FISNAR EP1320C User manual

EP1320C OPERATION MANUAL

Rev. A - November, 2013

1 | P a g e

CARTRIDGE PUMP

MODEL EP1320C

◀OPERATION MANUAL▶

EP1320C OPERATION MANUAL

Rev. A - November, 2013

2 | P a g e

CONTENTS

1. Safety - - - - - - - - - - - - - - - - - - - - - - - - - 3

2. Introduction - - - - - - - - - - - - - - - - - - - - - - - - - 7

3. Specification - - - - - - - - - - - - - - - - - - - - - - - - 8

4. Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

5. Installation / Set-up / Operation - - - - - - - - - - - - - - - - - - 11

6. Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - 14

7. Exploded View / Parts List- - - - - - - - - - - - - - - - - - - - - - 15

8. Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - 20

9. Technical Data - - - - - - - - - - - - - - - - - - - - - - - - 21

Read the manual before installation and maintenance

EP1320C OPERATION MANUAL

Rev. A - November, 2013

3 | P a g e

SECTION 1

GENERAL SAFETY WARNINGS

1. Equipment Misuse Hazards

Any misuse of the dispensing equipment or accessories such as over-

pressurizing, modifying parts, using incompatible chemicals and fluids, or using

worn or damaged parts, can cause item to rupture and result in fluid splashing in

the eyes or on to the skin.

Never alter or modify any part of this equipment, doing so could cause it to

malfunction.

Check all dispensing equipment regularly and repair, or replace worn or

damaged parts immediately.

Always wear protective eyewear, gloves and clothing, as recommended by the

material and solvent manufacturers.

Never exceed the maximum air inlet pressure of 7 bar (100 psi).

Do not exceed the maximum working pressure of any component or accessory

used in the system.

Be sure that all materials and solvents used are chemically compatible with the

wetted parts. Always read the manufacturer's literature before using material or

solvent in this pump.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

4 | P a g e

2. Hose Safety –High Pressure Hazards

High pressure fluid in the hoses can be very dangerous. If the hose develops a

leak, split or rupture due to any kind of wear, damage or misuse, the high

pressure spray emitted from it can cause material to splash in the eyes or on the

skin. Tighten all fluid connections securely before each use. High pressure fluid

can dislodge a loose coupling or allow high pressure spray to be emitted from the

coupling.

Never use a damaged hose. Before each use, check the entire hose for cuts,

leaks, abrasion or damage or movement of the hose couplings. If any of these

conditions exist, replace the hose immediately.

Do not try to re-couple high pressure hose or mend it with tape or any other

device. A repaired hose cannot safely contain the high pressure fluid.

Handle and route hoses carefully, do not pull on hoses to move equipment. Do

not use materials which are not chemically compatible with the hose.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

5 | P a g e

3. Moving Parts Hazards

In order to lessen the danger of an accident, keep hands and fingers away from

the priming piston while the pump is installed and while air is introduced to the

pump.

Always follow the procedure of depressurizing the system before disassembling

and/or servicing the machine.

The air motor, the fluid area of pump and the motor will move whenever the

machine is activated. Keep hands and fingers away from the air motor during the

priming and installation of the pump.

Keep hands away from the edge of the ram or the pump bracket, hose and pad

plate.

All moving parts are covered by guards. The guards are removable for machine

setting and maintenance. Whenever these guards are removed for setting or

maintenance keep hands clear of any moving parts and pinch hazards.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

6 | P a g e

4. Fire and Explosion Hazards

Static electricity may occur while fluid is in circulation through the pump and hose.

When not properly grounded, a spark may occur which can be dangerous. It can

occur whether the power cord is plugged or not. This spark may ignite any

solvent, dust particles and other combustible materials in or near the machine

and may cause fire, explosion, or serious injuries.

If you are shocked (even by a little) during the installation or normal operation,

stop dispensing immediately. Ground yourself properly to discharge any static

buildup. Do not use the equipment until the problem is completely checked and

safety is secured.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

7 | P a g e

SECTION 2

INTRODUCTION

The EP1320C is a powerful medium ratio system for controlled fluid transfer from 1/10th

gallon (310ml) plastic cartridges –suitable for silicone-type fluids. The system integrates

a dual (A+B) tandem cartridge arrangement for continuous-flow management. A low-

pulse design allows automatic control of dispensing application.

