Waterpilot FMX21 Table of contents

Endress+Hauser 3

Table of contents

1 Document information .............. 5

1.1 Document function ..................... 5

1.2 Symbols used .......................... 5

1.3 Documentation ........................ 6

1.4 Terms and abbreviations ................. 7

2 Basic safety instructions ............ 8

2.1 Requirements concerning the staff .......... 8

2.2 Designated use ........................ 8

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 9

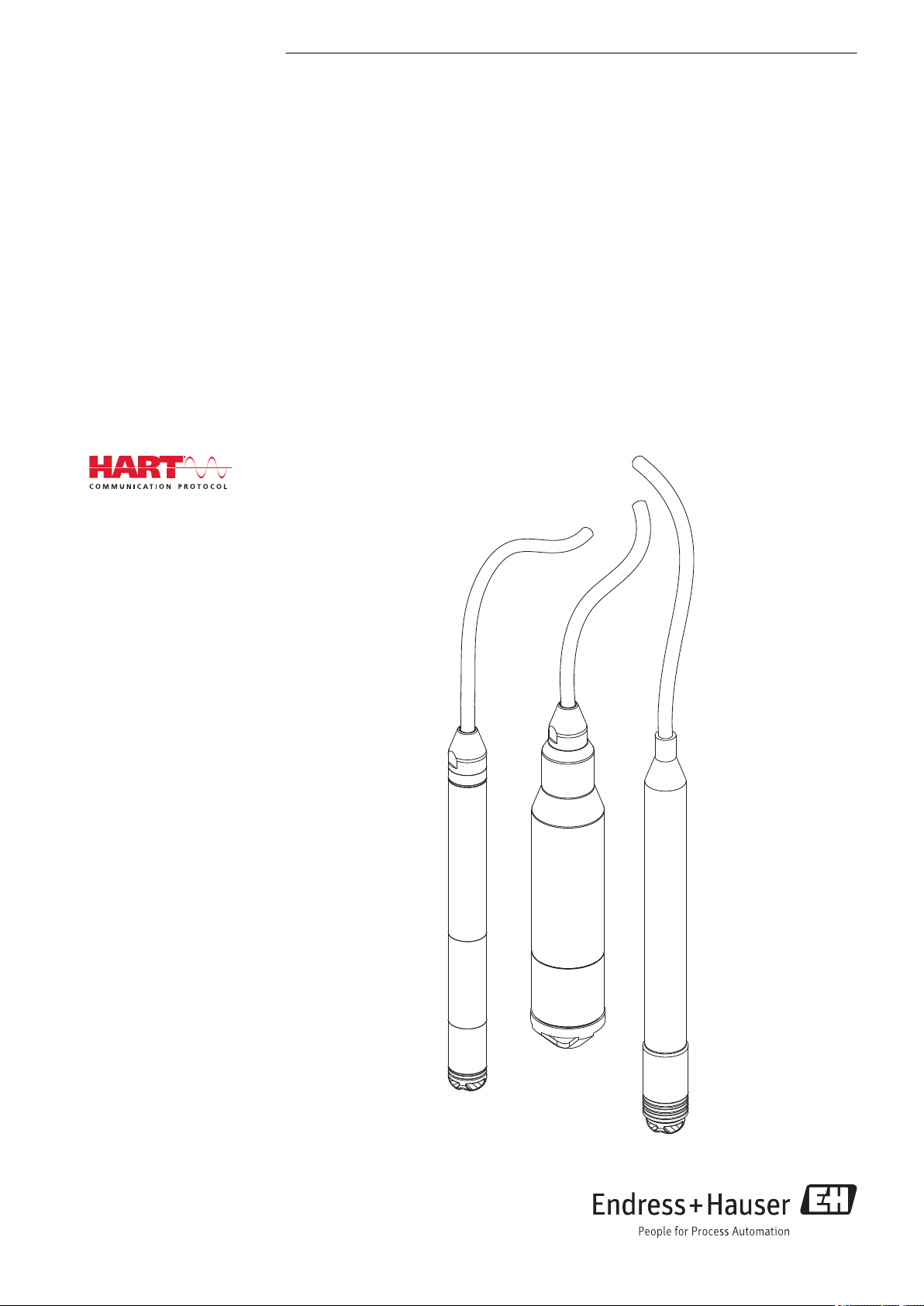

3 Product description ................ 10

3.1 Function ............................ 10

4 Incoming acceptance and product

identification ..................... 11

4.1 Incoming acceptance ................... 11

4.2 Product identification ................... 12

4.3 Nameplates .......................... 13

4.4 Identification of sensor type .............. 14

4.5 Storage and transport .................. 14

4.6 Scope of delivery ...................... 14

5 Installation ....................... 16

5.1 Installation conditions .................. 16

5.2 Additional mounting instructions .......... 17

5.3 Dimensions .......................... 17

5.4 Mounting the Waterpilot with a mounting

clamp .............................. 18

5.5 Mounting the Waterpilot with a cable

mounting screw ....................... 19

5.6 Mounting the terminal box .............. 20

5.7 Mounting the TMT182 temperature head

transmitter with terminal box ............ 20

5.8 Mounting the terminal strip for the Pt100

passive (without TMT182) ............... 21

5.9 Post-installation check .................. 21

6 Electrical connection .............. 23

6.1 Connecting the device .................. 23

6.2 Supply voltage ........................ 25

6.3 Cable specifications .................... 25

6.4 Power consumption .................... 25

6.5 Current consumption ................... 26

6.6 Maximum load ....................... 26

6.7 Connecting the measuring unit ........... 27

6.8 Post-connection check .................. 31

7 Operation options ................. 32

7.1 Overview of operating options ............ 32

7.2 Operating concept ..................... 33

7.3 Structure of the operating menu ........... 33

7.4 Locking/unlocking operation ............. 34

7.5 Resetting to factory settings (reset) ........ 35

8Integrating device via HART®

protocol .......................... 36

8.1 HART process variables and measured

values .............................. 36

8.2 Device variables and measured values ....... 37

9 Commissioning .................... 38

9.1 Post-installation check and function check ... 38

9.2 Unlocking/locking configuration .......... 38

9.3 Commissioning ....................... 38

9.4 Selecting the language .................. 39

9.5 Measuring mode selection ............... 39

9.6 For selecting the pressure engineering unit ... 40

9.7 Position adjustment .................... 40

9.8 Configuring the damping ................ 41

9.9 Configuring pressure measurement ........ 41

9.10 Configuring level measurement ........... 43

9.11 Automatic density compensation .......... 56

9.12 Linearization ......................... 59

9.13 Manual entry of a linearization table via

operating tool ........................ 62

9.14 Backing up or duplicating the device data .... 63

10 Diagnostics and troubleshooting ... 64

10.1 Troubleshooting ...................... 64

10.2 Diagnostic events ...................... 64

10.3 Troubleshooting specific to Waterpilot

FMX21 with optional Pt100 .............. 67

10.4 Troubleshooting specific to TMT182

temperature head transmitter ............ 68

10.5 Response of output to errors .............. 68

10.6 Firmware history ...................... 69

11 Maintenance ...................... 70

11.1 Exterior cleaning ...................... 70

12 Repairs ........................... 71

12.1 General notes ........................ 71

12.2 Spare parts .......................... 71

12.3 Return .............................. 71

12.4 Disposal ............................ 71