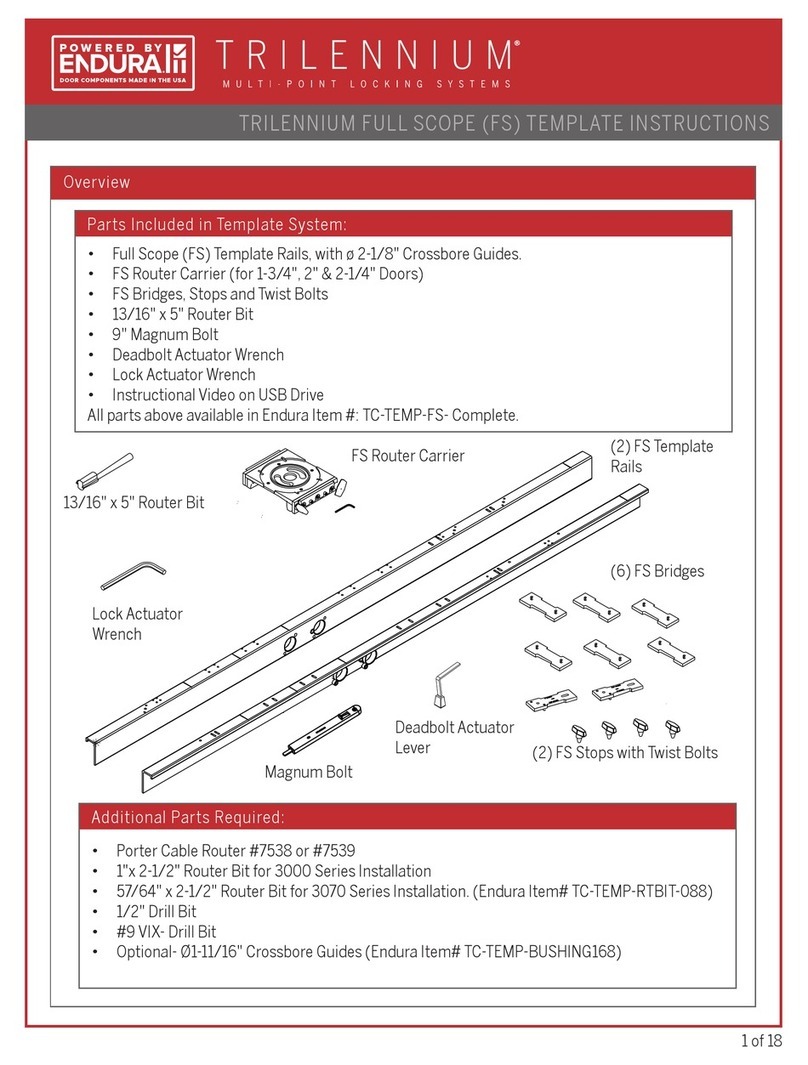

Endura TRILENNIUM Series User manual

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

1 of 12

OVERVIEW

TOOLS REQUIRED

PARTS INCLUDED

• Drill

• 1/4" Drill Bit

• Slotted Screwdriver

• Rocky Mountain Hardware

Mounting Template

(Recommended)

• Vix Bit

1. Assembled Interior Escutcheon

2. Assembled Exterior Escutcheon

3. Key Cylinder and Tailpiece with

key (Pre-assembled)

