Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

CAUTION: Avoid damaging hydraulic hose.

void sharp bends and kinks when routing

hydraulic hoses. Using a bent or kinked hose

will cause severe backpressure. Sharp

bends and kinks will internally damage the

hose leading to premature hose failure.

CAUTION: Do not drop heavy objects on

hose. A sharp impact may cause internal

damage to hose wire strands. Applying

pressure to a damaged hose may cause it to

rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel couplers.

Use the carrying handle or other means o

safe transport.

CAUTION: Keep hydraulic equipment away

IURPÀDPHVDQGKHDW([FHVVLYHKHDWZLOO

VRIWHQ SDFNLQJV DQG VHDOV UHVXOWLQJ LQ ÀXLG

leaks. Heat also weakens hose materials

and packings. For optimum performance do

not expose equipment to temperatures o

65°C [150°F] or higher. Protect hoses and

cylinders from weld spatter.

DANGER: Do not handle pressurized hoses.

Escaping oil under pressure can penetrate

the skin, causing serious injury. If oil is

injected under the skin, see a doctor

immediately

WARNING: Only use hydraulic cylinders in a

coupled system. Never use a cylinder with

unconnected couplers. If the cylinder

becomes extremely overloaded, components

can fail catastrophically causing severe

personal injury.

WARNING: be sure setup is stable before

lifting load. Cylinders should be placed on a

ÀDWVXUIDFHWKDWFDQVXSSRUWWKHORDG:KHUH

applicable, use a cylinder base for added

stability. Do not weld or otherwise modify the

cylinder to attach a base or other support.

CAUTION: Avoid situations where loads are

not directly centered on the cylinder plunger.

Off-center loads produce considerable strain

on cylinders and plungers. In addition, the

load may slip or fall, causing potentially

dangerous results.

