ENERCON SUPER SEAL Series User manual

3/21/2018

INDUCTION CAP SEALER

SUPER SEAL™ SERIES

ML0071-601-06

OWNERS REFERENCE MANUAL

Enercon Industries Corp.

W140 N9572 Fountain Blvd.

P.O. Box 773 (53052-0773)

Menomonee Falls, WI 53051-0773, USA

Phone: (262) 255-6070

Fax: (262) 255-7784

Web Site: www.enerconind.com

TABLE OF CONTENTS

SECTION 1 – INTRODUCTION ...........................................................................................................................................................1

SAFETY AND WARNINGS...............................................................................................................................................1

SAFETY PRECAUTIONS .................................................................................................................................................2

UNDERSTANDING INDUCTION SEALING......................................................................................................................3

GENERAL.........................................................................................................................................................................3

MATERIAL VARIATIONS..................................................................................................................................................3

MULTIPLE LAYER LINERS (Figure 1)..............................................................................................................................3

SINGLE PIECE LINERS (Figure 2)...................................................................................................................................3

THE SEALING PROCESS.............................................................................................................................................3-4

UNPACKING AND INSPECTION .....................................................................................................................................4

DOCUMENTATION...........................................................................................................................................................4

OPTIONAL EQUIPMENT..................................................................................................................................................4

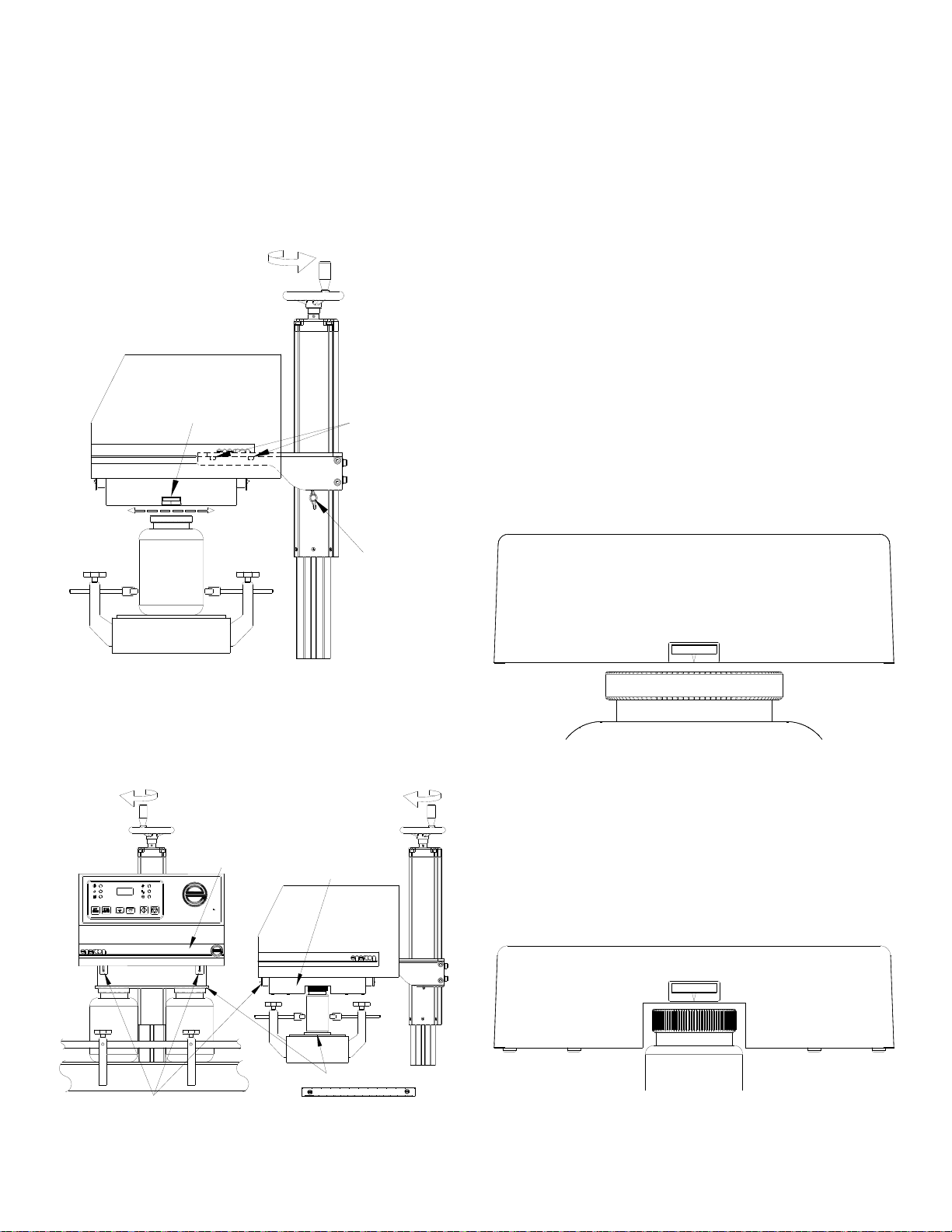

INDUCTION CAP SEALER FEATURES (Figure 3) ..........................................................................................................5

INFORMATION AND SAFETY LABELS (Figure 4)...........................................................................................................6

SECTION 2 – INSTALLATION..............................................................................................................................................................7

GENERAL.........................................................................................................................................................................7

SCREW ADJUSTABLE MOUNT OPERATION (Figures 5 & 6)........................................................................................7

FLOOR MOUNT INSTALLATION (Figure 7).....................................................................................................................7

POWER SUPPLY MOUNTING YOKE INSTALLATION (Figures 8 & 9) ...........................................................................8

MOUNT PLACEMENT AND INSTALLATION (Figures 10 & 11).......................................................................................8

ATTACHING POWER SUPPLY TO MOUNT (Figures 12 & 13) .......................................................................................9

MOBILE CART SYSTEM INSTALLATION (Figures 14 - 16)........................................................................................9-10

SYSTEM ALIGNMENT OVER CONTAINER...................................................................................................................10

THE SEALING HEAD AND SURROUNDING METAL ....................................................................................................10

CONTAINER PATH (Figure 17).................................................................................................................................10-11

SEALING HEAD CENTERING (Figure 18) .....................................................................................................................11

SETTING THE CONTAINER AND SEALING HEAD GAP (Figure 19)............................................................................11

DETAILED SEALING HEAD ALIGNMENT......................................................................................................................11

STANDARD FLAT SEALING HEAD (Figure 20).............................................................................................................11

STANDARD TUNNEL SEALING HEAD (Figure 21) ..................................................................................................11-12

DEEP TUNNEL SEALING HEAD (Figure 22) .................................................................................................................12

ALIGNMENT AND ADJUSTMENT "1" SEALING HEAD (Figure 23)...............................................................................12

SYSTEM REQUIREMENTS............................................................................................................................................12

TEMPERATURE.............................................................................................................................................................12

INPUT VOLTAGE REQUIREMENTS.........................................................................................................................12-13