4. 7 mm Spindle

5. 8-32 Threaded Inserts

• (4) Entrance Grip Full Length

• (1) Fleur de Lis Only Lever Set

6. Short Oval Head Machine Screws

• (4) Full Length Entrance Grip

• (1) Fleur de Lis Entry Set

7. (2) Machine Screws

8. (2) Binder Post

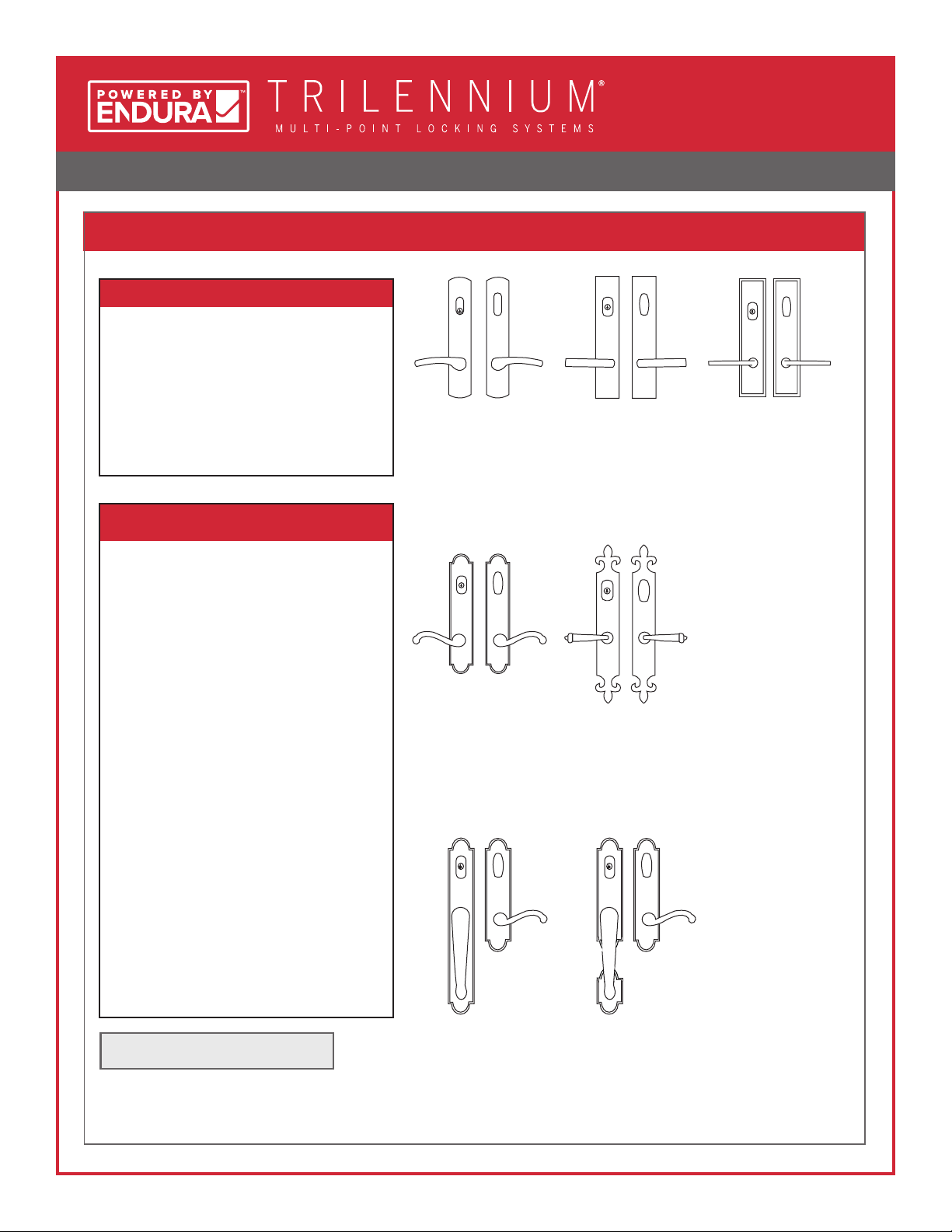

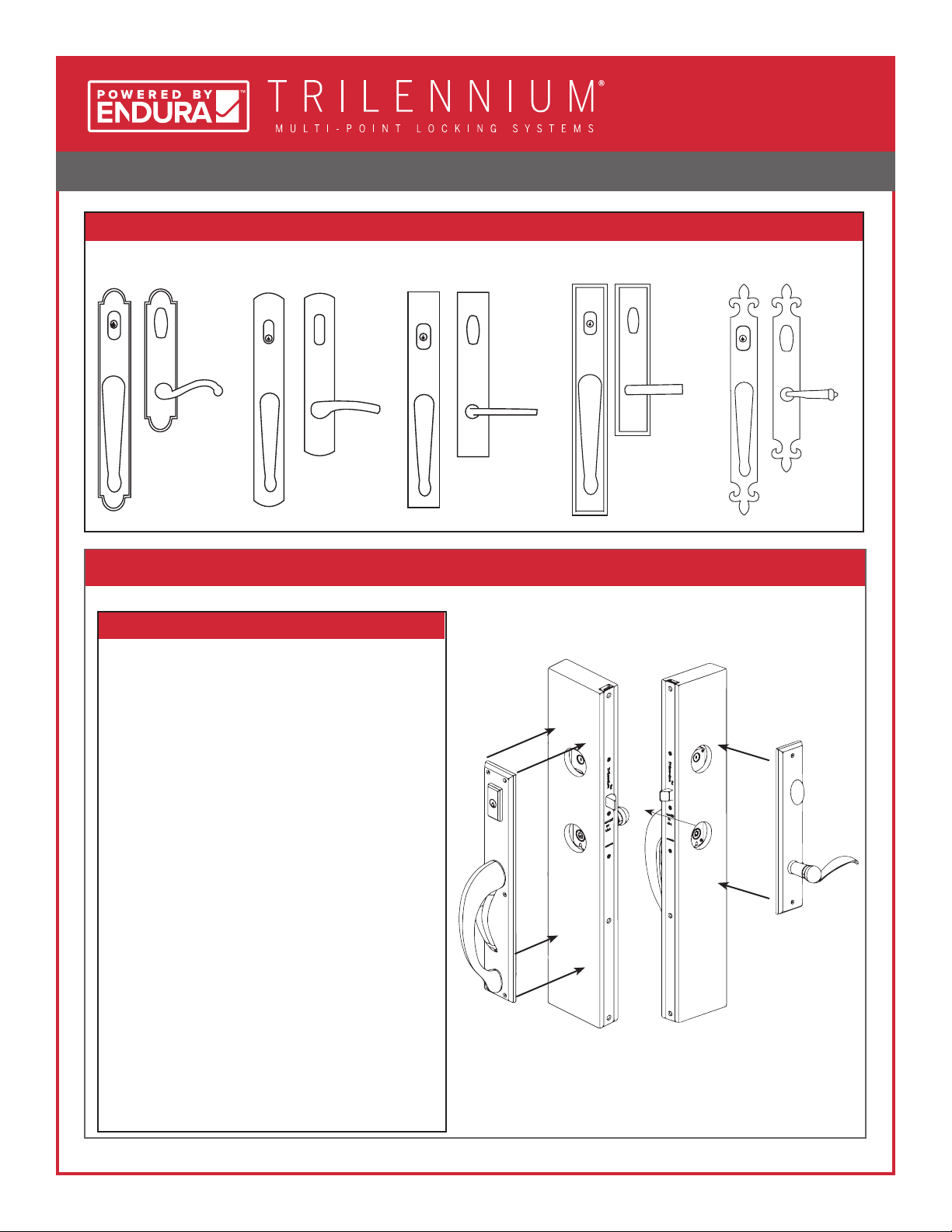

Curved Entry Set Rectangular

Entry Set

Stepped Entry

Set

Arched Entry

Set

Fleur de Lis Entry

Set

Full Length

Entrance Grip

Entry Set

Ø 2-1/8" Crossbore Recommended Sectional

Entrance Grip

Entry Set

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

2 of 12

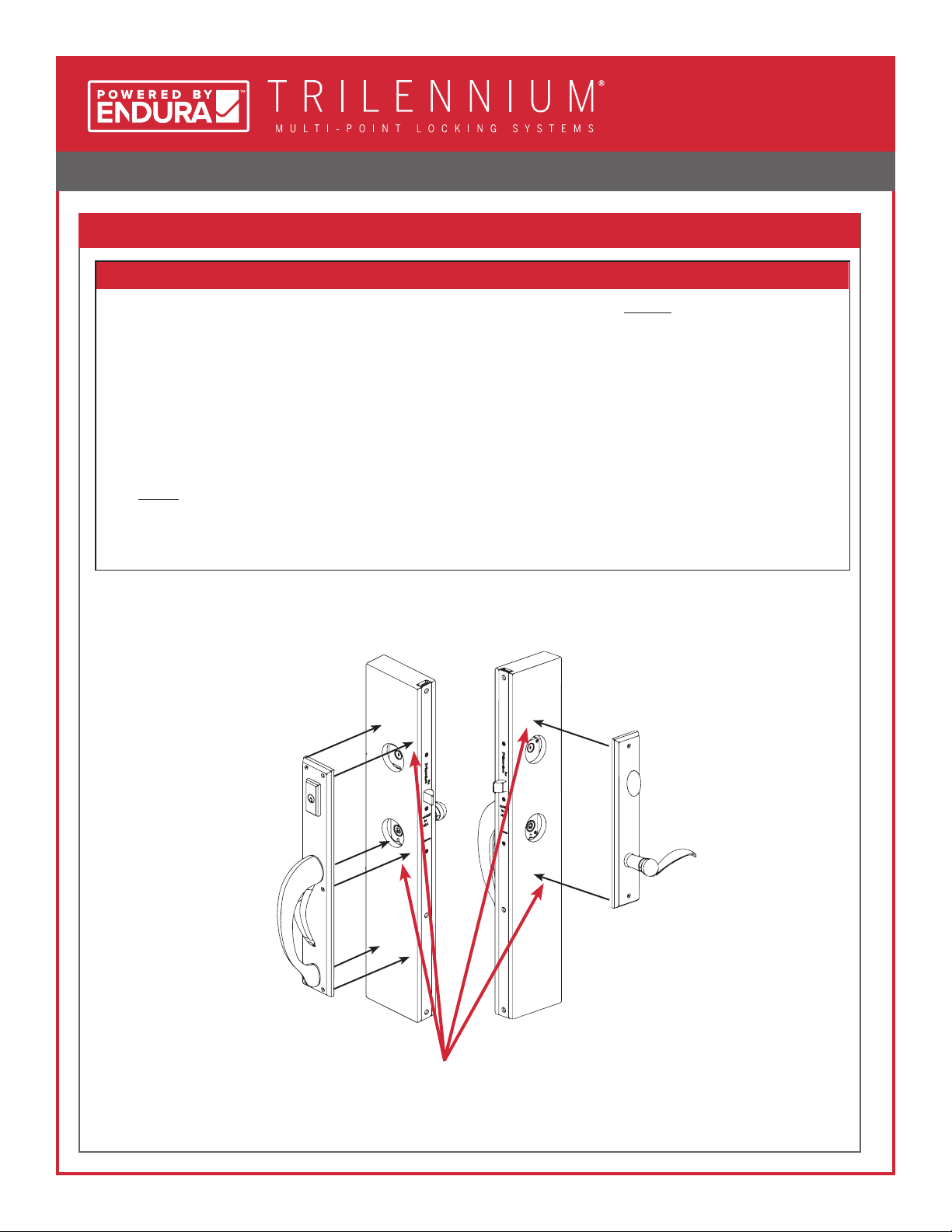

1. DETERMINE WHICH STYLE OF ROCKY MOUNTAIN HARDWARE YOU ARE INSTALLING

TYPE I TYPE II

TYPE III TYPE IV

Arched, Curved,

Rectangular, or

Stepped Lever

Set

Page 3 Page 5

Page 9Page 7

Fleur de Lis

Lever Set

Arched, Curved,

Rectangular,

Stepped, or

Fleur de Lis Full

Length Entrance

Grip

Arched, Curved,

Rectangular,

or Stepped

Sectional

Entrance Grip

Ø 2-1/8" Crossbore

Ø 2-1/8" Crossbore

Ø 2-1/8" Crossbore

Ø 2-1/8" Crossbore

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

3 of 12

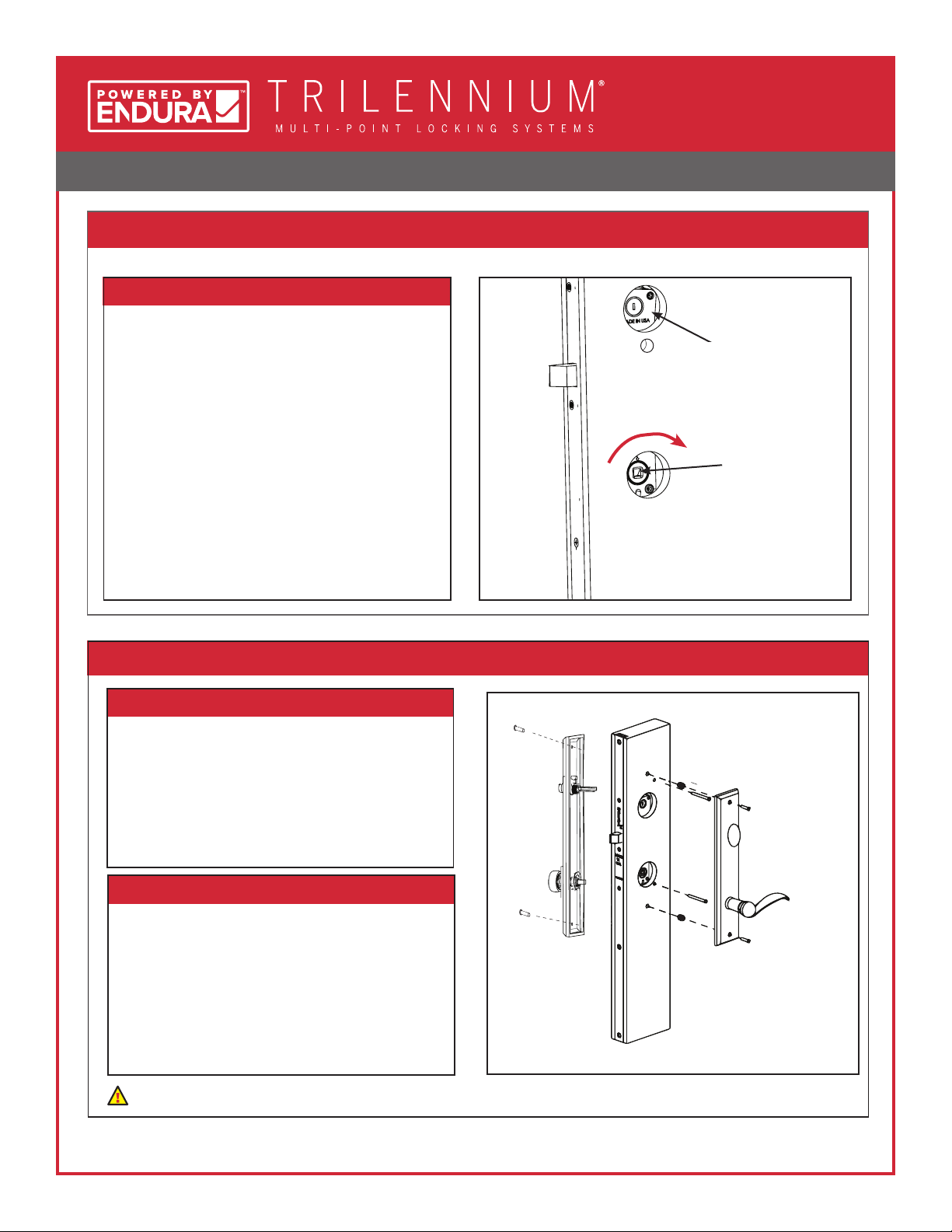

1. INSTALL ROCKY MOUNTAIN HARDWARE MOUNTING TEMPLATE

CAUTION:

• Align Rocky Mountain Hardware

template pins with the mounting screw

holes in the body of the Trilennium

