Gow-Mac 75-850-BV User manual

Operating Manual

Model 75-850-BV & 75-852-BV

Hydrogen Separator

with Manual Bypass Valve

Model 75-850-BV: 120 V, 50/60 Hz

Model 75-852-BV: 230 V, 50/60 Hz

September 2020

Rev. 7

READ INSTRUCTIONS

BEFORE OPERATING

277 Brodhead Road, Bethlehem, PA 18017-8600 U.S.A. Tel: (610) 954-9000

GOW-MAC Instrument Co.

2

Model 75-850-BV / 75-852-BV H2Separator w/ Manual Bypass Valve

09/20 Rev. 7

3

GOW-MAC Model 75-850-BV or 75-852-BV

Hydrogen Separator

1. Connections

1. ConnectAIRCYLINDERtothebackoftheHydrogenSeparatoratAIRtting.

2. Using the ROTAMETER located on the front panel of the Separator, set the AIR

FLOW to the optimum setting according to the chromatogram located at the back of

thismanual.Theowofaircanrangebetween100-300ml/min.

3. Using the 1/16" VCR tubing that is supplied, connect the Separator to the Series 590

DIDGCasfollows:

THE INLET/OUTLET FITTINGS ARE VCR TYPE AND

WASHERS MUST BE USED. CHECK THE CARRIER FLOW

RATE TO BE SURE THAT NOTHING HAS CHANGED.

a.Connectoneendofthesuppliedtubingto"FROMINST"ttinglocatedonthe

side of the Model 75-850-BV or 75-852-BV and the other end of the tubing to "TO

SEP"ttinglocatedontherearoftheGC.

b.Connectoneendofanotherpieceofthesuppliedtubingto"TOINST"tting

located on the side of the Model 75-850-BV or 75-852-BV and the other end of

thetubingto"FROMSEP"ttinglocatedontherearoftheGC.

c. Turn BYPASS VALVE to SERIES/RUN position.

GOW-MAC Instrument Co.

4

Separator/Series 590 GC Connections

FlowDiagram

2. Settings

1. At this point, turn the H2Separator ON and set the operating temperature according

to the optimum temperature setting on the chromatogram located at the back of this

manual.Theoperatingrangeforthetemperatureisbetween85°-450°C.

a.PresseitherUP-arroworDOWN-arrowkeyuntilthedesiredtemperatureis

displayed. Refer to the chromatogram located in the back of this manual for

correcttemperature.Afewsecondsafterthetemperatureisset,thecontrollerwill

start to adjust the temperature automatically.

b. Once the temperature is reached, the H2separator is ready for use. Inject H2

samplesjustliketheywereanynormalGCinjection,followingtheinstruments’

normal operating procedures.

c.Ifthehydrogenstartstopreventtheanalysisfrombeingperformed,lowertheair

owtoseeifthequalityoftheanalysisimproves.Ifitdoesnot,tryvaryingthe

temperature,inapproximately50°Cincrements,higherorloweruntilthereisa

reduction in the hydrogen breaking though. If the removal of the hydrogen is still

insucientenoughtoallowforaqualitativeandquantitativeanalysis,recondition

the Separator as directed in instructions found later in this manual entitled,

" Hydrogen Breakthrough."

AIR IN

AIR FLOWMETER

WITH VA LV E

FROM

INST.

VENT

HEATED BOX

H2 SEP.

TO

INST.

5

6

4

3

1

2

Model 75-850-BV / 75-852-BV H2Separator w/ Manual Bypass Valve

09/20 Rev. 7

5

3. Controls

A.PowerSwitch/CircuitBreaker:TurnsACpowerON/OFF.

B. Temperature Controller:

WATLOW

EZ-ZONE®

EZ

°F

°C

%

1

2

3

4

5

...

...

.

.

Z

O

N

E

C. BypassValve:AllowstheusertoconnecttheSeparatortotheSeries590DIDGC

or bypass the Separator.

4. Responding to a Displayed Message/Error Code

Anactivemessagewillcausethedisplaytotogglebetweenthenormalsettingsandthe

active message in the upper display and [Attn]inthelowerdisplay.