GROUNDING REQUIREMENTS....................................................................................................................................13

BASIC UNIT - CABLE PROVISIONS (Figure 24)............................................................................................................13

INSTALLATION - CONTROL PROVISIONS...................................................................................................................13

EXTERNAL INTERLOCK................................................................................................................................................13

USING THE REMOTE START / INTERLOCK CABLE....................................................................................................13

USING THE DEFEAT CONNECTOR..............................................................................................................................13

STALLED BOTTLE DEFEAT CONNECTOR .............................................................................................................13-14

LOSS OF SEALING INDICATOR (LSI)...........................................................................................................................14

SECTION 3 – PRINCIPLES OF OPERATION.................................................................................................................................15

GENERAL.......................................................................................................................................................................15

CONTROL FUNCTIONS (Figure 25) .............................................................................................................................15

SEQUENCE OF OPERATION........................................................................................................................................16

LOCAL OPERATION (Figure 26)...................................................................................................................................16

SEALING WINDOW SETUP .....................................................................................................................................16-17

ADJUSTING THE LOSS OF SEAL INDICATOR ALARM SETPOINT .......................................................................17-19

REMOTE START OPERATION......................................................................................................................................19

AUTO CONTROL............................................................................................................................................................19

SECTION 4 – OPTIONAL EQUIPMENT...........................................................................................................................................20

GENERAL.......................................................................................................................................................................20

OPTIONS AVAILABLE....................................................................................................................................................20

MOBILE CART (Figure 27)..............................................................................................................................................20

STACK LIGHT (Figure 28) .........................................................................................................................................20-21

MOTION / FOIL DETECTION GROUP ...........................................................................................................................21

MOTION / FOIL DETECTION GROUP INTALLATION (Figure 29)................................................................................21

MOTION DETECTION ONLY (STALLED BOTTLE) ..................................................................................................21-22

STALLED BOTTLE SENSOR INSTALLATION (Figure 30).............................................................................................22

STALLED BOTTLE SENSOR SETTINGS AND ADJUSTMENTS (Figure 31)................................................................22

SENSITIVITY ADJUSTMENT .........................................................................................................................................22

DELAY OFF ....................................................................................................................................................................22

DELAY ON......................................................................................................................................................................22

SENSOR ADJUSTMENT PROCEDURE ...................................................................................................................22-23

FOIL LINER DETECTOR ONLY (Figure 32)...................................................................................................................23

FOIL LINER DETECTOR INSTALLATION (Figure 33) ...................................................................................................23

FOIL LINER DETECTOR CONTACTS CABLE (Figure 34) .......................................................................................23-24

FOIL LINER DETECTOR ALIGNMENT AND ADJUSTMENT (Figure 35) ......................................................................24

BEAM SENSOR LED OPERATION................................................................................................................................24

BEAM SENSOR SENSITIVITY ADJUSTMENT (Figure 36)............................................................................................24

BEAM AND PROXIMITY SENSOR LED OPERATION...................................................................................................24

PROXIMITY SENSOR SENSITIVITY ADJUSTMENT (Figure 37).............................................................................24-25

AUTO MODE (Figure 38)................................................................................................................................................25

EJECTOR SYSTEM........................................................................................................................................................25

EJECTOR INSTALLATION (Figure 39)......................................................................................................................25-26

SPARE PART KITS AVALABLE .....................................................................................................................................26

SECTION 4 – MAINTENANCE...........................................................................................................................................................27

GENERAL.......................................................................................................................................................................27

ROUTINE INSPECTION AND SERVICING....................................................................................................................27

VISUAL INSPECTION.....................................................................................................................................................27

EXTERNAL CONNECTIONS..........................................................................................................................................27

SEALING HEAD INSPECTION.......................................................................................................................................27

COOLING FANS AND BASE PLATE INSPECTION (Figure 40)................................................................................27-28

INTERNAL CONNECTIONS...........................................................................................................................................28

MAINTENANCE RECORD..............................................................................................................................................28

SECTION 5 – TROUBLESHOOTING................................................................................................................................................29

GENERAL.......................................................................................................................................................................29

REMOVE/INSTALL THE POWER SUPPLY COVER......................................................................................................29

FRONT PANEL 'F' INDICATIONS...................................................................................................................................29

F00 - OVER CURRENT TRIP....................................................................................................................................29-30

F02 AND TEMP - CAP TRIP OR OVER-TEMPERATURE (Figures 41 & 42)............................................................30-32

F03 - INTERLOCK FAULT.........................................................................................................................................32-33

F04 - UNDER VOLTAGE TRIP.......................................................................................................................................33

F05 - UNDER FREQUENCY TRIP.............................................................................................................................33-34

FRONT PANEL BLANK..............................................................................................................................................34-35

FAULT.............................................................................................................................................................................35

PUSHBUTTONS DO NOT FUNCTION......................................................................................................................35-36

OUTPUT STUCK AT MINIMUM......................................................................................................................................36

AUTO MODE AT MINIMUM............................................................................................................................................37

DISPLAY FLICKERS..................................................................................................................................................37-38

RUN NOT LIT OR BLINKING..........................................................................................................................................38

INVERTER OHM CHECK PROCEDURE........................................................................................................................39

BRIDGE RECTIFIER OHM CHECK PROCEDURE........................................................................................................39

APPLICATION TROUBLESHOOTING.......................................................................................................................40-43

SECTION 6 – PARTS LISTS...............................................................................................................................................................44

GENERAL.......................................................................................................................................................................44

HOW TO USE THIS PARTS LIST...................................................................................................................................44

HOW TO ORDER PARTS...............................................................................................................................................44

SHIPPING INSTRUCTIONS FOR RETURNS.................................................................................................................44

SCREW ADJUSTABLE FLOOR MOUNT PARTS BREAKDOWN (Figure 43)...............................................................45

MOUNTING BRACKET PARTS BREAKDOWN (Figure 44)...........................................................................................46

STANDARD POWER SUPPLY PARTS BREAKDOWN (Figure 45) ..............................................................................47

CE POWER SUPPLY PARTS BREAKDOWN (Figure 46).............................................................................................48

FAN AND SEALING HEAD MOUNTING PARTS BREAKDOWN (Figure 47)................................................................49

FRONT PANEL PARTS BREAKDOWN (Figure 48) ......................................................................................................50

OPTIONAL STALLED BOTTLE SENSOR PARTS BREAKDOWN (Figure 49)...............................................................51

OPTIONAL FOIL LINER DETECTOR PARTS BREAKDOWN (Figure 50) .....................................................................52

OPTIONAL STACK LIGHT PARTS BREAKDOWN (Figure 51)......................................................................................53

OPTIONAL MOBILE CART PARTS BREAKDOWN (Figure 52).....................................................................................54

SECTION 8 – MISCELLANEOUS......................................................................................................................................................55

MAINTENANCE RECORD.........................................................................................................................................55-56

PRODUCTION INFORMATION.................................................................................................................................57-58

NOTES.......................................................................................................................................................................59-60

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

1

SECTION 1 – INTRODUCTION

WARNING!

