ENERCON SUPER SEAL 300 User manual

6/7/2023

SUPER SEAL™ 300 / 400 / 600

INDUCTION CAP SEALER

ML0185-001-01

OWNER’S REFERENCE MANUAL

DANGER: Read entire Owner’s Reference Manual

before installing, operating, or maintaining equipment.

Mailing Address:

Enercon Industries Corp.

P.O. Box 773

Menomonee Falls, WI 53052-0773

Shipping Address:

Enercon Industries Corp.

W140 N9572 Fountain Blvd.

Menomonee Falls, WI 53051

(262) 255-6070 - www.enerconind.com

Table of Contents

SECTION 1 – SAFETY AND WARNINGS ................................................................................................................................................. 1

1.1 GENERAL SAFETY INFORMATION ............................................................................................................................ 1

1.2 SAFETY PRECAUTIONS .............................................................................................................................................. 1

1.3 EQUIPMENT SAFETY LABELS .................................................................................................................................... 2

1.4 EQUIPMENT INFORMATION LABELS ......................................................................................................................... 3

SECTION 2 – INSTALLATION ................................................................................................................................................................... 4

2.1 GENERAL ..................................................................................................................................................................... 4

2.2 UNPACKING AND INSPECTION .................................................................................................................................. 5

2.3 CONTACT INFORMATION ........................................................................................................................................... 5

2.4 SYSTEM REQUIREMENTS .......................................................................................................................................... 5

2.41 Input Voltage Requirements .................................................................................................................................. 5

2.42 Grounding Requirements ...................................................................................................................................... 6

2.43 Temperature Rating .............................................................................................................................................. 6

2.5 INSTALLATION GUIDELINES ...................................................................................................................................... 6

2.51 Power Supply Enclosure Specs ............................................................................................................................ 6

2.6 FLOOR MOUNT INSTALLATION .................................................................................................................................. 6

2.61 Floor Mount Assembly .......................................................................................................................................... 6

2.62 Floor Mount Installation ......................................................................................................................................... 6

2.63 Power Supply Installation ...................................................................................................................................... 7

2.7 OPTIONAL MOBILE CART INSTALLATION ................................................................................................................. 7

2.8 SYSTEM ALIGNMENT .................................................................................................................................................. 8

2.81 Container Path and Standard Sealing Head Alignment ........................................................................................ 8

2.82 Deep Tunnel Sealing Head Setup ....................................................................................................................... 10

2.83 All-In-One Universal Sealing Head Setup ........................................................................................................... 10

2.9 CABLE CONNECTIONS ............................................................................................................................................. 10

2.10 INPUT VOLTAGE ...................................................................................................................................................... 10

SECTION 3 – PRINCIPLES OF OPERATION ......................................................................................................................................... 11

3.1 GENERAL ................................................................................................................................................................... 11

3.2 OPERATING INSTRUCTIONS .................................................................................................................................... 11

3.21 APPLYING THE INPUT VOLTAGE .................................................................................................................... 11

3.22 Power Supply Front Panel .................................................................................................................................. 12

3.3 BASIC OPERATION .................................................................................................................................................... 12

3.31 Local Operation ................................................................................................................................................... 12

3.32 Power Supply Output Range Verification ............................................................................................................ 13

3.4 POWER SUPPLY SETUP ........................................................................................................................................... 13

3.41 Start/Stop Setup .................................................................................................................................................. 13

3.42 Level Setup ......................................................................................................................................................... 13

3.43 Alarm Setup ........................................................................................................................................................ 13

3.5 OPERATING WINDOW SETUP .................................................................................................................................. 13

3.51 Minimum and Maximum Power Levels................................................................................................................ 13

3.52 Production Power Level ...................................................................................................................................... 14

3.6 REMOTE OPERATIONS ............................................................................................................................................. 14

3.61 Remote Start/Stop .............................................................................................................................................. 14

3.62 Remote Level Control ......................................................................................................................................... 14

SECTION 4 – EQUIPMENT INTERCONNECTION & OPERATION WITH OPTIONS ............................................................................. 15

4.1 GENERAL ................................................................................................................................................................... 15

4.2 MOBILE CARTS .......................................................................................................................................................... 15

4.3 AUTOMATION I/O CABLE .......................................................................................................................................... 15

4.31 External Interlock ................................................................................................................................................ 15

4.32 Loss of Seal Alarm .............................................................................................................................................. 16

4.33 Ready.................................................................................................................................................................. 16

4.4 STACK LIGHT ............................................................................................................................................................. 16

4.41 Installation ........................................................................................................................................................... 16

4.42 Setup................................................................................................................................................................... 17

4.43 Operation ............................................................................................................................................................ 17

4.5 STALLED BOTTLE DETECTION ................................................................................................................................ 17

4.51 Installation and Alignment ................................................................................................................................... 17

4.52 Setup................................................................................................................................................................... 17

4.521 Direction...................................................................................................................................................... 18

4.522 Stalled Bottle Time ...................................................................................................................................... 18

4.53 Operation ............................................................................................................................................................ 18

4.6 FOIL DETECTION ....................................................................................................................................................... 18

4.61 Installation and Alignment ................................................................................................................................... 18

4.62 Optional Cap Inspection Output Cable Wiring ..................................................................................................... 19

4.63 Setup................................................................................................................................................................... 19

4.631 Proximity Sensor Setup .............................................................................................................................. 19

4.632 Beam Sensor Setup .................................................................................................................................... 20

4.633 Optional Cap Inspection Output Cable Setup ............................................................................................. 20

4.64 Operation ............................................................................................................................................................ 20

4.7 BOTTLE BACKUP ....................................................................................................................................................... 20

4.71 Installation and Alignment ................................................................................................................................... 20

4.72 Setup................................................................................................................................................................... 21

4.73 Operation ............................................................................................................................................................ 21

4.8 EJECTOR .................................................................................................................................................................... 21

4.81 Installation ........................................................................................................................................................... 21

4.82 Setup................................................................................................................................................................... 22

4.821 Air Pressure Setup ...................................................................................................................................... 22

4.822 Eject Delay.................................................................................................................................................. 22

4.823 Eject Time ................................................................................................................................................... 22

4.83 Operation ............................................................................................................................................................ 22

4.9 SPARE PART KITS ..................................................................................................................................................... 23

SECTION 5 – MAINTENANCE ................................................................................................................................................................ 24

5.1 GENERAL ................................................................................................................................................................... 24

5.2 PREVENTIVE MAINTENANCE ................................................................................................................................... 24

5.3 WEEKLY CHECKS ...................................................................................................................................................... 24

5.31 Visual Inspection ................................................................................................................................................. 24

5.32 External Connections .......................................................................................................................................... 24

5.4 MONTHLY CHECKS ................................................................................................................................................... 24

5.41 Sealing Head Inspection ..................................................................................................................................... 24

5.42 Cooling Fans Inspection...................................................................................................................................... 25

5.43 Internal Connections ........................................................................................................................................... 25

5.5 MAINTENANCE RECORD .......................................................................................................................................... 25

SECTION 6 – TROUBLESHOOTING ...................................................................................................................................................... 26

6.1 GENERAL ................................................................................................................................................................... 26

6.2 FRONT PANEL ISSUES ............................................................................................................................................. 26

6.21 Blank Front Panel ............................................................................................................................................... 26

6.22 Buttons Do Not Function ..................................................................................................................................... 27

6.3 DISPLAYED FAULTS .................................................................................................................................................. 27

6.341 Removing/Installing Output Capacitors ............................................................................................................. 28

6.4 FACTORY RESET ...................................................................................................................................................... 30

6.5 INVERTER AND BRIDGE RECTIFIER ....................................................................................................................... 30

6.51 Inverter Ohm Check Procedure .......................................................................................................................... 30

6.52 Bridge Rectifier Ohm Check Procedure .............................................................................................................. 31

6.53 Replacing Inverters and Bridge Rectifiers ........................................................................................................... 31

6.6 FACTORY ASSISTANCE ............................................................................................................................................ 31

SECTION 7 – MISCELLANEOUS ............................................................................................................................................................ 32

MAINTENANCE RECORD ................................................................................................................................................ 32

PRODUCTION INFORMATION ........................................................................................................................................ 34

NOTES .............................................................................................................................................................................. 36

1

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

SECTION 1 – SAFETY AND WARNINGS

DANGER!

DO NOT OPERATE THIS EQUIPMENT IN AN EXPLOSIVE ENVIRONMENT!

1.1 GENERAL SAFETY INFORMATION

DANGER: Before placing this equipment into operation, you must read this manual carefully, in its entirety, to

ensure you understand all the safety and operational requirements for using this equipment.

This equipment produces an Electromagnetic Field to facilitate the induction sealing process. The

Electromagnetic Field quickly Heats any metal within the field and may, under certain conditions, Ignite

the metal or surrounding materials. Personnel should refrain from placing jewelry, such as rings and watches

beneath or within the sealing head’s electromagnetic field!

HIGH VOLTAGE is present within this equipment. As with any piece of ELECTRICAL equipment, one should

become familiar with the manual before applying power. Proper connections and operation are required for

safe use. FOLLOW INSTRUCTIONS for safety of personnel when operating or maintaining this equipment.

