ENDURAMAXX 200L Service manual

Disclaimer: All goods are sold in accordance with our standard terms and conditions for the sale of goods - available upon request. All prices exclude VAT. Product specifications and prices are

subject to change in line with our commitment to continuous improvement. Capacities and dimensions may vary due to manufacturing process. Colours represented may vary due to printing

process. Tank level graduations have been highlighted for visual effect. Tanks are not supplied from factory with highlighted graduations. E&OE.

Enduramaxx LLP |Outgang Road |The Fen |Baston |PE6 9PT |Telephone: 01778 562810 |Fax: 01778 560488

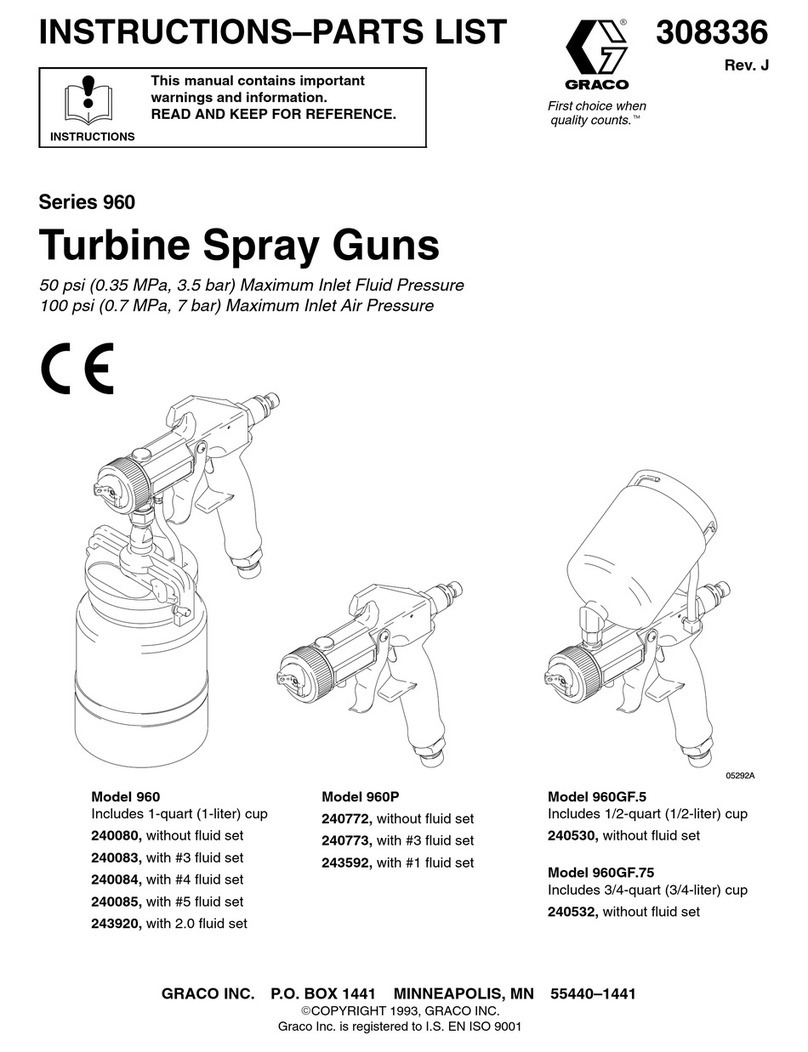

200L, 300L & 400L SKID SPRAYERS

OPERATOR’S

HANDBOOK

VALID FROM OCTOBER 2013

Outgang Road, Baston, PE6 9PT

www.enduramaxx.co.uk

0800

840

4030

F

R

E

E

P

H

O

N

E

©Enduramaxx LLP – Skid Sprayers – 04.10.13 Partnership Number OC370786

11

Warranty Card

Your Silver Series Sprayer is guaranteed free from defect in materials, workmanship

or manufacture for 12 months from the date of purchase. Any parts which appear to

us to be defective either in material or workmanship will be replaced or repaired at no

cost to the purchaser, subject to the following conditions:

The guidelines in this handbook have been adhered to in every respect.