The EP1320C tandem cartridge pump is designed to easily transfer material for

controlled dispensing via a high pressure valve. The suitable viscosity range is

10,000cps –600,000cps.

Rated at 15:1, the system provides a maximum of 995psi regulated material pressure.

The A&B cartridge management automatically switches from either A to B or B to A

when the cartridge is exhausted. Cartridges are contained in metal jacketed cylinders.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

8 | P a g e

SECTION 3

SPECIFICATION

Power Requirements

220VAC ± 10%, 50-60Hz

Power Consumption

10W

Max Air Inlet

9.9kgf/cm2

Pump Ratio

15:1

Weight

18.5kg

Temperature Range

-5oC ~ 40oC

Dimension

272mm (W)

288mm (D)

649mm (H)

EP1320C OPERATION MANUAL

Rev. A - November, 2013

9 | P a g e

SECTION 4

Control Panel

EP1320C OPERATION MANUAL

Rev. A - November, 2013

10 | P a g e

No

Menu

Operation

Description

1

Lamp is on when power on

Lamp is off when power of

Power On/Off switch

2

Lamp On/Off

Cartridge is empty when light

is ON.

3

Indicates which side cartridge

is being used and/or replaced

Pressing Using selects which

cartridge is being used

Pressing Replace indicates

cartridge us being replaced

4

Lamp On/Off

Cartridge is empty when light

is ON.

5

Indicates which side cartridge

is being used and/or replaced

Pressing Using selects which

cartridge is being used

Pressing Replace indicates

cartridge us being replaced

6

Warning sounds

Sounds an alarm when the

material level is low

Replace with a new cartridge

7

Alarm signal out

I/O signal when material is

low.

