ENEKA Greasly-A User manual

2

Free-standing Grease Separator

For room installation

Main parameters

Type :

Serial number :

Flow rate :

Client :

Installation place :

3

Table of Contents

1. GENERAL INFORMATION.....................................................................................5

1.1. Introduction.........................................................................................................5

1.2. Product description.............................................................................................5

1.3. Operation principle..............................................................................................5

1.4. Technical data ....................................................................................................6

2. MODELS ..............................................................................................................7

2.1. Model Base.........................................................................................................7

2.2. Model PRIMA......................................................................................................7

2.3. Model MIX...........................................................................................................8

2.4. Model PUMP.......................................................................................................8

2.5.

Component assemblies

........................................................................................9

2.6. Nameplate ........................................................................................................10

3. SAFETY..............................................................................................................10

3.1. Correct intended use.........................................................................................10

3.2. Staff ..................................................................................................................10

3.3. Electrical safety.................................................................................................10

3.4. Other safety precautions...................................................................................11

4. TRANSPORTATION...........................................................................................11

5. INSTALLATION..................................................................................................12

5.1. Selection of location..........................................................................................12

5.2. Assembly of components..................................................................................13

5.2.1. Inspection window........................................................................................13

5.2.2. Extraction pipe .............................................................................................13

5.2.3. Refilling unit..................................................................................................14

5.2.5. Grease alarm...................................................................................................15

5.2.6. Disposal Pump................................................................................................16

5.2.7. Control Panel for automatic operation (model Pump)......................................17

5.3. CONNECTIONS/SUPPLIES.............................................................................21

5.3.1. Inlet and outlet connections..........................................................................21

5.3.2. Pipeline insulation/heating ...........................................................................21

5.3.3. Sampling chamber.......................................................................................21

5.3.4. Ventilation ....................................................................................................22

5.3.5. Disposal line.................................................................................................22

5.3.6. Freshwater connection.................................................................................23

6. COMMISSIONING..............................................................................................23

6.1. Procedures .......................................................................................................23

4

6.2. Acceptance Report ...............................................................23

7. OPERATION.......................................................................................................23

7.1. Check................................................................................................................24

7.2. Disposal............................................................................................................24

7.3. Yearly maintenance..........................................................................................25

7.4. General inspection............................................................................................25

7.5. Service log........................................................................................................25

8. WARRANTY.......................................................................................................25

9. DECLARATION..................................................................................................26

5

1. GENERAL INFORMATION

1.1. Introduction

Dear customer,

We are pleased that you decided to purchase one of our products which will certainly

completely match your requirements. We wish you a smooth and successful installation and

operation. We try to keep our quality standards as high as possible therefore we are open for

your feedback on any possible improvements.

1.2. Product description

Grease separators described in this installation, operation and maintenance manual meet the

latest European regulations. GREASLY-A was designed according to EN 1825 and DIN 4040

standards. After treatment, the grease concentration shall not exceed 25 mg/l.

