Esta VACUMAT 1000 User manual

Operating Instructions

VACUMAT

Fan Unit

VACUMAT 1000 (order no.: 07100)

VACUMAT 2200 (order no.: 07220)

and variations

Do not use this product unless you have

read the operating instructions and understood them.

Original operating instructions

07220-08-03

Edition notice

Original operating instructions

Document no.: 07220-08-03

Publishing date: 04/10/2016

Model: VACUMAT fan unit

Article no.: 07100 // 07220 // and variants

Publisher

ESTA Apparatebau GmbH & Co. KG Tel.: +49 (0) 73 07 80 4 -0

Gotenstr. 2-6 Fax: +49 (0) 73 07 80 4 -500

Germany www.esta.com

Copyright notice (per DIN ISO 16016:2007-12)

Transfer or reproduction of this document, or the use or communication of its content, is forbidden

without explicit consent. Violators will be liable for damages. All rights to patent, utility or design

registration are reserved.

07220-52-03

VACUMAT fan unit

3

Table of contents

Table of contents...................................................................................................................3

1General instructions........................................................................................................4

1.1 Target group.............................................................................................................4

1.2 Tips ..........................................................................................................................4

2Product identification......................................................................................................5

2.1 Technical Data .........................................................................................................5

2.2 Intended application.................................................................................................6

3Product description.........................................................................................................8

3.1 Product illustration VACUMAT 1000 / 2200 active carbon filter................................8

3.2 Functional description ..............................................................................................9

4Safety..............................................................................................................................10

4.1 Hazard categories..................................................................................................10

4.2 Symbol explanation................................................................................................10

4.3 General safety instructions.....................................................................................12

4.4 Preventing mechanical hazards .............................................................................12

4.5 Preventing electrical hazards .................................................................................13

4.6 Preventing dust hazards.........................................................................................15

5Delivery and commissioning........................................................................................16

5.1 Delivery and transport ............................................................................................16

5.2 Connection.............................................................................................................17

5.3 Function check.......................................................................................................19

5.4 Commissioning.......................................................................................................20

5.5 Suction line connection ..........................................................................................20

5.6 Troubleshooting during commissioning..................................................................21

6Operating instructions..................................................................................................22

6.1 Control panel..........................................................................................................22

6.2 Operate product .....................................................................................................22

7Maintenance & troubleshooting...................................................................................23

7.1 Maintenance instructions........................................................................................23

7.2 Inspection and maintenance intervals ....................................................................24

7.3 Detaching the filter mat outlet element...................................................................26

7.4 Detaching the filter mat active carbon filter ............................................................27

7.5 Replace active carbon filter....................................................................................28

7.6 Clean product.........................................................................................................30

7.7 Store product..........................................................................................................30

7.8 Eliminating faults....................................................................................................30

8Disposal .........................................................................................................................32

8.1 Dispose of product .................................................................................................32

9EC/EU Declaration of Conformity.................................................................................33

Notes.....................................................................................................................................34

Notes.....................................................................................................................................35

4

VACUMAT fan unit

07220-52-03

1 General instructions

1.1 Target group

These instructions are intended for

Skilled warehousing and logistics personnel responsible for transport

Operators trained on the product who are familiar with the extraction

process,

service, cleaning and maintenance staff trained on the product.

Trained electrical specialists.

1.2 Tips

Before operation, all persons who are to use the product or perform maintenance

on it must be provided with information, instructions and training in using the

product and on the substances for which it is to be used, including the procedure

for safe disposal of the collected material. Responsibilities must be clearly

established for the following

Installation

Commissioning

Operation

Maintenance and repairs

Read the instructions carefully before working with the product.

The product may only be used by persons who have been instructed in its handling

and are explicitly authorised to use it.

Always keep the instructions at the place where the product is being used, so that

they can be seen by personnel at all times.

These instructions describe the product at the time of first delivery following

manufacture.

Keep the documents throughout the product's service life.

Pass these and other supplementary documents on to any subsequent

owners or users.

Add all changes to the documents that they obtain.

Check the completeness of the documents and pay attention to their content.

07220-52-03

VACUMAT fan unit

5

Further documents are available on top of these instructions. You can request any

documents required from ESTA.

