Table of Contents

Chapter 1.................................................................................................................................1

General Information....................................................................................................1

Safety............................................................................................................................................... 1

Chapter 2.................................................................................................................................8

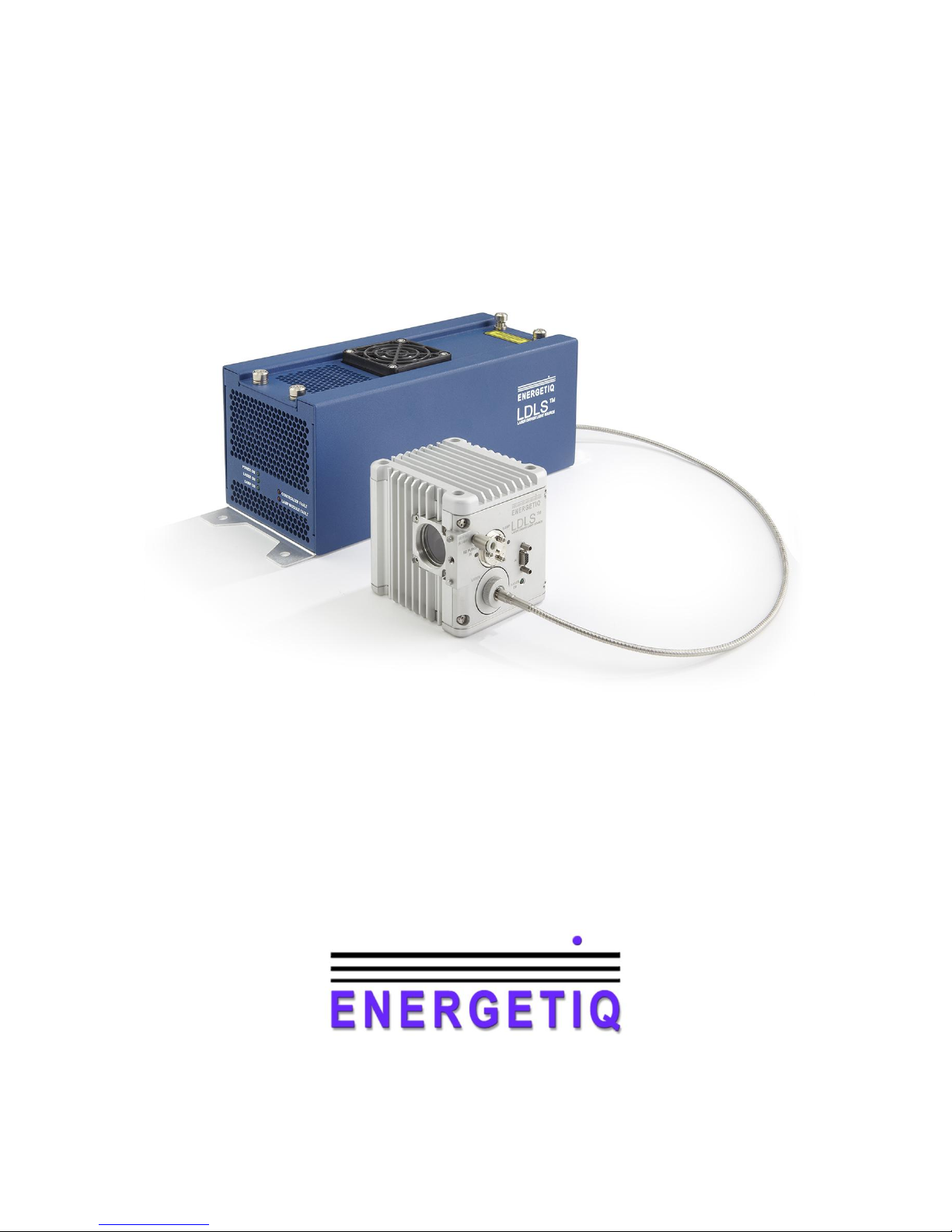

Description ....................................................................................................................8

General........................................................................................................................................... 8

System Description .................................................................................................................... 11

Power Supply Controller........................................................................................................... 12

Lamp House................................................................................................................................ 13

Chapter 3.............................................................................................................................. 16

Installation................................................................................................................... 16

Unpacking.................................................................................................................................... 16

Connections................................................................................................................................. 16

Installation Procedure................................................................................................................ 22

Water Cooling Installation for EQ-99-CAL ......................................................................... 23

Chapter 4.............................................................................................................................. 25

Operation.................................................................................................................... 25

Starting.......................................................................................................................................... 25

Stopping ....................................................................................................................................... 25

Chapter 5.............................................................................................................................. 27

Maintenance ................................................................................................................................ 27

EQ-99 SMA Fiber Cleaning Process...................................................................................... 27

Troubleshooting ......................................................................................................................... 31

Lamp Replacement .................................................................................................................... 32