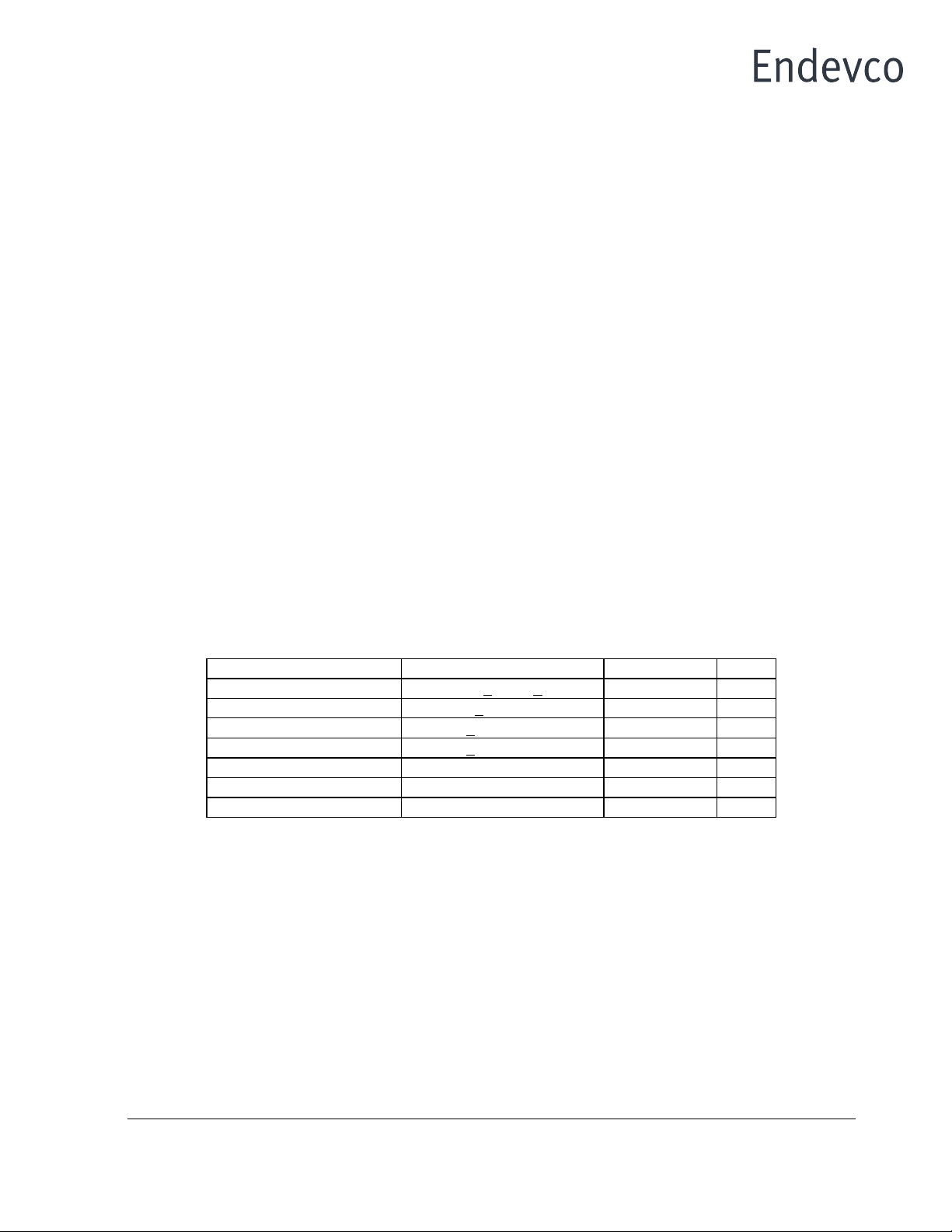

A cross-reference table between the calibration constants and the “Function LEDs” is shown below

(the input select and gain settings for each calibration constant is also shown).