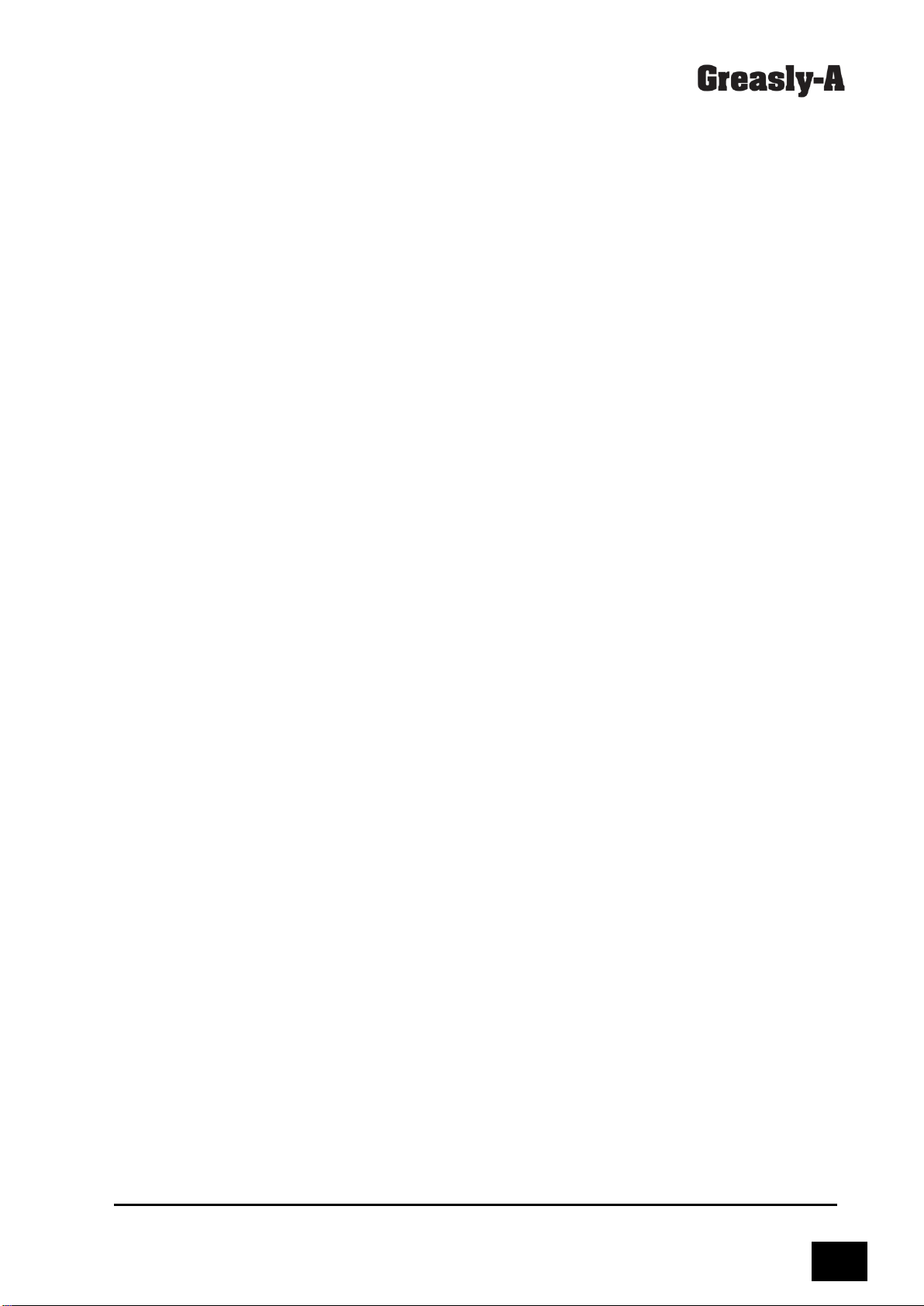

1.3. Operation principle

Figure 1. Operation of the Grease separator

Incoming greasy wastewater enters the grease separator through a unique inlet module which

creates the circular flow path. As water passes through the separator, grease particles, lighter

than water, are driven upwards by gravity and accumulated in the grease collection area on

the water surface. At the same time, solids and other impurities heavier than water settle to

sludge trap at the bottom of the tank. Treated water is discharged through the outlet pipe.

6

1.4. Technical data

Table 1. Technical data

Model

Flow

rate

l/s

Sludge

trap

volume,

litres

Grease

separation

volume,

litres

Grease

collection

volume,

litres

Total

volume,

litres

Dimensions mm

Weight kg, model

L

B

H

Base

Prima

Mix

Pump

Greasly-

2A

2

200

450

80

650

1940

700

1190

68

78

119

144

Greasly-

4A

4

400

450

160

850

1940

700

1430

81

91

132

157

7

2. MODELS

2.1. Model Base

Figure 2. Greasly-4A-BASE

Model BASE can be applied in areas where bad odour during maintenance is not causing any

inconvenience. Access cover shall be opened for disposal of accumulated grease and solids

by a vacuum truck.