The contact is broken when

material is low.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

11 | P a g e

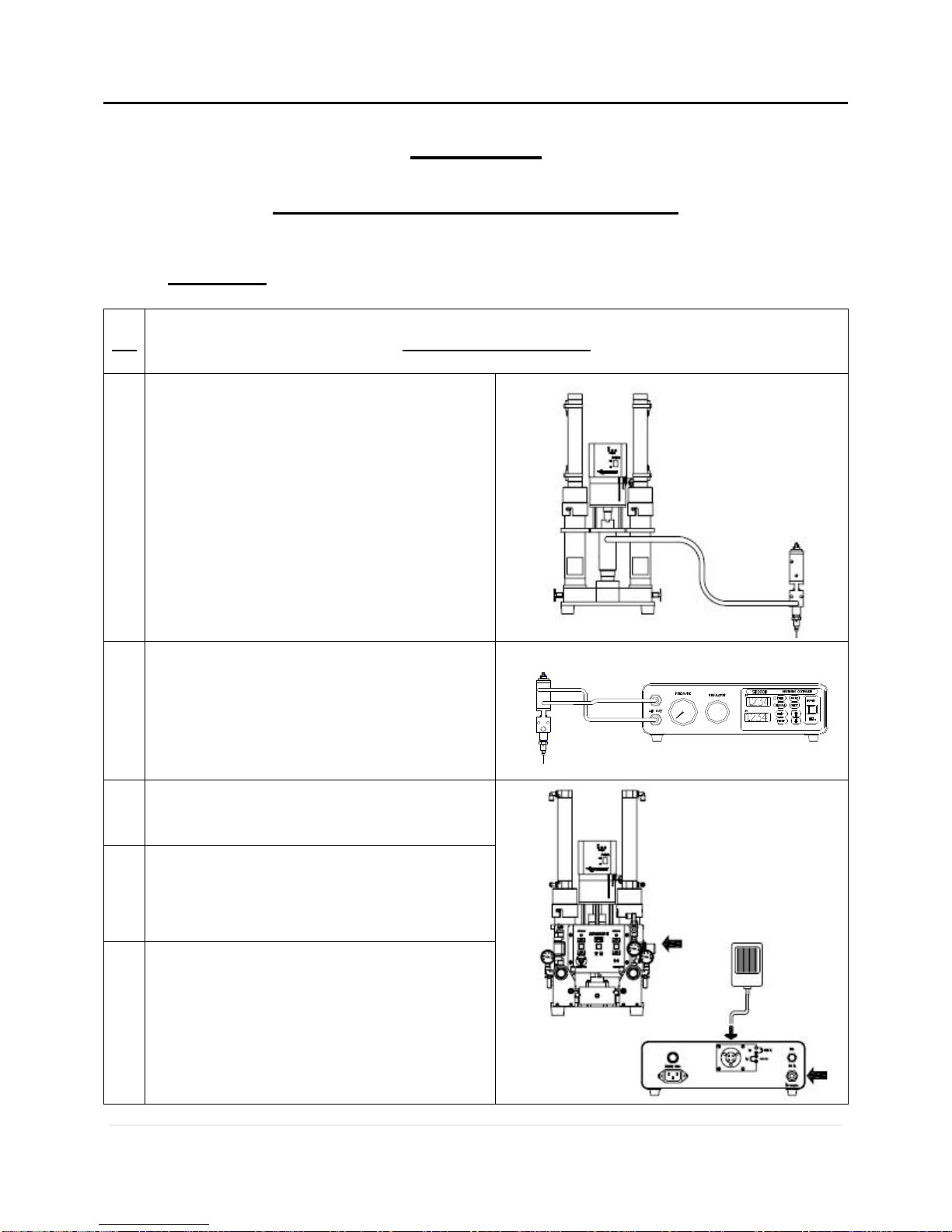

SECTION 5

INSTALLATION / SET-UP / OPERATION

1. Installation

No

Air Line Connections

1

Connect one end of the fluid line to the

fluid inlet of the dispensing valve and

the other to the fluid outlet of the pump.

Please refer to the valve manual for

additional information.

2

Connect air inlet of dispensing valve

and air outlet of controller with connect

tube.

Please refer to the valve and controller

manual for additional information.

3

Connect the air supply to the pump

4

Connect the air supply to the dispensing

controller.

5

Connect the foot pedal to the controller

I/O.

Please refer to the controller manual for

additional information.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

12 | P a g e

2. Set-Up

No

Installing / Replacing the Cartridge

1

Turn the cartridge holder counter

clockwise and pull to remove.

2

Insert the cartridge with the outlet

facing down.

3

Replace the cartridge holder. Turn in

clockwise direction to lock and

secure.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

13 | P a g e

3. Operation

No

Operation

1

Set the main air regulator (A) to the

required dispense pressure.

2

Open the bleed port (C) to extract

bubbles and close slowly.

3

Set air pressure over 30psi with air

regulator (B).

Open the air valve slowly until

material starts flowing.

If the does not stop running, open

the bleed port (D) to let trapped air

out.

Replace the bleed port when

completed.

EP1320C OPERATION MANUAL

Rev. A - November, 2013

14 | P a g e

SECTION 6

TROUBLESHOOTING

ISOLATE ALL AIR AND MATERIAL FEEDS FROM

THE PUMP PRIOR TO SERVICING.

PUMP 접액부의 하부 INTAKE VALVE

(도면 114A, 114B) 마모

분해 세척후 교체

공기통로의 막힘, AIR압력 부족

PUMPING AIR VALVE(도면8번)의 막힘

REGULATOR 작동불량

재료의 잔량 없음

재료 HOSE가 막힘

재료점도가 너무 높아서 PUMPING

할수 없다.

PUMP HEAD부의 MAGNET SENSOR의

위치 이탈

건조된 재료가 PISTON LOAD를 고착

시킴.

PUMP는 작동하지만 유량이 부족하다.

PUMP작동속도가 너무 빠르다.

원인

PUMP의 상승, 하강이 되지 않는다.

배관청소, 공기공급구 점검

AIR VALVE 교체

REGULATOR 교환

SENSOR의 위치 교정

올려본다.

REGULAROR의 AIR 압을

분해 세척후 OIL보충

CARTRIDGE 교환보충

HOSE 교환

보수

PUMP가 작동하지 않는다.

PUMP는 작동하지만 STROKE가 작다.