Please read this manual carefully before installing, operating, or servicing.

DO NOT OPERATE THIS EQUIPMENT IN A HAZARDOUS ENVIRONMENT!

THIS EQUIPMENT PRODUCES A ELECTROMAGNETIC FIELD TO FACILITATE THE INDUCTION

SEALING PROCESS. THE ELECTROMAGNETIC FIELD QUICKLY HEATS ANY METAL WITHIN THE

FIELD AND MAY, UNDER CERTAIN CONDITIONS, IGNITE THE METAL OR SURROUNDING

MATERIALS. PERSONNEL SHOULD REFRAIN FROM PLACING JEWELRY, SUCH AS RINGS AND

WATCHES BENEATH OR WITHIN THE SEALING HEAD’S ELECTROMAGNETIC FIELD!

HIGH VOLTAGE is present within this equipment. As with any piece of ELECTRICAL equipment, one should

become familiar with the manual before applying power. Proper connections and operation are required for

safe use. FOLLOW INSTRUCTIONS for safety of personnel when operating or maintaining this equipment.

INSTALLATION of this equipment must be done in accordance with this manual, Enercon installation drawings

and local codes to ensure the safety of personnel in the area and in the building.

SAFETY AND WARNINGS

Before placing this equipment into operation, we

strongly recommend that you take the time to read

this manual carefully in its entirety to ensure you

understand all the safety and operational

requirements for using this equipment.

The heating capability of this equipment and the

presence of high voltage have the potential to cause

severe personal injury or property damage. To avoid

ignition of product liners from excessive heat, do not

exceed your established production output level, or

product dwell time, for a given application. Do not

operate this equipment if any of the wiring or

connections are exposed or damaged.

Before starting, operating, or making adjustments;

identify the components of the Induction Cap Sealer,

using this manual as a guide.

Personnel should use common sense and good

working practices while operating and maintaining

this equipment. All codes and operational guidelines

should be followed and the starting and stopping

sequence should be understood. Check all safety

devices and follow the procedures contained in this

manual.

Maintenance should only be performed by qualified

personnel, adequately equipped with the proper

tools. Follow the maintenance schedules as outlined

in the manual to ensure problem-free operation after

startup.

Safety instructions in this manual are called out in

colored safety boxes with bold-faced text for

emphasis. The signal words CAUTION,WARNING,

and DANGER are used to indicate hazard

seriousness levels as follows:

CAUTION!

CAUTION is used to indicate the presence of

a potentially hazardous situation which, if not

avoided may result in minor personal injury

or property damage.

WARNING!

WARNING is used to indicate a potentially

hazardous situation which, if not avoided, can

result in serious injury or death.

DANGER!

DANGER is used to indicate an imminently

hazardous situation which, if not avoided, will

result in serious injury or death.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

2

SAFETY PRECAUTIONS

DANGER!

The use of high voltage is necessarily employed in

the operation of this equipment. Precautions have

been taken in the design of this equipment to make it

as safe as possible for both operator and service

personnel. However, since no amount of interlocks

and safety devices can be absolutely infallible,

precautionary measures must always be taken when

working on this equipment.

Do not reach into the equipment or any electrical

enclosure without first removing the input voltage.

Never apply input voltage to the unit without the

cover on and securely in place.

Capacitors Store Charge: Never trust a capacitor

to be bled off completely. A meter or ground strap

should be used to check each stud or lead before

handling. Some capacitor studs, including those not

tied to bus work (not used), may build up a

considerable static charge. GROUND BEFORE

HANDLING!

Do not stand in water or on grounded surfaces or

touch grounded surfaces while reaching in any

system enclosure. A piece of wood or other

insulating material will act as an additional barrier to

stand on.

WARNING!

Do not operate this equipment in a hazardous

environment! The presence of High Voltage within

this equipment may result in explosion or fire when

operated near flammable vapors, fuels, or other

combustibles.

With the exception of your conveyor body, do not

permanently mount metal objects within the sealing

head’s electromagnetic field! These objects will be

heated as long as the electromagnetic field is on and

can create a burn hazard!

Do not attempt to seal products with damaged or

improperly applied liners, as they may overheat

causing the liner and container contents to ignite.

Do not Tamper With Safety Interlocks: The use of

safety interlocks is optional with your induction cap

sealing equipment. If safety interlocks are required

for your system, then under no circumstances should

any of these safety interlocks be defeated nor should

any of the interlocks be relied upon for removal of

voltage from the equipment.

Lockout / Tag Out: To ensure that the input voltage

cannot be applied to the equipment, remove the

input voltage and use the appropriate Lockout / Tag

Out procedures prior to removing any access covers,

panels, or entering the equipment in any manner.

ALWAYS use safety as the first step.

CAUTION!

Familiarize Yourself Thoroughly with the

Equipment.

Never attempt to work on this equipment unless you

are completely familiar with it.

Never assume that a circuit is dead, MAKE SURE!!!

Always Wear Appropriate Protective clothing and

Eyewear while working within the enclosure.

Do not connect any external control or monitoring

equipment, with the exception of appropriate test

equipment, to the internal circuits of this equipment.

Connecting external equipment in this manner may

cause failure of this equipment and create a potential

hazard to personnel.

The Sealing Head may be heavy! Always use

support blocks when removing the sealing head for

maintenance or troubleshooting.

CONTACT:

Enercon Customer Service Department

Phone Number: (262) 255-6070

Fax Number: (262) 255-2462

Website: www.enerconind.com

24hr Customer Service is available.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

3

UNDERSTANDING INDUCTION SEALING

General

Induction Sealing is a process used to seal

containers hermetically by using an electromagnetic

field to heat a heat-sealable foil liner located within a

closure. The Super Seal™ Induction Cap Sealer

converts a line voltage (240 VAC 1Ø or 3Ø / 50/60

Hz) to a high-frequency electromagnetic field in the

sealing head. This electromagnetic field heats your

liner by inducing currents into the metal of the foil

liner located within the closures of your containers.

High sealing speeds can be obtained using this

process making it well suited for both production

lines and laboratory applications.

Material Variations

Depending on the type of polymer used, an induction

seal can meet FDA requirements for “tamper

evident” packaging, or may simply provide leakage

protection and shelf life extension, often referred to

as a “freshness seal”. Many varieties of inner seal

polymers have been developed and are available

from a number of suppliers. Suppliers can assist you

in the selection of the proper liner for the multitude of

products and packaging methods used in the

packaging industry.

Multiple Layer Liners

A multiple layer liner (Figure 1) typically consists of a

pulp board layer (A), a wax layer (B), and a layer of

aluminum foil (C) coated with a polymer (D).

(A)(B) (C)(D)

(A)(B)

(C)(D)

BEFORE INDUCTION SEALING

AFTER INDUCTION SEALING

Figure 1

The polymer (D) must be compatible with your

container material and capable of producing the seal

strength and removal force required by your

application.

Single Piece Liners

A single piece foil liner (Figure 2) typically consists

of a layer of aluminum foil (A) coated with a polymer

(B) inside a closure.