2.2. Model PRIMA

Figure 3. Greasly-2A-PRIMA

Model PRIMA provides odour-free operation without the need for opening of the cover. The

separator is equipped with manual disposal system. Accumulated grease and sludge are

disposed throughthe Extraction pipe by a vacuumtruck. After complete disposal,the separator

is filled-up with fresh water through the Refilling unit.

8

2.3. Model MIX

Figure 4. Greasly-4A-MIX

Model MIX is equipped with Grease alarm is indicating when the maximum level of

accumulated grease is reached. Before emptying, Mixer actuated for blending grease, water

and solid layersthus facilitatingemptying of the separator. Aspecial Extraction pipe is provided

for the emptying of grease separator by the vacuum truck. After complete disposal, the

separator is filled-up with freshwater.

2.4. Model PUMP

Figure 5. Greasly-4A-PUMP

Model PUMP is equipped with an automatic program-controlled emptying system including a

Disposal pump. When the maximum level of accumulated grease is reached, grease sensor

activates the alarm. After connecting the hose to a disposal truck, the operator starts the

disposal procedure by pushing a START button in the control box or remote controller. First of

all, the mixer is turned on for blending grease, water and solid layers. Then the Disposal pump

9

is actuated for emptying of the separator. After complete disposal, the

separator can be rinsed (option) by partial filling the freshwater through the Refilling unit,

mixing and emptying by the Disposal pump. After rinsing, the separator is completely filled-up

with freshwater again.