고장

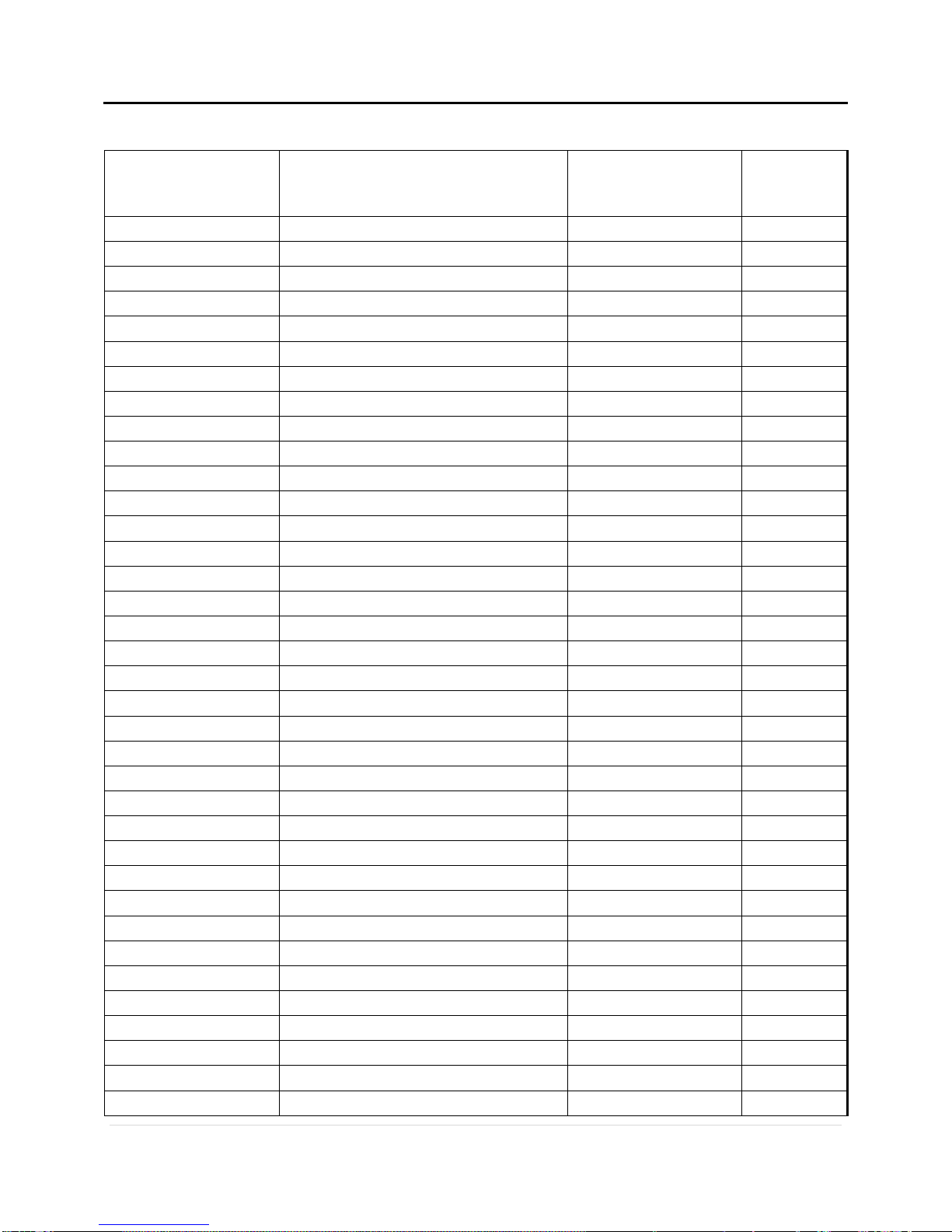

WARNING

Pump does not work.

Pump stroke is short.

Flow rate is slower than usual

Pump actuates quickly.

Pump does not go up & down.

