IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If any

shipping damage is found, notify carrier at once. Shipping

damage is NOT covered by warranty. The carrier is

responsible for all repair or replacement cost resulting from

damage in shipment.

SAFETY INFORMATION

To avoid personal injury or property damage during system

operation, read and follow all CAUTIONS, WARNINGS, and

INSTRUCTIONS included with or attached to each product.

The manufacturer CANNOT BE RESPONSIBLE FOR

DAMAGE OR INJURY RESULTING FROM UNSAFE USE OF

PRODUCT, LACK OF MAINTENANCE, OR INCORRECT

PRODUCT AND SYSTEM APPLICATIONS. Contact the

manufacturer when in doubt as to safety precautions or

applications.

CAUTION: Always use the handle to carry the

pump. Carrying the pump by the hose may

damage the hose and or the pump.

WARNING: Make sure that all system components

are protected from external sources of damage,

such as excessive heat, flame, moving machine

parts, sharp edges, and corrosive chemicals.

WARNING: Always check product limitations

regarding pressure ratings, load capacities, and

set-up requirements. The system operating

pressure must not exceed the pressure rating of the

lowest rated component in the system.

WARNING: NEVER set the relief valve to a higher

pressure than the maximum rated pressure of the

pump. Higher settings may result in equipment

damage and/or personal injury. See chart above for the

maximum pressure rating.

