2

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a flat

surface that can support the load. Where applicable,

use a cylinder base for added stability. Do not weld or

otherwise modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially

dangerous results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualified hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or damaged

parts by genuine ENERPAC parts. Standard grade

parts will break causing personal injury and property

damage. ENERPAC parts are designed to fit properly and

withstand high loads.

3.0 INSTALLATION INSTRUCTIONS

1. DO NOT INSTALL THIS PRODUCT UNTIL YOU HAVE READ

THIS ENTIRE PRODUCT INFORMATION SHEET.

Your unit has a polycarbonate bowl, so note the special

warnings.

2. EXCEPT as otherwise specified by the manufacturer, this

product is designed for compressed air service, and use with

any other fluid (liquid or gas) is a misapplication. For example,

use with, or injection of certain hazardous liquids or gases in

the system (such as alcohol or liquid petroleum gas) could be

harmful to the unit or result in a combustible condition or

hazardous external leakage. Before using with fluids other

than air, or for non-industrial applications, or for life support

systems, consult manufacturer for written approval.

Maximum temperature and pressure ratings for

polycarbonate bowls are 125 degrees Fahrenheit (52 degrees

Celsius) and 150 PSIG (10.3 Bar).

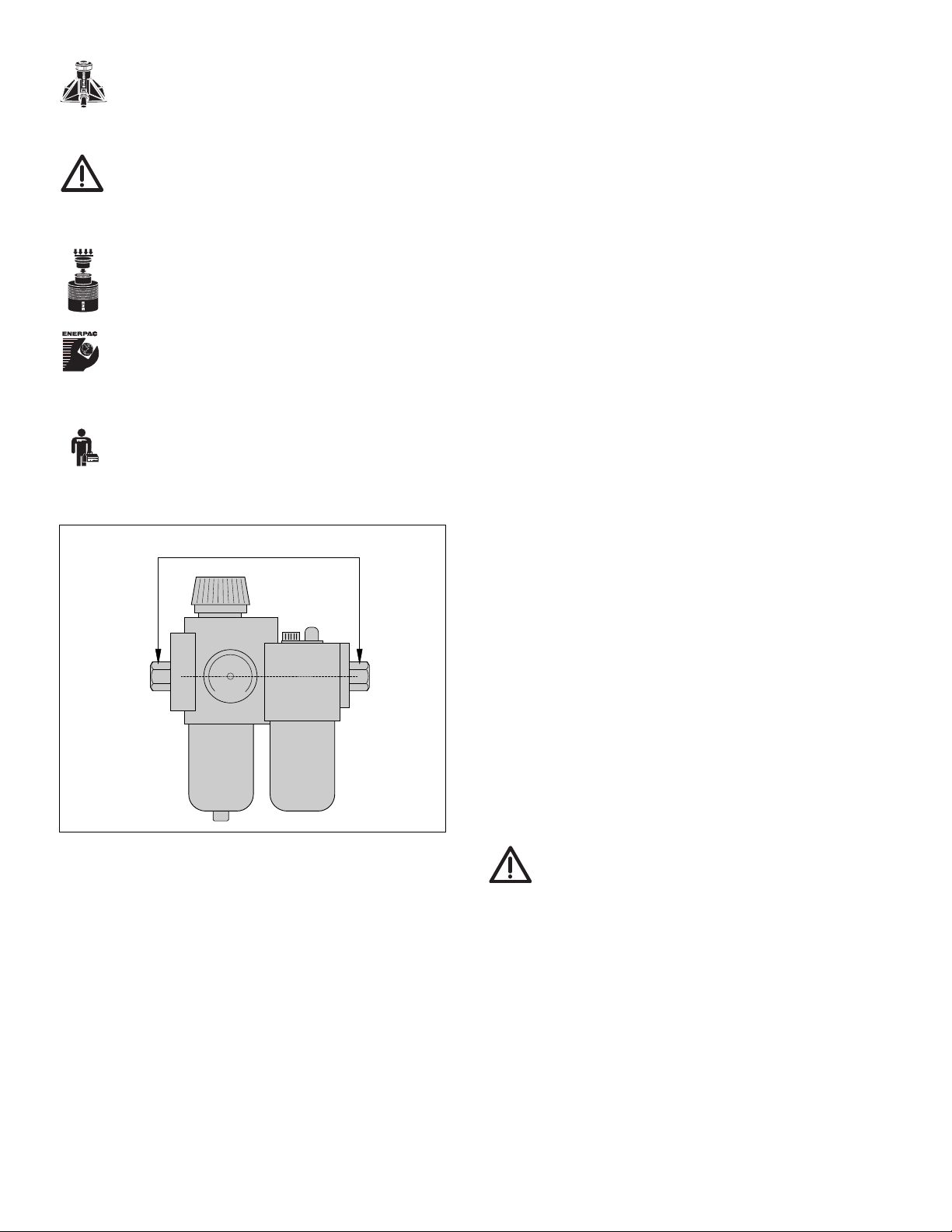

3. INSTALL as close as possible to point where air is being used

4. INSTALL unit with air flowing through the body in direction

indicated by arrow.

5. INSTALL unit ahead of equipment that requires regulated,

filtered, lubricated air.

6. INSTALL a Regulator/Filter/Lubricator that has the same size

as the pipe line on which it will be mounted. Avoid using

fittings, couplings, etc. that restrict the air flow.

7. INSTALL unit in a vertical position with pressure adjusting

handle up.

8. OTHER regulated air pressure lines may be run from the other

gauge port as well as the outlet port. In addition, the gauge

may be moved to the port on the opposite side of the

regulator.

