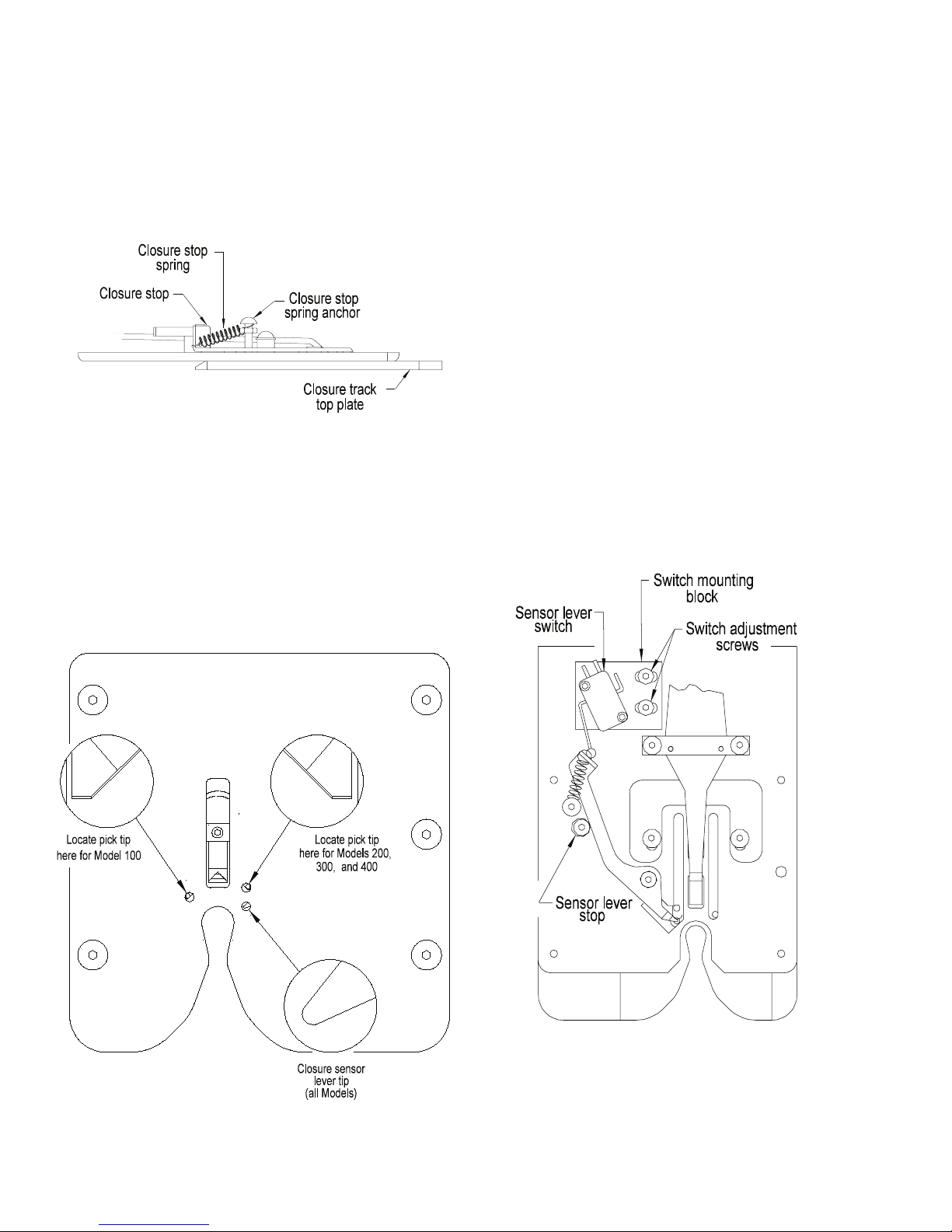

P 2.1

SECTION II

Operation

086A 08 08

Power switch

Ready light

Run switch

A. OPERATING SEQUENCE:

(Figure 2.1)

The closer is ready to run when the closure is in

closing position, the power switch is in the ”ON”

position, and the ”READY” light is on. When the

closed bag and closure are removed from the

closure track, the machine completes the closing

cycle placing the next closure in closing position.

The machine is again ready for the next bag.

During the completion of the closing cycle the

”READY” light will go off momentarily.