Probable Cause

Recommended Maintenance

Insufficient air pressure

Defective air valve

Defective regulator pressure

Insufficient material

Clogged hose

Change in material property

Trouble in magnetic sensor

Worn piston rod

Worn intake valve

Clear the air hose

Replace the air valve

Replace the regulator

Replace the cartridge

Replace the hose

Increase the dispense pressure

Adjust the sensor position

Clean and lubricate the rod

Clean and rebuild the valve

EP1320C OPERATION MANUAL

Rev. A - November, 2013

15 | P a g e

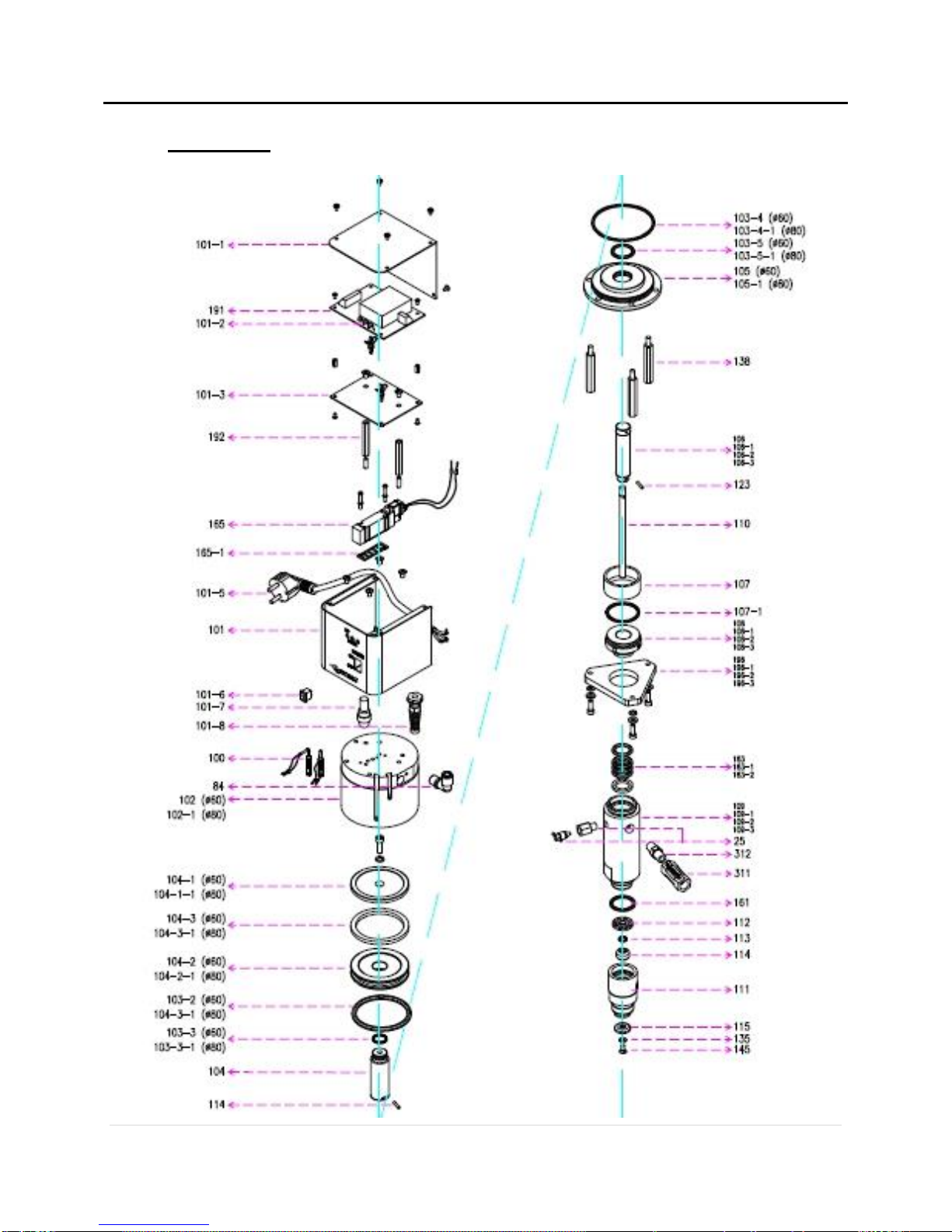

SECTION 7

EXPLODED VIEW AND PARTS LIST

1. Main Body

EP1320C OPERATION MANUAL

Rev. A - November, 2013

16 | P a g e

Part No.