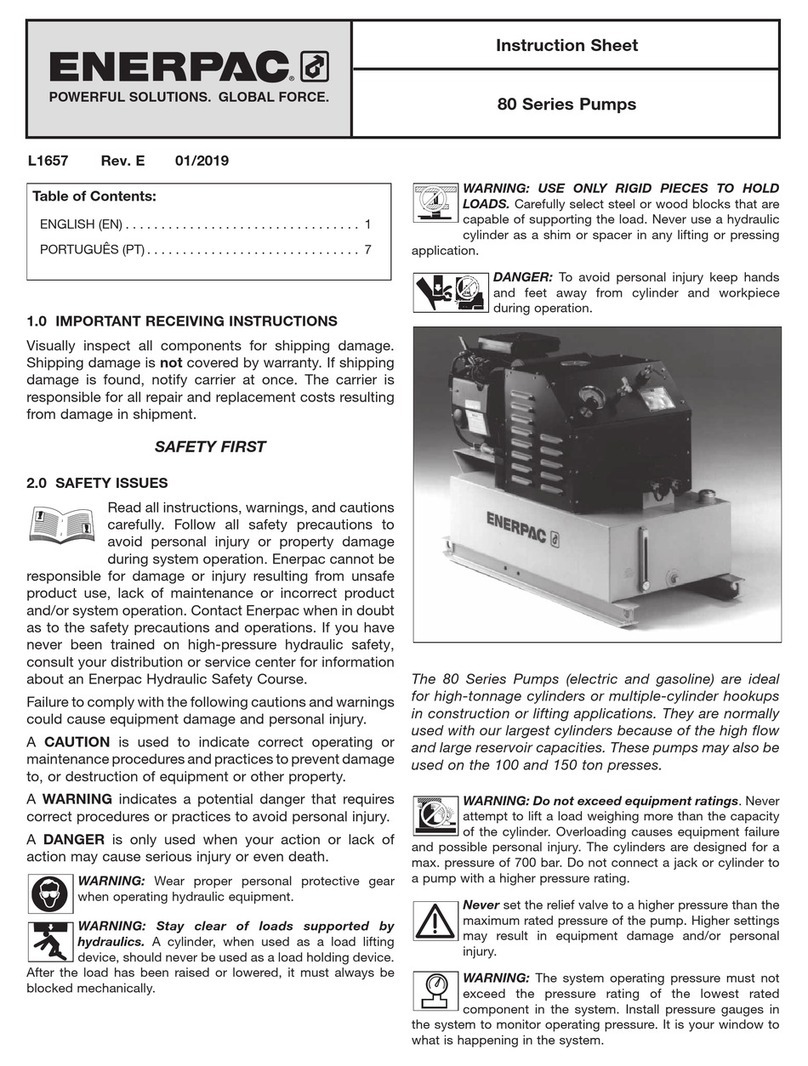

DESCRIPTION

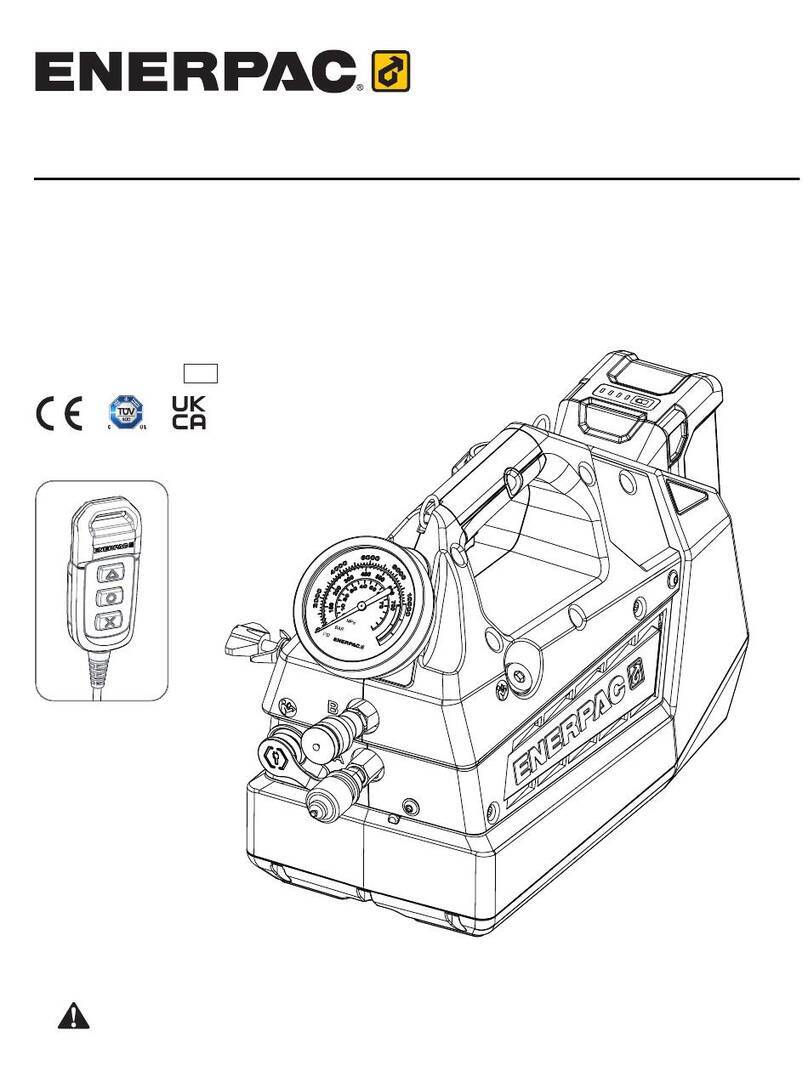

Figure 1 shows the main components of the pump. The dual-

purpose vent/fill camp acts as a pressure relief valve in case

of accidental reservoir pressurization. To provide an access

port at the rear of the reservoir for remote valves, use a

return-to-tank kit (model number PC-20).

INSTALLATION

Connecting the Pump

1. Thread hose into pump outlet. Use 1fi wraps of Teflon

tape (or suitable thread sealant) on the hose fitting,

leaving the first thread completely free of tape to ensure

that tape does not shed into hydraulic system, causing

damage.

2. Install a pressure gauge in-line from the pump for added

safety and better control.

3. Connect the hose to your cylinder or tool.

Pump Venting

This pump may be operated in a vented or unvented position.

(Vented pumps provide slightly better performance.) To vent,

turn the vent/vill cap counter-clockwise ⁄ turn. Close vent

prior to transporting pump to prevent leakage.

OPERATION

Before Using the Pump

1. Check all system fittings and connections to be sure they

are tight and leak free.

2. Check oil level in reservoir before operating pump. See

“Adding Oil to the Pump” on page 2.

Pumping / Using the Release Valve

1. Operate pump foot pedal to deliver hydraulic power to

system. Hydraulic pressure will be maintained until

release valve is open.