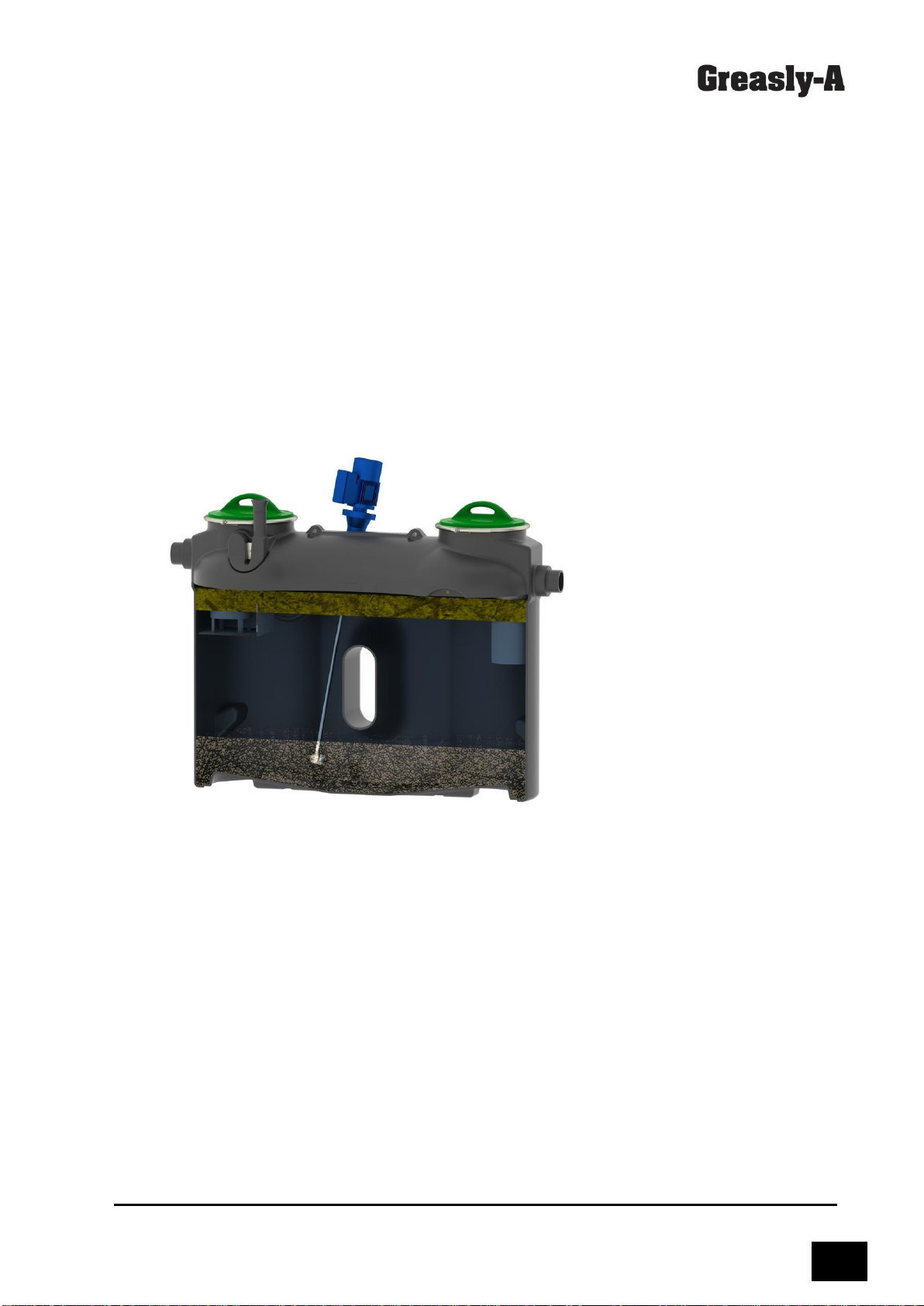

2.5.

Component assemblies

Model BASE / PIRIMA / MIX:

A - Separator body

B - Lid with locking ring and

gasket

C - Inspection window (Prima,

Mix)

D - Extraction pipe (Prima, Mix)

E - Manual Refi

lling unit (Prima,

Mix)

F - Mixer (model Mix)

G –Grease alarm (option)

Model PUMP:

A - Separator body

B - Lid with locking ring and

gasket

C - Inspection window

F - Mixer

G –Grease alarm

H –Control Panel

Y - Automatic Refi

lling unit

J –Disposal Pump

Figure 6. Components of

Greasly-A

10

2.6. Nameplate

Figure 7. Nameplate

3. SAFETY

3.1. Correct intended use

The Grease separator is intended only for separation of FOG (fats, oils & grease) of

vegetable or animal origin from wastewater. The use of the system for any other purpose

is not regarded as correct and the manufacturer is not liable for any damage resulting from

improper use; the responsibility is born by the owner/operator.

The correct intended use also includes adherence to assembly, commissioning, operating and

servicing conditions set out bythis manual. Forsafetyreasons, conversionworks atthe system

are not permitted.

The correct intended use also includes observing national laws and regulations.

The operatingmanual shall always be available at the location where theseparator is installed.

3.2. Staff

People who operate/or install the separator shall be of more than 18 years of age, shall have

been trained for the respective tasks, and shall follow the local safety regulations. The owner

of the system shall ensure that only qualified staff work on the grease separator.

3.3. Electrical safety

Note: All electrical connections shall be carried out by a qualified contractor.

The electricalinstallation shall comply withthe specifications accordingto European standards

EN1012 and EN60 204.

Before the maintenanceof any electrical component (mixer/disposal pump/Automatic Refilling

unit, Grease alarm) the electrical supply shall be turned off.

In case of smoke or strange sounds appear, immediately switch-off the separator from the

power supply.

11

3.4. Other safety precautions

Never take off the covers while operation.

Do not disassemble or turn off safety components.

Do not leave any hard objects and tools that can block free access to the separator.

During cleaning work, greasy liquid and/or grease can wet the floor. This results in a slipping

hazard. Always eliminate any liquid and/or grease that has leaked immediately, and wear

suitable footwear.

The wastewater contains bacteria. Any parts of the body which come into contact with

wastewater shall be cleaned immediately, change soiled clothing. Wear personal protective

equipment.