INSTALLATION of this equipment must be done in accordance with this manual, Enercon installation

drawings and local codes to ensure the safety of personnel in the area and in the building.

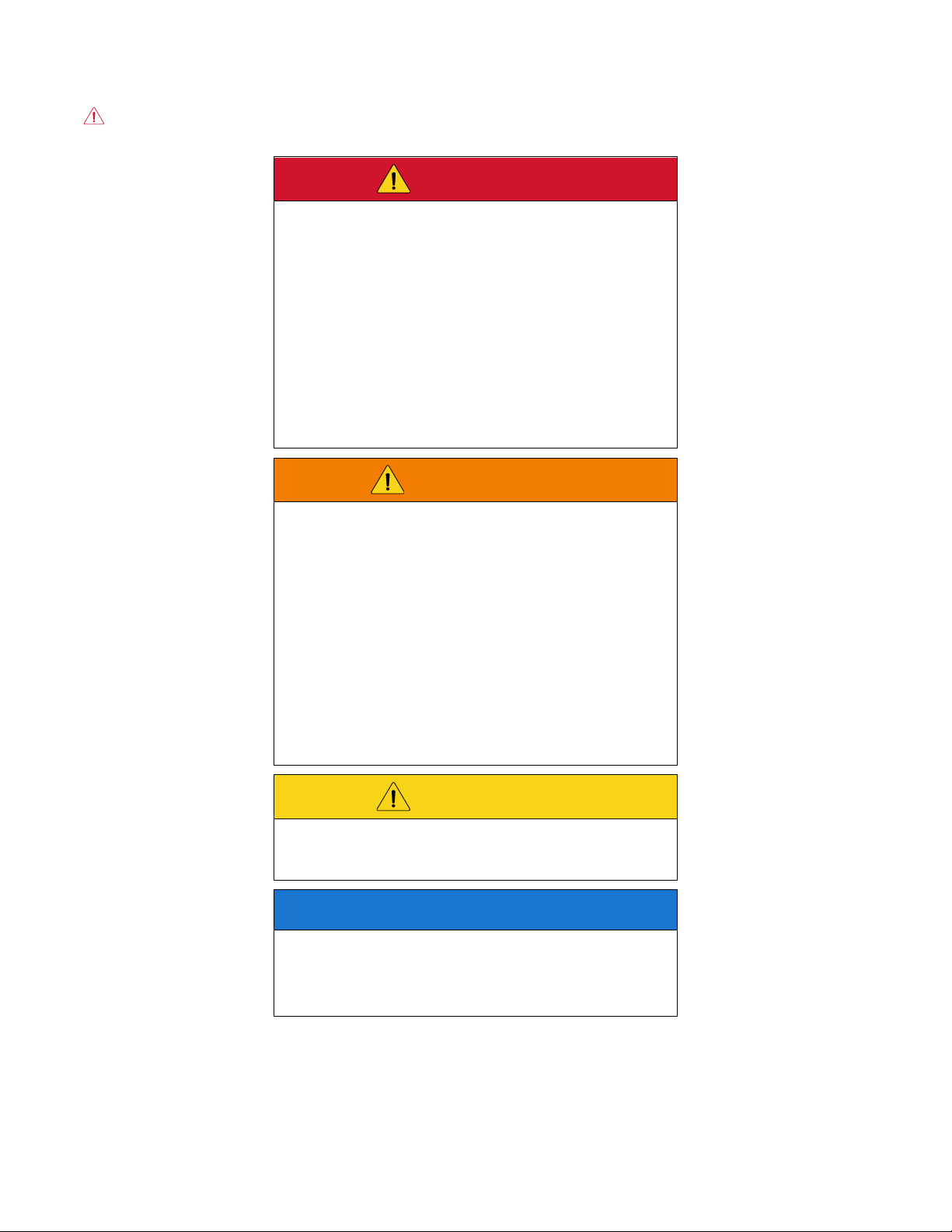

Safety instructions in this manual are called out in colored safety boxes with bold-faced text for emphasis.

The signal words CAUTION, WARNING, and DANGER are used to indicate hazard levels to personnel, and

NOTICE is used to indicate potential hazards to property.

DANGER

WARNING

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION

NOTICE

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

NOTICE: Indicates a potentially hazardous

situation which, if not avoided, could result in

damage to property.

1.2 SAFETY PRECAUTIONS

DANGER

Do not operate this equipment in an explosive environment, or in the presence of flammable materials! Operation

near flammable vapors, fuels, combustibles; including atmospheric product dust or particulates will result in

explosion or fire.

Before installing, wiring, starting, operating, or making any adjustments, identify the components of the

induction cap sealer using this manual as a guide.

The use of High Voltage is necessarily employed in the operation of this equipment. Precautions have been

taken in the design of this equipment to make it as safe as possible for both operator and service personnel.

However, since no amount of interlocks and safety devices can be absolutely infallible, precautionary

measures must always be taken when working on this equipment.

Do not reach into the equipment, or any electrical enclosure, without first removing the input voltage.

Do not apply voltage to the system without all covers on and securely in place.

Lockout / Tag Out: To insure that voltage cannot be applied to the equipment while work is performed, secure

or disconnect voltage supplies using the appropriate Lockout / Tag Out procedures. Ensure Lockout / Tag Out is

complete prior to entering the equipment in any manner. ALWAYS use safety as the first step!

2

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

Capacitors Store Charge: Never trust a capacitor to be bled off completely. A meter or ground strap should

be used to check each stud or lead before handling. Some capacitor studs, including those not tied to bus

work (not used), may build up a considerable static charge. GROUND BEFORE HANDLING!

Never assume that a circuit is dead, MAKE SURE!!!

Do not stand in water or on grounded surfaces or touch grounded surfaces while reaching in any system

enclosure. A piece of wood or other insulating material will act as an additional barrier to stand on.

WARNING

Do not tamper with Safety Interlocks: Under no circumstance should any of your system’s safety interlocks

be defeated, nor should any safety device be relied upon for removal of voltage from the equipment.

Test and Verify: Test all system safety interlocks to ensure they are fully functional before placing equipment

into production after maintenance, troubleshooting, or an extended shutdown. If an induction sealer is

integrated into an automated or partially automated system (e.g., integrated into a conveyance system) all

safety features and interlocks present in the entire system should be tested and checked at regular intervals

and after maintenance, troubleshooting, or an extended shutdown.

SEALING CONTAINERS OF FLAMMABLE OR COMBUSTIBLE MATERIAL:If an induction cap sealer will

be used to seal containers of flammable or combustible materials, it must be integrated into a conveyance

system, designed, and installed by a qualified professional integrator/installer with knowledge of the entire

conveyance system and product to be sealed. Such conveyance system must include all appropriate

safety features, including a stalled bottle detector and/or a bottle back-up sensor to detect

conveyance system failures. In the event of a conveyance system failure, containers remaining under

an induction cap sealer may overheat, causing damage to the container and product, and pose a

potential fire risk.

IMPORTANT – stalled bottle detectors and/or bottle back-up sensors are not substitutes for specific safety

features integrated into the entire conveyance system (e.g., manual emergency stops or other system safety

interlocks) and proper training on their use. Under no circumstance should operators be allowed to or required to

directly contact containers containing flammable or combustible material during the sealing process.

CAUTION

The equipment should only be installed, tested, operated and maintained by personnel familiar with the handling

and hazards of high voltage and electrostatic discharge, and are familiar with the instructions and safety

precautions contained within this manual.

Personnel should use common sense and good working practices while operating and maintaining this

equipment. Follow all codes and understand the starting and stopping sequence.

Familiarize yourself thoroughly with the equipment, and Never attempt to work on this equipment unless you

are completely familiar with it.

Always wear appropriate protective clothing and eyewear while working within the enclosure.

Only qualified personnel, equipped with the proper tools and protective gear, and following appropriate

safeguards, should perform system maintenance.

NOTICE

Follow the maintenance schedules as outlined in the manual to ensure problem free operation after startup.

Do not connect any 3rd party control or monitoring equipment, except for appropriate test equipment, to the

internal circuits of this equipment.

Connecting 3rd party equipment in this manner may result in failure of this equipment.

1.3 EQUIPMENT SAFETY LABELS

Safety labels alert personnel to potential hazardous situations. If for any reason a safety label is removed

or defaced, you must obtain a replacement label from Enercon.

Safety labels are located on system components where direct contact, or contact beyond a point, would

expose personnel to death or serious injury.

3

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

NA0056 – Located on the Sealing Head Connectors.

NA0136 – Located on the back of the power supply.

NA0137-01 – Located on the Sealing Head.