Function LED

Calibration Constant

Input Select

Gain

1. Input Select

k1 for 100 < Gain < 1000

Volt

200

2. Current Exc. (mA)

k2 for 10 < Gain < 100

Volt

20

3. Sensitivity

k3 for 0 < Gain < 10

Volt

2

4. Output Scaling

k4 for 0 < Gain < 10

Chrg

2

5. HP Filter

k7 for 0 < Gain < 10

Chrg

2

6. LP Filter

k5 to calib. slope of A/D

Chrg

2 & 1

7. Monitoring State

k6 to calib. offset of A/D

Chrg

2

a) Gain Calibration

Calibration constants k1 through k4 and k7 are used to calibrate the gain of the unit. This is

accomplished by applying a 300 Hz calibration signal into the ISOTRON input for k1, k2, and k3,

or into the Charge input for k4, and adjusting the calibration constant displayed on the LED display

until the desired output (input signal multiplied by gain) is obtained. The amplitude of the input

signal should be set to 30.0 mVRMS for k1, 0.300 VRMS for k2, 3.00 VRMS for k3, 3000 pC-RMS

for k4 and k7 (3.0 VRMS into a 1000 pF series capacitor).

b) A/D Calibration

Calibration constants k5 and k6 are used to calibrate the Analog to Digital converter of the unit.

The following procedure must be followed to accomplish this calibration:

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

18

®

1. Select Function LED # 6 (LP Filter) and apply an approximately 3 Vrms at 300 Hz

calibration signal into the Charge and adjust the calibration signal amplitude input

so that the output signal is set to 6.0 VRMS.

2. Press the LEFT or RIGHT edit push-buttons. The unit will display the raw

(uncalibrated) voltage read by the A/D for about 3 seconds (a number between 5

and 7). Then, waiting for about 5 seconds, the unit will change the gain to 1, and

will display the calibration constant for the slope of the A/D.

3. Select Function LED # 7 (Monitoring State). The unit will display the calibration

constant for the offset of the A/D.

8. Trouble Shooting Mode

This special mode selection allows the user to control any digital I/O port for troubleshooting

purposes.

This special mode is selected by pressing the “Select Function” push button while simultaneously

pressing the UP and DOWN EDIT push buttons. Pressing the “Select Function” push-button while

the “Monitoring State” function LED is flashing places the unit back into Normal mode.

2.4.6 Fault Indication

There are three (3) fault indicators (red LEDs) for each channel located on the front panel. The

fault indicator will turn on if the ISOTRON input is either open or short circuited, while the input

select function for the corresponding channel is set to ISOTRON, and the Current Exc. is turned

on (4 or 10 mA).

2.4.7 RS-232 Serial Communication

The unit has a standard RS-232 serial interface available through an RJ-11 connector located on

the rear panel (see Figures 3, 5 and 6).

In the accessories section of this manual lists all options available options for serial communication.

The Serial Communication Kit contains the necessary items to control up to three units. Should

additional units be added for serial communication additional cables and RJ-11 adapters would be

required.

Figure 5 shows how to connect a computer to control up to 16 Model 133 amplifiers. The following

functions can be executed through the serial interface from a controller:

1. Identification of the unit: Model Number (133, 136, etc.), firmware revision, address.

2. Send settings for all of the 7 functions programmable through the front panel.

3. Query settings for all of the 7 functions programmable through the front panel.

4. Send calibration constants. The new calibration constant will take effect immediately

and it will be stored into non-volatile memory.

5. Query calibration constants.

6. Query raw and calibrated output RMS data from A/D.

7. Query corner frequency of installed low pass filter.

8. Query error list.

9. Reset the unit.

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

19

®

2.4.8 Filter Options and Installation

1. Introduction

The ENDEVCO Model 31875 plug in, Low Pass Filter Modules are optional Butterworth filters

designed for use with the Endevco Model 133, PE and ISOTRON Signal Conditioner and Model

136, DC Amplifier. The filters are low-cost designs with sufficient corner frequencies to

accommodate most test requirements.

The self-identifying feature allows quick verification of the filter installed in a particular channel for

the model 133 or model 136. Each channel will display the filter corner frequency on the LED

digital panel meter. Only the filter corner frequency is displayed. The filter type (Butterworth) can

only be visually verified by removing the outer cover.