Description

Material

Quantity

2

CARTRIGE CAP

AL6061

2

2-A

O-RING

NBR

2

3

SENSER MAGNET

BS

2

4

HOLDER PIPE

STS304

2

5

SENSER MAGNET

BS

3

8

BALL VALVE

BS

1

10

PIN CONNECTOR

STS304

2

12

INLET HOUSING

AL6061

2

13

O-RING

NBR

3

14

MANIFOLD

AL6061

2

15A,B

BLEED COCK

BS

2

25

BLEED COCK

BS

1

27A,B,C

REGULATOR SET

TACO

3

28

ELBOW

BS

1

56

FOOT

BS

4

70

BASE PLATE

AL6061

1

101

CAP

STS

1

102

CYLINDER

AL6061

1

103A,B,C

O-RING

NBR

3

104A,B

PISTON

AL6061

1

106

ROD

SM45C

1

107

WET CUP

STS304

1

109

HOUSING ROD

AL6061

1

110

PRIMING ROD

SM45C

1

112

STOPPER

STS304

1

113

O-RING

NBR

1

114

INTAKE VALVE

ACETAL

1

115

PRIMING ROD

STS304

1

123

PIN

SPRING

1

138

SCREW HEX

BS

3

144

SCREW

STS

1

145

SCREW

STS

1

161

O-RING

NBR

1

162,3

V-PACKING

TEFLON

1

196

HOLDER BRAKET

AL6061

1

196A

BLAKET CLAMP

AL6061

2

EP1320C OPERATION MANUAL

Rev. A - November, 2013

17 | P a g e

2. Pump Head

EP1320C OPERATION MANUAL

Rev. A - November, 2013

18 | P a g e

Part No.

Description

Size

101-1

PUMP HEAD BOX COVER

191

PUMP HEAD PCB

101-2

LED LAMP(G.Y.R)

192

SPACE BAR-1

M3*10

101-3

PCB PLATE

165

SOLENOID VALVE

SY5140-5LZ(SMC)

101-5

POWER CORD

2P 220V

101

PUMP HEAD BOX COVER

101-6

POWER SWITCH

KCD11(RED)

101-7

FUSE(MEDIUM)

10A 250V AC중(FS-15)

101-8

POWER CORD HOLDER

10A 250V AC

100

PUMP HEAD SENSOR

D-W13(TPC)

102

PUMP HEAD CYLINDER-1

60Ø

102-1

PUMP HEAD CYLINDER-2

80Ø

84

FITTING

KQ2L08-02S

104-1

PUMP HEAD UPPER PISTON

60Ø

104-1-1

PUMP HEAD UPPER PISTON

80Ø

104-2

PUMP HEAD PISTON

60Ø

104-2-1

PUMP HEAD PISTON

80Ø

104-3

PUMP HEAD PISTON MAGNETIC

60Ø

104-3-1

PUMP HEAD PISTON MAGNETIC

80Ø

103-2

O-RING

60Ø

103-2-1

O-RING

80Ø

103-3

O-RING

60Ø

103-3-1

O-RING

80Ø

104

PUMP HEAD CYLINDER SHAFT

144

WITHOUT HEAD BOLT

103-4

O-RING

60Ø

103-4-1

O-RING

80Ø

103-5

O-RING

60Ø

103-5-1

O-RING

80Ø

105

PUMP HEAD CYLINDER UNDER CAP-1

60Ø

105-1

PUMP HEAD CYLINDER UNDER CAP-1

80Ø

140

PUMP HEAD BASE PLATE

60Ø

140-1

PUMP HEAD BASE PLATE

80Ø

138

SUPPORT BAR

106

PUMP SHAFT-1

EP1320C OPERATION MANUAL

Rev. A - November, 2013

19 | P a g e

Part No.

Description

Size

106-1

PUMP SHAFT-2

106-2

PUMP SHAFT-3

106-3

PUMP SHAFT-4

123

SPRING PIN

3Ø, 15

110

PUMP UNDER SHAFT

107

OIL CUP

107-1

O-RING

G40

108

PUMP V-PACKING PUSHER-1

108-1

PUMP V-PACKING PUSHER-2

108-2

PUMP V-PACKING PUSHER-3

108-3

PUMP V-PACKING PUSHER-4

196

PUMP FLUID HOUSING BASE-1

196-1

PUMP FLUID HOUSING BASE-2

196-2

PUMP FLUID HOUSING BASE-3

196-3

PUMP FLUID HOUSING BASE-4

163

PUMP FLUID V-PACKING-1

163-1

PUMP FLUID V-PACKING-2

163-2

PUMP FLUID V-PACKING-3

109

PUMP FLUID HOUSING-1

109-1

PUMP FLUID HOUSING-2

109-2

PUMP FLUID HOUSING-3

109-3

PUMP FLUID HOUSING-4

25

AIR EGEST

161

O-RING

P28(NBR)