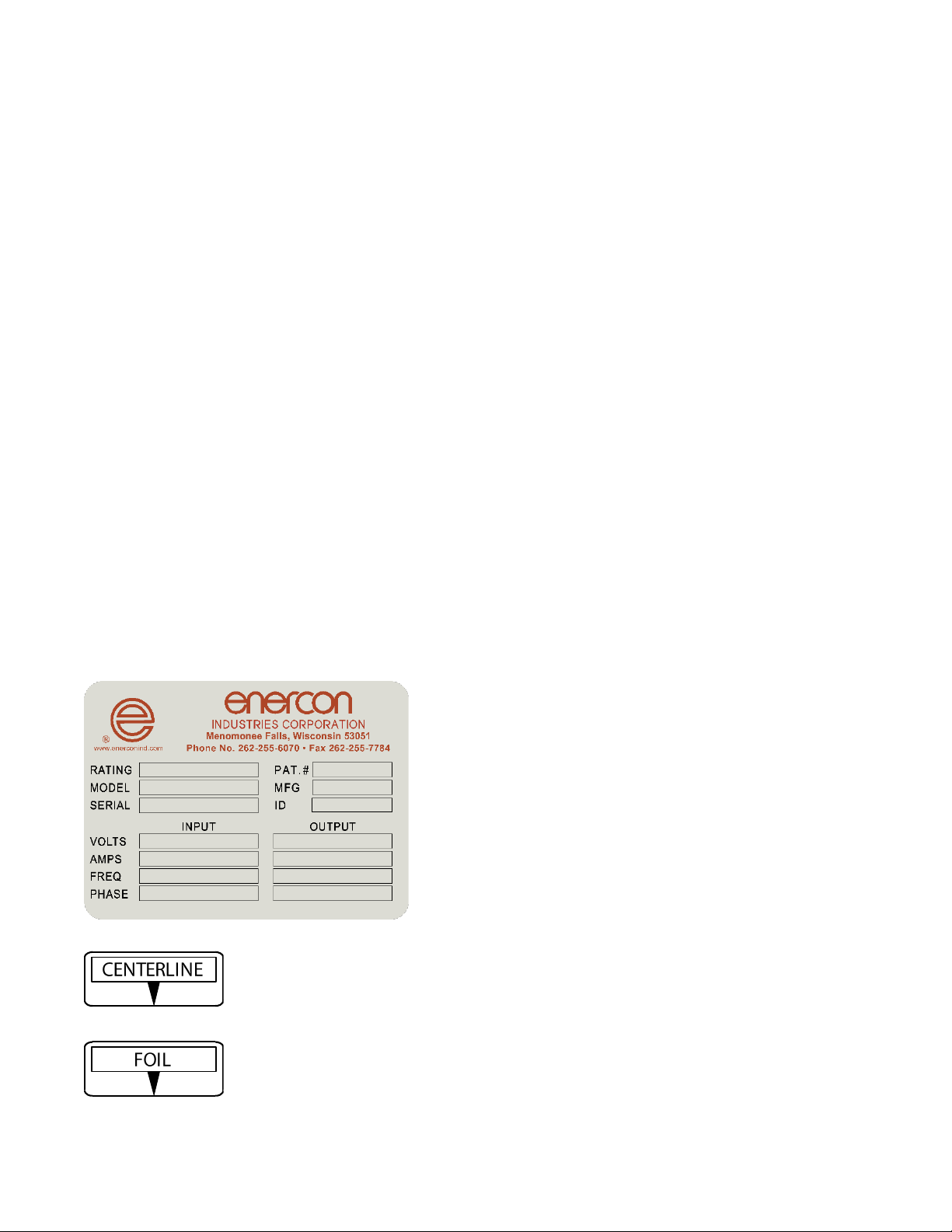

1.4 EQUIPMENT INFORMATION LABELS

Information labels provide information on equipment requirements that if not followed could result in damage

to the equipment. If for any reason an information label is removed or defaced, you should obtain a

replacement label from Enercon.

Rating Plate – Located on the side of the power supply.

NA0023 – Located on both ends of all Sealing Heads.

NA0181 – Located on the sides of each end of the Deep Tunnel Sealing Head openings.

4

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

SECTION 2 – INSTALLATION

2.1 GENERAL

DANGER: Before installing this equipment, please read this section completely, and refer to the safety warnings

of Section 1, to become familiar with all the safety requirements and precautions for this equipment.

All applicable safety requirements and precautions including those contained in this manual must be followed

for safe and efficient operation of an induction cap sealer.

Induction cap sealers should be installed and operated in accordance with all applicable Federal, state and

local laws and regulations.

Induction cap sealers (and all ancillary equipment) should be specified, integrated, and installed by qualified

professionals. Proper specification, integration, and installation should include a risk assessment of the entire

conveyance system (if used in conjunction with an induction cap sealer) in accordance with applicable

industry standards. This risk assessment can only be conducted by the owner or its contracted conveyance

system integrator/installer with knowledge of and access to the conveyance system equipment and product

to be sealed.

An induction cap sealer should be properly configured for the intended sealing operation, including proper

alignment and elevation with respect to a conveyance system (if used) and proper sealing window for the

application. Induction cap sealer configuration should be re-checked and adjusted following any changes to

the sealing operation (e.g., different container or product) and/or to the conveyance system in which an

induction cap sealer is used. As a reminder, Enercon offers a Start-Up Assistance program to help its

customers properly configure an induction cap sealer. Please contact Enercon regarding any

conveyance line or product changes.

All operators of an induction cap sealer should receive proper training regarding operation of an induction

cap sealer and the product being sealed. Training should include instruction on the specific safety features

integrated into the entire conveyance system (e.g., emergency stop operation and location(s)). Enercon

recommends that operators of an induction cap sealer be required to read and follow the most recent

applicable operating manual provided with the induction cap sealer and/or available from Enercon. Enercon

is also available to provide training and information to operators as part of its Start-Up Assistance program.

All equipment used on a conveyance system should be maintained in accordance with manufacturer

recommendations. As a reminder, Enercon recommends routine Preventative Maintenance visits,

which includes Enercon’s standard safety evaluation.

WARNING: SEALING CONTAINERS OF FLAMMABLE OR COMBUSTIBLE MATERIAL. If an induction

cap sealer will be used to seal containers of flammable or combustible materials, it must be integrated into a

conveyance system, designed and installed by a qualified professional integrator/installer with knowledge of

the entire conveyance system and product to be sealed. Such conveyance system must include all

appropriate safety features, including a stalled bottle detector and/or a bottle back-up sensor to

detect conveyance system failures. In the event of a conveyance system failure, containers remaining

under an induction cap sealer may overheat, causing damage to the container and product, and pose

a potential fire risk.

IMPORTANT - stalled bottle detectors and/or bottle back-up sensors are not substitutes for specific safety

features integrated into the entire conveyance system (e.g., manual emergency stops or other system safety

interlocks) and proper training on their use.

WARNING: Under no circumstance should operators be allowed to or required to directly contact containers

containing flammable or combustible material during the sealing process.

DANGER

The potential of electrical shock is present if all system

components are not properly grounded.

The power supply should not be operated without either

a 3-prong or 3-wire grounded line cord connected to a

grounded receptacle.

Do not by-pass the ground terminal.

High voltage is present within the cabinet, only qualified

personnel should be allowed to work within the

equipment.

Buss capacitors discharge very slowly, disconnect

power and verify they are discharged before working on

the power supply.

5

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

WARNING

Magnetic Field heats metal within the field.

Keep jewelry away from the sealing head.

Do not use damaged or improperly applied liners.

Liners may overheat causing liner and container

contents to ignite.

This equipment should not be used to seal containers

containing flammable or combustible contents unless

integrated into a conveyance system with proper

safety equipment including a stalled bottle detector

and/or bottle back-up sensor.

CAUTION

Small metal objects, such as screws, guiderails and

brackets, located within the electromagnetic field, will

continually heat creating a burn hazard.

NOTICE

Do not apply voltage across the interlocks!

Applying voltage to the interlock control circuits

may result in a failure of the control board

interlock circuit components.

Loosen the locking knob before adjusting the standard

mount height.

Ensure the standard mount safety nut remains securely

in place.

All other visible mount screws are factory set and

cannot be field adjusted.

2.2 UNPACKING AND INSPECTION

The carrier accepted responsibility for your shipment when they signed the Bill of Lading at the point of origin of

the shipment.

Your system may have shipped in more than one package. Compare the packing slip with the items received to

ensure that all items were delivered.

Inspect contents of each package for concealed loss or damage. If loss or damage is discovered after delivery,

notify the carrier at once to request an inspection. The carrier’s agent must perform an inspection and issue a

loss or damage report. This is absolutely necessary for the carrier to consider your claim.

If issues are found, contact Enercon Industries as soon as possible to expedite the shipment of replacement parts.

2.3 CONTACT INFORMATION

Enercon Customer Service Department 24hr

Customer Service Phone Number: (262) 255-6070

Service e-mail Address: service@enerconmail.com

Parts e-mail Address: parts@enerconmail.com

Website: www.enerconind.com

2.4 SYSTEM REQUIREMENTS

2.41 Input Voltage Requirements

The required input voltage is listed on the rating plate on the side of the power supply and in the

drawings provided with your system.

SS300

200 - 240VAC, 1Ø, 5 Amps, 50/60 Hz ± 10%

SS400

200 - 240VAC, 1Ø, 7.5 Amps, 50/60 Hz ± 10%

SS600

200 - 240VAC, 1Ø, 10 Amps, 50/60 Hz ± 10%

6

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

2.42 Grounding Requirements

All system components must be connected to a good earthen ground point using the green ground wire

provided in the power cord. Local codes will dictate the means of terminating the ground wire. A fused

disconnect switch must be located between the power source and the power supply.

