Table of contents Micropilot FMR56, FMR57 FOUNDATION Fieldbus

2 Endress+Hauser

Table of contents

1 Important document information .......................................... 3

1.1 Document conventions ........................................................... 3

2 Basic safety instructions ................................................... 6

2.1 Requirements for the personnel .................................................... 6

2.2 Designated use ................................................................. 6

2.3 Workplace safety ............................................................... 7

2.4 Operational safety .............................................................. 7

2.5 Product safety ................................................................. 7

3 Product description ........................................................ 8

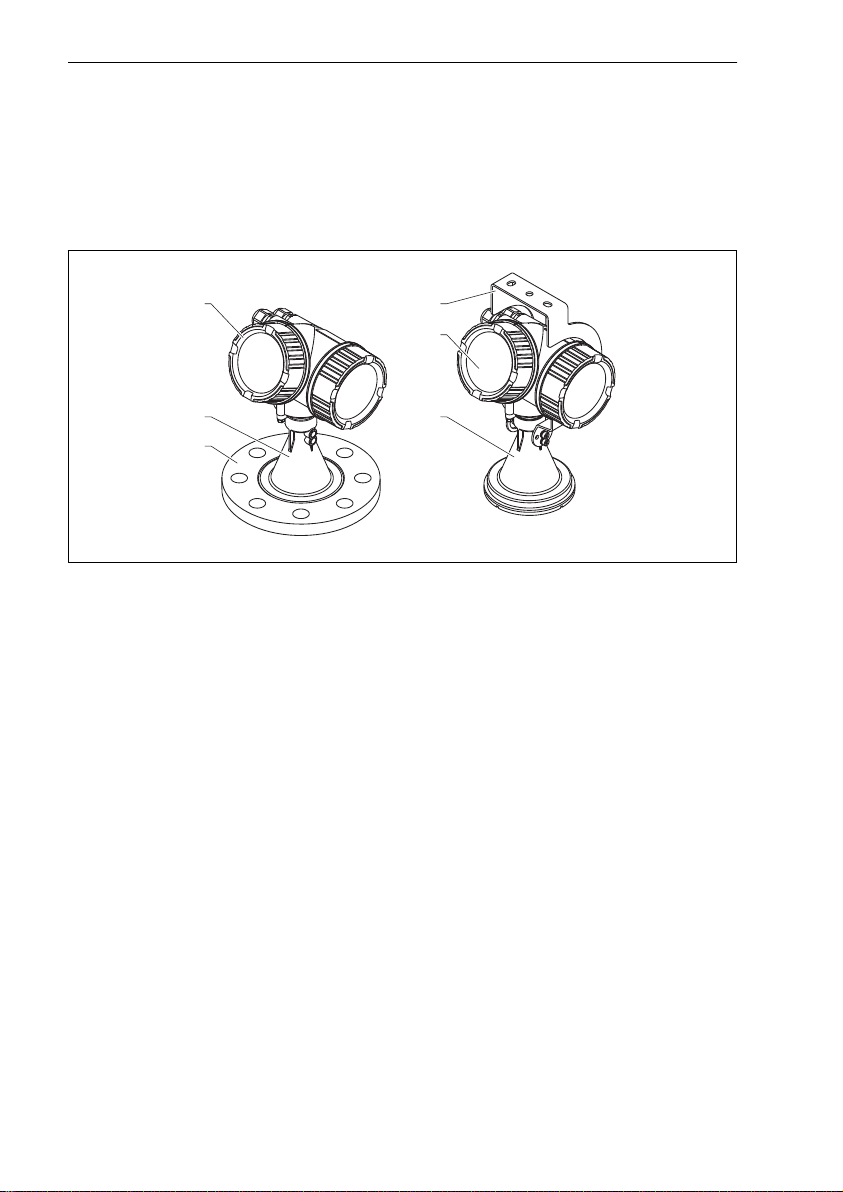

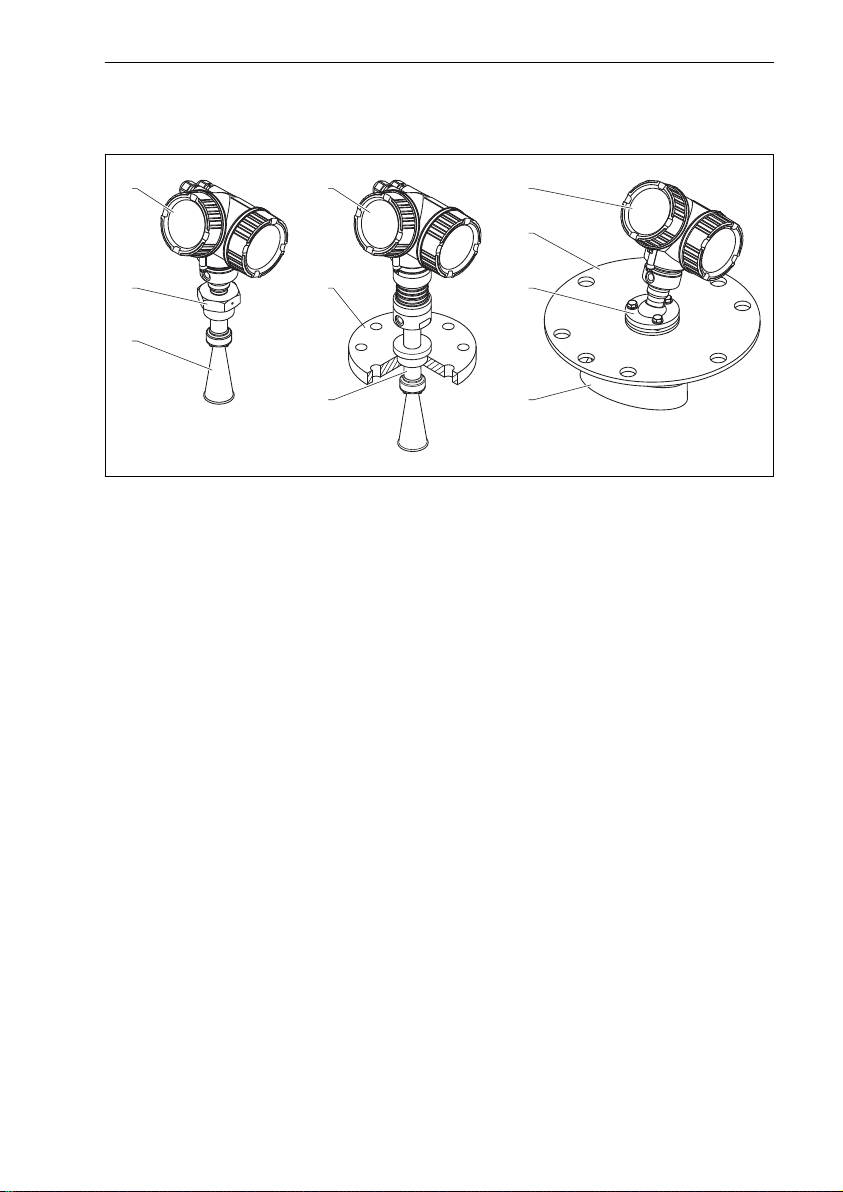

3.1 Product design ................................................................. 8

4 Incoming acceptance and product identification .......................... 11

4.1 Incoming acceptance ........................................................... 11

4.2 Product identification ........................................................... 13

5 Storage, Transport ....................................................... 14

5.1 Storage conditions ............................................................. 14

5.2 Transport product to the measuring point ............................................ 14

6 Installation ............................................................... 15

6.1 Installation conditions .......................................................... 15

6.2 Measuring conditions ........................................................... 22

6.3 Installation in vessel (free space) ................................................... 24

6.4 Vessels with heat insulation ...................................................... 35

6.5 Turning the transmitter housing ................................................... 35

6.6 Turning the display module ....................................................... 36

6.7 Post-installation check .......................................................... 36

7 Electrical connection ..................................................... 38

7.1 Connection conditions .......................................................... 38

7.2 Connecting the measuring device .................................................. 44

7.3 Post-connection check .......................................................... 47

8 Integration into a FOUNDATION Fieldbus network ....................... 47

8.1 Device Description (DD) ......................................................... 47

8.2 Integration into the FOUNDATION Fieldbus network .................................... 48

8.3 Device identification and addressing ................................................ 48

8.4 Block model .................................................................. 50

8.5 Assignment of the measured values (CHANNEL) in an AI Block ............................ 51

8.6 Methods ..................................................................... 53

9 Commissioning (via operating menu) .................................... 54

9.1 Display and operating module ..................................................... 54

9.2 Operating menu ............................................................... 56

9.3 Unlock the device .............................................................. 57

9.4 Setting the operating language .................................................... 57

9.5 Configuration of a level measurement ............................................... 58

9.6 User-specific applications ........................................................ 60

10 Commissioning (block-based operation) .................................. 60

10.1 Block configuration ............................................................. 60

10.2 Scaling of the measured value in an AI Block .......................................... 62

10.3 Language selection ............................................................. 63

10.4 Configuration of a level measurement ............................................... 64