Multi-Point Lock.

• Once the Rocky Mountain Hardware

Template is in place, use a 1/4" bit to

drill holes for mounting the hardware.

A. Position mounting template to the door.

• When installing the Arched, Curved,

Rectangular, or Stepped Escutcheon, use

the two holes on the center line of the

template.

Template Pins

Mounting

Screw

Holes

Use these holes

when installing

Arched, Curved,

Rectangular,

and Stepped

Entry Sets.

• Recommended: Drill approximately

halfway through the door on one side.

Remove template and repeat from other

side.

TYPE I

Arched, Curved, Rectangular, or Stepped Lever Set

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

4 of 12

2. ENTRY SET PRE-INSTALLATION SET UP

3. LEVER SET INSTALLATION

A. Check hardware in door for alignment.

• Door panel should be open. If not, rotate interior

lever actuator hub with at head screwdriver,

turning away from the edge of the door panel.

• Ensure deadbolt slot is in vertical position.

• Ensure latches are in latched position. The

latches should be so they can be easily pushed

in by hand.

• If the latches cannot be depressed, unlock the

door by rotating the deadbolt drive slot using the

cylinder tailpiece, turning away from door edge.

• The cylinder tailpiece projects through the

deadbolt hub slot and is close to ush with the

surface of the door panel (trim as necessary)

• The lever spindle mates to the lever hub of

Trilennium Multi-Point Lock.

• The escutcheon is parallel to panel edge.

• The cylinder tailpiece mates with the thumb turn

slot.

• The spindle mates to the lever hub.

Secure plates by inserting and hand tightening the

(2) #8 mounting screws.

• 2" long for 1- 3/4" doors.

• 2-1/2" long for 2-1/4" doors.

Vertical Deadbolt Slot

Turn to open

A. Install exterior escutcheon rst, then hold in place.

Ensure that:

Ensure that:

B. Install the interior escutcheon.

Check handle’s function (See Page 11) before you fully tighten the handle set to the door.

Interior View

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

5 of 12

1. INSTALL ROCKY MOUNTAIN HARDWARE MOUNTING TEMPLATE

CAUTION:

• Align Rocky Mountain Hardware

Template’s pins with the mounting

screw holes in the body of the

Trilennium Multi-Point Lock.

• Once the Rocky Mountain Hardware

Template is in place, use a 1/4" bit to

drill holes for the mounting hardware.

A. Position mounting template to the door. Template Pins

Mounting

Screw Holes

Use when

installing Fleur de

Lis Entry Set

Lever Set

Mounting

Template

• Recommended: Drill approximately

halfway through the door. Remove

template and repeat from other side.

• When Installing the Fleur de Lis Entry set

use the four holes along the edges.