2.43 Temperature Rating

The Super Seal™ is designed to operate in an ambient temperature range of 41º - 104F (5º - 40C) @

80% maximum relative humidity, non-condensing.

2.5 INSTALLATION GUIDELINES

For safe and proper operation, use this manual, your system drawings, and any other supplied documents

when installing system components.

2.51 Power Supply Enclosure Specs

Stainless Steel, IP55 Rated

Dimensions

Height*

Width

Depth

11 – 11/16” (297mm)

18 – 11/32” (466mm)

16 – 1/2” (419mm)

*Power Supply height is measured from the top of the cover to bottom of the output CT without a sealing head attached.

2.6 FLOOR MOUNT INSTALLATION

The basic Super Seal™ Induction Cap Sealing System consists of a Power Supply, Sealing Head and Adjustable

Floor Mount. The Floor Mount is designed for easy adjustment of the system height over your conveyor.

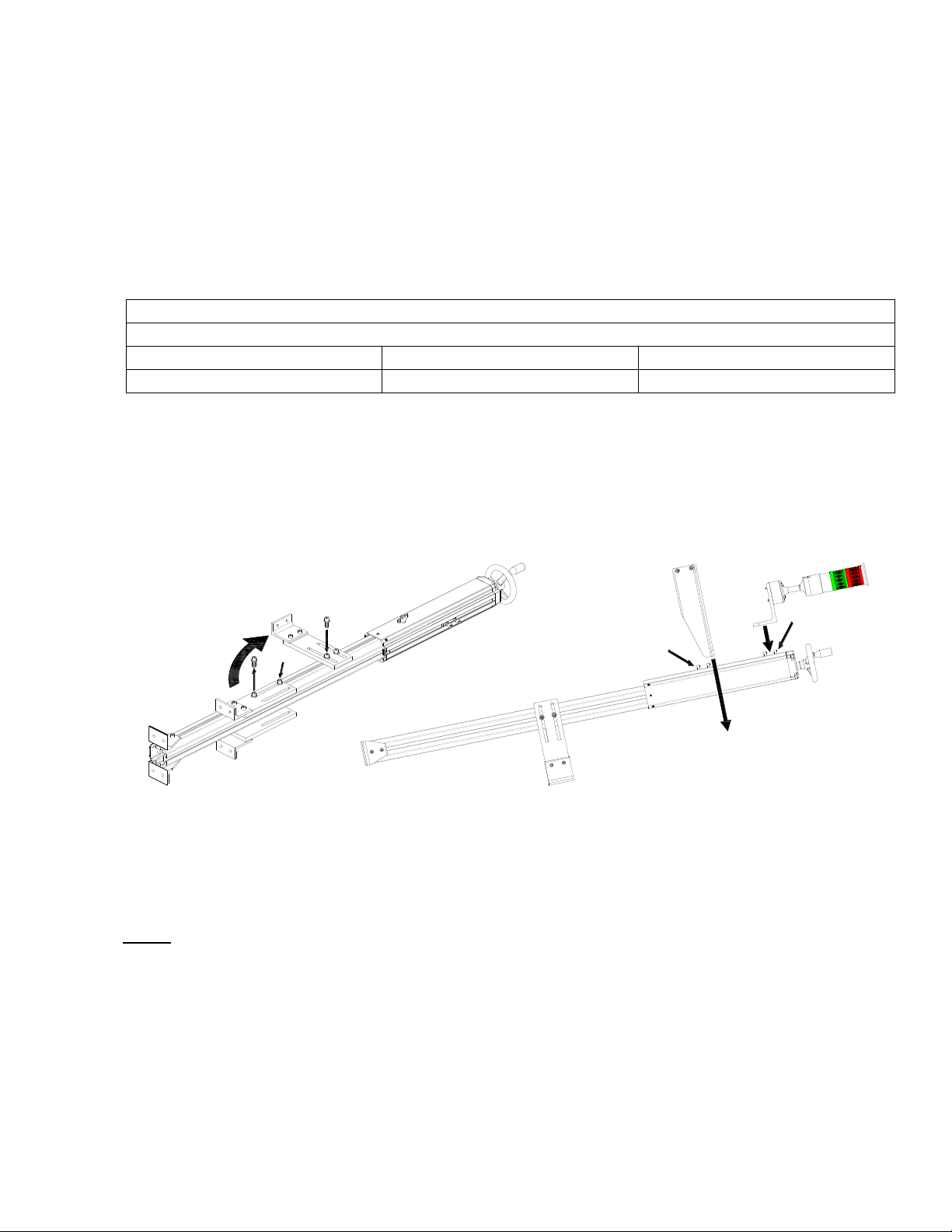

2.61 Floor Mount Assembly

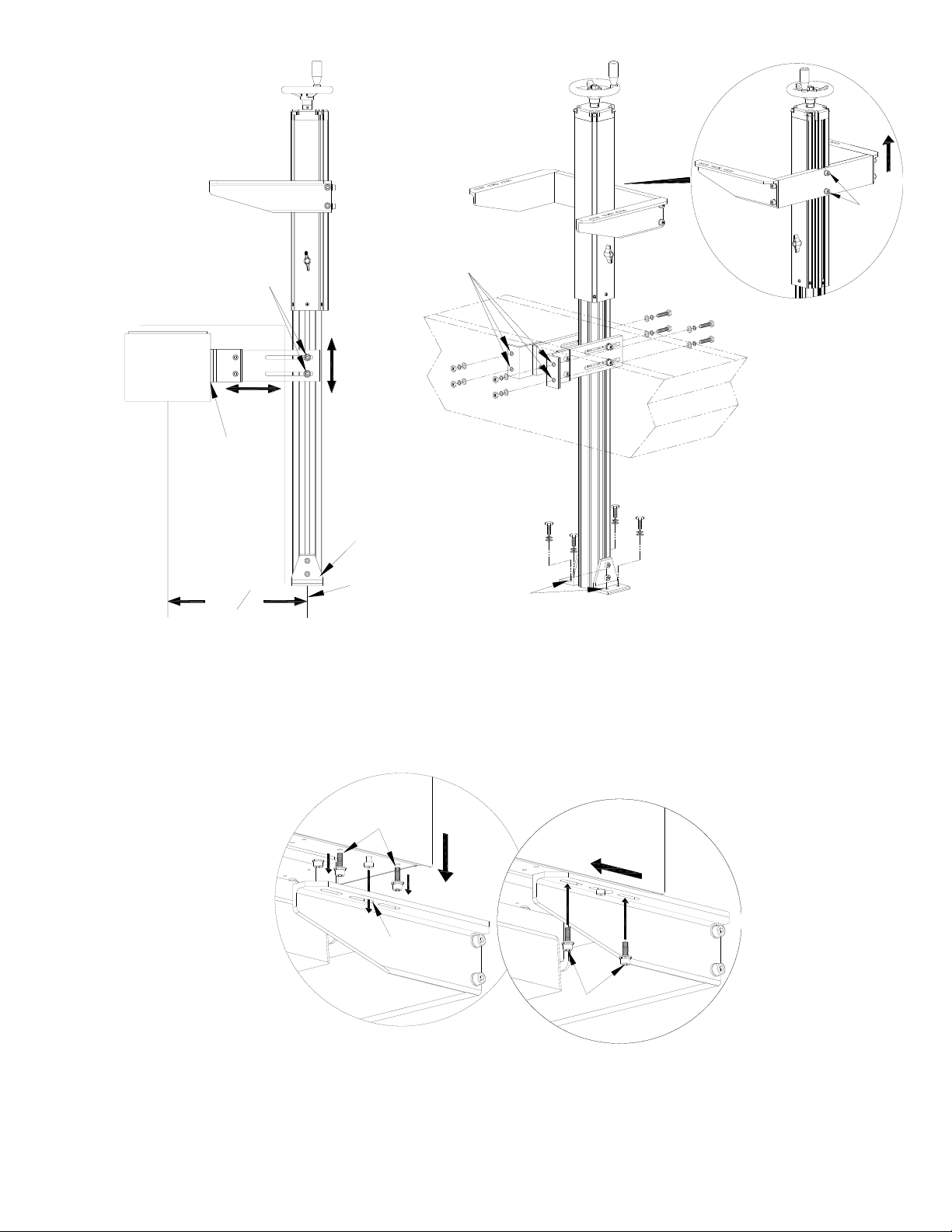

Lay the mount on its side to reposition the conveyor brackets. Remove the lower bolt [1] and loosen the upper

bolt [2], rotate the bracket [3] and reinstall [4] the lower bolt. Rotate the mount and repeat for the second

bracket and align the brackets (Figure 1).

Figure 1

Reposition the mount to install the power supply yoke [5]. Remove the bolts [6], place the yoke [7] over

the nuts and reinstall the mounting bolts. Slide the yoke high enough to allow the system to clear your

conveyor and tighten the yoke to the mount.

If the optional stack light [8] is supplied, remove the bolts [9], place the bracket [10] over the nuts and

reinstall the bolts. Slide the stack light to the highest point and tighten the bolts.

NOTE:

If a nut moves out of position, realign it with the bracket hole using a screwdriver or similar tool.