There are 20 corner frequencies available, ranging from 10 Hz to 80 kHz in 1, 2, 4, 6, and 8 steps

for each of the three filter types. The 31875 must be specified in the following manner: 31875-

XXXX-Y. The "XXXX" is the -3 dB corner frequency, determined by multiplying XXXX by 10. If

the "XXXX" is left blank, the standard 10 kHz filter is supplied (-1000). The Y indicates the filter

type desired, -0 for the Butterworth if the "Y" is left blank the standard Butterworth filter is supplied.

The filter options of 400 Hz and 2,000 Hz are not valid. The 400 Hz option has been replaced by

300 Hz. The 2,000 Hz option has been replaced by 1,650 Hz. These two lower frequency options

are specifically made to comply with the filter corner requirements of J211 and ISO6487.

If no filter is specified at time of order entry, the standard default filter installed is a 10 kHz low pass

Butterworth.

See Appendix 1 for the Model 31875 Low Pass filter data sheet and corner frequency selections.

2. Filter Change/Replacement

Place the model 133 on a level, firmly supported surface. Remove the two front panel screws.

Leave the front panel connector connected to the main board. Carefully slide the black cover from

the unit.

Reference Figure 7 for the location of the three filter modules. Carefully pry off the metal grounding

shield and locate the existing filter module(s) and gently pry it off (as you would an IC in a socket)

and store it for future use.

Observing the correct orientation of the new filter module(s), install it in the correct channel location

desired. Reinstall the grounding shield.

Ensure the front panel connector is firmly connected and re-assemble the cover and front panel.

CAUTION: Ensure that the two front panel mounting screws are not over tightened or cross

threaded. The aluminum rail screws mount into soft metal that can easily be

damaged. Should the rail become damaged, simply locate a replacement screw

of a 1/2 inch longer length and install into the damaged rail. (The screws are 4-

40, stainless steel, self-tapping.)

ENDEVCO www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM133, Page

20

®

2.4.9 Sample Set Up

The following information is intended for the first time or infrequent user of this amplifier.

A. Using figure 1 as a reference, perform the following initial setups:

1. Using the "Select Channel" button, select channel 1. (The LED illuminated is the channel

that is being monitored by the DPM.)

2. Using the "Select Function" button, select the appropriate sensor type. While the LED is

flashing for the Input Select function, press the "Edit" button directly above or below the word "Edit"

on the front panel. This will cause the DPM to display either "Chrg" or "Volt". Once the appropriate

sensor type is selected, press the "Select Function" button to save that configuration of input and the

"Select Function" LED will automatically advance to the next function. (Assume a PE accelerometer

is used with a sensitivity of 10.04 pC/g.)

3. With the "Current Exc. (mA)" LED flashing, use the button directly above or below the

word "Edit" to select either 0, 4 or 10 mA. If, in step two above, the configuration was set for a "Chrg"

type input then the current level will not affect the charge-type accelerometer. If a voltage or

ISOTRON accelerometer was selected, then it is acceptable to set the current level to 4 mA as a

starting point. (Only one common current level may be set for all three channels.) (Assume a PE

accelerometer is used, so any selection is acceptable.)

4. Press the "Select Function" button to advance to "Sensitivity (pC or mV/EU)". While the

LED is flashing, enter the correct sensitivity value of the sensor being used. (This is accomplished

with the top and bottom "Edit" buttons to increase or decrease the value. The left and right "Edit"

buttons move the digiton the DPM to be changed. The actual value must be within the range of

0.001 to 9999.) Using the same assumption, input 10.04 on the DPM.)

5. Press the "Select Function" button to advance to "Output Scaling (mV/EU)". While the

LED is flashing, enter in an appropriate value, which must be within the following limits: (The scaling

value entered is valid for 0.001 to 9999 along with the following limitation: 0 ≤Output Scaling /

Sensor sensitivity ≤1000.

To better understand the correct scaling value to enter, the following questions must be answered:

a. What is the desired full scale output voltage?

b. What is the maximum g range to be measured (in g's or EU)?

c. What is the sensor sensitivity?

Metal Shield

Cover

Unit Front Power Supply

Filter Modules

Channel 1

Channel 2

Channel 3

Figure 7

(Shown cut

away to

expose the

circuit board

and filter

locations.)

Table of contents

Other ENDEVCO Test Equipment manuals