BEFORE INDUCTION SEALING

AFTER INDUCTION SEALING

(A)(B)

(A)(B)

Figure 2

The polymer (B) must be compatible with your

container material and capable of producing the seal

strength and removal force required by your

application.

WARNING!

DO NOT attempt to induction seal damaged or

improperly applied liners as they may overheat

causing the liner and container contents to ignite.

The Sealing Process

When the closure is placed onto the container and

placed within the electromagnetic field produced by

the sealing head, several things occur.

1. An electrical current, called an eddy current, is

induced into the aluminum foil, resulting in a

resistance-type heating effect.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

4

2. The polymer coating melts and flows around the

lip of the container.

3. In Multiple Layer Liners the wax bond holding the

foil liner to the backing material is melted and the

wax is absorbed into the backing material.

When the electromagnetic field is shut off the

polymer cools and hardens, bonding the foil to the

container lip. When the closure is removed from the

container the metal foil will remain bonded to the lip

of the container and any backing materials (Multiple

layer liners only) will remain inside the closure.

NOTE:

A fundamental requirement for induction cap sealing

is to have the proper amount of torque on the cap,

which exerts a downward force when sealing.

Consult your cap supplier for the recommended

torque of your cap. A rule of thumb is to equate half

the liner’s millimeter size (diameter) to inch-pounds

of torque. For example, a 53mm liner would require

27 inch-pounds of torque. Also refer to the Torque

Requirement Table on Page 43 of this manual.

UNPACKING AND INSPECTION

IMPORTANT: The carrier accepted responsibility for

this shipment when the carrier signed the Bill of

Lading at the origin of shipment. If external damage

to the packaging was detected, it should have been

noted on the freight bill before signing it to

acknowledge receipt. If you give the carrier a clear

receipt for goods that have been damaged or lost in

transit, you do so at your own risk and expense. If

concealed loss or damage is discovered after

delivery, notify your carrier at once and request an

inspection. This is absolutely necessary for the

carrier to consider your claim. The carrier agent

should make an inspection and issue a loss or

damage report.

Your Super Seal™ Induction Cap Sealing System

may have been shipped in more than one container,

so compare the items received with the packing slip

to ensure all items that shipped were received. All

packages and crating should be carefully opened

and all items thoroughly inspected for damage.

NOTE:

Be extra careful if using a sharp instrument when

removing the protective wrapping from the

equipment. File a claim with the freight carrier for any

damage incurred during shipping. Enercon Industries

should also be contacted as soon as possible to

expedite the shipment of replacement parts.

CONTACT:

Enercon Customer Service Department

Phone Number: (262) 255-6070

Fax Number: (262) 255-2462

Website: www.enerconind.com

24hr Customer Service is available.

Enercon Parts Department

Phone Number: (262) 255-6070

Fax Number: (262) 255-2462

DOCUMENTATION

A system folder containing your printed System

Drawings, System and Safety Documentation, and

Miscellaneous Specification was provided with your

system. A CD-ROM was also provided with digital

copies of your system manuals, system drawings,

and the documents mentioned above.

OPTIONAL EQUIPMENT

Several options were available for purchase with

your Super Seal™ and the same care should be

used when opening these boxes. For installation and

setup of options included with your system refer to

SECTION 4 – OPTIONAL EQUIPMENT in this

manual.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

5

INDUCTION CAP SEALER FEATURES

Item # Description Item # Description

1 See Section 3 – Principles of Operation 4 Sealing Head

2 See Section 2 – Installation 5 Screw Adjustable Floor Mount

3 Rear of Power Supply

9.375"

(238mm)

15.5"

(394mm)

14.25"

(362mm)

65.5" (1664mm) Maximum Height

57.5 (1461mm) Minimum Height

23

CE

STANDARD

1

5

4

ON

I

O

OFF

SuperSeal

SuperSeal

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR FOIL DETECT

SENSORASSY

STACK

LIGHT

LSI

CONTACTS FOIL DETE CT

CONTACTS

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR FOIL DETECT

SENSORASSY

STACK

LIGHT

LSI

CONTACTS FOIL DETE CT

CONTACTS

Figure 3

Features Sealing Heads – Quick Change

1 Completely Air Cooled Part Number Type Of Head Cap Range

2 Electrical Rating:

208 or 240 VAC ± 10%, 50/60 Hz 1Ø SS50 – SS100 *

208 or 240 ± 10%, 50/60 Hz 3Ø SS100 3Ø (Non CE) *

LM4555-02

LM4555-102 “1” COIL 24 to 120mm

3 Stainless Steel Cabinet w/NEMA 4 rating. LM4033-32

LM4033 -132 WIDE FLAT 53 to 120mm

4 Screw Adjustable Floor Mount – Lockable.

5 Standard Control Features: LM4033-31

LM4033-131 WIDE TUNNEL 28 to 53mm

START/STOP

Output Adjustment / Digital Output % Meter LM4033-38

LM4033-138

LM4033-238

NARROW

TUNNEL 24 to 38mm

Built In Diagnostic Display

Remote Start Capabilities Consult Factory for Other Available Sealing Heads.

Capable of Interlocking with other equipment.

*See Rating Plate for Input Voltage Requirements. Failure to provide the input voltage shown on the system rating plate may cause system failure

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

6

INFORMATION AND SAFETY LABELS

This page contains representative examples of the

typical placement of the labels that appear on your

Super Seal™ Induction Cap Sealing System. These

labels are designed to provide technical, functional,

and safety information required for operation of this

equipment. If for any reason a label is removed,

defaced, painted over or underlying parts are

replaced, we recommend you obtain a replacement

label from Enercon and re-apply them in the

locations shown.

STANDARD

CE

ON

I

O

OFF

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR FOIL DETECT

SENSOR ASSY

STACK

LIGHT

LSI

CONTACTS FOIL DETECT

CONTACTS

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR FOIL DETECT

SENSOR ASSY

STACK

LIGHT

LSI

CONTACTS FOIL DETECT

CONTACTS

SuperSeal

SuperSeal

Figure 4

FOIL alignment decals are only

required on Deep Tunnel Coils.

Located on both ends of

Sealing Head.

Located on both ends of

Sealing Head.

Decal will be located on

Both power supply connectors

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

7

SECTION 2 – INSTALLATION

GENERAL

The basic Super Seal™ Induction Cap Sealing

Systems consist of a Power Supply, Sealing Head

(attached), Floor Mount, or optional Mobile Cart

Mounting System, and all required interconnection

cables. The system is designed to mount easily over

your conveyor using either the standard floor mount

or optional mobile cart, and this manual covers the

installation and setup of both types of mounting

systems. Your system may have been ordered with

some special, or optional, items that may have

requirements that deviate from standard. Therefore,

it is important to reference the system drawings and

paperwork to identify these items as well as to

understand any deviation from the standard

requirements listed in this manual.