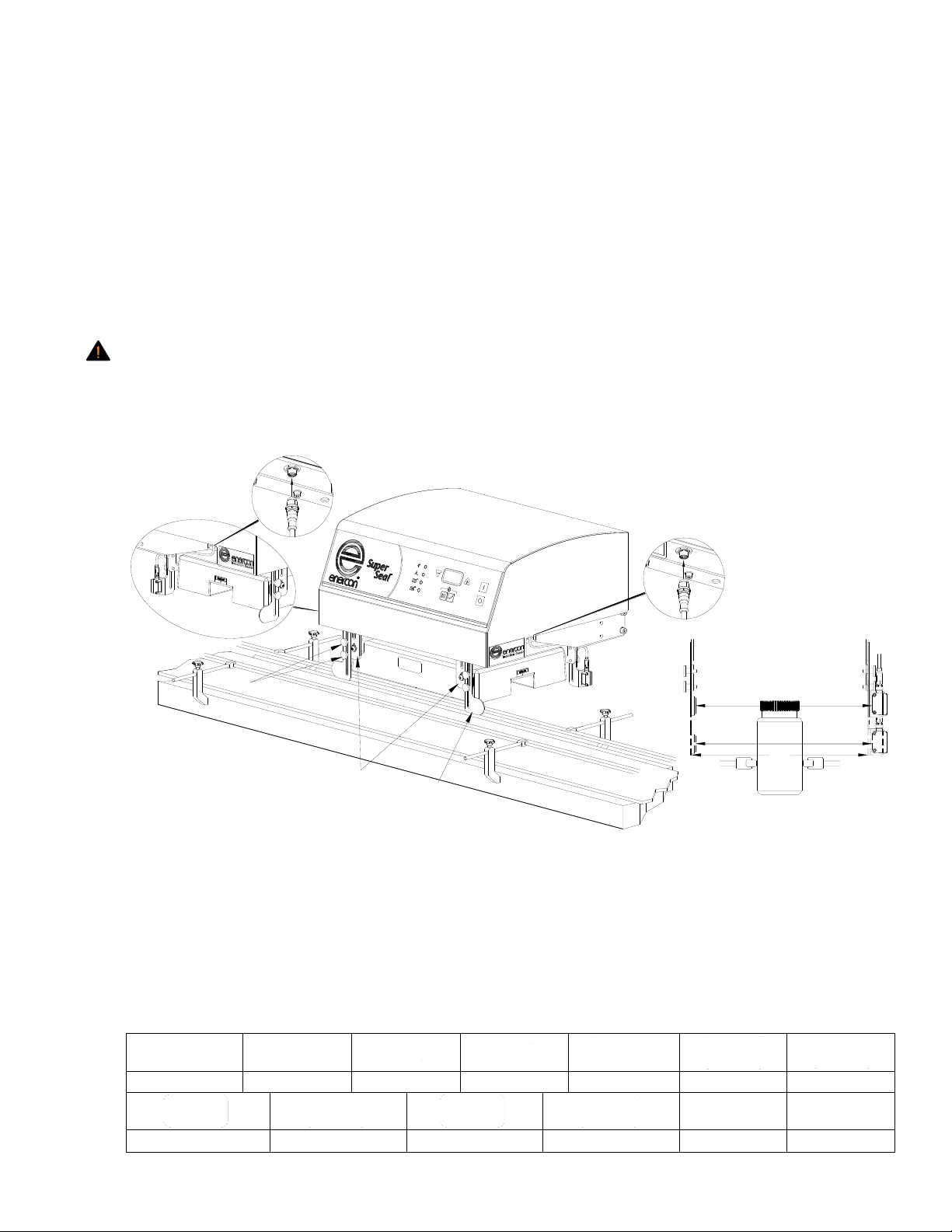

2.62 Floor Mount Installation

Choose a location with sufficient room for the power supply and options. Measure 12 ½” from the center

of the conveyor [1] and mark that point on your floor [2] (See Figure 2).

Place the mount against the conveyor [3] and adjust [4] the brackets to center them on your conveyor, and

to center the floor brackets [5] on the 12 ½” mark [2]. Ensure the mount is square [6] to your conveyor and

tighten the conveyor bracket bolts [7].

Mark the conveyor [8] and floor [9] mount hole locations, remove the mount and drill the holes. Install

appropriately sized anchors in the floor and realign the mount with the holes and bolt the mount securely

to the conveyor [10] and floor [11].

12

4

3

6

7

8

9

5

10

7

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

Figure 2

If the mounting yoke placement will not allow power supply to clear the conveyor, raise the yoke height

using the hand wheel [12], or by loosening the yoke mounting bolts [13] and raise the mounting yoke [14].

2.63 Power Supply Installation

Remove the power supply’s mounting bolts [1] and lift the power supply over the mounting yoke [2].

Align the guide bolts [3] with the keyholes [4], and lower [5] the power supply into position. Slide the

power supply forward [6] and reinstall the mounting bolts [1] (Figure 3).

Figure 3

2.7 OPTIONAL MOBILE CART INSTALLATION

When your system includes an optional Standard [1] or Deluxe [2] Mobile Cart, the power supply is shipped

mounted to the cart (See Figure 4).

Remove the leveling pads [3] from the cart base and install them so they clear the ground [4].

12 12"

3

2

6

10

8

10

4

5

9

11

11

4

1

7

13

14

12

42

3

5

1

2

1

6

8

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

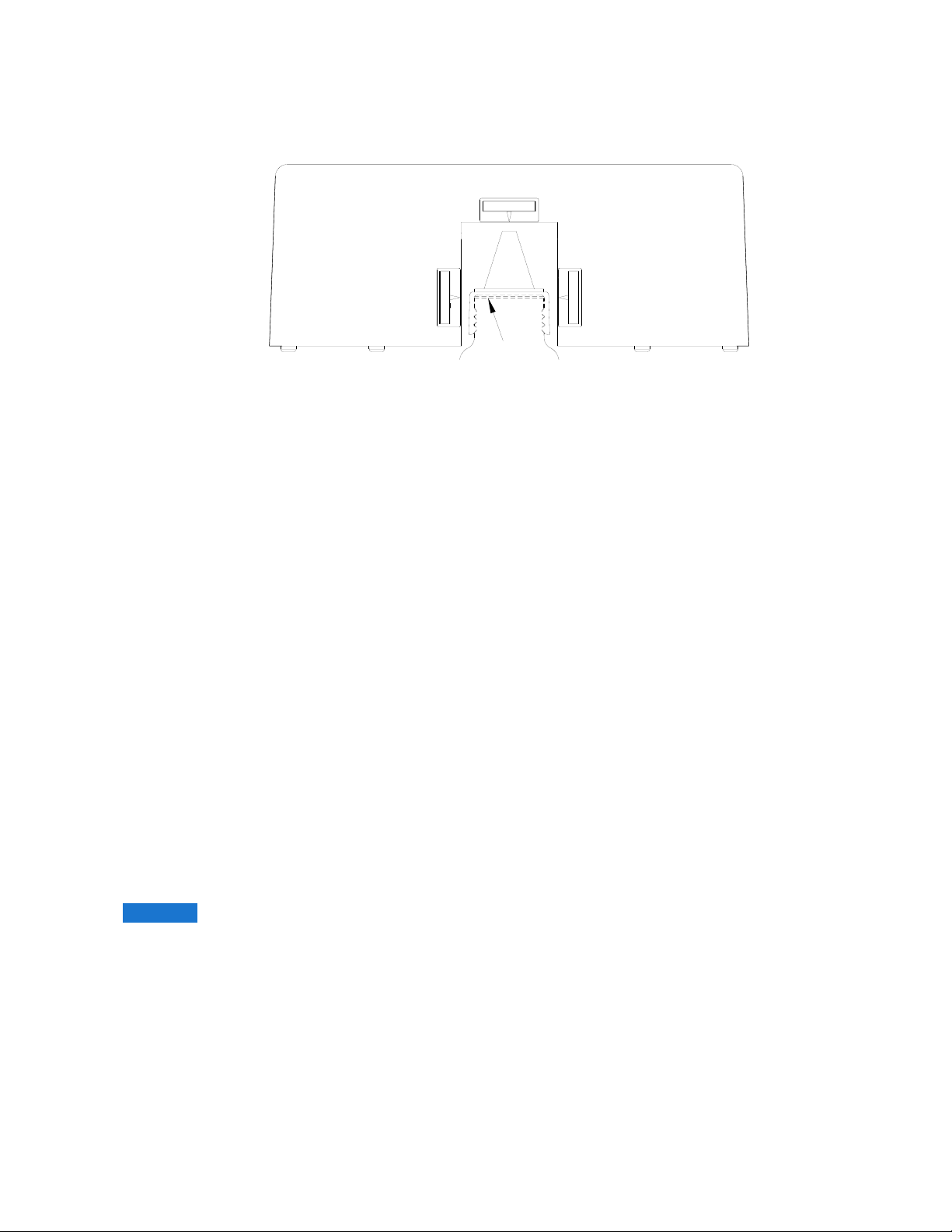

Figure 4

Choose a location with a sufficient footprint to accommodate the cart base, power supply, and options and

ensure the bottom of the sealing head [5] will clear the conveyor.

To raise the sealing head, loosen the locking knob [6] on the standard cart mount, not required on deluxe

cart, and rotate [7] the handle counterclockwise to raise the sealing head.