Yourresponsewilldependonthemessageandthecontrollersettings.Some

messages,suchasRampingandTuning,indicatethataprocessisunderway.Ifthe

messagewasgeneratedbyalatchedalarmorlimitcondition,themessagecanbe

clearedwhentheconditionnolongerexists.Ifanalarmhassilencingenabled,itcan

be silenced.

Upper Display: In the Home

page, displays the process

value,otherwise displaysthe

value of the parameter in the

lowerdisplay.

Lower Display: Indicates

thesetpointoroutputpower

value during operation, or

the parameter whose value

appears in the upper display.

EZ Key: Enables simple, one-

touchoperationofuserdened,

repetitive activities. This key

can be programmed to do

various tasks, such as locking

the keyboard, restoring user

settings, etc.

ZONE: Indicates the controller

zone (1-9).

Advance Key: Advances

through parameter prompts.

Up and Down Keys: In the Home

page, adjusts the set point in the

lower display. In other pages,

changes the upper display to a

higherorlowervalue,orchangesa

parameter selection.

Output 1 Indicator Light: When lit

it indicates Output 1 is energized.

Temperature Units: Indicates

whetherthetemperatureisdisplayed

in Fahrenheit or Celsius.

Output 2 Indicator Light:Litwhen

Output 2 is active. This output can

beconguredasacontroloralarm

output.

% Percent Power Indicator

Light: Lightswhenthecontrolleris

displaying values as a percentage

orwhentheopen-loopsetpointis

displayed.

Innity Key: Press to back up

once level, or press and hold for

twosecondstoreturntotheHome

page. From the Home page can

clear alarms and errors if clearable.

GOW-MAC Instrument Co.

6

Push the Advance Key to display [.9nr] in the upper display and the message

source (such as [L.hi])inthelowerdisplay.

UsetheUpandDownkeystoscrollthroughpossibleresponses,suchasClear

[CLr] or Silence [S.L].ThenpushtheAdvanceorInnitykeytoexecutetheaction.

Er. 1 - Error Input 1:Thesensorinputgeneratedavaluelowerthantheallowable

signal range. Enter a valid input.

100 - Device Error:ControllerdisplaysinternalmalfunctionmessageatPower

Up.

i. Set Point

a.Tosetthesetpoint:turntheunit“on”andthenpushtheUporDownarrowto

adjust to the desired operating temperature.

5. Hydrogen Breakthrough

The H2Separatorisequippedwithapalladium/silveralloymembrane.Itsfunctionisto

quantitativelyremovethehydrogenbalancegasfromahydrogensampleleavingonly

the impurities in the helium carrier gas stream. After using the system for a period of

timewithhydrogen,theappearanceofahydrogenpeakwillbeseen.Thisiscaused

bythebuildupofcarbonaceousdepositsinsidethepalladiumtube.Byallowingairto

pass through the tube at operating temperature it is possible to remove this buildup and

restore the Separator to its original state.

1. Turn the BYPASS VALVE to "Bypass/Recondition" position.

2. SettheAIRowratetotheoptimumowsettingasdirectedbythechromatogram

locatedatthebackofthismanual.Settemperatureto450°Cfor1hour.Thisburns

oanydepositsonthepalladium/silveralloymembrane.

3. Turn BYPASS VALVE to the "Series/Run" position to connect the Separator to the

GC. Purge for 15 minutes.

IT IS IMPORTANT THAT THE AIR SUPPLY USED FOR

THIS INSTRUMENT BE AT LEAST ZERO GRADE

(CONTAINING < 1PPM OF HYDROCARBONS). IMPURE

AIR CAN HELP TO CAUSE THE SEPARATOR TO NEED

RECONDITIONING MORE FREQUENTLY. ALSO

HALOGENS, ORGANOMETALS, SULFUR COMPOUNDS,

DOPING GASES AND OTHER HEAVY METALS CAN CAUSE

PLUGGING OF THE SEPARATOR TUBE AND REQUIRE

TUBE REPLACEMENT.