In the unlikely event of sprayer failure, this should be reported to your dealer who

will act on your behalf to resolve the issue to your satisfaction.

Any defective parts will be returned by your dealer within 7 days of failure,

together with a report describing the failure and conditions in which the failure

occurred.

The following are specifically excluded from the terms of warranty –

• Fair wear and tear to pump moving parts and diaphragms

• Fair wear and tear to nozzles and nozzle bodies

• Damage caused by neglect or lack of lubrication

• Damage caused by misuse or abuse

• Damage caused while the sprayer is in transit.

1

2

3

4

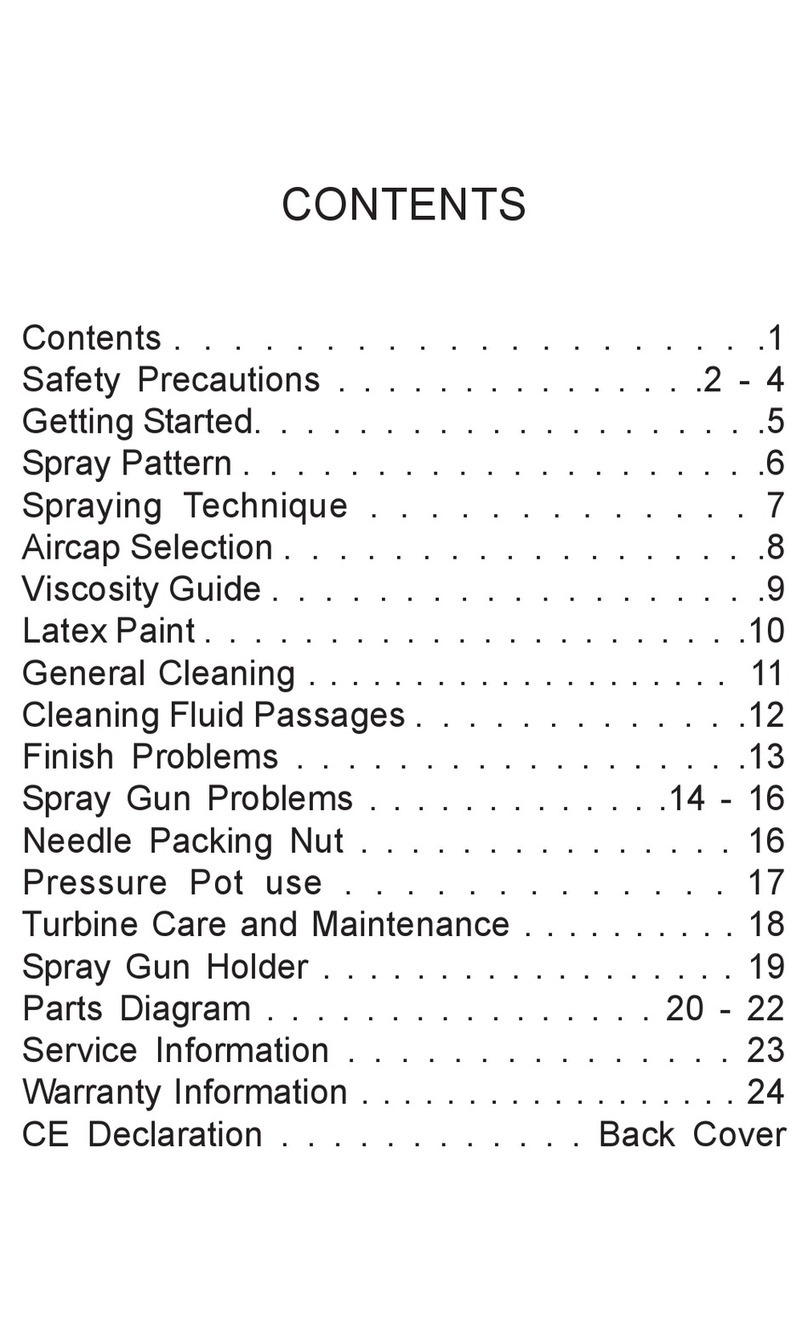

CONTENTS

Introduction

Risk Assessment

Operating Instructions

Mixing and Filling

Spraying

Decontamination and Maintenance

Calibration

Calibration Procedures

Warranty

READ YOUR OPERATOR’S HANDBOOK CAREFULLY BEFORE MOUNTING AND

USING YOUR SPRAYER, KEEP YOUR HANDBOOK IN A SAFE PLACE.