Unlock [8] the casters and roll the cart under the conveyor [9]. Center the sealing head over the conveyor,

lock [10] the casters once the cart is in position and lower the leveling pads [11] to contact the ground to

prevent accidental movement while continuing setup.

NOTE:

If the optional Stack Light is included with your system, it is factory installed to the cart.

2.8 SYSTEM ALIGNMENT

During the induction sealing process, the liner position must be uniform through the electromagnetic field to allow

repeatable sealing results. This is achieved with a consistent gap and path beneath the sealing head.

CAUTION: Due to the nature of an electromagnetic field, it will induct into metal located within the field,

heating it to varying degrees.

Small metal objects: such as screws, guiderails, and brackets, that experience continual heating may become

burn hazards and must be removed from the field or located at least 6 inches (15cm) below the sealing head.

Large metal objects, such as your conveyor, tend not to heat due to their mass, but may cause a slight change

in performance of the sealer. This is typically unnoticeable, and is considered normal, and safe, to both personnel

and equipment.

2.81 Container Path and Standard Sealing Head Alignment

The container path and air gap must be consistent along the full length of the sealing head.

Ensure the power supply is high enough to place your container beneath the sealing head [1] and center

your container on the conveyor [2] using guide rails [3] or other guidance system (See Figure 5).

Ensure both ends of the sealing head are centered over the container [4]. If needed, loosen the power

supply mounting bolts [5] and slide [6] the power supply over the container [6], and retighten the bolts.

If the sealing head is not aligned with the conveyor, refer to Figure 2 or 4, and adjust the alignment of

the mount or cart to correct the power supply alignment to the conveyor.

3

LEVELING PADS

2

110

8

6

4

44

99

11 11

55

77

11 11

9

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

Figure 5

To set the air gap, place a container at each end of the sealing head, with the supplied 3mm (1/8”) gap

gauge [1] between the containers and sealing head. Place the gauge between the container and

conveyor on a tunnel sealing head [2], or between the sealing head and your container on a flat sealing

head [3] (Figure 6).

Figure 6

Lower the power supply until it contacts the container cap [4] or gap gauge [5], by loosening the locking knob

[6] on the standard mount and optional standard mobile cart mount [A] and adjusting the hand wheel [7]. With

an optional deluxe mobile cart [B] you only need to adjust the handle [8] to lower the power supply.

Once the air gap is properly set, tighten the locking knob [6], if required, and remove the gap gauge.

51

33

Induction Sealer

6

2

33

4

5

Induction Sealer

6

1

1

2

4

Induction Sealer

1

7

8

A

B

3

26

54

10

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

2.82 Deep Tunnel Sealing Head Setup

Deep tunnel sealing heads are a specialty sealing head and are typically used in applications where

the cap or container won’t allow the product to fit within the standard tunnel sealing head. Deep tunnel

sealing heads have a standard centerline indicator [1] and two foil indicators [2] on each end of the

sealing head (Figure 7).

Figure 7

The initial setup of the deep tunnel sealing head is the same as a standard tunnel sealing head (Refer to

Figure 5). After the initial setup, ensure the cap is removed from your container and lower the sealing head

to align the foil indicators with the lip of the container [3] where the foil liner rests.

If cap or container dimensions prevent the lip of the container from reaching the foil indicators, position the

container lip into the tunnel as far as possible, ensuring the container can still pass without contacting the

sealing head.

2.83 All-In-One Universal Sealing Head Setup

The All-In-One Universal Sealing Head is designed to run a variety of applications, typically 24mm to

120mm, by allowing adjustment of the coil’s position within the housing. The adjustments do not require

tools, allowing single hand adjustments.

Center the sealing head over the cap with a 3mm (1/8”) gap between the sealing head and cap (Refer to

Figure 5).

Once the sealing head is aligned, determine the appropriate liner position for the liner size you will be

running, and adjust the sealing head accordingly (Figure 8).

Figure 8

NOTICE The adjustment knob and locking pin are spring loaded.

Release the locking pin by pulling out the adjustment knob [1] and slide the pin assembly to the appropriate

liner range position [2].

Release the knob, ensuring the pin seats firmly into the appropriate groove [3].

2.9 CABLE CONNECTIONS

The Super Seal™ Induction Cap Sealer includes connectors on the rear of the power supply for connecting available

options. Refer to SECTION 4 for details of your system’s connections.

2.10 INPUT VOLTAGE

Once the system components are installed, run the input voltage cable from the power supply to the fused

disconnect switch. Refer to the power supply rating plate and your system drawings for details on the required.

CENTER LINE

FOIL

FOIL

1

2

3

2

11

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

SECTION 3 – PRINCIPLES OF OPERATION

3.1 GENERAL

DANGER: Before operating this equipment, please read this section completely, and refer to the safety

warnings of Section 1, to become familiar with all the safety requirements and precautions for this equipment.

DANGER

Do not operate this equipment in an explosive

environment.

The potential of electrical shock is present if all system

components are not properly grounded.

The power supply should not be operated without either

a 3-prong or 3-wire grounded line cord connected to a

grounded receptacle.

Do not by-pass the ground terminal.

High voltage is present within the power supply.

Buss capacitors discharge very slowly, disconnect

power, and verify they are discharged before working on

the power supply.

WARNING

Magnetic Field heats metal within the field.

Keep jewelry away from the sealing head.

Do not use damaged or improperly applied liners.

If dwell time is too long, liners may overheat causing

liner and container contents to ignite.

If containers stop beneath the sealing head,

liners may overheat causing liner and container

contents to ignite.

This equipment should not be used to seal containers

containing flammable or combustible contents unless

integrated into a conveyance system with proper

safety equipment including a stalled bottle detector

and/or bottle back-up sensor.

CAUTION

Small metal objects, such as screws, guiderails, and

brackets, located within the electromagnetic field, will

continually heat creating a burn hazard.

NOTICE

Do not apply voltage across the interlocks!

Applying voltage to the interlock control circuits

may result in a failure of the control board

interlock circuit components.

3.2 OPERATING INSTRUCTIONS

3.21 APPLYING THE INPUT VOLTAGE

Ensure the system installation and alignment is complete, including options, and rotate the power

supply’s disconnect switch to the ON position.

The display will illuminate and flash the last output % setpoint (See Figure 9).

12

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

Figure 9

3.22 Power Supply Front Panel

The Super Seal™ Induction Cap Sealer utilizes a Digital Display and Pushbuttons to monitor and control

the power supply output and settings.

Controls and Indicators

Display Meter

Displays the output % and setup information.

Settings

Menu: Press to enter and exit

Setup Mode.

OK: Press to select and

acknowledge changes.

Start

Local Start/Stop Mode: Starts the power

supply.

Remote Start/Stop Mode: Inactive.

Stop

Local Start/Stop: Stops the power

supply and resets faults.

Remote Start/Stop: Stops the power

supply and resets faults.

Increase

Increases the output %, scrolls up through

settings and enables modes.

Decrease

Decreases the output %, scrolls down

through settings and enables modes.

Run

Blank = Idle

Green = Running

Fault

Blank = No Fault

Red = Faulted

Remote

Start / Stop

Blank = Local

Amber = Remote

Remote Level

Blank = Local

Amber = Remote

3.3 BASIC OPERATION

The Super Seal™ Induction Cap Sealer is designed for easy operation and was fully tested and setup for Local

operation. You will be able to operate the sealer in Local control modes once installation is complete.

WARNING: If containers stop beneath the sealing head, liners may overheat causing liner and container

contents to ignite.

3.31 Local Operation

With the disconnect switch ON, verify Local Start/Stop, No Fault and the correct output level is flashing

on the Display Meter.

13

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

If required, press Increase or Decrease to correct the output.

If Faulted is displayed, address any fault issue and press Stop to reset the fault.

If Remote Start/Stop is displayed, refer to 3.5 POWER SUPPLY SETUP to enable Local Start/Stop.

Press Start and the power supply will run, the meter stops flashing, and Running is displayed.

Press Stop and the power supply sill stop, the Display Meter will flash and Idle is displayed.

3.32 Power Supply Output Range Verification

Once the power supply is running, you should verify the full output range. Maximum output is always 100%,

but the minimum output varies depending on the size of the power supply.

Super Seal™ 300

Super Seal™ 400

Super Seal™ 600

55% – 100%

40% – 100%

35% – 100%

3.4 POWER SUPPLY SETUP

The basic system is set to Local Start/Stop and Level modes, and options are set to factory defaults. Setup

is required for remote operations and to customize options settings, refer to SECTION 4.

Press Menu to enter setup, and Increase / Decrease to scroll through setup functions.

Start/Stop Setup

Output Level Setup

Alarm Setup

Local

Remote

3.41 Start/Stop Setup

Start/Stop control determines how you will start and stop the power supply. Remote Start/Stop requires

use of the optional Automation I/O cable (Refer to Figure 10).

Scroll through setup functions to display Start/Stop Setup, press OK to edit Start/Stop mode.

Press Increase to enable Local, press Decrease to enable Remote mode.

Press OK to save the new setting, or Menu to exit setup without saving the new setting.

3.42 Level Setup

Level control determines how you will increase and decrease the output % setpoint of the power supply.

Remote Level requires use of the optional Automation I/O cable (Refer to Figure 10) and an isolated 0-

10VDC signal.

Scroll through setup functions to display Output Level Setup, press OK to edit Level mode.

Press Increase to enable Local, press Decrease to enable Remote mode.

Press OK to save the new setting, or Menu to exit setup without saving the new setting.

3.43 Alarm Setup

Alarm is a setpoint, 2 - 10%, that sets the percentage of change to the power supply output that will trip

the alarm circuit. The Alarm function is most useful with the optional Stack Light or Automation I/O

Cable, but they are not required.

Scroll through setup functions to display Alarm Setup, press OK to edit the Alarm setpoint.

Press Increase or Decrease to change the alarm setpoint percentage.

Press OK to save the new setting, or Menu to exit setup without saving the new setting.

3.5 OPERATING WINDOW SETUP

You should determine the operating window for each package you will be sealing, finding the minimum and

maximum output power settings that achieve a good seal. Then determine the exact production output level you

will use for each package.

WARNING: If containers stop beneath the sealing head, liners may overheat causing liner and container

contents to ignite.

3.51 Minimum and Maximum Power Levels

For each product package, initially set the output power to a midpoint of your sealer’s output range and set

your conveyor to your production speed. Run a sample, check the seal, and refer to the information below

to determine the operating window.

14

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

No Seal

Partial Seal

Good Seal

Overheated

OPERATING WINDOW

Window Minimum Output

Raise output 5% and run a new container.

Repeat as needed.

Lower the output 1%, running a new

container, to find the minimum output level

where a good seal is achieved.

Lower output 5% and run a new

container. Repeat as needed.

Window Maximum Output

From the Window Minimum Output, raise

the output 1%, running a new container, to

find the maximum output level where a

good seal is achieved.

3.52 Production Power Level

With the Operating Window defined, use the output power level at the midpoint of the window. Run samples

to refine the production output power level that gives you the desired sealing results. Ensure any output

power level adjustments are within the operating window.

Run the power supply at the production output level and run several containers back to back and ensure

they all seal.

NOTE:

Each of your packages may have unique characteristics that will change the sealer’s setup between

packages. For easy change over, record each package’s Product, Cap size / Liner type, Container type,

Line Speed, Production output %, and the operating window Min and Max output % in the Production

Information table in SECTION 7.

3.6 REMOTE OPERATIONS

The Super Seal™ Induction Cap Sealer includes Remote Start/Stop and Level control. Refer to 3.5 POWER

SUPPLY SETUP to enable the remote modes.

Display Meter

Increase

Decrease

Start

Stop - Reset

No Fault

Faulted

Local Start/Stop

Remote Start/Stop

Local Level Control

Remote Level Control

Running

3.61 Remote Start/Stop

With the disconnect switch ON, verify Remote Start/Stop, No Fault and the correct output level is

flashing on the Display Meter.

If required, press Increase / Decrease, or adjust the isolated 0-10VDC remote level control signal to correct

the output.

If Remote Start/Stop is not displayed, refer to 3.51 Start/Stop Setup to enable remote start/stop.

If Faulted is displayed, address any fault issues and press Stop - Reset to reset the fault.

Close the remote start/stop contact across the Automation I/O cable (Refer to Figure 10). The power

supply will run, the Display Meter stops flashing, and Running is displayed.

3.62 Remote Level Control

Remote level control allows you to adjust the output power % using an isolated 0-10VDC connected

across the optional Automation I/O cable (Refer to Figure 10).

If Remote Level Control is not displayed, refer to 3.52 Level Setup to enable remote level control.

NOTE:

The Increase / Decrease arrows will not function when Remote Level Control is enabled.

Whether the power supply is idle or running, you will be able to raise and lower the power supply output %

by adjusting the 0-10VDC signal.

15

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

SECTION 4 – EQUIPMENT INTERCONNECTION & OPERATION WITH OPTIONS

4.1 GENERAL

DANGER: Before installing or operating any optional equipment, please read this section completely, and refer

to the safety warnings of Section 1, to become familiar with all the safety requirements and precautions for this

equipment.

Several options were available when purchasing your Super Seal™ Induction Cap Sealing System but can

also be ordered as needed. Options should be requested when placing the original order with Enercon, as

some options may require changes to the power supply or its attachments.

4.2 MOBILE CARTS

The optional mobile cart systems provide portability, ease of installation and adjustment of your Super Seal™

Induction Cap Sealing System.

Standard Mobile Cart System: Includes a shortened adjustable floor mount attached to the mobile cart

frame.

Deluxe Mobile Cart System: Includes a stainless steel adjustable mount attached to a mobile frame.

Refer to 2.7 OPTIONAL MOBILE CART INSTALLATION and Figure 4 for details on installing your mobile

cart and refer to 2.8 SYSTEM ALIGNMENT and Figures 5 & 6 for setup details.

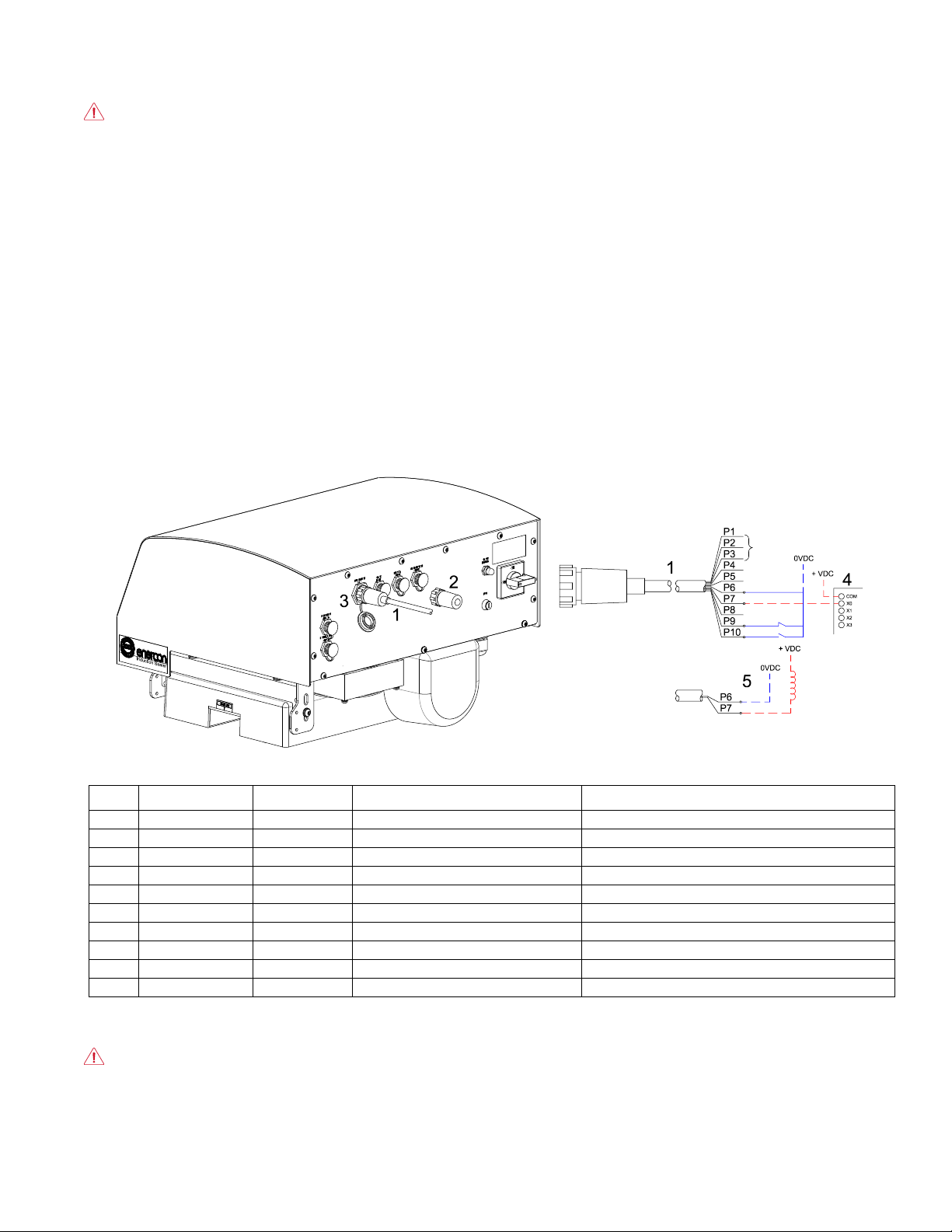

4.3 AUTOMATION I/O CABLE

Remote Start/Stop, Remote Level Control, Alarm, Ready and Customer Interlock functions require the

Automation I/O Cable [1]. Remove the defeat connector [2] and connect the I/O cable to your control and

monitoring equipment and to the AUTOMATION I/O connector [3] on the rear of the power supply (Figure 10).

Figure 10

Pin #

Cable Cores

Function

IO

Connects To:

P1

Black

Alarm N.O.

Sealer Alarm Output – Potential Free

Customer Alarm

P2

White

Alarm N.C.

Sealer Alarm Output – Potential Free

Customer Alarm

P3

Red

Alarm Com.