Where applicable, instructions on optional equipment

2 Product identification

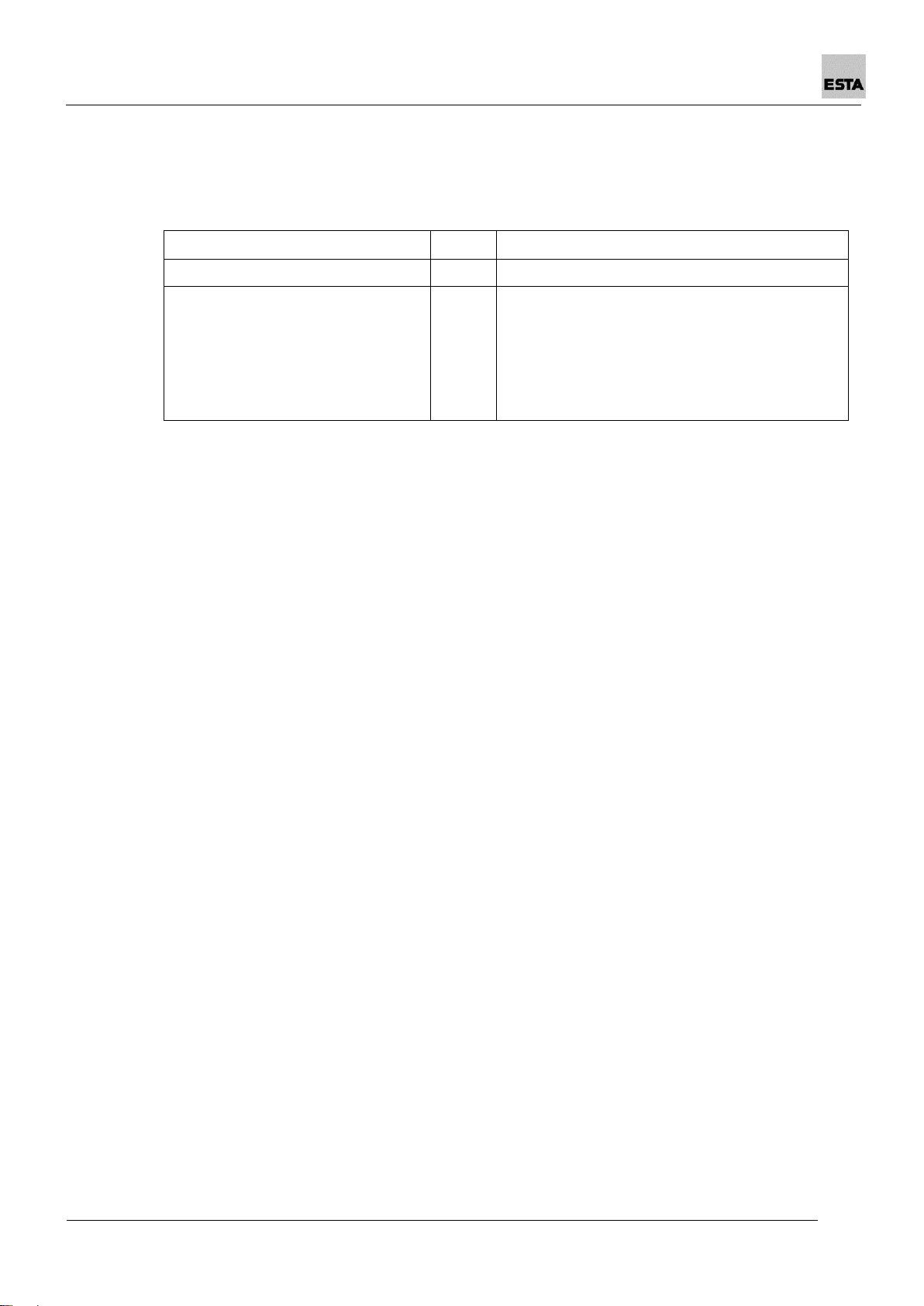

2.1 Technical Data

We reserve the right to make technical changes

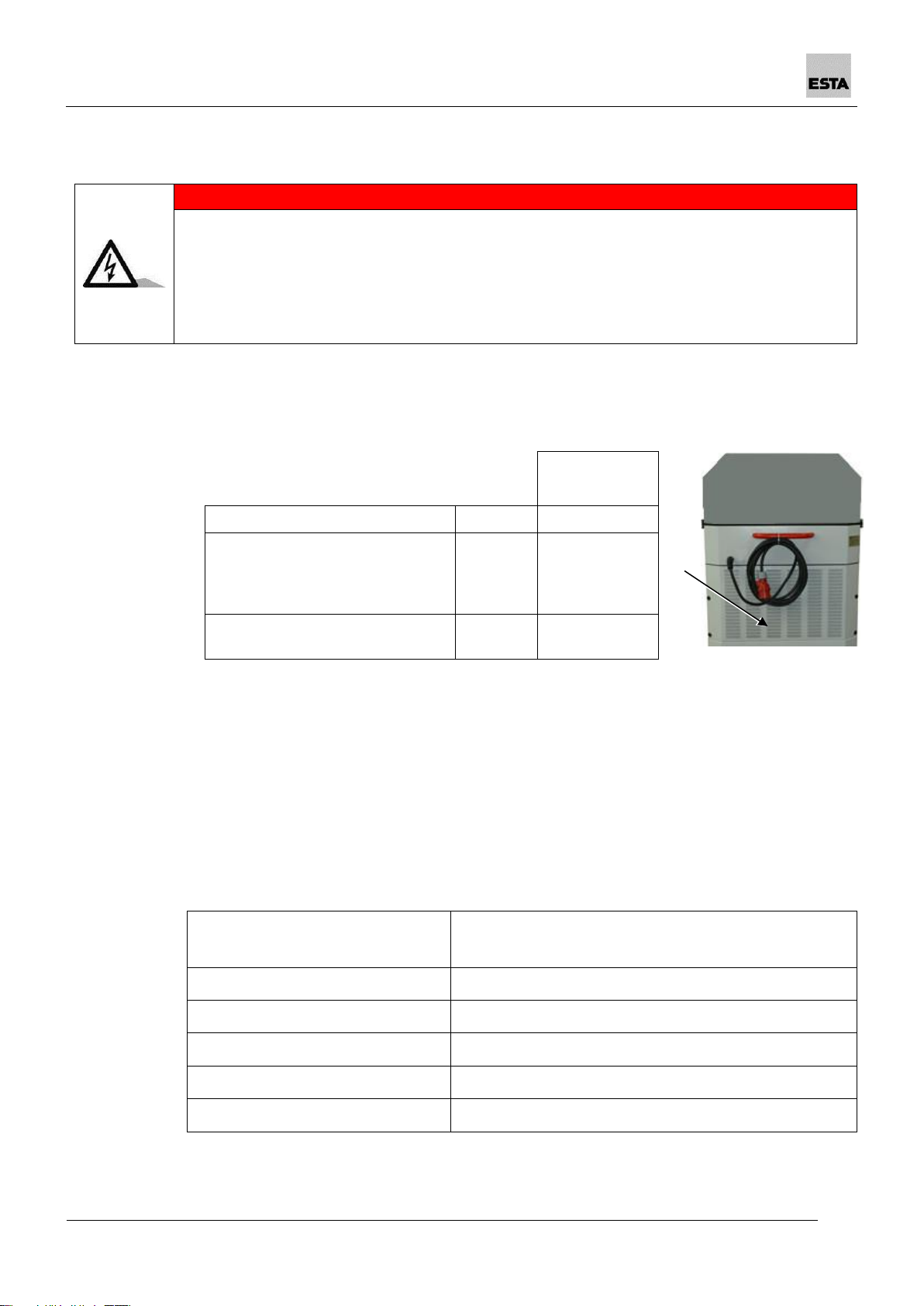

Item no.