Blocked pipelines may cause a pressure rise which may damage the system and harm to

maintenance personnel. While disposal of the system, ensure good ventilation to avoid the

building of vacuum inside of separator which may cause the damage of the separator body.

4. TRANSPORTATION

Following rules shall be kept during transportation:

Normally, the system is supplied completely mounted and fixed on a wooden pallet and

wrapped in a foil.

The capacity of the forklift truck / any other lifting equipment shall exceed the weight of the

separator.

When lifting the separator, the ropes/chains must be attached only to the appropriate lifting

lugs.

If ropes/chains are touching the body of the separator, the extra soft spacers are needed to

keep body undamaged.

While lifting and transporting it is necessary to avoid the active shaking of the separator.

Transportation protections that are mounted on the device can be removed only when the

separator is in its working space.

12

5. INSTALLATION

5.1. Selection of location

Figure 8. Example of installation

Grease separators shallbe installed close to the source of wastewater. Do not site the systems

in unventilated rooms, on roads, car parks or in storage areas. The separators shall be easily

accessible to cleaning vehicles.

Before installation of grease separator following conditions shall be checked:

- The room shall be protected from frost (recommended temperature >15 °C).

- The room shall be well vented/ventilated.

- The floor shall be a horizontal, rigid surface capable of bearing an appropriate load.

- The floor shall be equipped with an integrated drain.

- To prevent bad odour, separators shall not be sited close to residential buildings, close

to windows and air intakes.

- The installation location of the separator shall have sufficient light.

- Separator shall be easily accessible to vacuum vehicles.

- Space shall be sufficient for the maintenance. Room height shall be 60 cm higher than

grease separator to enable the opening of the covers during the maintenance. Free space of

1 m in front of separator shall be available.

- Cold and hot water connections available.

- Inlet pipe with stilling section of min. 1 m available.

- The inlet and outlet pipelines shall have a gradient of 2%.

- If the inlet pipe is longer than 10 m it shall be equipped with a separate vent.