TYPE II

Fleur de Lis Lever Set

Installed

Template

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

6 of 12

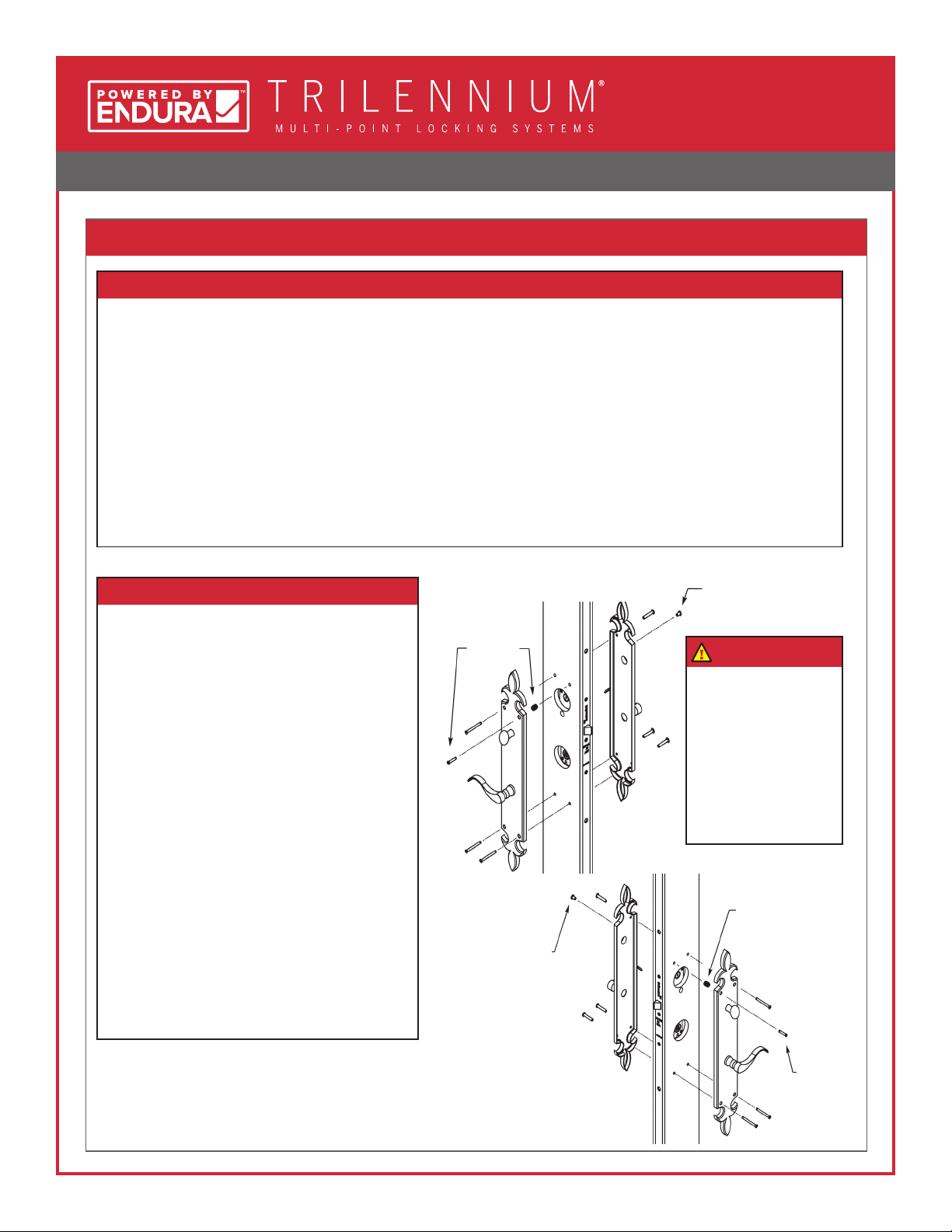

2. FLEUR DE LIS HANDLE SETS INSTALLATION

Right Hand Application See Note

See Note

Left Hand Application

Note: Short

binder post is

pressed into

the exterior

escutcheon.

Note: 8-32

Threaded insert

is installed into

a 1⁄4" Dia. hole

in the door stile

The short

OHMS

screws

into the

threaded

insert.

NOTE:

The top mounting screw,

closest to the edge of

the door cannot be

through-bolted using

the 1-1/4" long binder

post and machine

screw. It interferes with

the operation of the

Trilennium Multi-Point

Lock.

• Install an 8-32 Threaded Insert into the top hole closest to the edge on the interior face of the door.

• Install the short (3/4") Binder Post into the exterior escutcheon’s top hole closest to the edge of the door.

• Insert 1-1/4" Binder Posts into the exterior escutcheon in the remaining 3 holes.

• Guide Cylinder Tailpiece and Lever Spindle on the exterior escutcheon into the respective hubs in the Trilennium

Multi-Point Lock.

Ensure that:

• The cylinder tailpiece projects through the deadbolt hub slot and is close to ush to the door surface (trim as

necessary).

• The lever spindle mates to the lever hub of the Trilennium Multi-Point Lock.

• The escutcheon is parallel to the panel edge.

Ensure that:

• The cylinder tailpiece mates with the

Thumbturn slot.

• The lever spindle mates to the lever hub

of the Trilennium Multi-Point Lock.

• Insert the short (7/8") Oval Head Machine

Screw into top mounting screw hole closest

to the edge of the door and into the Threaded

Insert and loosely tighten. DO NOT FULLY

TIGHTEN.

• Insert the longer Oval Head Machine Screws

into the other 3 mounting holes and loosely

tighten. DO NOT FULLY TIGHTEN.

• Check the handle set’s function (see page 10)

before you fully tighten the handle set to the

door.

• Once you’ve checked the function, re-check

that the escutcheons are parallel to the panel

edge and hand tighten snug. DO NOT OVER-

TIGHTEN.

Additional Parts Included:

(1) 8-32 Threaded insert

(1) 7/8" 8-32 Mounting Screw

(1) 3/4" Binder Post

A. Install the exterior escutcheon rst, then hold in place.

B. Install the interior escutcheon and hold in place.

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

7 of 12

1. INSTALL ROCKY MOUNTAIN HARDWARE MOUNTING TEMPLATE

• Recommended: Drill approximately

halfway through the door. Remove

template and repeat from other side.

• When Installing the Sectional Entry Grip

set use the two holes on the centerline of

the template.

CAUTION:

• Align Rocky Mountain Hardware

Template’s pins with the mounting

screw holes in the body of the

Trilennium Multi-Point Lock.

• Once the Rocky Mountain Hardware

Template is in place, use a 1/4" drill

bit to drill holes for the mounting

hardware.

Position mounting template to the door. Template Pins

Mounting

Screw

Holes

Use when

installing

Sectional

Entry Grip Set

Lever Set

Mounting

Template

TYPE III

Arched, Curved, Rectangular, or Stepped Sectional Entrance Grip

Installed

Template

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

8 of 12

2. ENTRANCE GRIP HANDLES INSTALLATION

Exterior Application

• Insert 1-1/4" Binder Posts into the main exterior escutcheon's

2 holes.