07100

07220

VACUMAT type

1000

2200

Drive power

[kW]

1.1

2.2

Connection voltage

[V]

400

Nominal frequency

[Hz]

50

Nominal current

[A]

2.4

4.5

Circuit breaker

[A]

16 (circuit breaker)

Protection class

IP 54

Max. vacuum

[Pa]

1,250

2,550

Max. volume flow

[m³/h]

1,010

2,250

Filter class

F9

average sound pressure level LpA*

[dBA]

62

71

Dimensions L x W x H

(incl. filter unit)

[mm]

1,050 x 800 x 1,330

Weight of active carbon filter

[kg]

30

Dimensions of active carbon filter

[kg]

25

Total weight (including filter unit)

[kg]

215

218

Production year

See model plate

* using the enveloping surface method DIN EN ISO 3744, measured at minimum volume flow; noise measurement margin

of error approx. 4 dBA

** Custom voltage on request

6

VACUMAT fan unit

07220-52-03

2.2 Intended application

2.2.1 Ambient conditions

Ambient temperature

[°C]

540

Rel. humidity

[%]

30 - 70

min. spatial requirement around the

product

Operator's side (front)

Inlet

Outlet

Rear

Top

[mm]

1,000

1,000

1,000

500

1,000

2.2.2 Intended use

The product has been manufactured based on state-of-the-art technology and

according to recognized safety regulations and must be used as intended:

as central extraction system for environmental pollutants and noxious

odours,

for commercial use, such as in industrial enterprises and workshops,

for extraction in individual workplaces.

Only for dry cleaning.

Other applications are considered unintended use. ESTA is not liable for damages

due to unintended use!

07220-52-03

VACUMAT fan unit

7

2.2.3 Improper use

The product has been manufactured according to the state of the art and

recognized safety regulations. Unintended use may cause hazards.

Therefore:

Do not use or store outdoors or in wet conditions.

Do not change the location of the product during suction operation.

Do not set up or operate in dust/gas-explosive areas.

Do not use in painting operations.

Do not connect to processing machines that may produce active ignition

sparks or hot embers.

Do not suck up liquids.

Do not suck up aggressive gases.

Do not suck up any readily flammable or glowing particles.

Do not suck up dusts and particles.

2.2.4 Reasonably foreseeable misuse

Do not suck up hot embers, such as cigarette butts.

Do not cause complete closure of the suction openings.