Model 75-850-BV / 75-852-BV H2Separator w/ Manual Bypass Valve

09/20 Rev. 7

7

6. GeneralSpecicationsfortheTemperatureController

Part Number 124-261

Control Mode: - Microprocessor-based

- Single input, dual output

-Ramptosetpoint:0to550°

- Heat and cool auto-tune

-PIDwithautomatictuning

Sensor Input Type: Platinum RTD, 100 ohms

Supply Voltage: 85 - 264 VAC, 50/60 Hz (75-850-BV/75-852-BV)

Mechanical Relay Life Span: 100,000 cycles

Sensor Input Type: Platinum RTD, 100 ohms

AmbientTemperatureRange: Operating: -18to65°C

Storage: -40to85°C

7. SeparatorSpecications

Operatingtemperature: 300°C

Max. Operating Pressure: 250 psig

OperatingCarrierGasFlowRate: 30-50mL/min.

Standard Fittings: 1/8" VCR

Weight (net): 15 lbs.

Dimensions: 15-½”D x 6-½”W x 12"H

8. Waste Disposal

ThisprocedureisforGOW-MACMiniPurierPartNo.180-542(Helium)and

180-542-AR (Argon).

Ifthepurierisused,thenthegettermaterialinsidethepurierisalreadyinanon-

reactivestate,(i.e.willnotreactwithair).

Ifthematerialisstillinareactivestate(i.e.thepurierisnotcompletely"usedup"),

itstillwillnotsustaincombustioninairexceptattemperaturesover350°C,

andwithacontinuedaccesstoair.

TheoperatorshouldplaceaVCRcapovertheinlet/outletttingsforsucient

precautionbeforedisposal.Itisthenacceptabletodepositinanapprovedlandll,

inaccordancewithlocal,stateand/orfederalregulations.Whendisposedofinthis

manner,thewasteposesnoknownenvironmentalproblems.

GOW-MAC Instrument Co.