SCREW ADJUSTABLE MOUNT OPERATION

The Screw Adjustable Mount is an assembly

designed to aid personnel in adjusting the power

supply height over the conveyor. With the sealing

head centered over the conveyor, the mount adjusts

to achieve the required gap between sealing head

and container by rotating the hand wheel either CCW

to raise, or CW to lower, the sealer over the

conveyor. Once the gap is set, a clamping system is

used to aid in maintaining the position of the mount.

A locking knob is used to loosen or tighten the

clamp. The locking knob rotates CCW to loosen,

allowing height to be adjusted, and CW to tighten

once the height is correctly set (Figure 5).

Lower

Raise

Locking

Knob Safety

Nut

DO NOT Remove the

Safety Nut unless

instructed

Figure 5

CAUTION!

Loosen the clamp before adjusting the mount

height.

Ensure that the safety nut located at the

bottom of the extrusion track is securely in

place.

All other visible screws on the mount, such as

the nylon tipped corner set screws, should not

be field adjusted as they are factory set.

The nuts used for mounting hardware and

accessories onto the screw adjustable mount may

slide within the extrusion track (Figure 6). If possible,

ensure the affected track is parallel to the floor when

removing bolts.

Figure 6

FLOOR MOUNT INSTALLATION

Once the floor mount has been unpacked the

conveyor mounting brackets will need to be

repositioned. Lay the mount on its side and remove

the lower bolt (1) and loosen the upper bolt (2) on

each bracket and rotate the bracket (3) into the

position shown. Reinstall the lower bolt (4) and

tighten the upper bolt (5). Repeat for the second

bracket (Figure 7).

12

45

3

Repeat For

Second Bracket

Figure 7

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

8

POWER SUPPLY MOUNTING YOKE

INSTALLATION

Remove the 4 yoke mounting bolts from beneath the

power supply and slide the mounting bracket out

(Figure 8).

Figure 8

NOTE:

If the Optional Stack Light is included with your

system it should be installed at the same time as the

Power Supply Mounting Yoke.

When installing the yoke onto the mount, take into

account the dimensions of the power supply, sealing

head, and container when choosing its placement on

the mount. Ensure the yoke is at a height that will

allow your container to pass easily beneath the

sealing head. Place the optional stack light at the

highest point on the channel to allow the greatest

visibility. Remove the mounting bolts and affix the

yoke and stack light onto the mount (Figure 9).

Power Supply

Yoke Mounting Bolts

Stack Light

Mounting Bolts

Figure 9

MOUNT PLACEMENT AND INSTALLATION

Next find a suitable location along the conveyor that

allows sufficient space for installing the power supply

and any options that mount to the conveyor. Place

the mount against the conveyor and measure from

the center of your conveyor to the center of the floor

mounting brackets 11 ¼“ (Figure 10).

1114"

Recommended

distance

Conveyor Mounting

Brackets

Floor Mounting

Brackets

Figure 10

Drill holes in the conveyor and floor to secure the

mount, and bolt the mount in place (Figure 11).

Figure 11

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

9

ATTACHING POWER SUPPLY TO MOUNT

It is recommended that the sealing head be removed

for ease of installation of the power supply. Remove

the 4 bolts from the 2 mounting brackets. The power

supply can be lifted up off of the sealing head by

raising the mount, or the head can be pulled straight

down from the power supply (Figure 12).

Figure 12

Install the power supply by lowering it onto the yoke

and aligning the Baseplate holes with the holes in

the yoke. Secure the power supply to the yoke using

the power supply mounting bolts removed earlier

(Figure 13). Once the power supply is secure,

reinstall the sealing head (Figure 12).

SuperSeal

SuperSeal

Figure 13

NOTE:

The sealing head should be reinstalled to the lowest

points in the slots on the mounting brackets to help

ensure the most consistent gap.

MOBILE CART SYSTEM INSTALLATION

When the cart system has been removed from its

crating, locate the leveling pads and remove them

from their packaging. Remove the protective yellow

sleeves and thread the pads into the mobile cart

base far enough that they do not contact the floor

(Figure 14).

LEVELING PADS

SuperSeal

SuperSeal

Figure 14

Next find a suitable location along the conveyor that

allows sufficient space for installing the cart and

power supply and any options that mount to the

conveyor. Unlock the casters and roll the system up

to the conveyor. Center the sealing head over the

conveyor, or product path, and lock all 4 casters.

Level the power supply to the conveyor by lowering

the leveling pads as required. Once set, tighten each

leveling pad’s lock nut (Figure 15).

Unlocked

Locked

SuperSeal

SuperSeal

Figure 15

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

10

NOTE:

If the Optional Stack Light is included with your

system it will have been factory installed.

Depending upon the combined height of your

conveyor and container, it may be necessary to

adjust the rough height of the power supply. Due to

the weight, the power supply will need to be securely

supported before loosening the yoke mounting bolts.

Once the power supply is securely supported, adjust

the height by raising or lowering the mount within the

yoke’s channel. Once the adjustment has been

made ensure all hardware is retightened (Figure 16).

Lower

Raise

Locking

Knob

Safety

Nut

DO NOT Remove the

Safety Nut unless

instructed

Yoke

Mounting

Bolts

SuperSeal

SuperSeal

Figure 16

CAUTION!

Loosen the clamp before adjusting the mount

height.

Ensure that the safety nut located at the

bottom of the extrusion track is securely in

place.

All other visible screws on the mount, such as

the nylon tipped corner set screws, should not

be field adjusted as they are factory set.

SYSTEM ALIGNMENT OVER CONVEYOR

It is important that each end of the sealing head be

equal in height and alignment in relation to the

conveyor. This will be critical for ensuring the

containers are entering and exiting at the same gap

and centering on the sealing head. The better the

liner is positioned within the sealing head’s

electromagnetic field, the more efficiently the liner

will be heated as it passes.

WARNING!

.

The sealing head produces a electromagnetic

field that quickly heats any metal within the

field.

With the exception of the metal frame of your

conveyor, DO NOT mount any metal objects

within 6” (15cm) of the sealing head.

The Sealing Head and Surrounding Metal

Due to the nature of induction heating, the sealing

head will induct into all metal objects that are

mounted within range of its electromagnetic field.

The electromagnetic field weakens as it moves away

from the sealing head until it dissipates at a distance

of approximately 6” (15cm) at the farthest. Even at its

weakest point the electromagnetic field will

inductively heat metal objects, though the rate of

heating will be slower.

Smaller metal objects, such as screws or brackets,

which are mounted within the sealing head’s

electromagnetic field will be continually heated

whenever the electromagnetic field is active. This

scenario has the potential to create a severe burn

hazard and should be eliminated if possible.

Larger metal objects, such as your conveyor’s metal

frame, which are located within the electromagnetic

field, tend not to show signs of heating due to the

mass of these objects. The only adverse affect

typically associated with large metal objects is a

slight change in the performance of the sealer, which

in most cases is not noticeable due to the

insignificance of the change. This scenario is

considered normal in most production atmospheres

and is safe to both operators and the equipment.