8

VACUMAT fan unit

07220-52-03

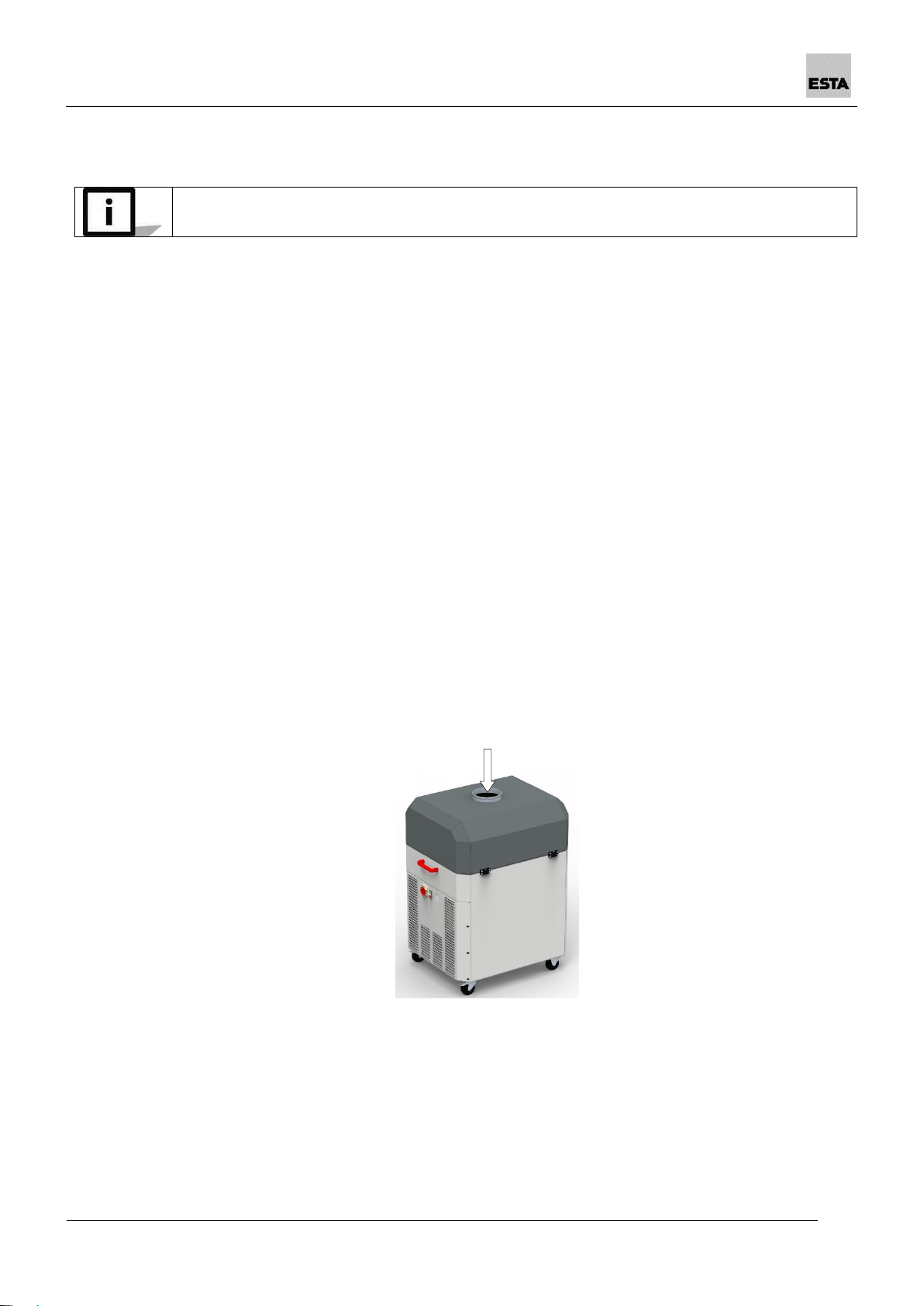

3 Product description

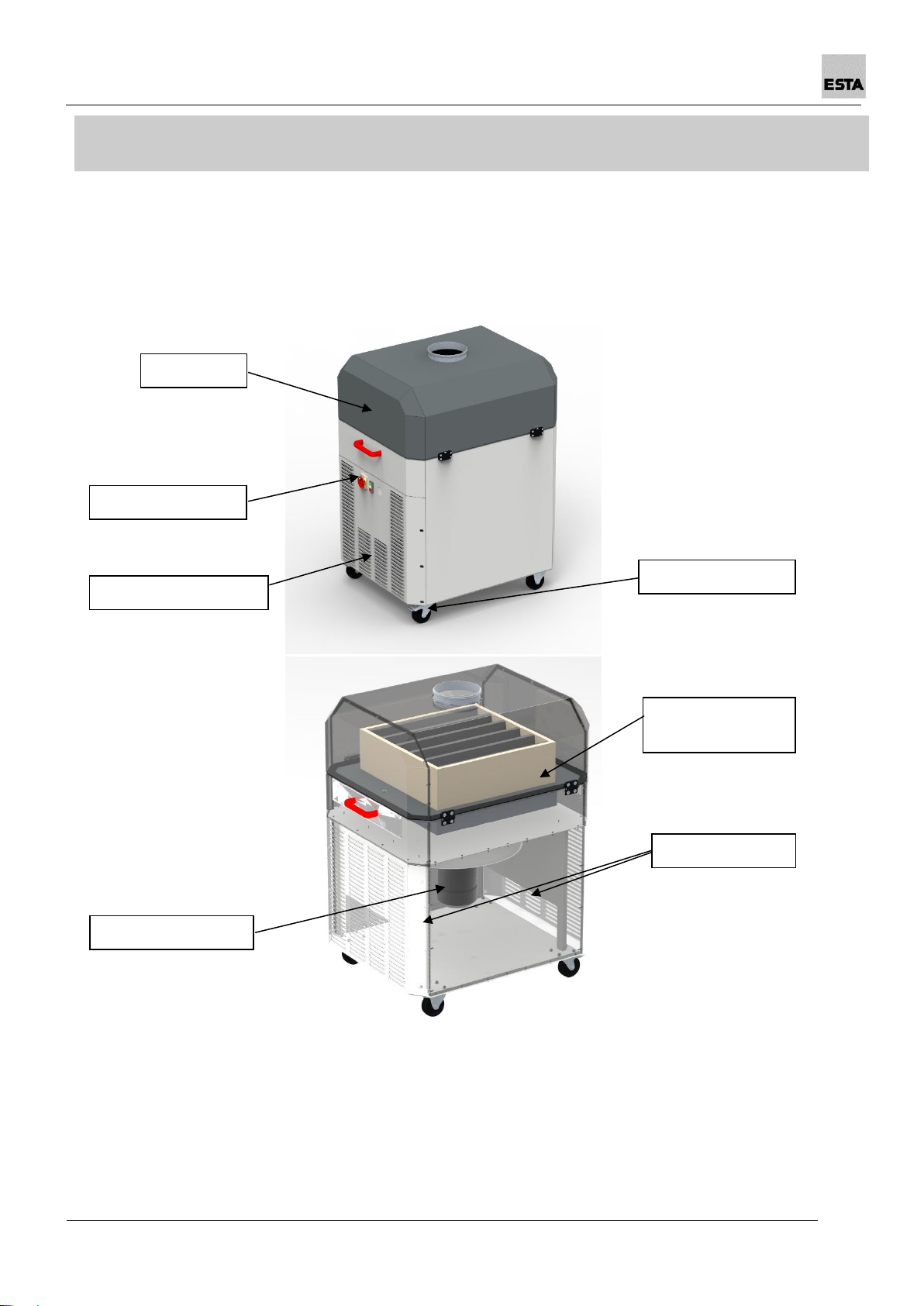

3.1 Product illustration VACUMAT 1000 / 2200 active carbon filter

Control panel

Cover

Outlet element

Fan unit

Filter mats

Active carbon

filter

Locking castor

07220-52-03

VACUMAT fan unit

9

3.2 Functional description

The product is equipped with a three-phase motor which drives a radial fan. The

product is supplied with or disconnected from the requisite power via a main switch.

The fan is turned on and off via the control panel. The operating hourscounter serves

for orientation for filter change and maintenance intervals.

Due to the negative pressure produced by the fan, air is sucked in through the active

carbon filter unit. This separates the odours and pollutants located in the air which is

sucked in. The purified air is guided back into the room through the outlet openings

on the exhaust air grilles.