9. PLUG any unused port.

10. To adjust air pressure, turn adjustment knob clockwise to

raise the regulated pressure and counterclockwise to lower

the regulated pressure.

11. FILL lubricator by pouring the oil into the bowl through the fill

port. Lubricator can be filled while pressurized.

12. USE CLEAN, NONDETERGENT OIL, preferably SAE 10 or

lighter. The rate of oil delivery may be controlled by turning

the adjusting screw counterclockwise for more, and

clockwise for less oil delivered. Once set, the variable orifice

in the lubricator will maintain the same ratio of oil to airflow

regardless of any change in airflow rate.

4.0 MAINTENANCE INSTRUCTIONS

1. DEPRESSURIZE UNIT BEFORE REMOVING GUARD

AND/OR BOWL.

2. INSPECT BOWL daily to detect crazing, cracking, damage, or

deterioration. Immediately replace any crazed, cracked,

damaged or deteriorated bowl with a new polycarbonate

bowl and metal bowl guard.

3. CLEAN FILTER ELEMENT periodically by removing from filter,

tapping on hard surface and blowing off with an airgun.

4. DRAIN filter bowl at least once per work shift.

5. IF BOWL SEAL is crazed, cracked, damaged or deteriorated,

replace with manufacturer's approved seal.

6. PERIODICALLY REMOVE the adjusting screw and clean the

needle and the seat in the body by blowing off with airgun.

7 DRAIN OFF any contaminants which may collect in the

bottom of the bowl.

CAUTION: YOUR UNIT HAS A POLYCARBONATE

PLASTIC BOWL

1 DO NOT INSTALL unit with polycarbonate bowl where it will

be subject to temperatures higher than 125 degrees

Fahrenheit (52 degrees Celsius) or where pressures exceed

150 PSIG (10.3 Bar).

2. WHEN BOWL becomes dirty, replace polycarbonate bowl, or

wipe clean with dry clean cloth.

3. DO NOT use polycarbonate bowl near, or clean bowl with,

materials such as alcohol, chloride, alkalies, amines, ketones,

esters, aromatic hydrocarbons or other materials included in

the list on page 4. Do not subject bowl to oils listed on the

chart on page 4.

4. DO NOT INSTALL unit with polycarbonate bowl on a

compressed air line where the compressor is lubricated with,

or the air contains, a synthetic, fire-resistant lubricant.