13

5.2. Assembly of components

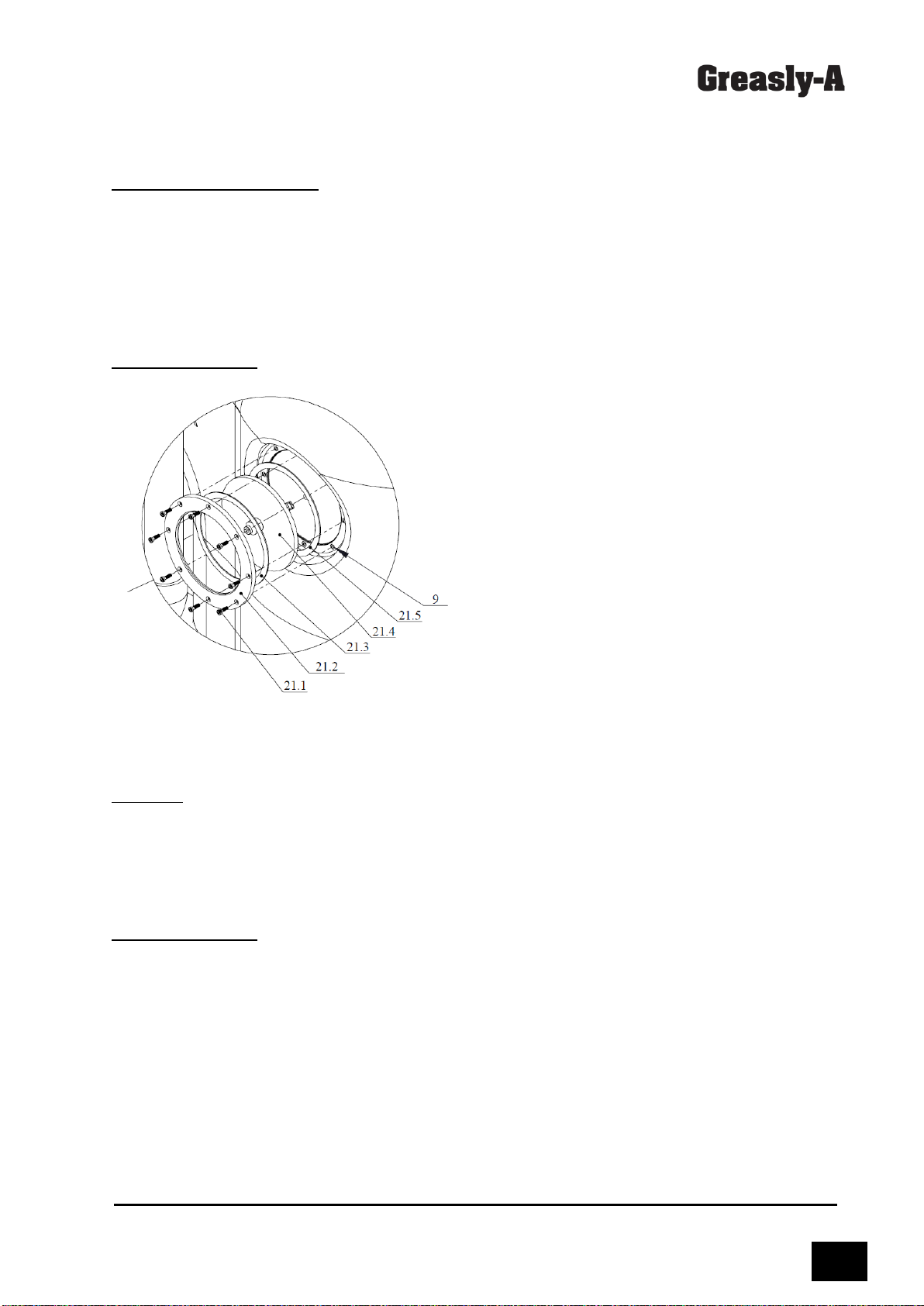

5.2.1. Inspection window

Package (please see fig.9):

- 1 pc Window with wiper no. 21.4

- 1 pc Flange no. 21.2, material stainless steel

- 1 pc Gasket between flange and window no. 21.3 (C4400 material)

- 1 pc Gasket between window and separator body no. 21.5 (rubber material)

- 8 pcs Screws M6 no. 21.1

Special tools required: Ø 177 mm drill crown

Installation process

Figure 9. Installation of inspection window

Select the side for installation of inspection

window depending on the layout of the

system and inlet and outlet pipes in the room.

Cut an opening using a drill crown of Ø177

mm diameter. The inspection window is to be

placed in the following order: 1) rubber

gasket, 2) window with a wiper; 3) C4400

gasket; 4) Flange.Tighten the flange with the

screws.

5.2.2. Extraction pipe

Package:

- 1 pc Extraction pipe DN65, polyethylene

- 1 pc Rubber coupling ø75 mm

- 1 pc Pipe bracket 2½”

Special tools required: Ø 65 mm drill crown

Installation process

14

5.2.3. Refilling unit

Package:

- 1 pc Siphon no. 23.1

- 1 pc Siphon retainer no. 23.2 with screw M6 no. 23.7

- 1 pc Manual ball valve DN20 no. 23.4

- 1 pc Valve holder no. 23.3 with screw M8 no. 23.5 and bracket 23.8

- 1 pc Solenoid valve no. 23.10 (model Pump only)

- 1 pc Gasket DN50/65 NBR no. 23.9

Special tools required: Ø 70 mm drill crown.

Installation process

2 locations for connection of the

Refilling unit are available on both

sides of the separator. Cut the opening

at the market area by a Ø70 mm drill

crown. Insert a rubber gasket into the

opening and attach a siphon. Tighten

the siphon to the separator housing

from by stainless steel retainer plate

and a screw. Do not apply too much

force. Install the valves to their holder.