Sealer Alarm Common – Potential Free

Customer Alarm

P4

Blue

0-10V Out

Sealer Output

PLC – Level Control

P5

Orange

0-10V Com.

Common

PLC – Level Control

P6

Black/White

Common (0V)

Common

Interlock, Ready and Remote Start/Stop

P7

White/Black

Ready

Sealer Output

PLC – System Status

P8

Red/White

0-10V In

Sealer Input

PLC – Level Control

P9

Blue/White

Interlock

Sealer Input

Customer N.O. Dry Contact – Must Be Closed to Run

P10

Orange/Black

Start/Stop

Sealer Input

Customer N.O. Dry Contact – Close = Run / Open = Stop

Note: Alarm outputs are dry relay contacts. All other discreet outputs are transistor outputs that sink low when active. Cables

Displayed – – – – and – – – – are optional and are only required when using the Ready circuit. Contact Enercon if assistance is

needed when using the Automation I/O Cable outputs.

DANGER: Remove all external power, ensuring proper lockout / tag out procedures are followed, before

connecting or disconnecting external cables.

4.31 External Interlock

To interlock the power supply with your production line, connect the Automation I/O Cable’s Blue/White

[P9] and Black/White [P6] wires to a normally closed (N.C.), potential free interlock contact.

16

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

The contact must be closed for operation, and when open, it will shut down, or prevent the power supply

from running.

NOTICE Do not apply voltage across the interlock contacts on the Automation I/O cable.

NOTE:

If an External Interlock is not provided when using the Automation I/O Cable for other functions, the

Blue/White [P9] and Black/White [P6] wires must be tied together to defeat the interlock function.

4.32 Loss of Seal Alarm

To monitor the power supply status, connect the Automation I/O Cable’s Black [P1] (N.O.), White [P2]

(N.C.) and Red [P3] (COM) wires to an external alarm or PLC. The alarm contacts are dry but should

only be wired into a circuit that does not exceed 24 volts and 3 amperes.

When the input voltage is applied, but the power supply is not running, or is running and the actual

output is outside of the alarm set point window, the alarm contacts will be in their de-energized state

(N.C. contact is closed).

When the unit is running and the actual output is within the alarm set point window, the relay contacts

will be in their energized state (N.C. contact is open).

Refer to 3.53 Alarm Setup for a detailed description on setting the alarm set point window.

4.33 Ready

To monitor the power supply readiness, use the Automation I/O Cable’s Ready signal, White/Black [P7]

and Black/White [P6] wires.

The Ready signal can be run to your PLC [4] input, to a relay coil [5], or one side of a controlled light or

alarm. When using the Ready signal, provide +24 VDC to the circuit and 0VDC to common [P6].

When the power supply is ready, the output signal will sink low to system common, to indicate ready.

NOTE:

The remaining Automation I/O Cable functions are addressed in SECTION 3 – PRINCIPLE OF

OPERATION.

4.4 STACK LIGHT

The optional stack light provides a visual, or visual / audible indication of the power supply’s operating status, which

is pole mounted on a bracket at the top of the adjustable mount [1], or to the power supply mounting bracket

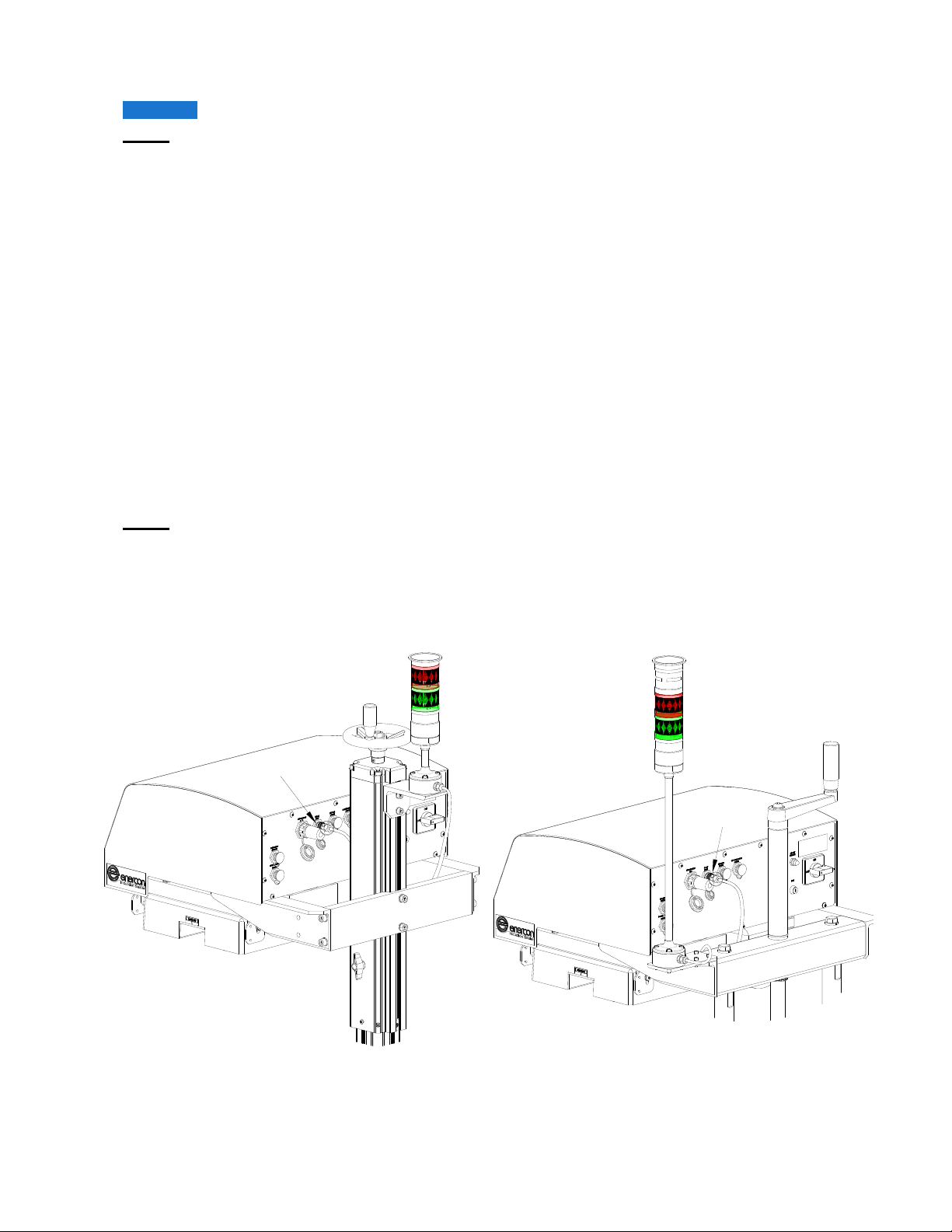

on a deluxe mobile cart [2] (Figure 11).

Figure 11

4.41 Installation

The stack light is factory mounted on both optional mobile cart systems, but must be installed on the

adjustable floor mount, refer to 2.61 Floor Mount Assembly and Figure 1 for details.

Once mounted, connect the stack light cable to the STACK LIGHT connector [3].

1

3

2

5

4

6

5

4

3

17

ML0185-001-01 Super Seal™ 300 / 400 / 600 Induction Cap Sealer Owner’s Reference Manual Rev. H Enercon Industries

4.42 Setup

For the stack light to operate as designed, you will need to ensure the Alarm Setpoint is correct, refer

to 3.53 Alarm Setup.

4.43 Operation

The standard stack light includes Green [4] and Red [5] indicator lights, and the audible stack light

includes the indicators and a buzzer [6].

Green Solid – The power supply is running, and the output is within the range of the alarm setpoint.

Red Solid – The power supply is running, and the output is below the range of the alarm setpoint.

Red Flashing – The power supply has experienced a Fault condition.

4.5 STALLED BOTTLE DETECTION

Optional stalled bottle detection allows you to automatically stop the power supply whenever a container is

detected entering the sealing head but is not detected exiting the sealing head. This prevents containers

from overheating if they stop beneath the sealing head.

WARNING: If containers stop beneath the sealing head, liners may overheat causing liner and container

contents to ignite.

4.51 Installation and Alignment

The stalled bottle option includes 2 bracket mounted sensors [1], loose cables [2], bracket mounted

reflectors [3] and mounting hardware [4] (Figure 12).

Figure 12

Install the right hand [5] and left hand [6] sensors to the sealing head mounting brackets [7] and connect the

cables to the connectors [8] on the power supply baseplate.

With no consistent spacing between containers, align the sensor and reflector to the cap or shoulder of the

container [9], if there is consistent spacing between the containers, align the sensor and reflector to the body

of the container [10], then align the bottoms of the brackets [11].

4.52 Setup

Stalled bottle detection is setup and tested before your induction sealing system was shipped, but you will

need to set the stalled bottle timing and ensure the conveyor and sealers direction of travel match.

Menu

OK

Increase

Decrease

Display Meter

Direction

Left to Right

Right to Left

Stall

Blocked

Stalled Bottle Time

Start

Stop - Reset

1

2

4

2

1

3

8

6

5

7

11

10

9

8

Other manuals for SUPER SEAL 300

1

This manual suits for next models

2

Table of contents

Other ENERCON Food Saver manuals