PAGE

2

3

4

5

6

7

8

9

10

Introduction

Congratulations on your purchase of a Enduramaxx Skid Unit which is complete and ready to fit

to your vehicle. You need to read carefully and take note of the following warnings before

attempting to operate or install this sprayer.

Failure to comply with these warnings may result in serious injury or death.

WARNINGS

When fitting to any vehicle ensure that you have read the Vehicle Owner’s Manual and that you

comply with all the weight restrictions as specified by the vehicle Manufacturer, as overloading

can cause injury or death. Remember that 1 litre of water weighs 1 kilogram.

To ensure your own safety and that of your employees if applicable you must comply with all

relevant environmental, work place, health & safety legislation and codes of practice.

Exercise extreme care when operating in hilly or uneven terrain to ensure proper stability and

braking ability. Refer also to the vehicle manufacturer’s operating and safety instructions.

Select and wear appropriate Personal Protection Equipment in accordance with the label of the

product you intend using and your own safe work practices.

Care should be taken if using your trailer for spraying in windy conditions as spray drift may

contaminate the air and may affect the operator or damage adjacent non target vegetation.

Once the spraying operation has been completed, decontaminate the spray tank and spray

accessories. Dispose of tank rinsings in compliance with current environmental, work place

health and safety regulations.

Personal Protection Equipment must still be worn while decontaminating your sprayer as per

warning at 4 above.

Improper or careless use of this trailer can cause serious injury or death. Minors should never

be allowed to use this sprayer.

You must be in good mental health to operate this sprayer and not be under the influence of

alcohol or any drugs that could impair your vision, physical strength, dexterity, judgment or

other mental capacity.

Do not point spray gun at any part of the human body. Do not pump flammable liquids or

operate the pump in an explosive environment.

1

2

3

4

5

6

7

8

9

10

2

Risk Assessment

ENDURAMAXX PRODUCT INFORMATION RISK ASSESSMENT SHEET

Operating Instructions

The Enduramaxx Skid Sprayers have been designed for the application of agricultural

chemicals to plants and may be used with a handgun or in conjunction with a boom.

Setup

BEFORE USE

Check all hoses, connections and hose clamps to ensure that the unit has been

delivered to you without transportation loss or damage.

Before attempting any spraying with your new unit, partially fill with water and

operate it to familiarize yourself with its features and capabilities and to ensure

that your unit has arrived in a safe working condition.

Please contact your dealer immediately should anything appear to have been

damaged.

CONNECTING TO 12 VOLT DC SUPPLY

The Sprayer requires a 12 volt DC power source. A 2 metre loom is provided with the

sprayer to allow the sprayer to be connected to the 12 volt DC source available. The

red wire is positive and the black is negative. If you extend the wire, use wire of the

same gauge or larger. An on/off switch is fitted to the sprayer control box to allow

the sprayer to be switched off from the 12 volt DC source to prevent accidental drain

of power. The switch also allows the pump to be shut down when the tank is empty

preventing overheating and damage to pump. An in-line fuse is fitted to prevent any

potential damage to the electrical system of the vehicle. Consult your vehicle

instruction manual for correct electrical connection.

FITTING INSTRUCTIONS

It is recommended that the sprayer be securely attached to any ATV or other vehicle.

Refer to manufacturer’s instructions for appropriate load limits and fitting positions.

Note: 1 litre of water = 1kg.

Never fill spray tank to a capacity beyond the specified overall weight limits set by

your vehicle manufacturer. When fitted these should be firmly secured to approved

attachment points on the ATV or other vehicle.