Container Path

The container path beneath the sealing head must

be as consistent as possible, and this can be

achieved with the use of guide rails. If guide rails are

used, ensure that the metal rails beneath the sealing

head are removed, or at least 6 inches (15cm) below

the sealing head (Figure 17).

Guide Rails

Figure 17

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

11

Sealing Head Centering

Raise the system height, if needed, by loosening the

locking knob and rotating the hand wheel counter-

clockwise, and then retighten the locking knob.

Loosen the power supply mounting bolts on each

side to allow free movement of the power supply

over the container. Align both the input and exit side

centerline labels to the center of the container’s cap.

Retighten the mounting bolts (Figure 18).

CENTERLINE

Locking

Knob

Power Supply

Mounting Bolts

Centerline

Label

Raise

Figure 18

Setting the Container and Sealing Head Gap

Use the 1/8 inch (3mm) thick gap gauge provided by

Enercon to set the gap between the container and

sealing head (Figure 19).

Sealing Head Mounting Brackets

STOPSTART

AUTO

FAULT

TEMP

OUTPUT (%)

RUN

REMOTE

READY

Gap Gauge

Tunnel Sealing

Head

Flat Sealing

Head

Lower

Lower

Super Seal

Super Seal

Figure 19

As shown, the gap gauge placement will depend

upon the type of sealing head supplied with the

system. Once the gap gauge is in place, loosen the

locking knob and lower the system by rotating the

hand wheel clockwise until the bottom of the flat

head or the top of the tunnel touches the gauge or

cap. Ensure the gap is equal on both ends of the

sealing head. Retighten the locking knob and

remove the gap gauge.

DETAILED SEALING HEAD ALIGNMENT

To ensure repeatability of your sealing process,

proper alignment of the sealing head is critical. Use

the following steps to help achieve proper alignment.

Standard Flat Sealing Head

The standard Flat Sealing Head is typically used on

larger containers between 53mm and 120mm. The

sealing head must be centered over the cap with a

1/8” (3mm) air gap between the bottom of the sealing

head and the top of the cap (Figure 20).The 1/8”

(3mm) gap will allow the highest line speeds with the

most consistent seal results.

CENTER LINE

Figure 20

Standard Tunnel Sealing Head

The Standard Tunnel Sealing Head is typically used

on containers 53mm and smaller. The sealing head

must be centered over the cap with a 1/8” (3mm) air

gap between the top of the sealing heads tunnel and

the top of the cap (See Figure 21).The 1/8” (3mm)

gap will allow the highest line speeds with the most

consistent seal results.

CENTER LINE

Figure 21

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

12

Deep Tunnel Sealing Head

The Deep Tunnel Head is typically used on special

applications where the cap or container will not allow

the product to fit within the standard tunnel head.

Deep tunnel head have a centerline indicator at the

top of the tunnel and foil indicators on both sides of

the tunnel. In these applications, the center

alignment should be set with the cap in place but the

sealing head height should be set with the cap

removed. Align the foil indicators to the lip of the

container where the foil liner rests. If cap or container

dimensions prevent the lip of the container from

reaching the centering marks then position the

container lip into the tunnel as far as possible

(Figure 22).

CENTER LINE

FOIL

FOIL

LINER &

CONTAINER LIP

Cap & Liner must be

aligned with all 3

labels.

Figure 22

Alignment And Adjustment “1” Sealing Head

In many instances, multiple cap sizes will be run on

the same power supply. The “1” Sealing Head and

Pivot Kit allows for moving the sealing head to

accommodate various size caps without having to

exchange the sealing head. The “1” sealing head

can be pivoted in approximately seven (7) degree

increments to four different positions (Figure 23).

100 - 120

63 - 89

20 - 38

43 - 58

CAP

(mm) CAP

(mm)

63 - 89

100 - 120

43 - 58

20 - 38

4

4

3

2

1

3

2

1

Figure 23

The table that follows indicates the desired pivot

position for the listed liner sizes. The pivot assembly

brackets serve to guide the sealing head rotation,

providing the proper pivot angle for the liner sizes you

are sealing. The knurled locking knobs serve to lock the

sealing head in place.

NOTE:

No tools are required to change the position of the

sealing head. Loosen both of the knurled locking knobs,

one at each end of the sealing head. Rotate the sealing

head to the proper position for the cap size in use.

Center the proper indicator line on the locking knobs at

each end of the sealing head and hand tighten the

locking knobs.

Item # Description

1 20 – 38mm Position

2 43 – 58mm Position

3 63 – 89mm Position

4 100 – 120mm Position

Proper alignment of the “1” Sealing Head is critical, use

the following steps for proper set up.

1. First align the power supply and sealing head over

the conveyor with the sealing head in the #1

position. The mount / cart must be secure.

2. Align and gap the product to the sealing head using

the same criteria used for a Flat Sealing Head (See

Figure 20) ensuring that it runs centered along the

entire length of the sealing head.

3. Choose the proper position for the caps size to be

run and pivot the sealing head to that position, Refer

to table above.

NOTE:

Check alignment whenever the pivot angle is to be

changed to ensure proper sealing.

SYSTEM REQUIREMENTS

Temperature

The Super Seal™ has been designed to operate in

an ambient air temperature range of 32º-104º F (0º-

40º C) @ 80% relative humidity, non-condensing.

Input Voltage Requirements

The Super Seal™ requires a specific input voltage to

function properly. The required input voltage is listed

on the rating plate on the side of the power supply

(See Figure 4 on Page 6), and in the drawing list

provided with your system. The standard voltages

required are 208 or 240 VAC ± 10%, 1Ø / 3Ø, 50/60

hertz.

WARNING!

The power supply should not be operated

without the grounded line cord connected to a

grounded receptacle.

DO NOT bypass the ground terminal.

Grounding Requirements

All system components must be connected to a good

earthen ground point using the green ground wire

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

13

provided in the power cord. Local codes will dictate

the means of terminating the ground wire. A fused

disconnect switch must be located between the input

voltage source and the power supply.

BASIC SYSTEM

Each Super Seal™ is supplied with 2 standard cables

and 2 defeat connectors. The two cables provided are

the Remote Start / Interlocks Cable (1) and the Alarm

Connector Cable (2). The 2 defeat connectors are for

the REMOTE START / INTERLOCKS circuit (1) and

STALLED BOTTLE SENSOR circuit (3). Both the

cables and defeat connectors will connect to the rear

panel of the power supply (Figure 24).