Attach the metal bracket is attached to

the siphon neck and tighten the valve

holder by the screw.

Figure 11. Fitting of Refilling unit

Figure 10. Extraction pipe and rubber coupling

Drill an opening of Ø65 mm using a

drill crown in thenozzle at the bottom

of the unit. Attach the extraction pipe

by the rubber coupling to the nozzle,

and tighten the metal clamps

15

5.2.4. Mixer

Package:

- 1 pc Mixer with motor

- 4 pcs Screw M12

- 1 pc Gasket

Special tools required: 32 mm drill

Installation process

The mixer shall be installed at the

top of the tank. Drill an opening by

the drill bit of 32 mm diameter, the

center is marked. Place the gasket

between the tank body and the

mixer’s flange. Tighten the flange to

the separator body with 4 bolts. Do

not apply too much force.

Figure 12. Fitting of Mixer

5.2.5. Grease alarm

Package:

- 1 pc grease alarm type GA-1 (panel and sensor)

- 2 pcs bracket for the alarm unit

- 2 pcs screws M6 & 4 pcs screws M4

Installation process

The grease alarm panel is to be fitted to the bracket which is attached to the separator body.

Tighten two metal brackets to the housing by 2 screws M6 provided. Fit the panel to the

brackets by 4 crews M4.

Drill a ø12 mm opening for the sensor cable on the top of the separator body in the area as

indicated in figure 13. Route the cable through the cable duct. Screw the cable duct to the

separator wall. The sensor is to be suspended at the height of 150 mm below the static water

level i.e. the bottom of the outlet nozzle.

Electrical connections of Grease alarm shall be installed according to figure 13.

16

Figure 13. Installation of Grease alarm

5.2.6. Disposal Pump

Package:

1 pc Heavy-duty disposal pump with Vortex impeller, motor 2,2kW 400V 50Hz

1 pc Gate valve DN65

1 pc Suction pipe DN65, PE

1 pc Rubber coupling ø75 mm with 2 clamps

1 pc Double flanged pipe DN65, cast iron

1 pc Pipe adapter DN50/65

Installation process

•The disposal pump unit (pump with motor, double flanged pipe, adapter) is supplied

completely assembled.

•Drill an opening of Ø65 mm using a drill crown in the nozzle at the bottom of the tank.

•Place the disposal pump on a rubber anti-vibration matt.

•Attach the suction pipe by the rubbercoupling tothe tank, and tightenthe metalclamps.

•Connect the suction pipe and gate valve to the double flanged pipe.

17

•Bolt the pump to the floor.

Figure 14. Fitting of Disposal Pump

5.2.7. Control Panel for automatic operation (model Pump)

Package:

- 1 pc Control Panel

- 1 pc Remote controller (option)

Installation process

•Attach the control panel to the wall in an easily accessible area.

•Connect the power supply, cables to a mixer, disposal pump, solenoid valve and

remote controller to the marked terminals and according to the wiring diagram (fig.

15).

18

Figure 15. Wiring diagram

19

Operation

After connecting the hose to a disposal

truck, the operator starts the disposal

procedure by pushing a START button in

the control box or remote controller.

Disposal steps:

- Mixing for a preset time.

- Emptying by the disposal pump.

- Rinsing (optional), i.e. partial filling

with freshwater and emptying.

- Complete filling with freshwater.

During operation, the control panel

monitors the current used by the mixer

and pump motors and compares it with a

preset rated current. If the current is too

low, the "dry run" is recorded, if it is too

high, the overload is recorded. In both

cases, the motor will be switched off.

In case of an emergency, the process can

be stopped by pressing the Red / STOP

button.

Fig. 16. Control panel and remote controller

Standby mode

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

Y

S

T

E

M

R

E

A

D

Y

2

M

I

X

E

R

O

F

F

I

:

1

,

5

A

3

P

U

M

P

O

F

F

I

:

7

,

5

A

4

W

A

T

E

R

O

F

F

2nd row: indication of the preset current of a mixer motor.