TA S K HAZARDS RISK CONTROL MEASURES

Partially fill the tank

with water, connect

the battery or motor

(whatever is applicable)

& test the spray unit.

Manual handling; slips,

trips or falls;

fingers jammed;

electric shock or

electricity.

MED Concentrate on task; follow safe

manual handling techniques:- don’t lift

on your own if >20kg, bend knees & keep

back straight; keep fingers clear; keep unit at

least 8m away from overhead power lines;

ensure AS 3760: 2001 Testing Electrical

Equipment applies; water away from

electrical sources.

Check weather conditions

& select the appropriate

PPE to Suit the chemicals

to be used.

Manual handling; slips

trips or falls.

LOW Put on PPE as per the chemical requirements

in the Material Safety Data Sheet – coveralls,

gloves, safety footwear, glasses & respirator;

follow safe manual handling techniques;-

don’t lift on your own if > 20kg, bend knees

& keep back straight.

Mix chemicals & fill spray

Tank units.

As above; spray drift,

Chemical spillage, emission

Of vapours or flammability;

Weather; untrained visitors.

MED As above; user trained in the state’s chemical

mixing & administration course eg. Chem Cert;

follow the relevant Environment Protection

Authority requirements; fire extinguisher

present; keep visitors away from the job

unless wearing full PPE.

Check that transport

vehicle is safe before use,

ie. Where Applicable;-

wheel nuts, tyre Pressure,

bearings, tow hitch, has

Been serviced, etc.

Off road use only

As above; loss of load; heat

& cold; noise; exceed load

Limit of ATV vehicle/trailer;

Hose entanglement; exhaust

Fumes; terrain & slopes

HIGH As above; wear clothes to suit heat & cold;

wear hearing protection if noise > 85dBA;

check straps; follow the manufacturer’s safe

operation instructions for the vehicle, trailer

& the spray unit; don’t overload water weighs

1kg for every 1 litre; secure load;

keep hose tidy.

Clean up, maintenance &

storage

As above LOW As above; continue to wear PPE for clean up;

store unit in dry, well-ventilated area.

1

2

3

4

5

3 4

Mixing and Filling

The following steps are given as a guide for mixing and filling the sprayer.

1. Read the product label and follow the instructions carefully, taking special note with

regard to the order in which the products are added to the tank.

2. Half-fill the spray tank with water only and commence agitation by following these

steps:

• Turn regulator valve knob in anti-clock wise direction to reduce pressure

to “O” bar.

• Commence pumping and fluid circulation

• Measure the correct quantity of pesticides, using clean measuring jugs used

only for this purpose and add to the spray tank while still agitating.

• Rinse out the measuring jugs and empty containers and pour all rinsings into

the spray tank.

• Top up the spray tank with clean water to the required level.

3. Your spray tank has now been correctly filled and the product thoroughly mixed,

spraying can now commence.

4. To commence spraying close the spray gun or boom and turn the adjustment knob

in a clockwise direction to the desired pressure and operate sprayer.

Spraying

For effective spraying ensure you have taken the following factors into account

1. Work Rates

• Speed of operation

• Water points or nurse tanks

• Rate of travel

• Swath width

• Spray volume applied

2. Wind and Drift

• Wind Speed

• Wind Direction

• Airspeed at boom height

(Avoid spraying on still warm days as convection currents may cause drift in

unpredictable directions. Optimum wind speeds are between 3km/h to

7km/h)

• Wind direction and drift is controlled by;

- Reducing nozzle height

- Reducing pressure and using larger nozzles

- Fit low-drift nozzles producing larger droplets

3. Field Work (see diagram below)

Swath marking and spraying

• Mark out to ensure proper pass matching – use flags foam markers or

tramlines

• Where large obstructions exist in the middle of an area to be sprayed, mark

out and spray the area like a separate headland.

• The perimeter of the field should be sprayed first. The width of two swaths

will give adequate turning space at the ends of spray runs.

• Never spray while turning.

4. Speed

Maintain a constant speed when spraying. Should you need to increase your spraying

speed, larger delivery nozzles must be fitted. Re-calibrate as required.