10

VACUMAT fan unit

07220-52-03

4 Safety

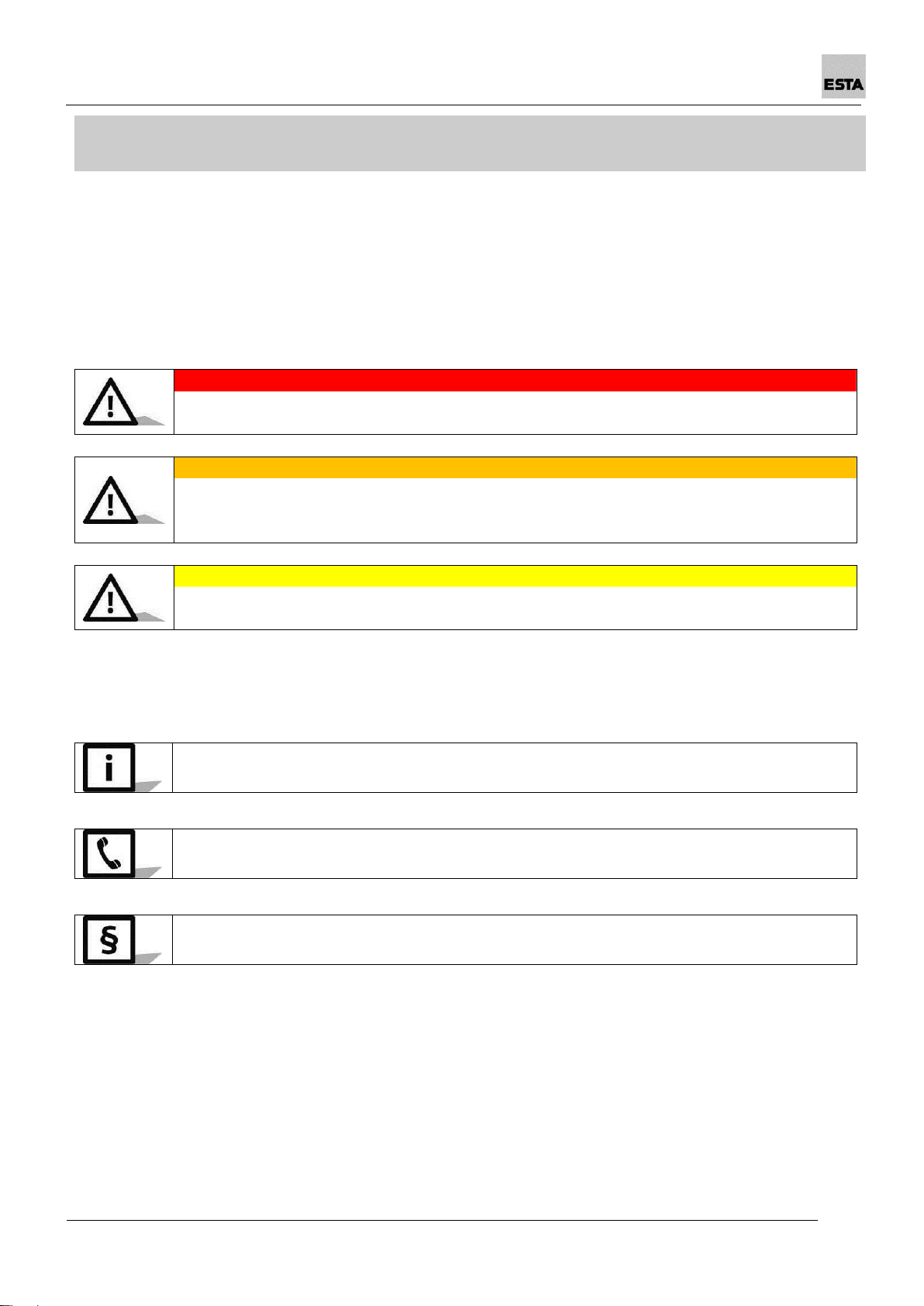

4.1 Hazard categories

Safety instructions and cross-topic information are indicated in this manual by

symbols.

Based on the severity of the hazard, the hazard warnings are categorized as

follows:

DANGER

Hazard warning about an immediate danger to people.

Failure to comply can lead to severe injury or death.

WARNING

Warning about a recognisable hazard.

Failure to comply can lead to severe injury or death, and can destroy the product

or parts of it.

CAUTION

Instruction about a hazard.

Failure to comply can lead to slight injury and to damage to the product.

4.2 Symbol explanation

Further information

Reference to ESTA customer service

Reference to legal regulations

07220-52-03

VACUMAT fan unit

11

4.2.1 Symbols on the product

Before commissioning, read and observe the operating instructions and safety

instructions (per ISO 11684)

Do not take in glowing dust or other sources of ignition. Do not use in

conjunction with spark-generating machinery.

Warning of hand injuries (as per BGV A8 W27)

Type plate:

12

VACUMAT fan unit

07220-52-03

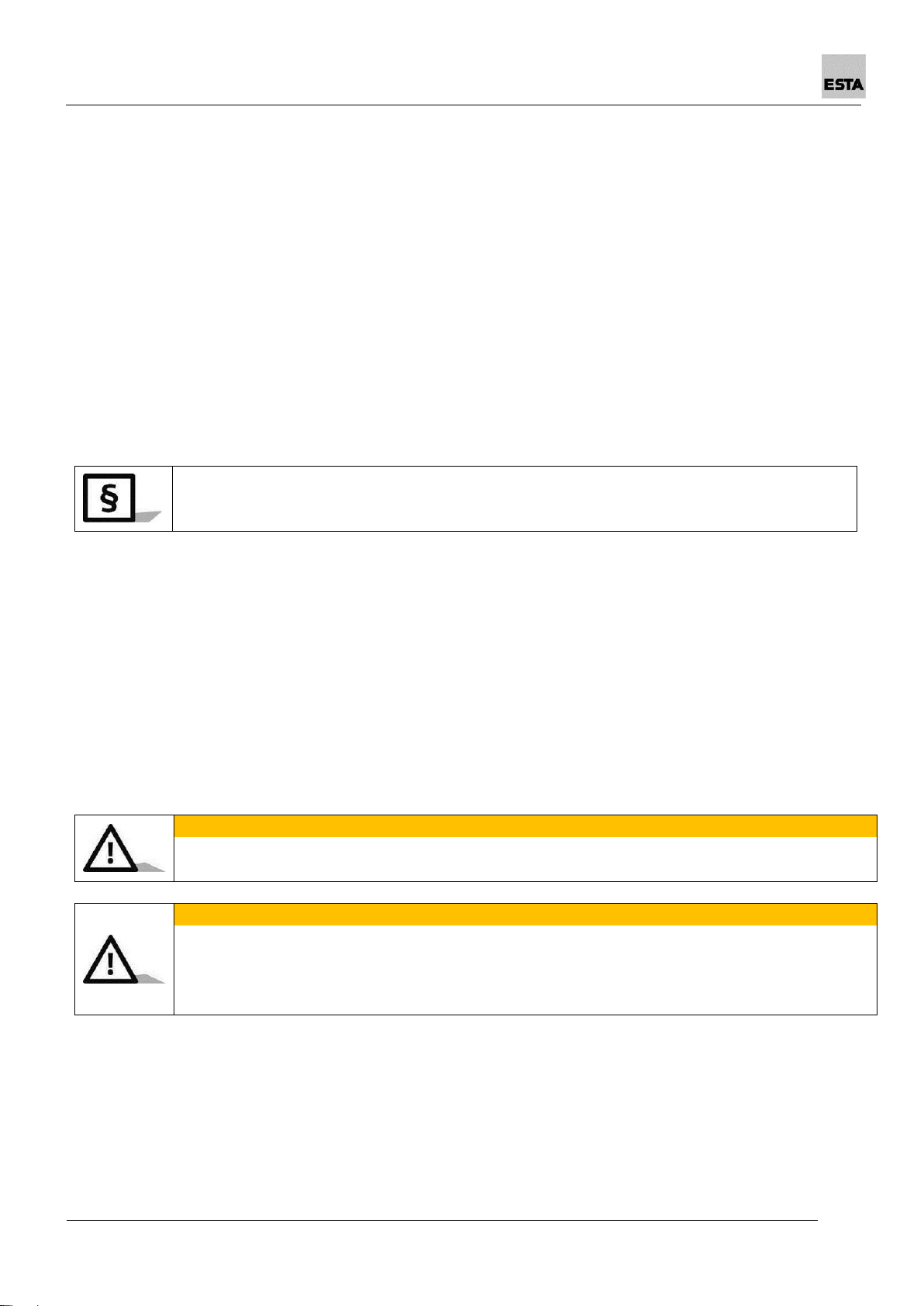

4.3 General safety instructions

During extraction, the volume flow returned from the product into the room should

be no more than 50% of the air supplied. With open room ventilation, supply air

flow should be assumed as equal to the room volume every hour. This means that

the rate of air replacement must be once per hour.

Supply air flow [m³/h] = room volume [m³] air replacement rate [1/h]

Example:

When the product is operating at the nominal airflow volume of 1,060 m³/h, the

same volume of fresh air must be fed in. This occurs with natural ventilation if the

volume of the work room is 1,060 m³ (e.g., 353 m² surface with a 3 m ceiling

height).

According to work equipment user directives 2009/104/EG and TRGS 560,

safety devices for prevention or removal of hazards must be regularly maintained

and regularly inspected by an expert for safe, flawless operation.

In all emergencies, the product must be disconnected from the power supply

immediately, turned off at the main switch and the plug pulled immediately.

If there is a fire, alert the fire department immediately, and contain the fire by

appropriate means. Therefore keep a suitable extinguishing agent near the

product before start-up and during operation.

4.4 Preventing mechanical hazards

WARNING

Crushing hazard due to loose or open covers during operation

Keep covers tightly closed during operation!

WARNING

Risk of falling due to improper handling of the lifting device.

Always pay attention to the local accident prevention regulations.

The lifting device protrudes from the product when at rest.

Do not stand on the lifting device.

All movable machine parts driven by electric motors must be covered by fixed,

securely fastened protective covers that can be removed only with tools.

07220-52-03

VACUMAT fan unit

13

CAUTION

Injuries from spontaneous movement by running over and crushing

Wear personal protective equipment. (safety shoes)

Do not place the product on a sloping surface.

Always make sure that the castor’s lock is activated during placement.

Make sure that the surface can be driven on, is level and sufficiently load

bearing.

Watch out for pipe or hose connections and other valves, or disconnect if

required.

CAUTION

Risk of tipping over when moving the product with the filter unit lid open.

Keep the filter unit lid closed when moving.

CAUTION

Risk of spontaneous movement due to unsuitable floor

Make sure that the surface can be driven on, is level and sufficiently load

bearing.

4.5 Preventing electrical hazards

DANGER

Electric shock from high voltages

Follow the safety rules for working with electrical products!

Secure the product against reactivation with a padlock!

Render the product voltage-free by pulling the mains connector!

Any work on the electrical grid and on voltage-conducting parts may only

be performed by an electrical specialist.

DANGER

Electric shock from high voltages when power cable is damaged

Do not damage by running over, crushing, straining, etc.

Regularly check the power cable for damage and ageing.

Do not use if damage has been found on the power cable!

Any work on the electrical grid and on voltage-conducting parts may only

be performed by an electrical specialist.

Use only original ESTA replacement parts.

14

VACUMAT fan unit

07220-52-03

DANGER

High-voltage electric shock when working on the running product

Turn off at the main switch and secure with a padlock against reactivation!

Render the product voltage-free by pulling the mains connector!

Any work on the electrical grid and on voltage-conducting parts may only

be performed by an electrical specialist.

DANGER

Residual hazard from loose or open covers

Keep covers closed during operation!

Any work on the electrical grid and on voltage-conducting parts may only

be performed by an electrical specialist.

All electrical parts must be covered by fixed, securely fastened protective covers

that can be removed only with tools. The product complies with Protection Class I

according to EN 60335.

After use, before moving the product to another site and before cleaning,

maintenance, or replacement or removal of movable parts, switch off the product

at the main switch and unplug the mains connector.

07220-52-03

VACUMAT fan unit

15

4.6 Preventing dust hazards

CAUTION

Damage due to dust release

Maintenance, cleaning, repair and emptying work must be done only by

expert personnel.

Wear personal protective gear.

- Respirator mask (particle filter class P3)

- Protective clothing

- Protective gloves

Set up locally filtered forced-air ventilation where the product is being

maintained, inspected or cleaned.

Operate the product only with the complete filtration system.

Seal the intake port with a sealing plug so it is dust-tight when transporting.

CAUTION

Damage due to dust build-up in the pipe system

Check the connected piping system regularly for dust deposits.

Observe the minimum air speed required for your application and the

resulting minimum airflow volume.

CAUTION

Damage due to dust build-up in the pipe system

Check the connected piping system regularly for dust deposits.

Observe the minimum air speed required for your application and the

resulting minimum airflow volume.

When replacing the active carbon filter, it is impossible to

preclude the inhalation of dust. That is why all servicing, cleaning

and maintenance procedures, including removal and emptying, is

only to be performed by specialist personal with personal

protective equipment.

The people assigned to cleaning work must be instructed on the

aspirated toxic materials. Harm to bystanders and the

environment must be prevented by all means. Clean the

maintenance area thoroughly once maintenance is complete.

16

VACUMAT fan unit

07220-52-03

5 Delivery and commissioning

5.1 Delivery and transport

DANGER

Danger from falling product

Do not walk under heavy and suspended loads.

The lifting and transporting equipment must be designed for the weight of

the product.

WARNING

Crushing hazard if the product settles during transport

Secure the product during transport.

Wear safety shoes.

CAUTION

Risk of damaging the product due to improper transport.

Do not push the product over the floor if it does not have any rollers.

Use only suitable lifting and transport equipment (such as a forklift or lift

truck) when transporting the product to its set-up location.

Watch out for the centre of gravity –which is not in the centre –when

positioning.

Make sure the floor has adequate weight capacity and can be properly driven on

when transporting the product.

Upon delivery inspect the product for transportation damage. Damage determined

must be reported and documented immediately.