INTERLOCK DEFEAT CONNECTOR

(USED WHEN NEITHER INTERLOCKS NOR

REMOTE START ARE REQUIRED)

TO CUSTOMER

N.O. INTERLOCK

CONTACT

TO CUSTOMER

N.O. REMOTE

START CONTACT

BLACK

RED

WHITE

GREEN

BLACK

RED

WHITE

FOR CUSTOMER LOSS OF

SEALING INDICATOR (LSI) ALARM,

USE AS REQUIRED

1

2

REMOTE START /

INTERLOCKS

AUTO

CONTROL

STALLED

BOTTLE SENSOR FOIL DETECT

SENSOR ASSY

STACK

LIGHT

LSI

CONTACTS FOIL DETECT

CONTACTS

1

2

33

STALLED BOTTLE DEFEAT CONNECTOR

(REQUIRED WHEN NEITHER OF THE THE MOTION

OPTIONS ARE INCLUDED WITH YOUR SYSTEM)

Figure 24

BASIC INTERCONNECTIONS

Using The Remote Start / Interlocks Cable

A cable is provided to extend the wiring of the

Remote Start / Interlock cable to external contacts as

shown in Figure 24. Connect the Remote Start /

Interlock cable securely to the rear panel of the

power supply and run the open end of the cable to

your N.O. dry contacts. Ensure you use the Black

and Red wires for the Interlock function and the

White and Green wires for the Remote Start function.

The Remote Start function is tied to the

LOCAL/REMOTE pushbutton located on the front

panel of the unit.

External Interlock

The Super Seal™ comes standard with provisions

for interlocking the control circuits. The two interlock

wires must be connected to a normally open contact

that closes when the interlock is met for the unit to

start. This “closed circuit” may be accomplished in a

number of different ways but is absolutely necessary

for the unit to start and run. Do not apply any voltage

across these wires.

WARNING!

Applying voltage to the interlock control

circuits may result in a failure of circuit

components.

DO NOT APPLY VOLTAGE ACROSS THE

INTERLOCKS!

Remote Start

The Super Seal™ comes standard with provisions

for starting and stopping the power supply remotely.

The two remote start wires must be connected to a

normally open contact and the contact must be

closed to start the power supply and open to stop it

(Refer to REMOTE START OPERATION on Page

19). Do not apply any voltage across these wires.

USING THE DEFEAT CONNECTORS

Remote Start / Interlocks

A defeat connector is included to provide the

required closed circuit for the interlocks when the

interlock and remote start functions are not used.

This simply requires connecting the defeat connector

to the REMOTE START / INTERLOCKS connector

on the rear panel of the power supply. The jumper

wire inside the defeat connector allows the unit to

start without providing an external closed contact.

Stalled Bottle Sensor

A second defeat connector is included to provide the

required closed circuit for the Stalled Bottle Sensor

circuit when none of the Motion options is included

with your system. This simply requires connecting

the defeat connector to the STALLED BOTTLE

SENSOR connector on the rear panel of the power

supply. The jumper wire inside the defeat connector

allows the unit to start without having the optional

stalled bottle sensor connected to the power supply.

Refer to SECTION 4 – OPTIONS for further details

on the Motion Options that are available.

NOTE:

Even if you are not using either of the defeat

connectors, ensure you do not discard either of

them. Keep them in a safe place, as they may be

required to substitute for the Remote Start /

Interlocks cable or the Stalled Bottle Sensor,if

they are damaged, or for troubleshooting these

circuits.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

14

LOSS OF SEALING INDICATOR ALARM (LSI)

The Loss of Sealing Indicator Alarm provides you

with a set of dry contacts that will allow you to drive

an external alarm, or monitor the power supply’s

output status using a monitoring circuit of your

choice.

The alarm circuit is programmable from the power

supply front panel, giving you the ability to quickly

and easily customize the alarm setpoint for a wide

variety of products.

As shown in Figure 24 on Page 13, a contact cable

is provided to extend the alarm contacts to your

alarm or monitoring circuit. The alarm contacts

consist of a Common (COM), Normally Open (N.O.)

and a Normally Closed (N.C.) contact. The contact

cable connects to the LSI CONTACTS connector on

the rear panel of the power supply and the open end

of the contact cable can be run to your external

alarm or monitoring circuit.

Typically the N.C contact will be used for triggering

your alarm circuit, as this is the non-powered state of

the relay contacts. The relay will only change state

when the power supply is running and the output

percentage is greater than the programmed trip

setpoint; see ADJUSTING THE LOSS OF SEAL

INDICATOR ALARM SETPOINT on Pages 17-18.

When using the alarm contacts to an alarm circuit,

ensure the supplied voltage does not exceed the

contacts rating of 24 VDC, 2 Amps.

DANGER!

The contact cable is provided to extend the dry

contacts of the alarm circuit only.

All necessary precautions should be taken

when wiring the contact cable to powered

external circuitry.

When the contact cable is connected to

external powered circuits, proper lockout / tag

out procedures should be observed for the

external circuits.

This must be done before disconnecting the

connector cable from the power supply to

prevent the cable from being energized when

disconnected.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

15

SECTION 3 – PRINCIPLES OF OPERATION

GENERAL

Before operating this equipment, we

recommend reading this section in its entirety to

ensure you understand all the safety and operational

requirements for using this equipment. Also, please

refer to SECTION 1 – INTRODUCTION, Pages 1

and 2, to become familiar with all safety

requirements and precautions.

WARNING!

DO NOT operate this equipment in a hazardous

environment.

Operating this equipment near flammable vapors,

fuels, or combustibles; including atmospheric

product dust or particulates, may result in

explosion or fire, causing serious injury or death.

CONTROL FUNCTIONS

The power supply utilizes a Digital Output Meter to

represent its output level as a percent of available

output, colored LED’s to represent control and fault

status, and pushbuttons to control the power

supply’s output and operational modes (Figure 25).

Figure 25

Front Panel Indicators

The power supply front panel includes the following

indicators to represent its control and fault status.

Control Display Lamps

Green; breaker/switch energized

- input voltage applied.

Green; output current applied to

the sealing head, and regulated.

Amber; Remote Start Mode

Selected.

Amber; AUTO Mode Selected.

Fault Display Lamps

Red; Temperature Fault.

Red; Power Supply Failure.

Digital Output Meter

The Output Meter displays power supply’s

output in percentage of available output. The Output

Meter will flash the selected output level setpoint

when the circuit breaker or disconnect switch is

placed in the ON position. Once the START

command is applied, the number displayed on the

Output Meter will stop flashing. This is the actual

output level of the power supply.

Front Panel Push Pushbuttons

START Starts Power Supply locally.

STOP Stops Power Supply locally, Resets

Faults.

UP For adjusting output level up.

DOWN For adjusting output level down (Limited

at minimum setting).

LOCAL/

REMOTE For selecting either LOCAL or REMOTE

Start Mode.

AUTO/

MANUAL For selecting either AUTO or MANUAL

power control Mode.

WARNING!

The sealing head produces an electromagnetic

field that quickly heats any metal within the field.

DO NOT pass metal objects, other than

appropriate liner materials, beneath the sealing

head.

Personnel should keep jewelry, such as rings

and watches, from placement beneath or within

the sealing head’s electromagnetic field.

WARNING!

Never allow the liners to reach a temperature

sufficient to ignite the liner or container contents.

Ensure the dwell time beneath the sealing head is

correct and DO NOT allow containers to stop

within the electromagnetic field.

Failure to observe these requirements may lead

to fire or explosion.

WARNING!

DO NOT attempt to induction seal damaged or

improperly applied liners as they may overheat

causing the liner and container contents to

ignite.