3rd row: indication of the preset current of a pump motor.

Indication after START

a) Mixing cycle

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

T

A

R

T

T

I

M

E

0

:

2

0

T

M

3

0

2

M

I

X

E

R

O

N

T

0

:

1

5

T

M

2

0

3

P

U

M

P

O

F

F

4

W

A

T

E

R

O

F

F

1st row: Disposal period after the start. TM –preset time of all disposal steps.

2nd row: Time in reverse mode from the beginning of the mixing cycle until the preset time

TM.

20

b) Emptying cycle

The disposal pump is running. At the end of the emptying cycle, the solenoid valve is opened

to supply the freshwater and to facilitate the complete emptying. The pump is switched off

when the consumption of electrical current is decreasing after complete emptying of the

separator contents.

3rd row:

Time in

reverse mode from the beginning of the Emptying cycle until the preset time TM.

4th row: Time in reverse mode from the opening of the solenoid valve until the preset time TM.

c) Rinsing cycle (option)

The separator is filled up to half of its volume with freshwater by opening the solenoid valve of

the refilling unit. Then the water is emptied.

Partial filling

4th row: Time in reverse mode from the opening of the solenoid valve until the preset time TM.

Emptying

3rd row:

Time in

reverse mode from the beginning of the Emptying cycle until the preset time TM.

e) Filling cycle

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

T

A

R

T

T

I

M

E

0

:

2

5

T

M

3

0

2

M

I

X

E

R

O

F

F

T

M

2

0

3

P

U

M

P

O

F

F

T

M

1

0

4

W

A

T

E

R

O

N

T

0

:

1

2

T

M

1

5

Settings

The grease separator is supplied with the factory settings. If necessary, the setting can be

modified with the rotary knob SET. The SET knob has two control functions. The seting is

selected by pressing the knob. The value of the parameter is reduced by turning the knob

counterclockwise and increased by turning it clockwise.

1 - Start

By pressing the rotary knob, the disposal cycle is started (the same as after pressing the start

button).

2 –Manual

In the manual mode, each device can be turned on and off.

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

T

A

R

T

T

I

M

E

0

:

2

5

T

M

3

0

2

M

I

X

E

R

O

F

F

T

M

2

0

3

P

U

M

P

O

N

T

0

:

1

5

T

M

1

0

4

W

A

T

E

R

O

N

T

0

:

5

T

M

8

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

T

A

R

T

T

I

M

E

0

:

2

5

T

M

3

0

2

M

I

X

E

R

O

F

F

T

M

2

0

3

P

U

M

P

O

F

F

T

M

1

0

4

W

A

T

E

R

O

N

T

0

:

1

2

T

M

8

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

S

T

A

R

T

T

I

M

E

0

:

2

5

T

M

3

0

2

M

I

X

E

R

O

F

F

T

M

2

0

3

P

U

M

P

O

N

T

0

:

1

5

T

M

1

0

4

W

A

T

E

R

O

N

T

0

:

5

T

M

8

This manual suits for next models

7

Table of contents

Popular Water Filtration System manuals by other brands

Nimbus Water Systems

Nimbus Water Systems Cascade NS-14 Owner's manual and installation guide

EFI

EFI DPF12015R Instruction bulletin

Celestron

Celestron ECLIPSMART 94248 manual

Oase

Oase BioSmart 5000 operating instructions

Zenith

Zenith Filter Tap Installation and operating instructions

Goldine Controls

Goldine Controls Pro Logic PL-P-4 installation manual

Aquasana

Aquasana Claryum 2-Stage owner's manual

Esta

Esta VACUMAT 1000 operating instructions

Lucent Technologies

Lucent Technologies AnyMedia PFU500 manual

Culligan

Culligan AQUA-CLEER BXL Series Installation and operating instructions

urmet domus

urmet domus Agora 1372 Installation sheet

Gow-Mac

Gow-Mac 75-850-BV operating manual