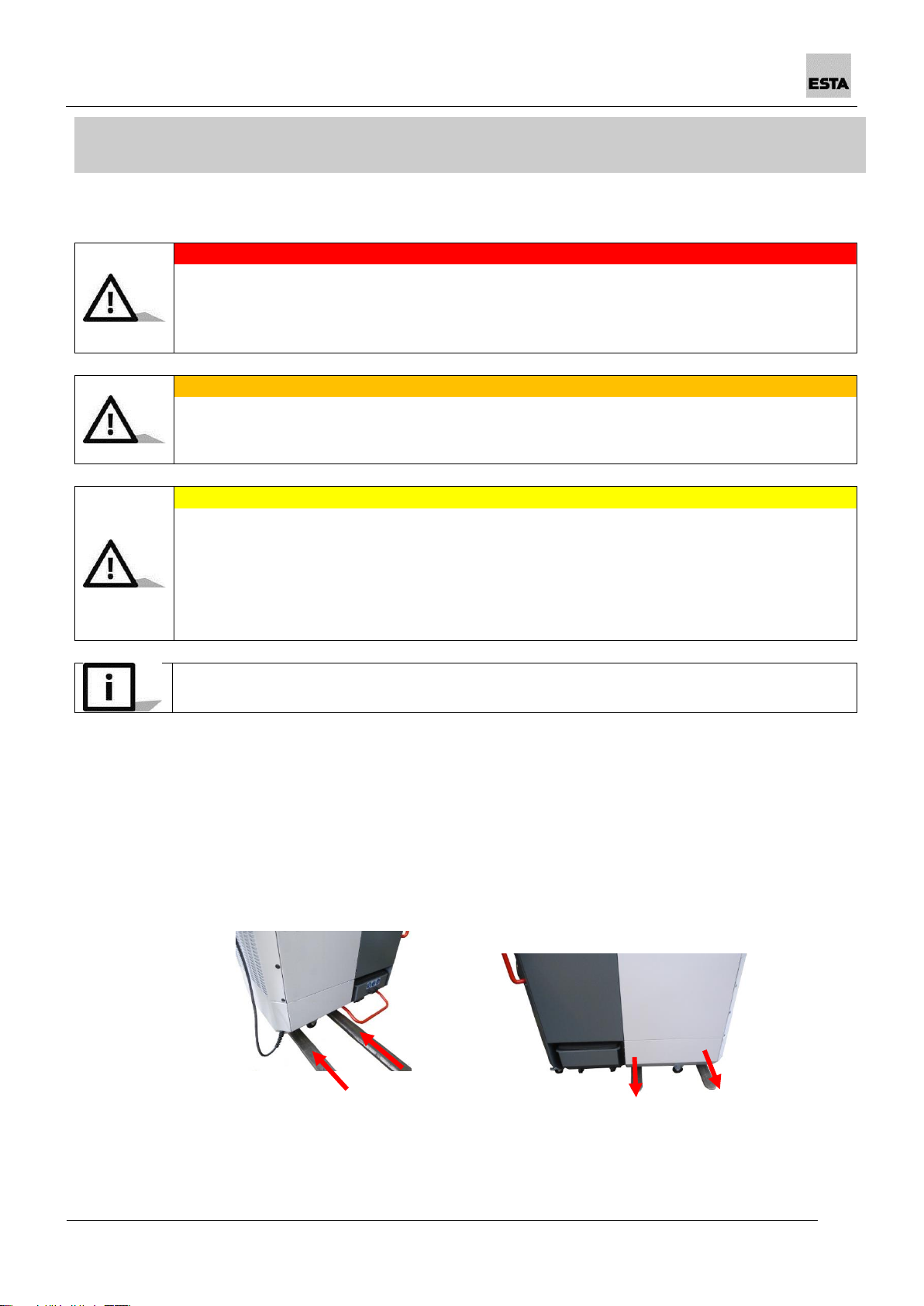

At delivery, the product is fastened to a pallet.

Remove the protective cover and floor securing devices.

Check the delivery is complete

Suspend the product using sling gear (e.g. a lifting belt, round sling) at the

positions provided, lift it from the pallet and place it down on the ground.

Lift the product from the pallet using a forklift at the positions provided and

place it down on the ground.

Note total weight and centre of gravity during all transport work.

Use the attached rollers for further transport to its installation location.

07220-52-03

VACUMAT fan unit

17

ESTA customer service: +49 (0) 7307 804 - 0

5.2 Connection

Before establishing cable connections between the product and the mains, check

whether the operating voltage specified on the rating plate matches that of the

mains.

Place the product on an even surface as close as possible to the source of odour

or pollutant. Ensure the product is aligned horizontally when setting it up.