• Install the short end of the square drive spindle into the

exterior grip assembly, as shown on the right.

• Guide Cylinder Tailpiece and Lever Spindle on the exterior

escutcheon into the respective hubs in the Trilennium Multi-

Point Lock.

Ensure that:

• The cylinder tailpiece projects through the deadbolt hub

slot and is approximately ush to the door surface (trim as

necessary).

• The drive spindle mates to the lever hub of the Trilennium

Multi-Point Lock.

• The escutcheon is parallel to the panel edge.

Ensure that:

• The cylinder tailpiece mates with the thumb-

turn slot.

• The lever spindle mates to the lever hub of the

Trilennium Multi-Point Lock.

• Insert the Oval Head Machine Screws into the

2 mounting holes and loosely tighten. DO NOT

FULLY TIGHTEN.

• Check the handle set's function (see page 10)

before you fully tighten the handle set to the

door.

• Once you have checked the function, re-check

that the escutcheons are parallel to the panel

edge and hand tighten snug. DO NOT OVER-

TIGHTEN

• Using a Vix bit, drill pilot holes for the 4 screws

holding the small plate at the bottom of the

exterior grip.

• Install the 4 short Oval Head Wood Screws

directly into the door.

A. Install exterior escutcheon rst, then hold in place.

B. Install the interior escutcheon and hold in place.

1- 3/4" Panel

Application

5/8"

7/8"

2-1/4" Panel

Application

1/4"

1/4"

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

9 of 12

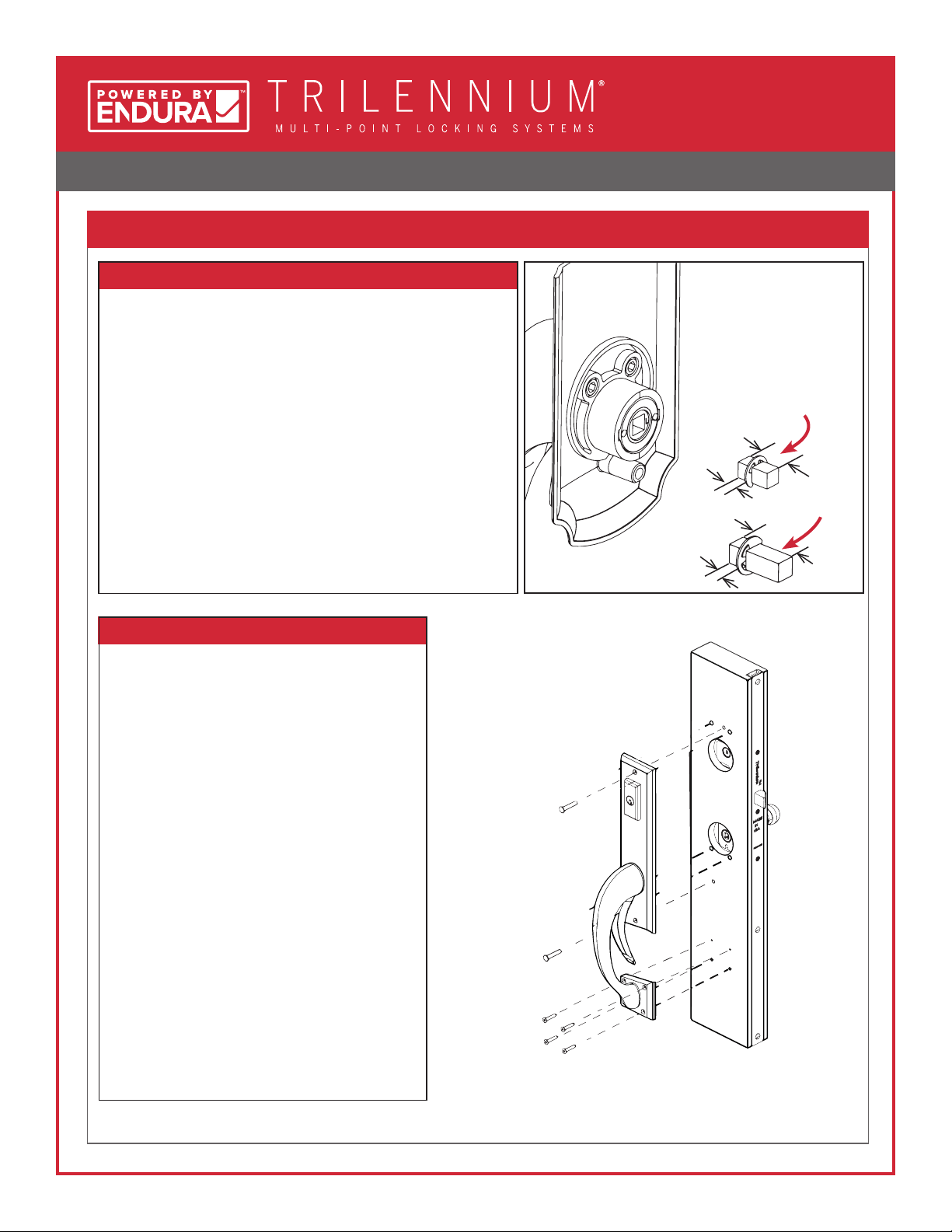

TYPE IV

Arched, Curved, Rectangular, Stepped, or Fleur de Lis Full Length Entrance Grip

1. DETERMINE THE MOUNTING HOLE LOCATIONS

A. Position exterior escutcheon on the door.

• Locate the Exterior Grip Assembly on the door

with the cylinder tailpiece and square drive

spindle installed. Hold against the surface of the

door

• Check to be sure the cylinder tailpiece is

horizontal (the assembly is very heavy and

has a tendency to sag, causing the tailpiece

to point upwards)

• Using a Vix bit or small bit, drill pilot holes in the

center of the top (4) mounting screw locations.