If no closure is available to move into the closing

position, the machine will continue to cycle and the

”READY light will flash repeatedly until the run

switch is turned to the ”STOP” position.

The power switch and light must be off to cut

off power to the two sensor switches. Utilizing

the power switch instead of the run switch may

result in the machine not stopping in the neutral

position as required for loading the closure

strip. Use the power switch when clearing the

machine of debris or preforming minor service

work.

1. Plug in the closer.

2. Press the power switch to ”ON”.

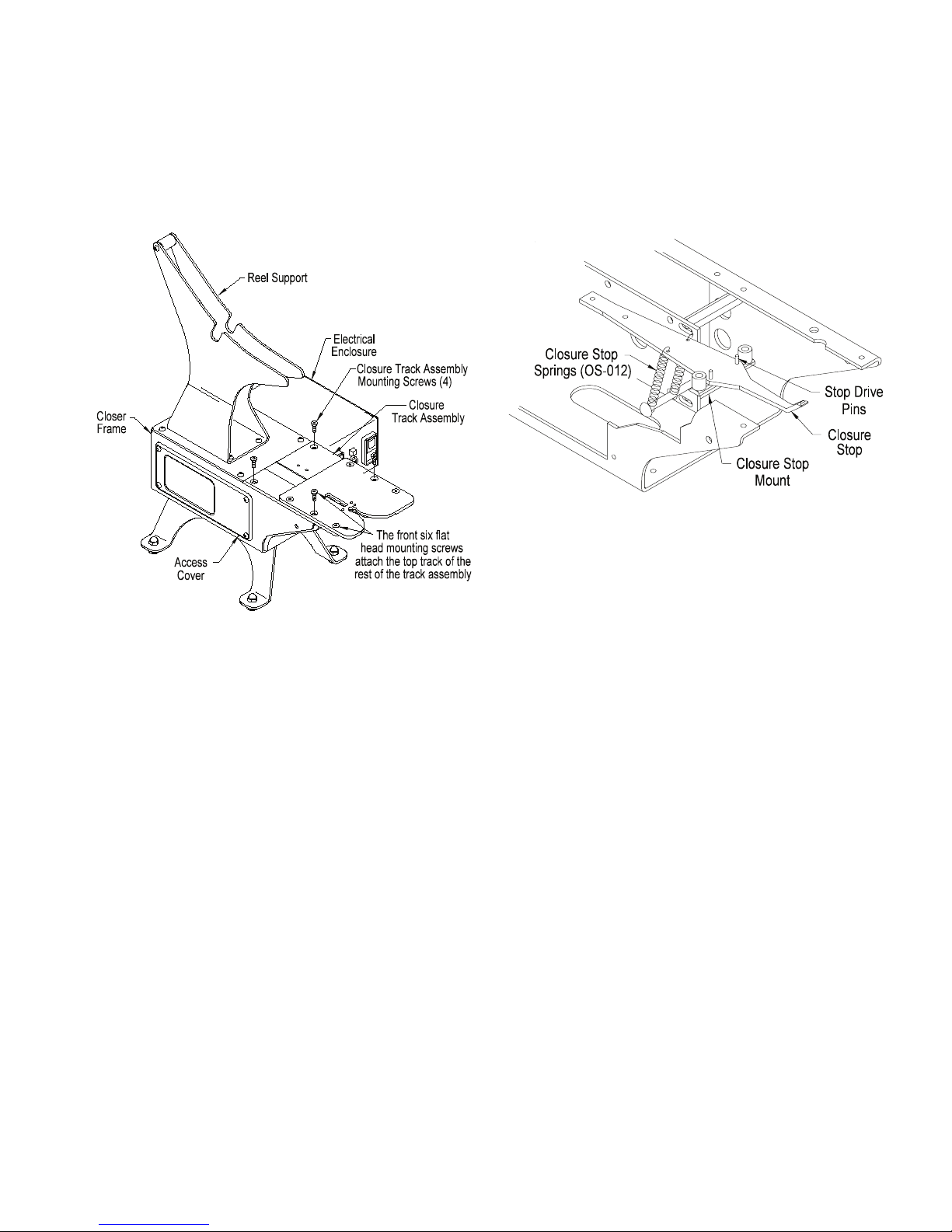

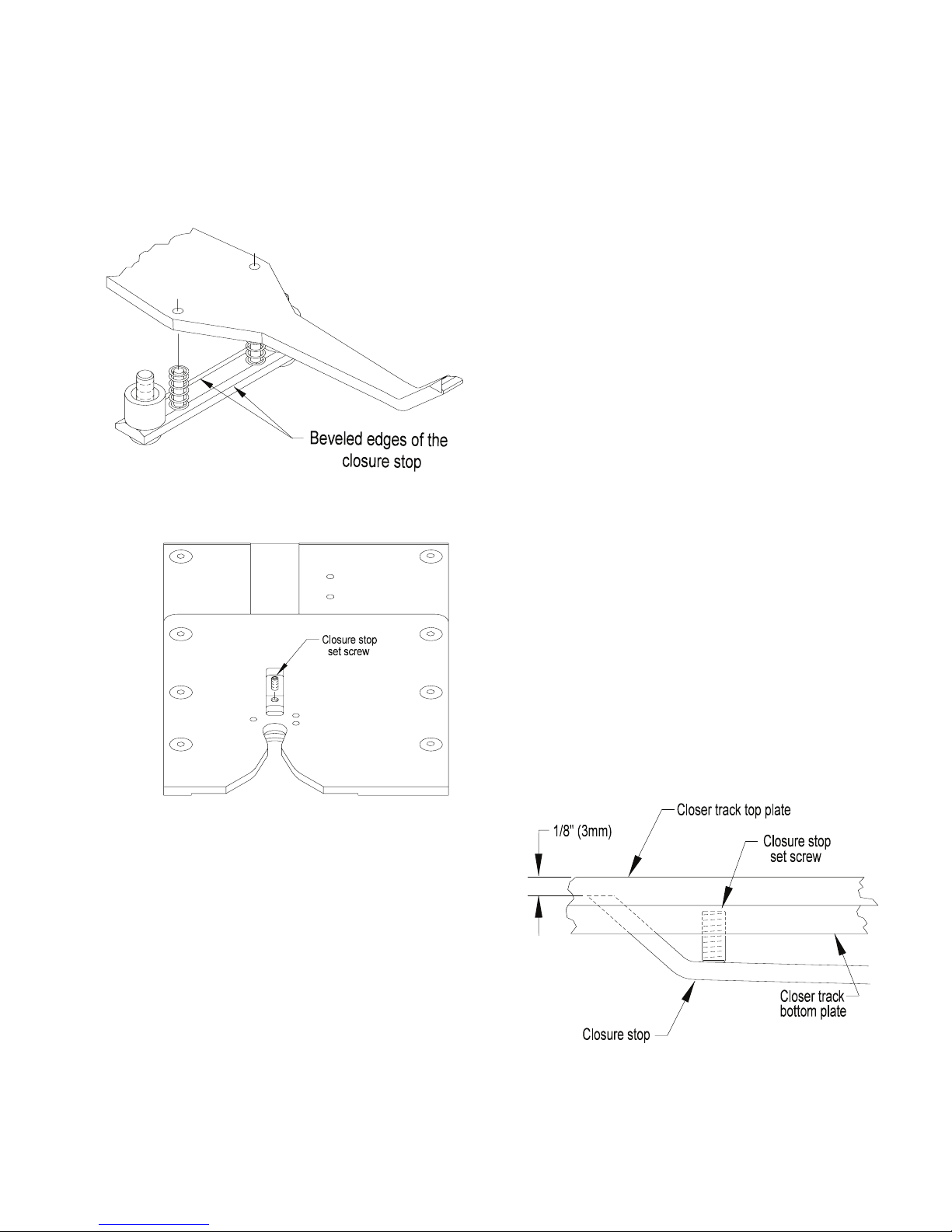

3. Slide the closure strip into the closure track until

the strip stops (refer to part B in this section).

4. Press the run switch to ”RUN” . A closure will

move into the closing position, if one is not

already there, and the ”READY” light goes on

indicating the the closer is ready to close.

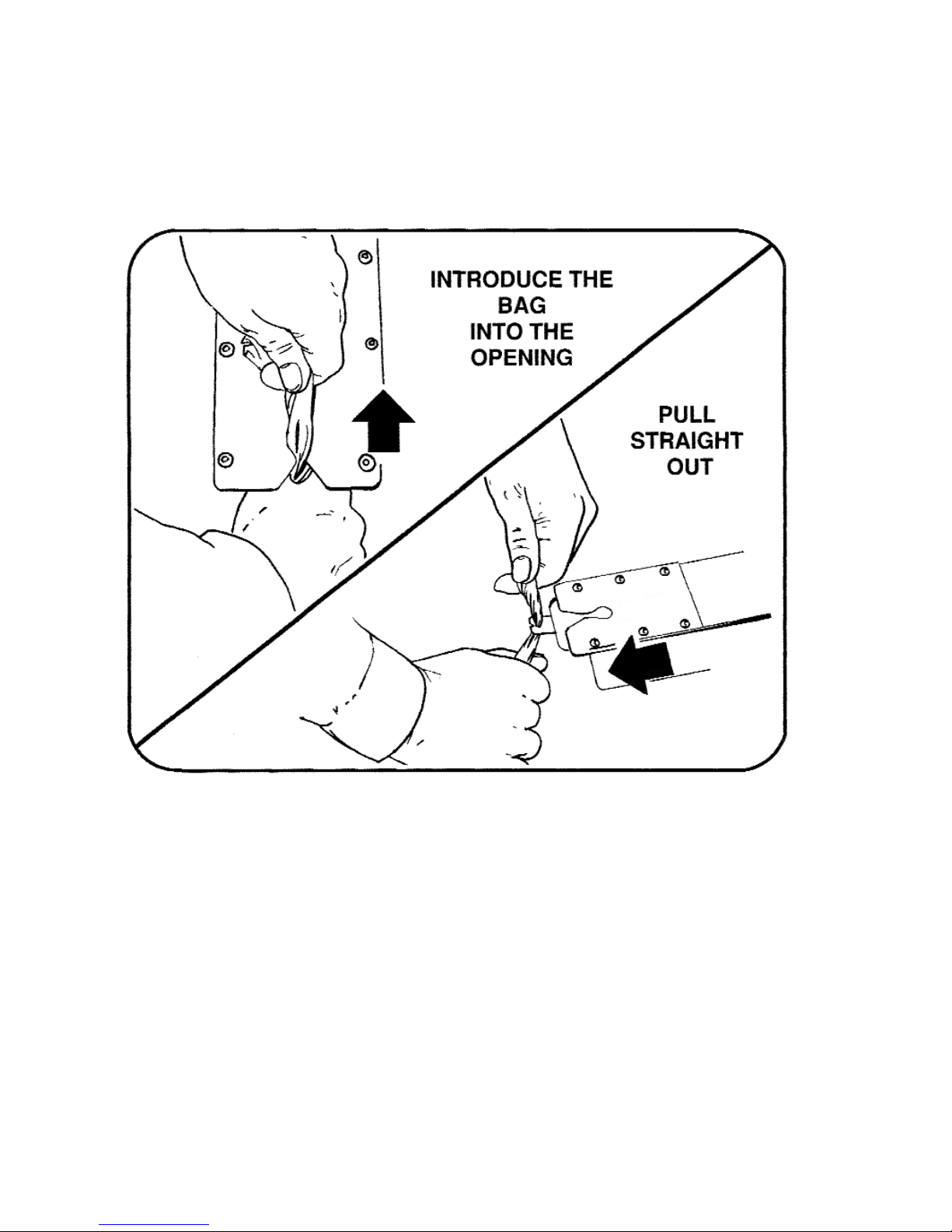

5. Close the bag and remove it from the closer

(refer to part C in this section).

6. The closer cycles to position a new closure into

the closing position, ready for the next bag.

The ”READY” light will go off momentarily as

the closure is loading.

7. If no closure is available to move into the

closing position, the machine will cycle and the

”READY” light will flash on and off repeatedly

until the run switch is pressed to ”STOP”. The

machine will then cycle back to neutral and

stop. The machine at this point is again ready

to load.

B. LOADING A ROLL OF CLOSURES:

1. Cycle the closer until there are no closures left

in the closure track. Avoid cycling the closer

more than necessary when there is no closure

in the closing position.

2. Move the run switch to “STOP” so the

mechanism is properly positioned.

3. When closing with closures, insert the closure

hub into a new roll of closures. Be certain the

closures feed forward from the bottom of the

roll.

When closing with labels, insert the closure

hub so that the label of the closure is right

side up when the closure strip is in the closure

track.

4. Install the hub and roll.

Figure 2.1