Endress+Hauser Micropilot NMR81 Instructions for use

Other Endress+Hauser Radar manuals

Endress+Hauser

Endress+Hauser Micropilot M FMR230 User manual

Endress+Hauser

Endress+Hauser Micropilot FMR51 User manual

Endress+Hauser

Endress+Hauser Micropilot FMR62B PROFINET with Ethernet-APL User manual

Endress+Hauser

Endress+Hauser Micropilot M FMR240 User manual

Endress+Hauser

Endress+Hauser Levelflex FMP56 Technical specifications

Endress+Hauser

Endress+Hauser micropilot M FMR 230 User manual

Endress+Hauser

Endress+Hauser Micropilot FMR51 Technical specifications

Endress+Hauser

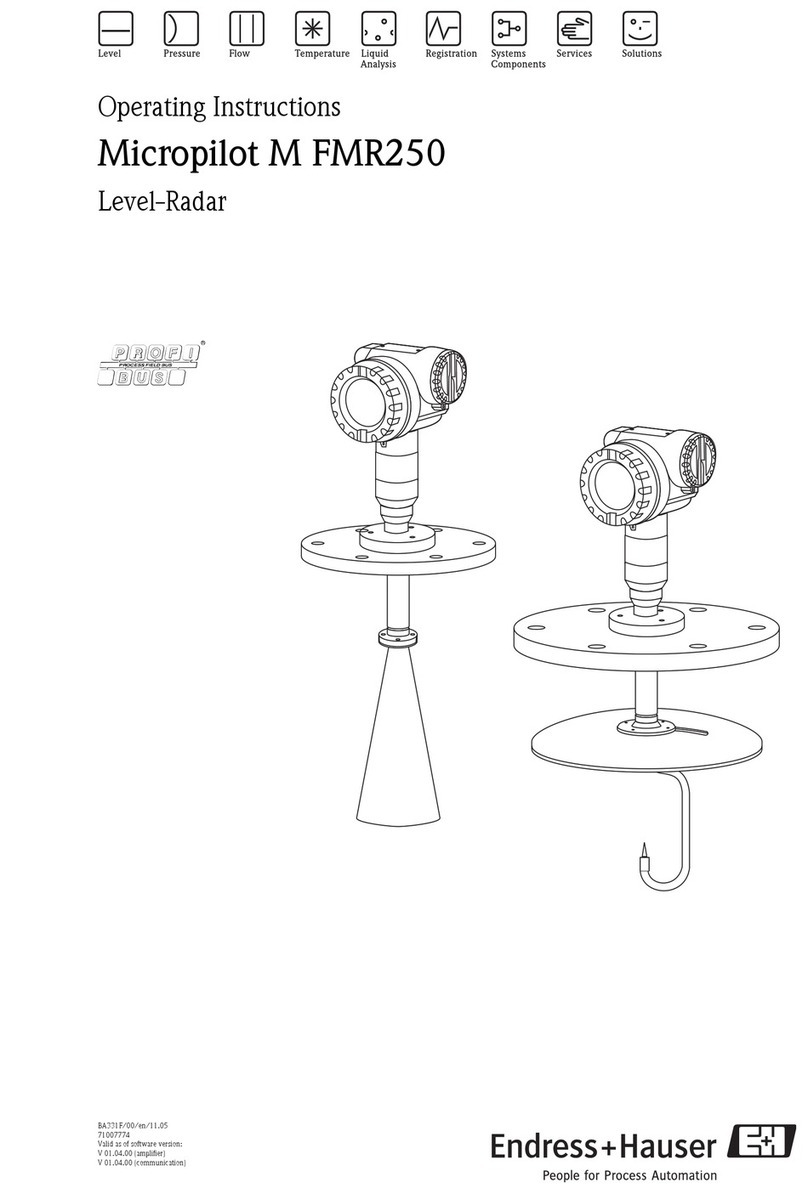

Endress+Hauser Micropilot M FMR250 User manual

Endress+Hauser

Endress+Hauser Micropilot FWR30 User manual

Endress+Hauser

Endress+Hauser Micropilot M FMR250 User manual

Endress+Hauser

Endress+Hauser Micropilot FMR56 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR53 Manual

Endress+Hauser

Endress+Hauser FOUNDATION Fieldbus Levelflex FMP51 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR50 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR67B User manual

Endress+Hauser

Endress+Hauser Micropilot M FMR244 User manual

Endress+Hauser

Endress+Hauser FOUNDATION Fieldbus Micropilot FMR50 Technical specifications

Endress+Hauser

Endress+Hauser Levelflex FMP53 User manual

Endress+Hauser

Endress+Hauser PROFIBUS PA Micropilot FMR56 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot S FMR530 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR66B PROFINET with Ethernet-APL Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR66B User manual

Endress+Hauser

Endress+Hauser FOUNDATION Fieldbus Micropilot FMR56 Technical specifications

Endress+Hauser

Endress+Hauser Levelflex FMP55 PROFIBUS PA Technical specifications