Remove the Exterior Grip Assembly.

• Locate the (2) mounting locations that will have

threaded inserts. These are the top and center

location, CLOSEST to the edge of the door. Using

a 1/4" bit, drill these holes 3/8" to 1/2" deep and

install the threaded inserts ush to the face of

the door.

• Locate the (2) mounting locations that will be

through-bolted. These are the top and center

location, FURTHEST from the edge of the door.

Using a 1/4" bit, drill these (2) holes through the

door.

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

10 of 12

2. FULL LENGTH ENTRANCE GRIP HANDLE INSTALLATION

• Install the Exterior Grip Assembly on the door using the (4) locations from Step 1. DO NOT install the bottom (2) wood

screws yet.

• Check that the Exterior Grip Assembly is parallel to the edge of the door.

• Hand tighten the mounting screws and check the function.

• Locate the Interior Lever Assembly with the cylinder tailpiece engaged in the thumbturn and the square spindle in the

lever. Hold against the surface of the door.

• Using a Vix bit or small bit, drill pilot holes in the center of the mounting screw locations. There are (4) screws for the

Fleur de Lis and (2) for all other styles.Remove the Interior Lever Assembly.

• Using a 1/4" bit, drill these holes 3/8" to 1/2" deep and install the threaded inserts ush to the face of the door.

• Install the Interior Lever Assembly on the door. Hand tighten the mounting screws and check the function.

• Before tightening the mounting screws further, engage the deadbolt and use the interior panic release several times.

• This will allow the handle set to nd it's "sweet spot" and function smoothly. Once you are happy with the function,

recheck the escutcheon plates are parallel to the edge of the door, hand tighten the screws and add the (2) wood

screws to the bottom of the Exterior Grip Assembly.

A. Install exterior escutcheon rst, then hold in place.

Exterior Application Interior Application

Note: 8-32 Threaded insert is

installed into a 1⁄4" Dia. hole in

the door stile (4 places).

Note: You can use the

Rocky Mountain Hardware

Template for the INTERIOR

ONLY as it is done for Type I.

(See Step #1, Page 3)

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

11 of 12

4. CHECK OPERATION OF ENTRY SET

A. Verify lock and handle operation with the door open.

• Rotate thumbturn 90°. Latch bolts should extend to deadbolted position. Rotate 90° the other direction. The

latch bolts should retract to original position.

• Rotate thumbturn 90° again. Latch bolts should extend to deadbolted position.

• Press on the end of each latch bolt individually to ensure they do not collapse. If they do, the door is not fully

deadbolted. Check the fabrication to see where the interference is.

• Operate exterior grip trigger. The latch bolts should remain in deadbolted position.

• Operate interior lever downward. The latch bolts should fully retract.

• Operate exterior grip lever. The latch bolts should fully retract.