5 6

Sprayer Decontamination and Maintenance

After use, the sprayer must be thoroughly decontaminated, inside and outside –

including pump, hoses, boom and hand lance, to avoid damage to crops from harmful

spray residues. Decontamination prevents sprayer corrosion and abrasion. As a guide

follow the decontamination procedure below.

• After spraying, rinse out the tank with several changes of water plus a

recommended cleaning fluid, brushing the inside of the tank.

• The suction filter mounted on the sprayer frame must be cleared regularly. Unscrew

the filter cover and remove the filter screen and gasket. Soak in clean water, brushing

with a nozzle brush. Ensure gasket is in position when re-assembling.

• The filter basket strainer is removed by lifting it out of the filter ring. Clean the

basket strainer the same way as the suction filler. Replace the basket strainer by

exerting a quick downward push ensuring the strainer has seated correctly.

• Nozzles, nozzle filters, nozzle caps and gaskets should be cleaned by soaking in

water, brushing with a nozzle brush and allowed to dry. Never blow through the

nozzles with your mouth nor use wipe or pins to clear any blockages.

When re-assembling, ensure that the nozzle cap gasket is correctly positioned

when reassembled.

When storing the sprayer, ensure that it is clean and dry and kept in a ventilated place.

If heavy frosts are experienced, run the pump to make sure pump and spray lines are

dry. This will prevent water freezing in the pump or spray lines and damaging sprayer.

All products are sold in accordance with our terms and conditions of sales of goods

dated 25.09.13. These terms and conditions can be found on our website. They are

also available upon request.

Calibration

Accurate calibration is an essential element of any spraying function as it ensures that

the pesticide is applied at the rate on the product label. Application in excess of the

recommended rate is prohibited, can damage crops and is uneconomical.

Calibration must always be carried out:

• When spraying for the first time with new spray equipment

• At the beginning of each season

• After changes of nozzle tips, spraying pressure or speed

• After every 100 hectares of spraying

When calibrating a sprayer, a minimum of coverall, gloves and boots must be worn.

A face shield and PVC apron may be included depending on the task and the cleanliness

of the sprayer.

1

2

3

7 8

Calibration Procedures

The following table gives a step by step guidance on the standard method of sprayer

calibration.

BOOM SPRAYERS HYDRAULIC NOZZLES EXAMPLE

Read the LABEL Spray VOLUME

Product Dose

Spray QUALITY

200 litres / hectare

50 litres / hectare

Medium

Measure TIME per 100 Metres Measure time in seconds over land

Similar to that to be sprayed

41.9 seconds

Calculate SPEED SPEED = 360 divided by TIME

Km/h in seconds

360/41.9 = 8.6km/h

Measure nozzle SPACING Normally 0.5 metres (50cm) 0.5 metre

Measure TIME per 100 Metres OUTPUT = VOLUME X SPEED X SPACE

÷600 Litres/min litres/hectare km/h

metre

As above; continue to wear PPE for clean up;

store unit in dry, well-ventilated area.

Select NOZZLE Refer to nozzle manufacturers data charts

or other sources and select the size and

type of nozzle that will produce the

calculated OUPUT and required spray

QUALITY

As above; continue to wear PPE for clean up;

store unit in dry, well-ventilated area.