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

16

SEQUENCE OF OPERATION

LOCAL OPERATION

A Circuit Breaker or Disconnect Switch is

provided on the rear panel of the power supply for

applying the input voltage to the power supply

(Figure 26).

Disconnect Switch

ONI

O

OFF

Circuit Breaker

Figure 26

Placing the circuit breaker or disconnect switch into

the ON position will apply the input voltage, and all of

the LEDs on the front panel will initially be lit and the

output meter will flash 888. After the initial startup, all

of the LEDs except the READY LED will go out, and

the output meter will revert to flashing the last

selected output level setpoint. If the power supply

was in either the REMOTE or AUTO modes when

the input voltage was last removed, the

corresponding LED will also be lit.

If either of the fault LEDs is lit, press the STOP

pushbutton to reset the fault. If the fault will not reset,

refer to SECTION 5 – TROUBLESHOOTING.

If either the REMOTE or AUTO LEDs are lit, press

the LOCAL/REMOTE pushbutton to allow

LOCAL start control, and/or the AUTO/MANUAL

pushbutton to allow MANUAL power control.

With the power supply in LOCAL and MANUAL

modes with no faults indicated, use the UP /

DOWN arrows to increase or decrease the

output level until the desired output level setpoint is

displayed. Press the START pushbutton to start

the power supply.

Once the power supply is running, the RUN

LED will be lit and the Output Meter will

stop blinking and display the actual output level as a

solid number .

NOTE:

The Output Level can be adjusted while the output

meter is blinking and when the power supply is

running.

Press the STOP pushbutton to stop the power

supply. When the STOP pushbutton is pressed, only

the READY lamp should be lit and the number on

the output meter will again be flashing the output

level setpoint.

Ensure you always STOP the power supply prior to

placing the circuit breaker or disconnect switch into

the OFF position. This will remove the input voltage

from the power supply and all of the LEDs and the

output meter will go out. Failure to STOP the power

supply may result in damage to the power supply

components.

NOTE:

If the RUN LED is not lit when the

power supply is running, output meter is not flashing,

the Loss of Seal Indicator Alarm setpoint is above

the output level you are running at. (Refer to

ADJUSTING THE LOSS OF SEAL INDICATOR

ALARM SETPOINT on Pages 17-18).

SEALING WINDOW SETUP

In the induction sealing process there are several

variables that make almost every application unique.

Keep in mind that rarely is one set up solution right

for every application. Most applications will have

their own unique variables for the perfect seal and

each variance must be given consideration when

determining the output level for a given application.

WARNING!

Never allow the liners to reach a temperature

sufficient to ignite the liner or container contents.

Ensure the dwell time beneath the sealing head is

correct and DO NOT allow containers to stop

within the electromagnetic field.

Failure to observe these requirements may lead

to fire or explosion.

WARNING!

DO NOT attempt to induction seal damaged or

improperly applied liners as they may overheat

causing the liner and container contents to

ignite.

NOTE:

An application consists of the package (container,

liner, cap), product (type, temperature, fill level),

dwell time (length of time the liner is in the inductive

field), sealing head alignment (gap, centering, level)

and the induction sealer (inductive field strength

and frequency) being used. For more detailed

application information, refer to “APPLICATION

ML0071-601-06 Super Seal™ Operations Manual Rev. A ENERCON INDUSTRIES

17

TROUBLESHOOTING” in SECTION 6 –

TROUBLESHOOTING.

Once the system is running it is recommended that

you attempt to determine the sealing window of the

products that will be sealed by this power supply.

This test will require several containers, caps, and

liners and should be performed at the line speed

each product will be run at during actual production.

NOTE:

The initial output level chosen for this test can be a

level determined by the testing results of your

product samples by Enercon, or an output level of

your own choosing. If no samples were sent for

testing, it is recommended that the initial output level

be 50% or lower. For the following examples, we will

be using 50% as the initial output level.

With the circuit breaker or disconnect switch ON,

press the UP /DOWN arrows until the

desired output level setpoint is reached. Press the

START pushbutton and ensure the unit starts

and is running at the output level you selected.

Run a single container under the sealing head at

your production line speed. Once through the sealer,

wait at least 30 seconds for the liner to cool and then

remove the cap and inspect the liner condition.

NOTE:

Do not perform this test on a container that has been

previously run, as this can give inaccurate test

results. A new container, liner, and cap should be

used each time the test requires a container to be

run.

No Seal

If no seal was achieved, raise the output in 5%

increments and continue running a single container

until the liner begins to adhere. Continue the test,

raising the output by 1% or 2%, until the liner seals

around the entire lip of the container. This is the

lower limit of the sealing window. Continue the test,

raising the output by 1%, until the liner shows signs

of overheating then lower the output by 1% and this

is the upper limit of the sealing window. Choose the

output level, within this window, that gives the

desired strength and peelability as your production

output level.

Burned Liner

If the initial test results in a burned liner, lower the

output in 5% increments and continue running a

single container until the burning subsides. Continue

the test, lowering the output by 1% or 2%, until the

liner shows no signs of overheating. This is the

upper limit of the sealing window. Continue the test,

lowering the output by 1%, until the liner no longer

seals the entire lip of the container. Raise the output

by 1% and this is the lower limit of the sealing

window. Choose the output level, within this window,

that gives the desired strength and peelability as

your production output level.

Good Seal

If a good seal was achieved, note the output level,

then lower the output 1% and continue running a

single container until the liner no longer seals the

entire lip of the container. Raise the output by 1%

and this is the lower limit of the sealing window.

Reset the output to the level noted after the initial

test. Continue the test raising the output by 1% until

the liner shows signs of overheating. Lower the

output by 1% and this is the upper limit of the sealing

window. Choose the output level, within this window,

that gives the desired strength and peelability as

your production output level.

Production Test

When the sealing window and production output %

have been determined, a production test should be

run. Set up a group of containers that is at least

twice the length of the sealing head. The grouping

should be back to back to simulate a worst case

scenario. Press the START pushbutton and

verify the unit is running at your production output

level determined in the previous steps. Run the

containers at your production line speed and then

verify that all containers sealed properly.

If not all of the containers sealed, double check the

results of the sealing window setup and refer to

“APPLICATION TROUBLESHOOTING” in

SECTION 6 – TROUBLESHOOTING of this manual.

If all of the containers sealed properly, then the

system is ready to be put into production.

ADJUSTING THE LOSS OF SEAL INDICATOR

ALARM SETPOINT

The Loss of Sealing Indicator Alarm (LSI) is

programmable to allow setting the power supply’s

lower output limit, or threshold, for the alarm circuit

operation. If, for any reason, the output displayed on

the output meter falls below this programmed alarm

setpoint the alarm relay contacts will change state.

Refer to LOSS OF SEALING INDICATOR ALARM

(LSI) on Page 14 for more information.

The default alarm setpoint is 60%, and is set during

the testing phase of the power supply. You will be

able to adjust the alarm setpoint to any level through

the full output range of your power supply.

Table of contents

Other ENERCON Food Saver manuals