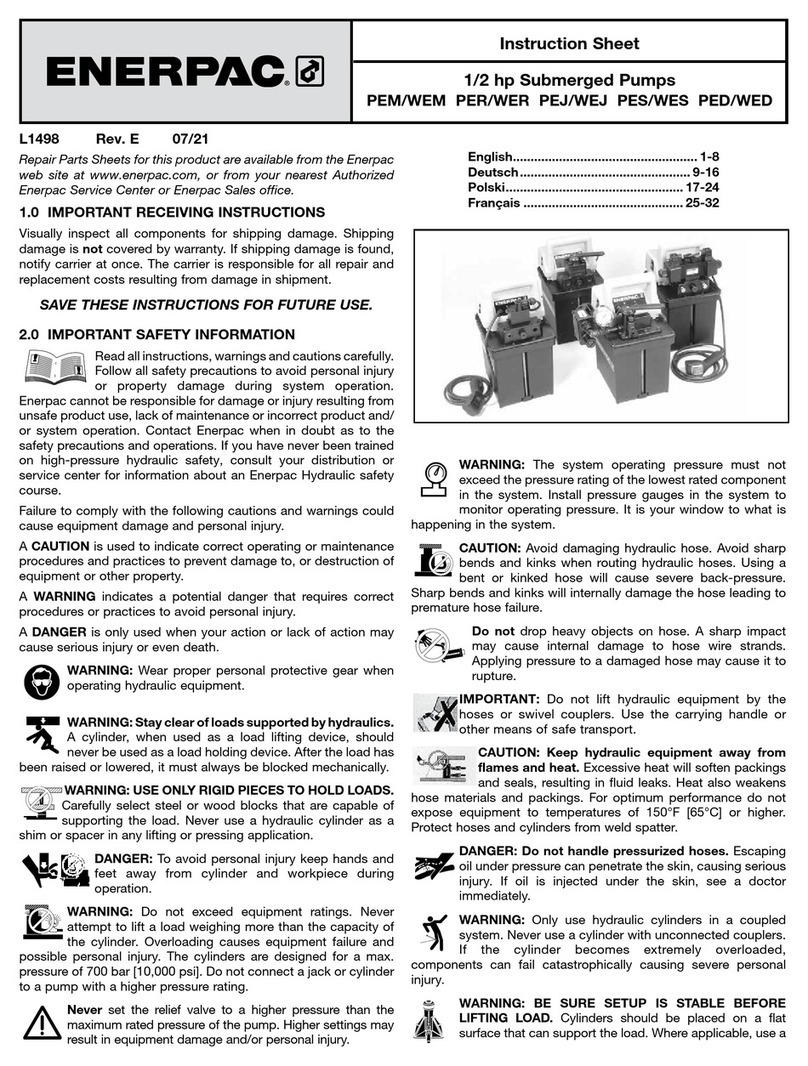

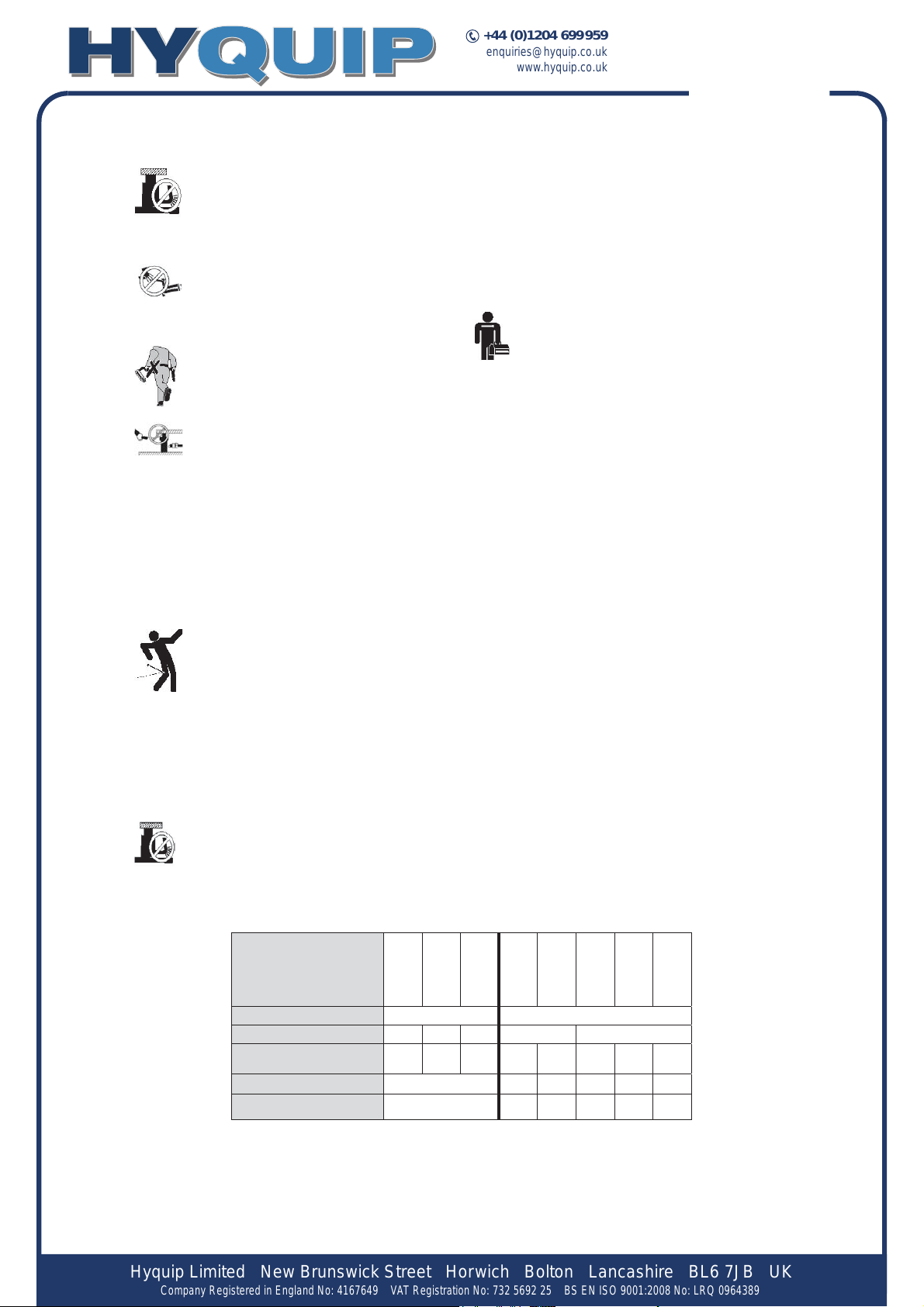

3.0 SPECIFICATIONS

The system is composed by a powerpack which

commands 4 double acting cylinders.

There are different models of powerpack depending on

the number of outlets and flow. Check in the next table

the features of the powerpack concerning to the

equipment acquired

PUMP MODEL

SFP213SW

SFP213MW

SFP404SW

SFP404MW

SFP604SW

SFP604MW

SFP228SW

SFP228MW

SFP242SW

SFP242MW

SFP409SW

SFP409MW

SFP414SW

SFP414MW

SFP421SW

SFP421MW

RESERVOIR CAPACITY (L) 40 150

OUTLETS (points) 2 4 6 2 4

FLOW (l/min) at 700 BAR 1,3 0,45 0,45 2,8 4,2 0,9 1,4 2,1

MOTOR POWER KW 5,5 7,5 11 5,5 7,5 11

WEIGHT (Kg) 240 488 526 475 488 526

CAUTION: Distribute the load evenly across

the entire saddle surface. Always use a

saddle to protect the plunger.

IMPORTANT: Hydraulic equipment mus

RQO\ EH VHUYLFHG E\ D TXDOL¿HG K\GUDXOLF

technician. For repair service, contact the

uthorized ENERPAC Service Center in

your area.

WARNING: In case of leakage contact

ENERPAC parts. Standard grade parts will

break causing personal injury and propert

GDPDJH(1(53$&SDUWVDUHGHVLJQHGWR¿W

properly and withstand high loads.

WARNING: Do not use electric pumps in an

explosive atmosphere. Adhere to all local

and national electrical codes. A qualified

electrician must do installation and

modification

WARNING: Start the pump with the valve in

the neutral position to prevent accidental

cylinder operation. Keep hands clear o

moving parts and pressurized hoses.

WARNING: These pumps have internal

factory adjusted relief valves, which must not

be repaired or adjusted except by an

uthorized Enerpac Service Center.

CAUTION: To prevent damage to pump

electric motor, check specifications. Use o

incorrect power source will damage the

motor.

CAUTION: Check motor rotation direction to

prevent damage to hydraulic pump (See 4.0

installation)

2