This manual suits for next models

2

Table of contents

Other ENDURAMAXX Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Air Gunsa

Air Gunsa AZ3 HTE2 instruction manual

Parkside

Parkside PFS 400 A1 Translation of the original instructions

Solo

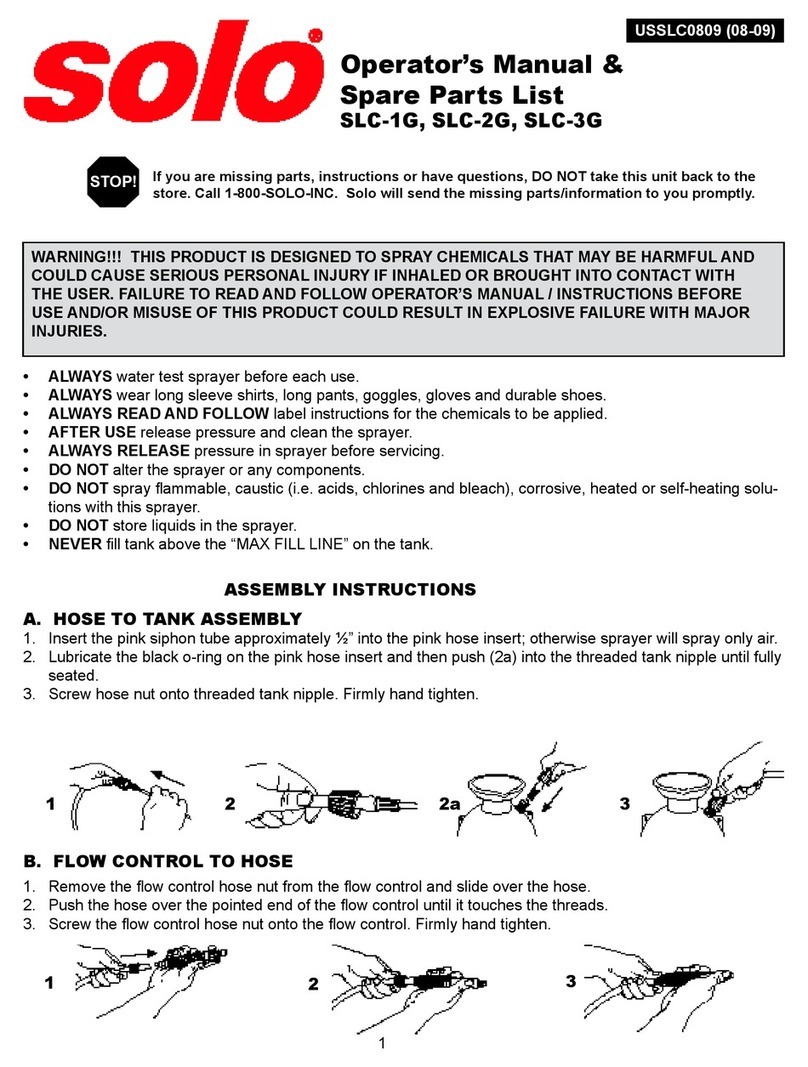

Solo SLC-1G Operator's manual & spare parts list

Graco

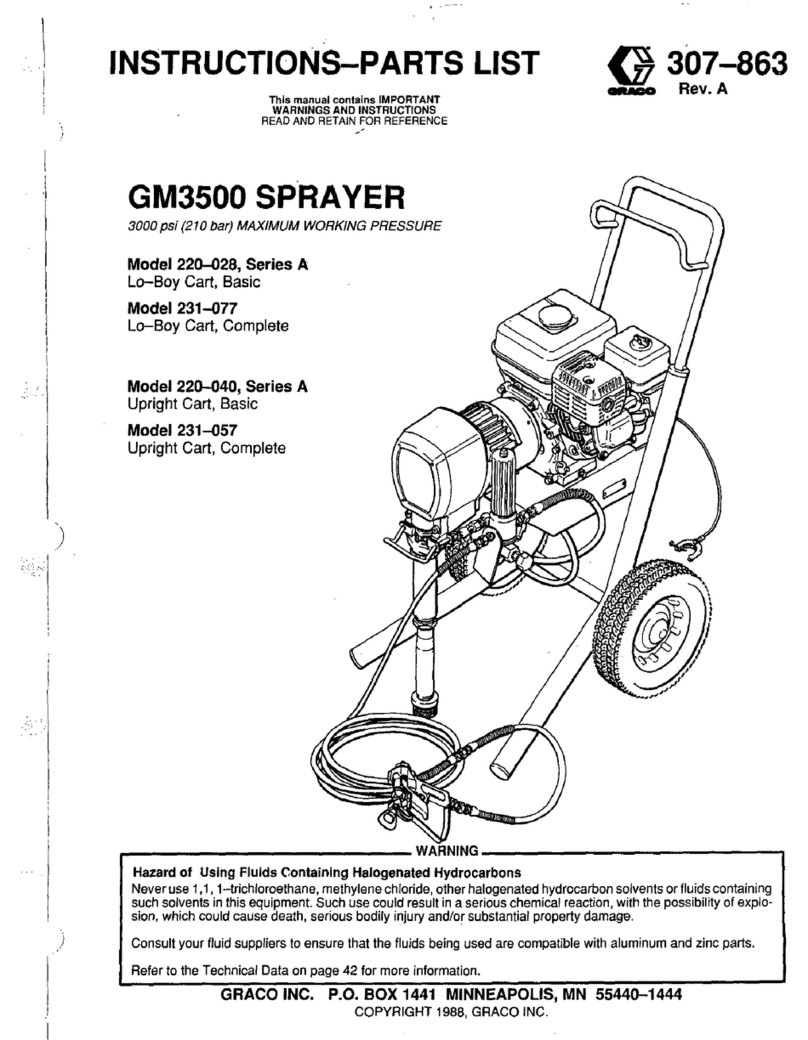

Graco 231-077 Instructions-parts list

C.A. Technologies

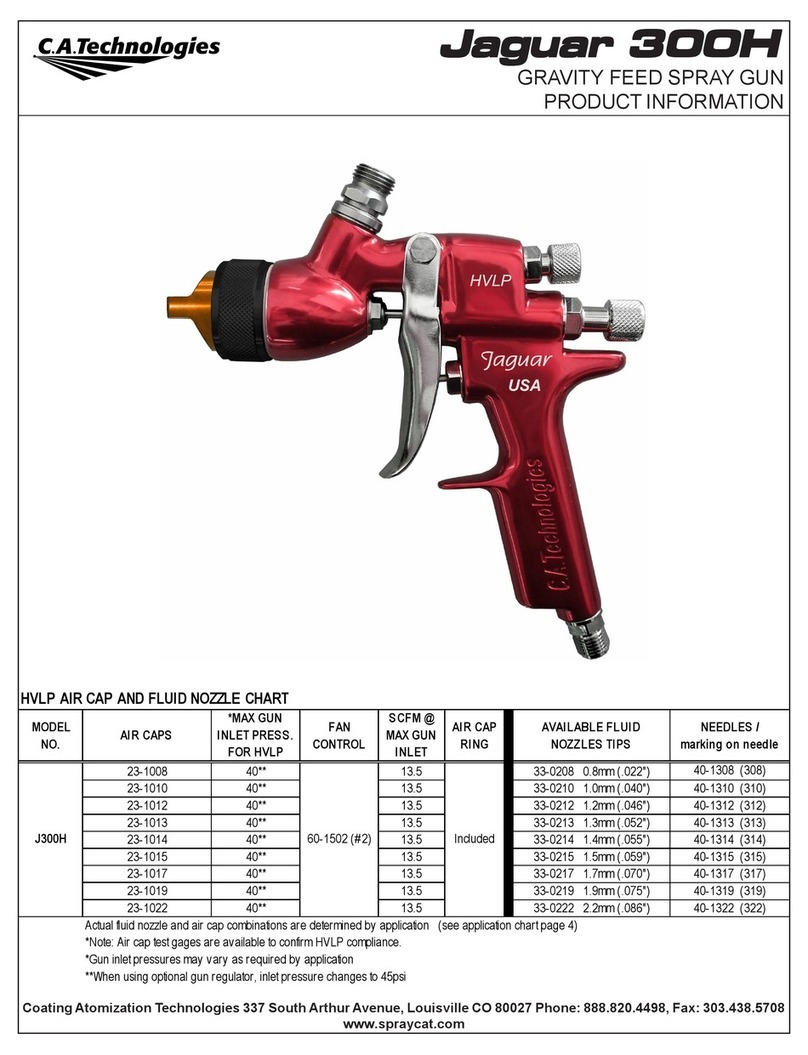

C.A. Technologies Jaguar 300H Product information

BorMann

BorMann PRO BBP4015 manual