8

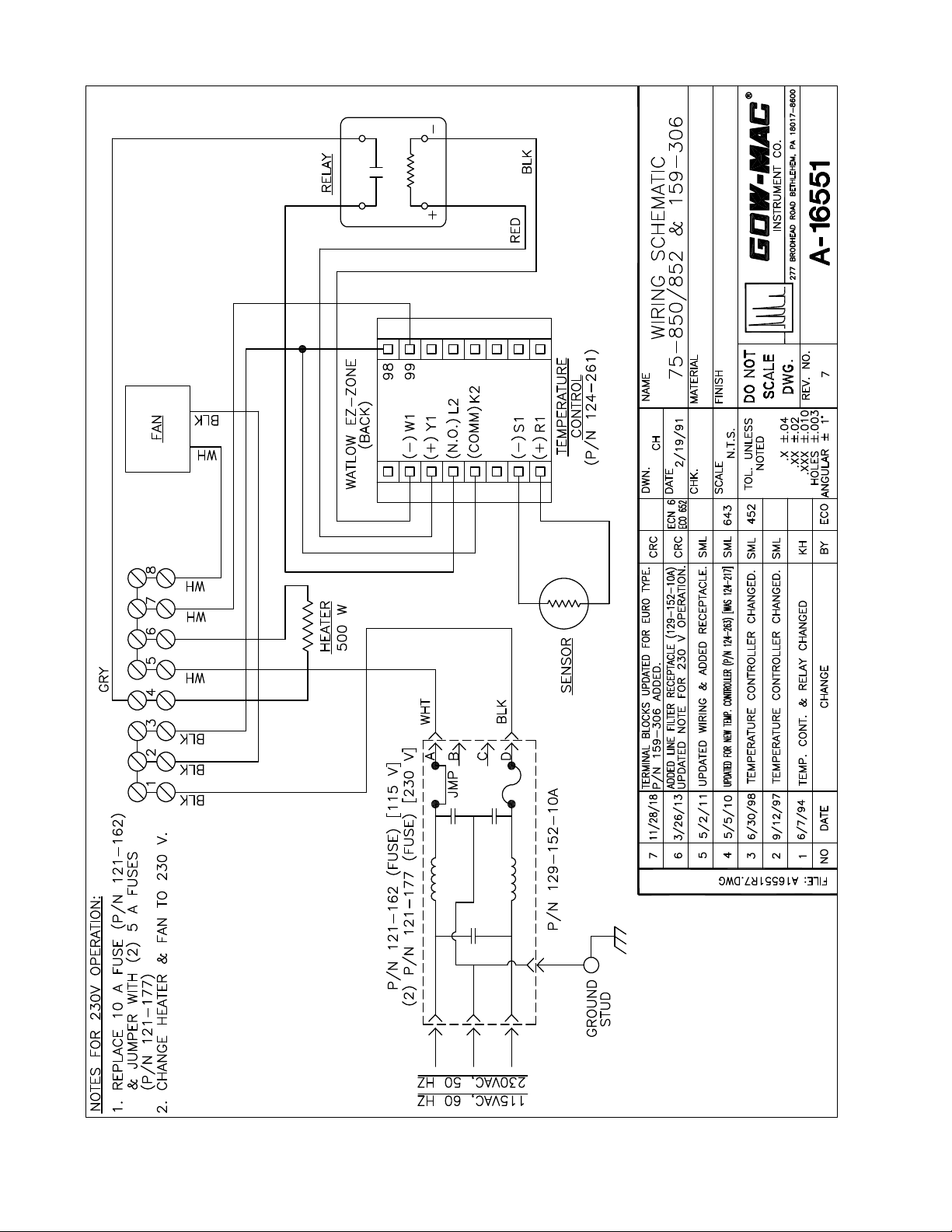

9. Replacement Parts

Description Part No.

Fuse, 10 A (115 V)...................................................121-162

Fuse, 5 A (230 V) ....................................................121-177

Fan (115 V) .............................................................124-156

Fan (230 V) .............................................................124-162

Sensor.....................................................................124-175

Heater (115 V).........................................................124-197

Heater (230 V).........................................................124-200

Temperature Controller ...........................................124-261

PowerCord,3conductorshielded..........................127-407

Receptacle,powerswitchw/linelter(115V)........ 129-152-10A

Flowmeter ...............................................................180-138

Palladium Tube, Replacement ................................180-544-VCR-3

Valve, 6-port ............................................................181-643

Contact GOW-MAC for replacement parts:

GOW-MAC Instrument Co.

277 Brodhead Road

Bethlehem, PA 18017 U.S.A.

Tel: (610) 954-9000

Fax: (610) 954-0599

URL:www.gow-mac.com

Model 75-850-BV / 75-852-BV H2Separator w/ Manual Bypass Valve

09/20 Rev. 7

9

AIR IN

FROM

INST.

VENT

HEATED BOX

H2 SEP.

TO

INST.

5

6

4

3

1

2

VENT

INST.

TO

5

4

6

1

3

2

FROM

INST.

TO

SEP.

FROM

SEP.

AIR IN AIR IN

CW - SERIES/RUN

VENT

3

4

SEP.

FROM

CCW - BYPASS/RECONDITION

INST.

TO

5

6

INST.

FROM

SEP.

2

TO

1

AIR FLOWMETER

WITH VA LV E

R

FINISH

MATERIAL

DO NOT

NAME

SCALE

REV. NO.

CHANGENO DATE BY ANGULAR±1°

ECO

FILE:

DWN.

SCALE

DATE

CHK.

TOL. UNLESS

HOLES ±.003

NOTED

.XXX ±.010

.XX ±.02

.X ±.04 INSTRUMENT CO.

277 BRODHEAD ROAD BETHLEHEM, PA 18017-8600

DWG.

FLOW DIAGRAM

75-850-BV

A-18845

1

KH

8/25/99

N.T.S.

A18845.DWG

FLOW ADJ.

110/31/07 ADDED METERING VALVE KH

GOW-MAC Instrument Co.

10

This manual suits for next models

1

Table of contents

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual