Energy Carbon AirUnit Compact controller Pro Parts list manual

mfh systems

modern floor heating

mfh systems

modern floor heating

AirUnit

Compact controller Pro

Installation instructions & operating manual

List of contents, Installation instructions

Seite

1. General information ............................................................................................................................03

2. Technical Data ....................................................................................................................................04

3. Norms fulfilled ....................................................................................................................................04

4. Installation of AirUnit compact controller pro .....................................................................................04

5. Electrical connection ...........................................................................................................................05

5.1 Connection AirUnit ventilation unit(s) – AirUnit compact controller pro .............................................05

6. External digital input (bath ventilation operation) ..............................................................................06

7. Sensor operation .................................................................................................................................06

8. Settings ventilation mode ...................................................................................................................08

9. Operation amd display elements AirUnit compact controller pro ........................................................09

10. Service ................................................................................................................................................10

11. Operating hour counter ......................................................................................................................11

12. Errors ..................................................................................................................................................11

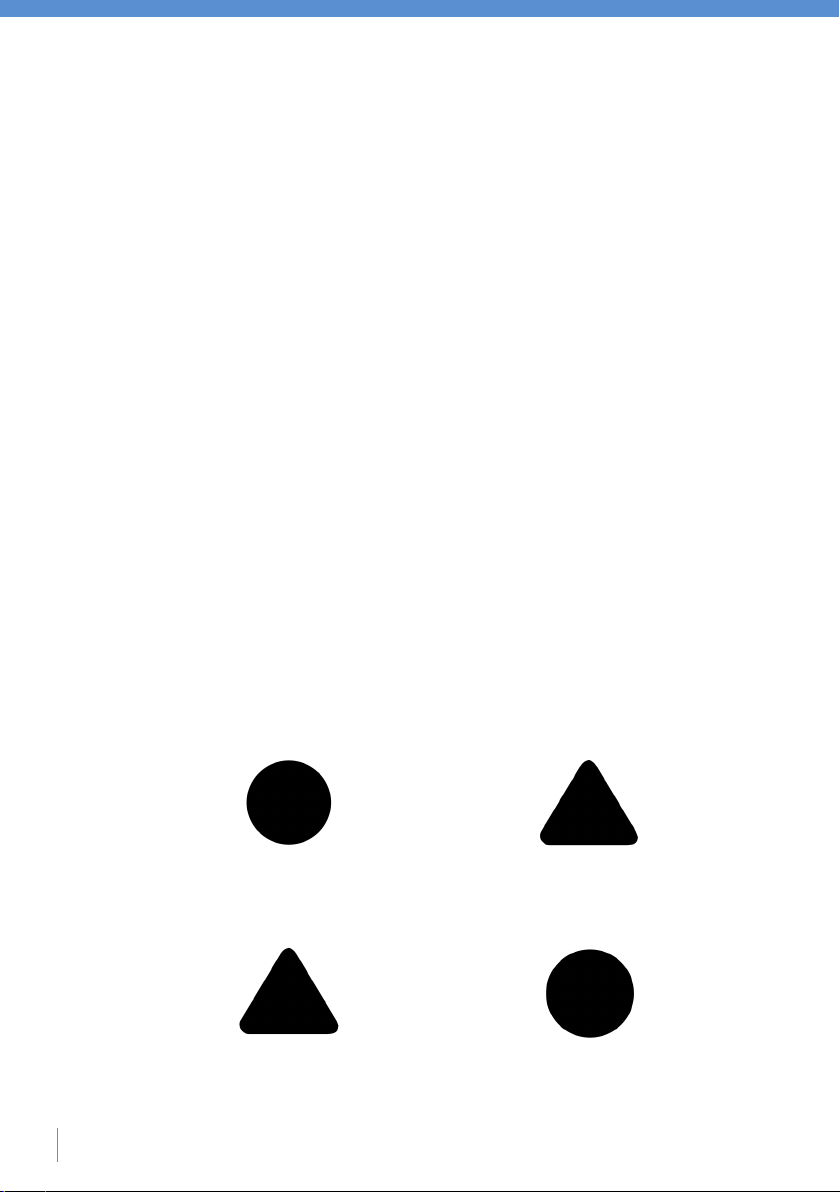

Symbols

The following symbols are used in the manual for labelling particular information:

General information / information Warning information

Information: Hazard due

to electrical voltage

Installation / maintenance information

02

1. General information

The AirUnit and controller are constructed according to state of the art technology and the recognised

safety regulations.

Installation and maintenance work of the ventilation unit may only be implemented by trained specialist

personnel under compliance with the regulations for occupational safety and accident prevention.

The electrical connection must be implemented according to VDE 0100. For installation and

maintenance work, disconnection from the mains at all poles with at least a 3 mm contact

opening width must be undertaken. The mains disconnection is to be secured against re-connection!

Use of this device is only permitted for the intended use. Incorrect usage, defectively implemented installation or

maintenance work and design changes can impair the function and safety of the ventilation unit and lead to the

termination of any warranty claims.

Prior to beginning installation / maintenance work, read this manual carefully and observe the information

provided for installation and maintenance.

Prior to the installation of the device, check the delivery with regard to completeness and integrity, and in case

of missing or damaged parts contact your supplier directly.

Intended use

AirUnit with heat recovery are designed for controlled room ventilation. The devices may only be used exclusively

for the conveyance of air. The conveyance of aggressive, flammable or extremely dusty media is not permissible.

Never operate the device without the filter which is inserted in the device.

The connection of ventilation ducts is not permissible. AirUnits are not suitable for construction drying; operation

of the device should only be implemented after completion of the construction activity.

The operation of the device in connection with fireplaces possibly requires additional safety equipment (Feuerungs-

verordnung FeuV - German Fire Code Ordinance). Corresponding information can be obtained from the chimney

sweep responsible for your region.

Device location

AirUnits may only be installed and operated indoors. When selecting the location for the device, take into

consideration that the ventilation unit is accessible for inspection and maintenance work. Installation of the device

in close proximity to flammable liquids or gases is not permissible. A mains connection (230 V / 50 Hz) is required

to the controller for operation of the device.

Installation

For the installation of the AirUnits, the recognised rules of engineering (ARdT) are to be observed with regard to

device installation, electrical work, fire protection etc. and the specifications for the ventilation of living spaces

(DIN 1946-6).

03

04

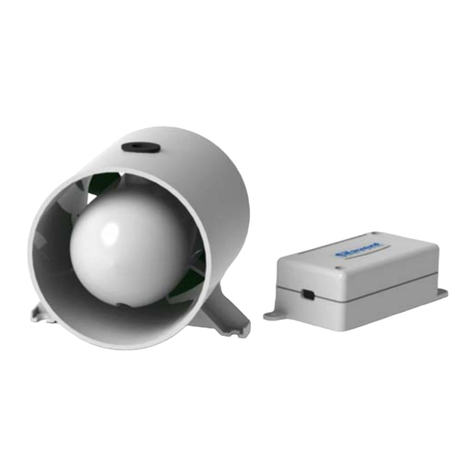

AirUnit compact controller pro

Controller 4 performance levels

Operating modes winter and summer mode

Power unit up to 4 devices

Switch range including cover frame,

cannot be combined with other swith programms

Protection type IP 20

Protection class III

Power supply 200–250Vac, 50/60 Hz

Standby power consumption < 0,5 W

Digital input 100-250Vac,50/60Hz

Bus connection RS-485, USB

Outputs 2x 12V,0,75A | 2x0-5V PWM

Dimensions 80 x 80 x 49 mm

Operating temperature 0 – 45 °C

2. Technical data

3. Norms fulfilled

The control unit conforms the safety- and health requirements of the EG guideline 2004/108/EG as well as the

EG guideline low voltage in conception and design as well as in the performance, which we have manufactured.

The following norms are considered, as far as they are applicable for that device.

• EN 61000-6-1:2007 • EN 61000-3-3:2008 • EN 61000-6-1:2007 • EN 61000-6-3:2007/A1:2011

• EN 60335-1

4. Installation AirUnit compact controller pro

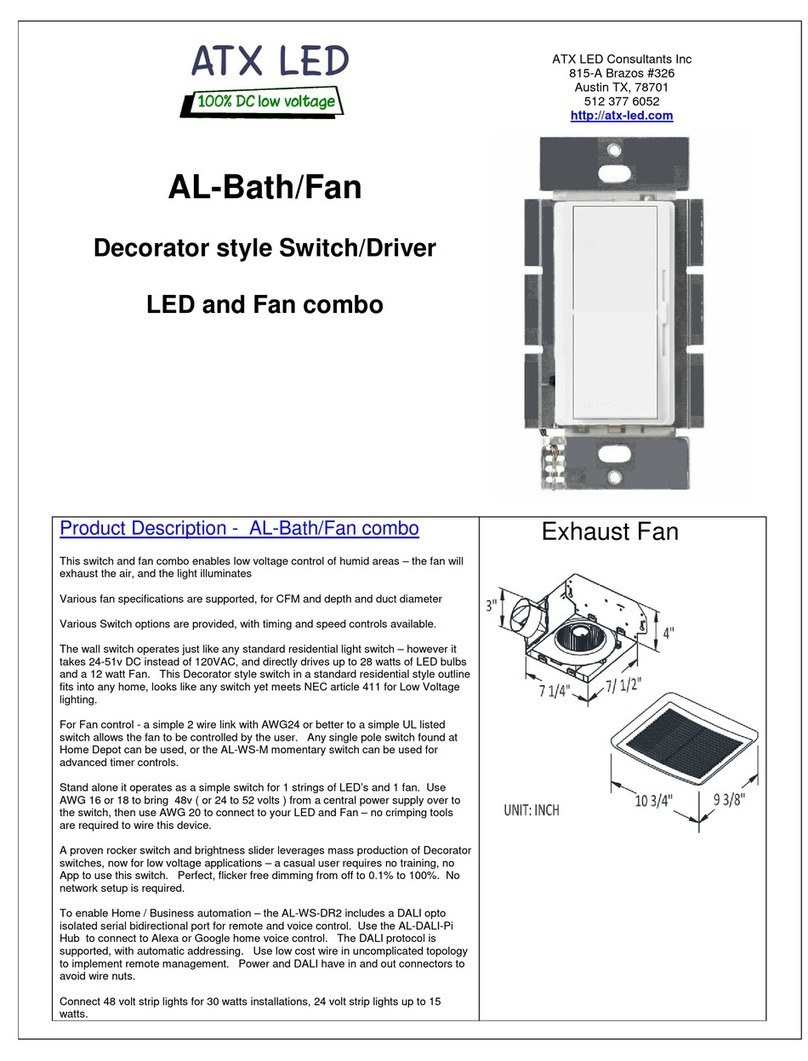

The AirUnit controller is designed for the installation in a

simple cavity wall box. It can be used for the control of up

to 4 AirUnit ventilation units. The AirUnit controller is to be

connected as a stationary equipment with fixed laid cables.

Electrical connection diagram see page 06.

The supply voltage of the AirUnit controller amounts 230 V/50 Hz, as supply line a sheathed cable 3 x 1,5 mm2

(for example NYM-J 3 x 1,5 mm2) is recommended.

The control of the ventilation unit is powered by 12 V voltage (DC). The ventilation units should therefore not be

connected with the 230 V supply voltage of the control electronics. As the terminal strip for the AirUnit ventilation

units a sheathed cable of minimum 3 x 0,6 mm2is recommended.

05

5. Elektrical connection

The electrical connection must be implemented according to VDE 0100. For installation and

maintenance work, disconnection from the mains on all poles with at least 3 mm contact opening width

must be undertaken. The mains disconnection is to be secured against reconnection!

• Connection of AirUnit compact controller pro

5.1 Connection AirUnit(s) – controller

The connection of the devices occurs arranged in pairs at the plug connectors. In paired operation one device of a

device pair operates in feed mode, the second assigned device in exhaust air mode The air flow direction of both

devices is alternated at intervals.

Maximum 4 AirUnit ventilation units can be operated with the AirUnit compact controller pro. Therefore

maximum 2 AirUnit ventilation units are to be connected in parallel on plug-in connector Fan 1 and maximum 2

AirUnit ventilation units on plug-in connector Fan 2.

Those AirUnit ventilation units, which are connected on the plug-in connector Fan 1 serve as exhaust fan regar-

ding to the function “summer mode”. AirUnit ventilation units which are connected to plug-in connector Fan 2

become supply fan in “summer mode”. If several units are used, cross ventilation can be provided, e.g. to convey

cool outside air into the building during the night hours in summer.

By using a single device, the AirUnit ventilation unit can be used as supply- or exhaust fan in “summer mode”.

The connection of the AirUnits to the connection line of the controller is implemented via a plug connector

contained within the scope of delivery of the ventilation units, as depicted previously. Please observe the polarity

feed / exhaust devices (see Fig. above)!

Ventilation device Controller

+12 V – RED

PWM – PURPLE

Gnd – BLUE

RED – +12 V

PURPLE – PWM

BLUE – Gnd

Connecting terminal

1 RS485-A

2 RS485-B

3 12V Bus

4 GND

5 12V

6PWM A

7 GND

8 12V

9 PWM B

10 GND

Net terminal

1L1

2N

3

External Input L1´

must be in phase

with L1!

Abluft Zuluft

06

6. External digital input (bath fan operation)

ATTENTION

It is mandatory that the input as well as the ventilation unit are supplied electrically from the

same phase, otherwise an impermissibly high voltage and therefore the destruction of the device

may occur.

Alternative air performances

The external digital input is a 230 Vac input

and can be used as an offset of exhaust

volume flows for the operation bath

ventilators.

The external input is connected in parallel

to the bath fan. Make sure, that bath fan

and ventilation unit are switched in the

same phase! While the bath fan is in use, a

dysbalance of supply air power 30 m3/h and

exhaust duct 15 m3/h per device is being

used instead of the standard air performan-

ce, whereby the exhaust air volume flow of

the bath fan can be compensated.

Abluft Zuluft

NL1

L1´

L1´

Light switch

L1

7. Sensor operation

Controller

...

up to

Sensor 1 Sensor 4

BUS

A

1

B

2

+

3

-

4

BUS

A

1

B

2

+

3

-

4

07

Via the integrated bus-interface of the device different air quality sensors (max. 4 sensors) of the controller can be

switched off. The digital air quality sensors send their measured values to the controller. Based on these values the

ventilation unit can increase or reduce the air stages, if required.

The number of connected sensors has to be established via the control element (see graph).

The type of the sensor will be automatically detected and then, the suitable threshold values will be used.

Depending on the air quality (e.g. air humidity) the air stages will be automatically increased or reduced. If the air

stages will be reduced manually, the demand-based ventilation system will be deactivated for a period of 60 minutes.

The number of the used sensors has to be set in accordance with the following graphs.

Keep both switches pressed simultaneously for 5

seconds, to enter the configuration menu.

By single pressing the left button, the combination of

the left LEDs must be selected as shown.

APress long for saving.

Flashes when successfully saved.

BPress long for leaving the configuration menu.

By single pressing the right button (arrow UP / arrow

DOWN) the combination of the right LEDs must be

selected as shown.

1

3

2

AN

AN

BLINKEN

A

B

4

No sensor

OFF

OFF

ON

OFF

Three sensors

ON

OFF

OFF

OFF

Four sensors

ON

OFF

ON

OFF

One sensor

OFF

ON

OFF

OFF

Two sensors

OFF

ON

ON

OFF

08

• Function summer mode (feed or exhaust air mode without heat recovery):

The AirUnit(s) operate constantly in feed* or exhaust air mode*; in this setting, heat recovery does not take place.

A change to winter operation with heat recovery occurs automatically after 8 hours.

*Der Betriebsmodus wird durch den Elektroanschluss definiert, das Gerät kann als Zu- oder Abluftgerät an der

AirUnit Regelung angeschlossen werden (see Electrical connection page 06).

• The winter mode function (feed or exhaust air mode with heat recovery):

The AirUnit(s) operate alternately in 2 adjustable time intervals. In the first interval (exhaust air phase) the „used“

room air is extracted outside via the ventilation unit. In the process, the air flows through the ceramic heat accumula-

tor, which absorbs and stores the heat of the room air. In the second interval (feed phase) the „fresh“ outside air is

conveyed into the room via the ventilation unit. The outside air similarly flows through the heat accumulator, absorbs

the previously stored heat and introduces this back into the room. In case of AirUnit operating in pairs, the devices of

the device pair work in opposite directions, i.e. the first device in feed and the second device in exhaust air mode;

in the next interval this is vice versa. In this way, a heat recovery of up to 90% occurserfolgt eine Wärmerückgewin-

nung von bis zu 90%.

•AirUnit ventilation system with 2 feed and 2 exhaust air units:

Feed devices in „summer mode“ Exhaust devices in „summer mode“

8. Einstellungen Lüftungsbetrieb

The operating mode variants of the AirUnit ventilation units are adjusted via the operating panel of the

controller. Two basic functions with different ventilator performance can be set:

Function summer mode (without heat recovery)) →

Function winter mode (with heat recovery)) →

09

The device is set to feed or exhaust air mode

2

without heat recovery (= summer mode by pressing

this button. The summer mode is automatically reset to winter mode 8 hours after activation.

Summer mode is extended by a further 8 hours by actuating this button again.

2

Is dependent on the electrical connection, see page 06

The device is set to alternate feed / exhaust air mode with heat recovery (winter mode) by pressing

this button. During the heating period, the device should be constantly operated in this setting.

If the adjacent symbol lights up, then the device is in performance level 3. Performance level 3

is automatically reset to performance level 2 an hour after its activation. If the adjacent

symbol pulsates, the device is controlled in sensor operation.

If the adjacent symbol lights up, then the device is in performance level 2. If the adjacent

symbol pulsates, the device is controlled in sensor operation.

If the adjacent symbol lights up, then the device is in performance level 1. If the adjacent

symbol pulsates, the device is controlled in sensor operation.

If the adjacent symbol lights up, then the device is in performance level minimum ventilation.

By actuating “DOWN”, the device is switched off and the symbol pulsates quickly. If the adjacent

symbol pulsates, the device is controlled in sensor operation.

Constant illumination of this display indicates that inspection / cleaning of the filter insert of the

ventilation unit is due. The maintenance of the filter inserts is described on page 11. If this display

flashes, it signalises a malfunction on the control panel of the controller. The control electronics

or the control panel must be checked by an electrician, see Malfunction page 12.

The device is switched on to performance level 1 by pressing this button. By pressing the button

again, the next-higher performance level is selected.

The device is reset to the next lower performance level by pressing this button. If the device is at

minimum ventilation, then the device is switched off by pressing this button again.

Sleep-Timer Funktion: The sleep timer is activated by pressing and holding the button. This

display of the performance level is maintained and the bottom LED is pulsing. After two hours, the

device switches back to the last selected performance level. A touch of the upward button deletes

the sleep timer and switches the device back into normal operation.

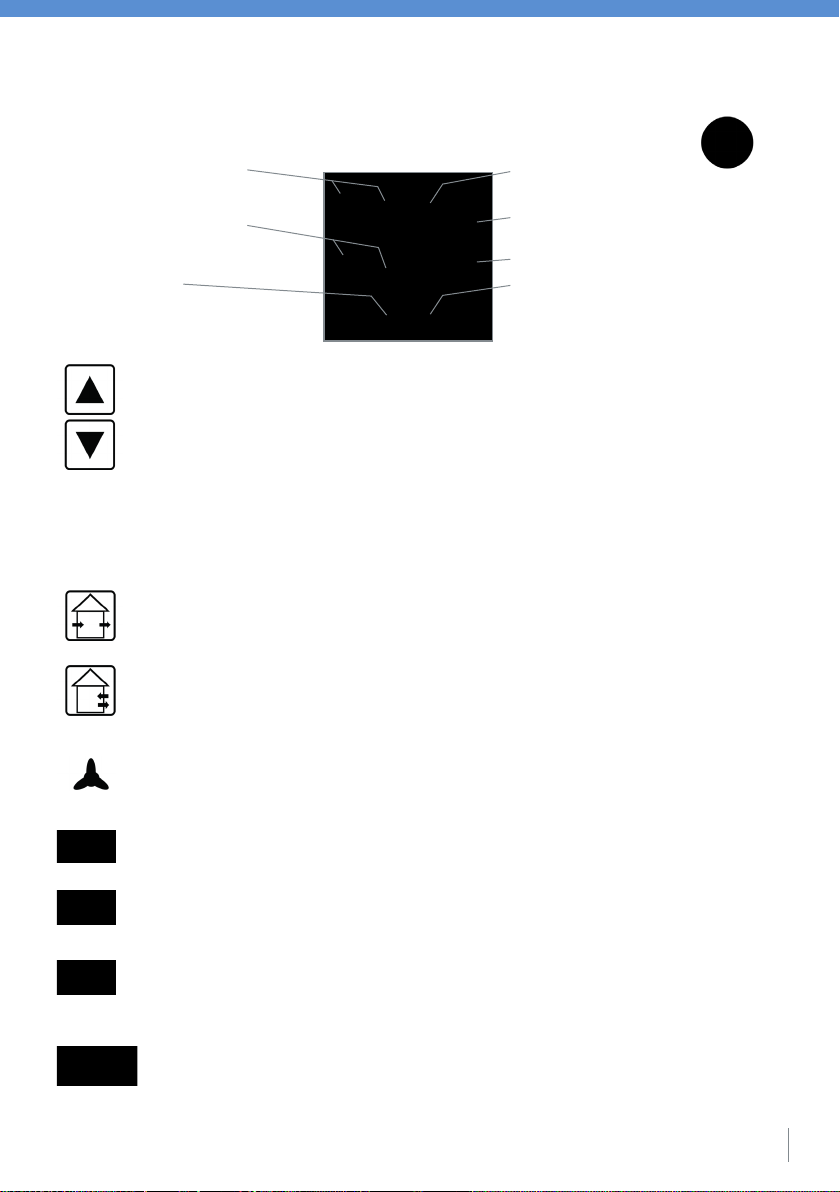

9. Operating and display elements of the compact controller pro

Function key / signal lamp

„summer mode” (without heat recovery)

Signal lamps

„Performance level 1-3”

Function key „Performance level DOWN“

Function key „Performance level UP“

Signal lamp „OFF / minimum ventilation“

Function key / signal lamp

„winter mode” (with heat recovery)

Signal lamp

„Filter change / fault”

10

10. Maintenance filter insert

The filter inserted into the ventilation unit is monitored in the control electronics by means of an operation

time measurement. After the expiry of 3 months continuous operation (2190 operation hours), the required

inspection of the filter insert is indicated on the control panel of the controller when the signal lamp „Filter change /

fault“ is continuously lit up. Checking / cleaning of the filter insert is described below.

Caution:

Prior to all maintenance work, the power supply of the ventilation unit must be interrupted at all

poles. The mains disconnection must be secured against reconnection!

To check the filter, the inner screen of the ventilation unit must be pulled off in an upward direction. The plug connection

of the connection line is to be disconnected and the sound insulation mat removed. Subsequently, the ventilator unit can

be removed from the wall duct. Pull the wire assembly backwards out of the housing pipe and remove the filter for any

cleaning work due.

In case of slight contamination (no or little dust deposition),

the filter insert can be vacuumed or beaten clean. In case of heavy

contamination, the filter insert can be washed using warm water

(approx. 40° C) and a conventional household mild detergent.

In the process, the filter should not be tumbled if possible. Allow

the cleaned filter insert to dry completely prior to reinsertion

into the ventilation unit; dust deposits will occur immediately on

a damp filter! In order to ensure continued good filtration, a filter

replacement is necessary at the latest with the destruction of the

fibre structure. Insert the dried filter insert into the ventilator unit

again and assemble the AirUnit ventilation unit in the reverse

order. After the inspection / cleaning of the filter insert and

switch-on of the power supply for the AirUnit, the operation time

measurement must be restarted for monitoring the filter insert.

Restart occurs via the control panel of the controller:

Restart of the operation time measurement occurs by simultaneously

pressing the buttons „UP“ and „DOWN“. Hold down both buttons

until the red LED „Filter change / fault“ goes off (approx. 5 seconds).

The re-start of the filter monitoring can be implemented as described

above, also without prior output from the filter change display, e.g.

within the scope of a scheduled inspection.

The prompt for a filter check is issued dependent on time after a 3-month operation period; the actual

contamination level of the filter is not taken into consideration. Depending on the level of contamination,

an earlier filter replacement may be expedient. It is therefore recommended that you check the filter insert at

three-month intervals in the first year after commissioning the AirUnit, and in case of recognisable heavy

contamination of the filters, that you reduce the inspection / cleaning intervals.

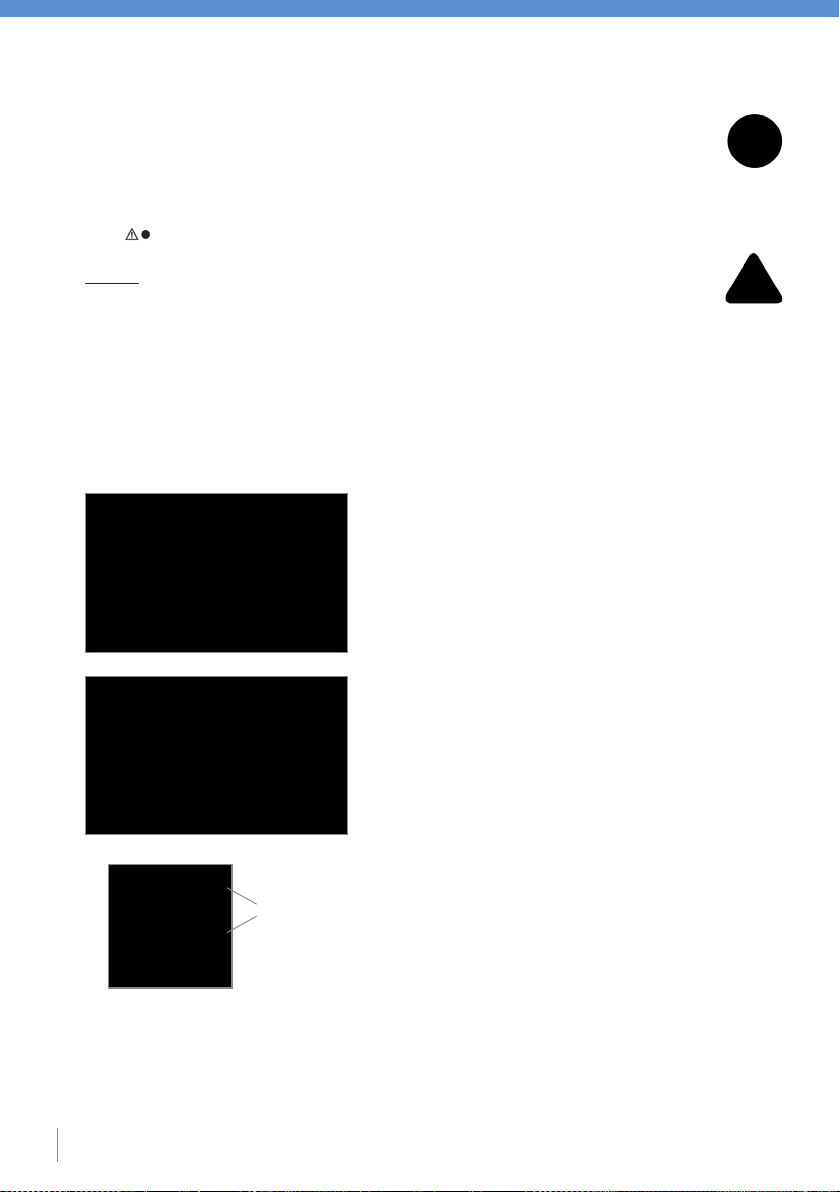

• Filter insert removal

5 seconds

11

11. Operating hours counter

12. Errors

No. Error Blink-Code Measure

1 Filter change necessary Light indicates

2 Self-test-error 2 flashes – pause

3

Communication disturbance sensor

3 flashes – pause

4 Temperature-error 4 flashes – pause

The ventilation system has an integrated operating hours counter.

The display of the operating hours shows the sum of the operating hours during which the device was operated in an

air stage of at least the moisture protection. The display is based on the number of flashing pulses of the individual

LEDs. The LED for moisture protection represents the 10th digit of the operating hours. The reduced ventilation led is

the 100 digit. The led for the nominal ventilation is the 1000 digit. The Led for the intensive ventilation the 10000er

digit. The number of flashing pulses ranges from 0 to 9 and the LEDs flash through their flashing patterns starting

from the lowest one in sequence. After one run, the display starts again with the 10 digit.

10.000 digit

1.000 digit

100 digit

10 digit

Keep both switches pressed simultaneously for

5 seconds, to enter the configuration menu.

By single pressing the left button, the combination of

the left LEDs must be selected as shown.

APress and hold to exit the configuration menu.

1

3

2

AN

AN

AN

A

4

Table of contents

Popular Fan manuals by other brands

Polypipe

Polypipe Silavent GLA100LV installation instructions

emerio

emerio TFN-214473.4 instruction manual

Viessmann

Viessmann VITOVENT 300 Technical guide

Somogyi Elektronic

Somogyi Elektronic home TF32/BK instruction manual

Marta

Marta MT-FN2544 user manual

Vallox

Vallox 70 COMPACT R Instructions for use and maintenance