HANDLE SET INSTALLATION - ROCKY MOUNTAIN HARDWARE

12 of 12

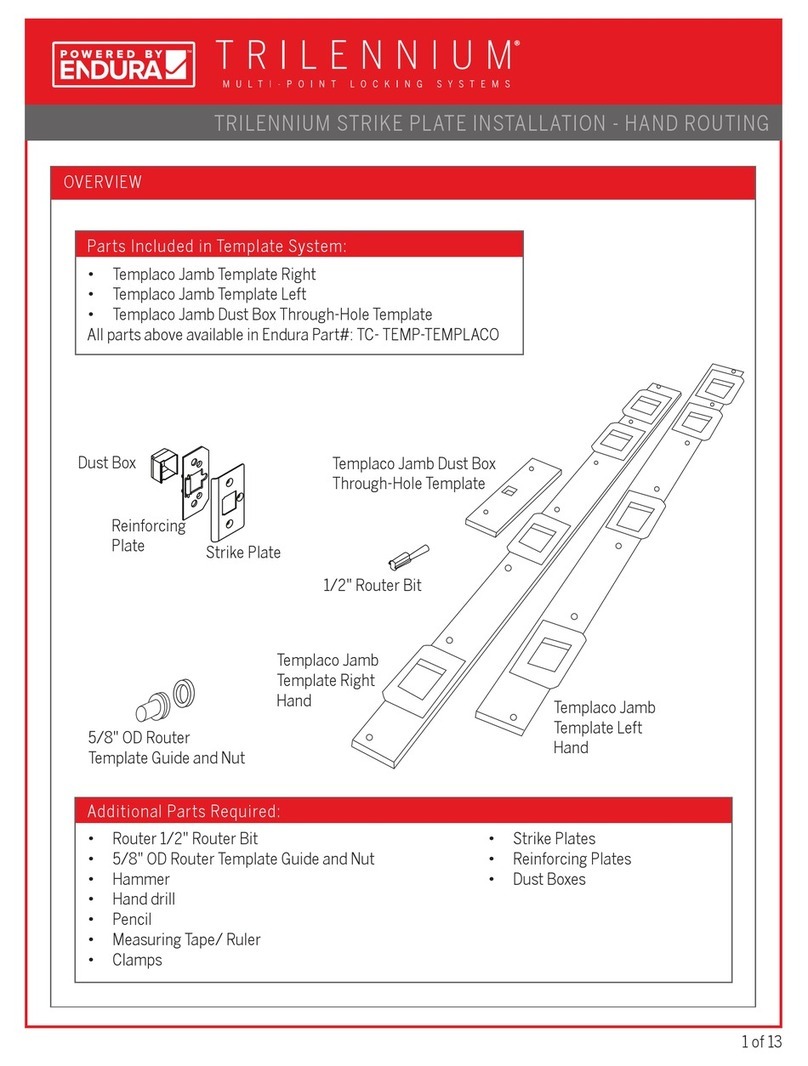

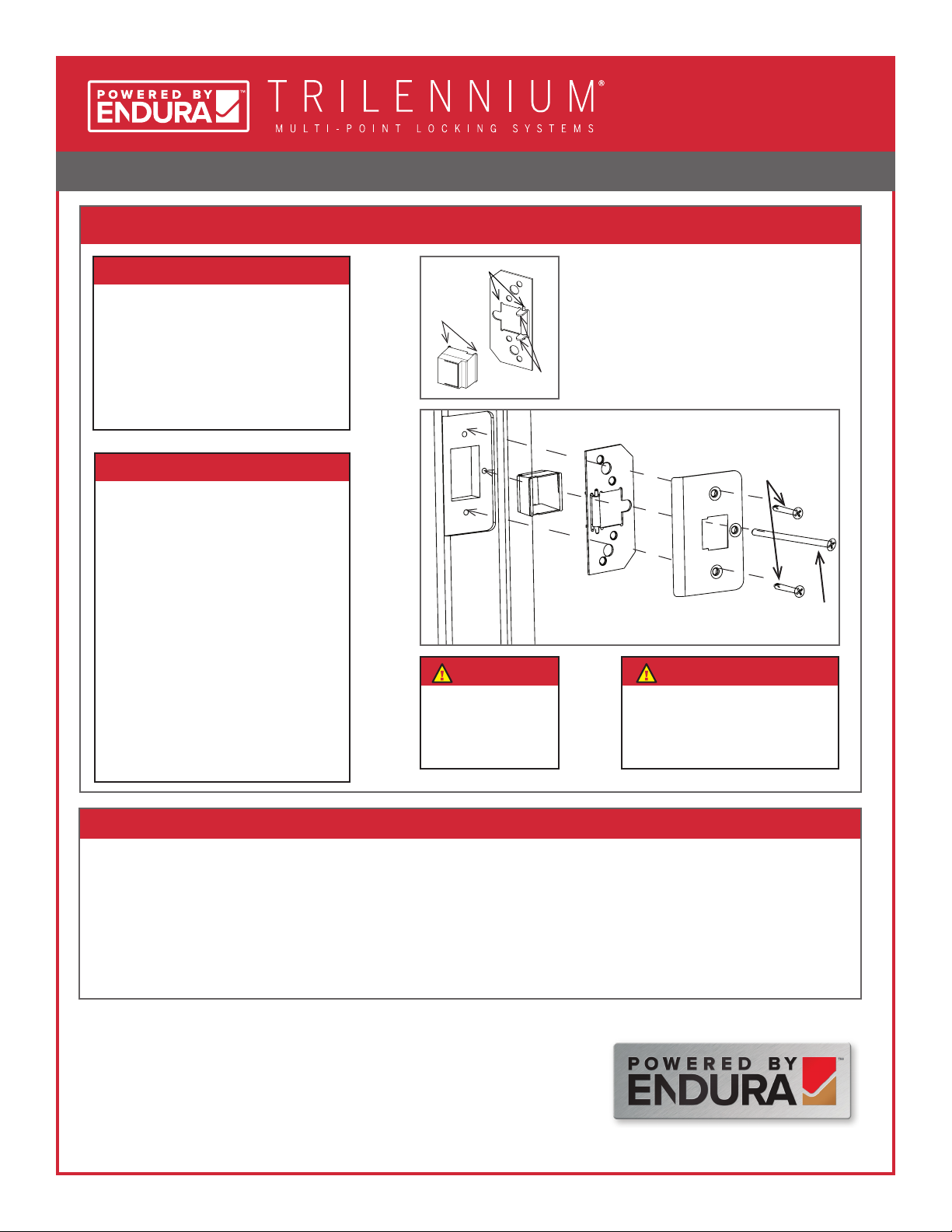

5. Strike Plate Assembly

• Attach the Dust Box to the

Reinforcing Plate.

• Align the 3 holes on the Strike Plate

with the Reinforcing Plate.

• Orient as shown.

• Use 3/4" screws in top and bottom

holes of each strike.

• Use long #10 x 2-1/2" Screw in

center hole. (The purpose is to

anchor each Strike Plate to the

structural framing for added

security.)

• Repeat for remaining strike

locations.

• Close the door.

• All three bolts should engage strikes as door is closed.

• Turn thumbturn 90° to extend bolts (all three) an additional 1/2" to deadbolted position.

• From interior, rotate lever downward to totally disengage bolts and open door. Bolts can also be disengaged (to latched

position) by turning thumbturn.

• Engage deadbolt again. From the exterior, operate the lever and ensure it does not move. Ensure latches only move when

the door is unlocked with a key.

Attach strike plates to jamb

6. Final Operation Check

A 1/8" Ø pilot hole

should be drilled into

the rough framing

for the long screw.

Note:

Solid shimming should be

placed behind the jamb at each

strike location to allow for rm

anchoring to structure.

Note:

8817 W. Market St., Colfax, NC 27235

1.800.334.2006 www.enduraproducts.com

The information contained in this document is the condential and proprietary information and trade secrets of Endura Products, Inc. Any disclosure,

use or dissemination of such information without the express written permission of Endura Products, Inc. is strictly prohibited. Endura Products, Inc.

also owns any and all intellectual property rights embodied in such information, including patent rights, copyrights, and trademark rights, and no

license of any intellectual property right is intended, nor should any license be implied, as a result of the receipt of this document.

Rev. 01.16.2018

Parts Required

• (3) Dust Boxes

• (3) Reinforcing Plates

• (3) Strike Plates

• (6) 3/4" screws

• (3) #10 x 2-1/2" screws

• The Dust Box Feet should align with the

slots in the reinforcing plate.

• The reinforcing plate arms should sit inside

the dust box.

Dust Box

Reinforcing Plate

Strike Plate

3/4" Screws

#10 x 2-1/2"

Screw

Dust Box

Feet

Reinforcing

Plate Arms

Slots for Dust Box Feet

Other manuals for TRILENNIUM Series

2

Other Endura Power Tools Accessories manuals