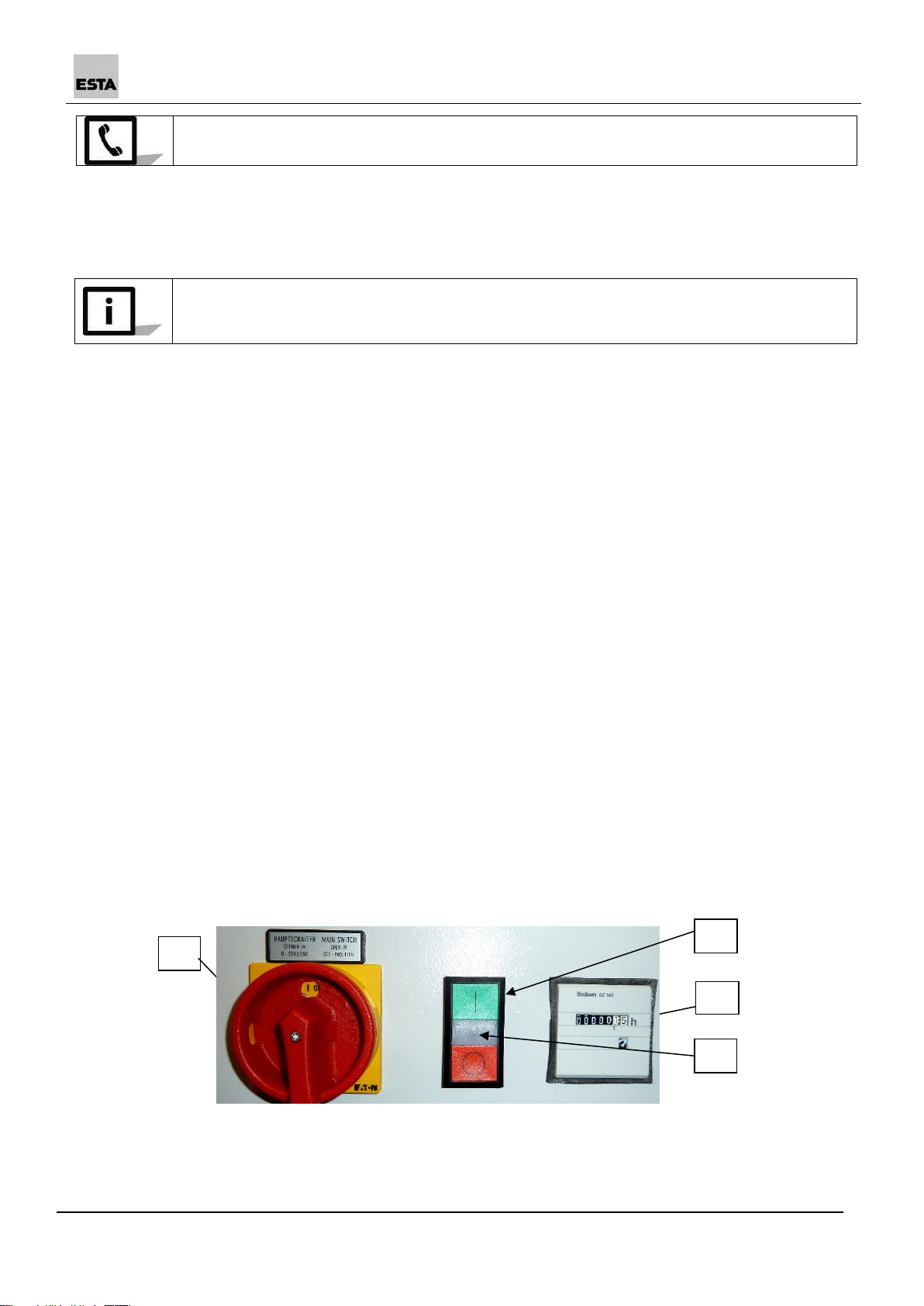

5.2.1 Control unit description

The control unit is equipped with the following elements.

1) MAIN SWITCH

For switching the product on and off.

This switch also serves as an EMERGENCY STOP switch and can be secured

with a lock against unintentional activation.

2) OPERATING UNIT

Extraction is started and stopped on the control panel and serves to control rotation

direction.

3) PHASE SEQUENCE CONTROL

The control lights of the phase sequence monitor light up when the fan rotor of the

motor turns in the wrong direction.

4) OPERATING HOURS COUNTER

The operating hours counter serves for orientation of the intervals for filter change

and filter maintenance.

1

4

2

3

18

VACUMAT fan unit

07220-52-03

5.2.2 Electrical connection

DANGER

Electric shock from high voltages

Follow the safety rules for working with electrical products!

Secure the main switch against reactivation with a padlock when working

on the product.

Any work on the electrical grid and on voltage-conducting parts may only

be performed by an electrical specialist.

A CEE wall socket with a slow-blow fuse must be in place to supply the product

with power.

Connection to the building's power supply is made at the installation location.

VACUMAT

1000 / 2200

Connection plug

[Amp.]

CEE 16 Amp.

Mains (standard)

Three-phase

current

400V/50Hz

3N ~

Fuse

[Amp.]

C16A (circuit

breaker)

* Custom voltage on request; observe the specifications on the rating plate.

5.2.3 Activation operations for motors:

Motors with high output without frequency converters should be not be switched

on and off within a short period of time too frequently. Otherwise, electrical

components could be overloaded. Please observe the specifications for the

number of activation operations:

Motor output

Activation operations per hour

1 –4 KW

Up to 8 starts

4 –7.5 KW

Up to 6 starts

7.5 –15 KW

Up to 4 starts

15 –30 KW

Up to 3 starts

From 30 KW

Electronically controlled overrun time

07220-52-03

VACUMAT fan unit

19

5.3 Function check

Before the product is first used, a function check must be performed.

Turn the main switch to position "I" for a product function check.

5.3.1 Rotation direction monitoring

When the direction of rotation is incorrect, the product becomes impermissibly hot,

the volume increases, the airflow volume falls, and the product’s suction performance

suffers. Damage to the product cannot be ruled out.

After first switching on the product, you should check that the fan rotor’s direction of

rotation is correct.

1. Switch on the product at the main switch.

2. Rotation direction monitor light lights up.

3. Turn the product off at the main switch.

4. Pull the power plug.

DANGER

Electric shock from high voltages

Any work on the electrical grid and on voltage-conducting parts may only be

performed by an electrical specialist.

5. Insert the power plug.

6. Turn the product on at the main switch.

7. The product is ready for operation.

8. Turn the product off at the main switch.

20

VACUMAT fan unit

07220-52-03

5.4 Commissioning

Use original ESTA accessories.

Once a functional inspection has been completed, the connection is made to the

processing apparatus that is to be extracted.

1. Disconnect the compressed air supply.

2. Pull the power plug.

3. Place the product on an even surface as close as possible to the work

station.

4. Insert the power plug.

5. Connect the compressed air.

5.5 Suction line connection

Connect the processing machine to be vacuumed to the filter unit's intake port

through a pipe or hose line.

For a suction line, use

an appropriate suction hose that meets the national requirements for

this application.

an appropriate pipe (wrap fold) that meets the national requirements

for this application.

approved adapters for short diameter on the connection piece

This manual suits for next models

3

Table of contents

Other Esta Water Filtration System manuals

Popular Water Filtration System manuals by other brands

BWT

BWT PERMAQ PRO 1810 Installation and operating instruction

VGE

VGE Xclear IMMERSION UV-C 40W AMALGAM manual

Bluewater

Bluewater Pro Installation quick guide

Sentera Controls

Sentera Controls FIMX8 Mounting and operating instructions

Hydac

Hydac MFU-30E Operating and maintenance instructions

Jet

Jet AFS-1000B Operating instructions and parts manual

Spear & Jackson

Spear & Jackson BoilerMagXL Installation and servicing instructions

Oase

Oase Bitron 550 LM operating instructions

wpro

wpro APP100 Procedure for installation and replacement

Grunbeck

Grunbeck desaliQ Operation manual

ELECTOR

ELECTOR Clarimax user guide

Standen

Standen MEGASTAR GEN-2 Operator's handbook