112

PUMP FLUID, LOW CHECK STOPPER

113

O-RING

P8N

114

PUMP FLUID LOW CHECK

111

PUMP FLUID UNDER HOUSING

115

PRIMING

135

PLAIN WASHER

M5

145

PLATE HEAD BOLT

M5*10

312

TWO NIPPLE 1/4

1/4 SUS

311

CHECK VALVE 1/4

1/4 (VITON)

EP1320C OPERATION MANUAL

Rev. A - November, 2013

20 | P a g e

SECTION 8

DIMENSIONS

Table of contents

Popular Water Pump manuals by other brands

Sears

Sears CRAFTSMAN 390.269152 owner's manual

Pentair

Pentair Myers MSK60 Installation and operator's manual

Becker

Becker VariAir VASF 2.50/1-0.AC230 BASIC operating instructions

hecht

hecht 3635 TRANSLATION OF ORIGINAL INSTRUCTIONS FOR USE

FloJak

FloJak F-50 Instructions & assembly

Wayne

Wayne 352205-001 Operating instructions and parts manual

Nocchi

Nocchi BIOX 200/8 manual

Pfeiffer Vacuum

Pfeiffer Vacuum UnoLine UNO 35 Translation of the original operating instructions

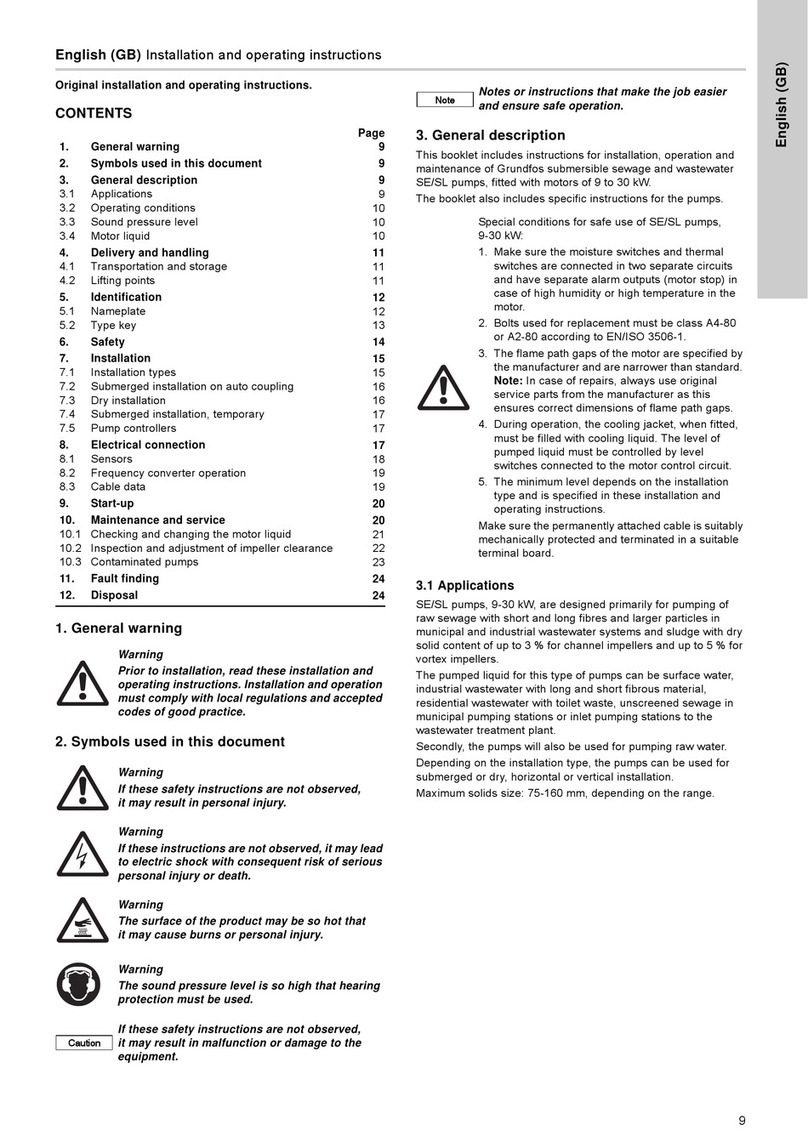

Grundfos

Grundfos SL Series Installation and operating instructions

Koshin

Koshin SEH-50X instruction manual

BUSCH

BUSCH COBRA ATEX NC 2000 B VR instruction manual

Silverline

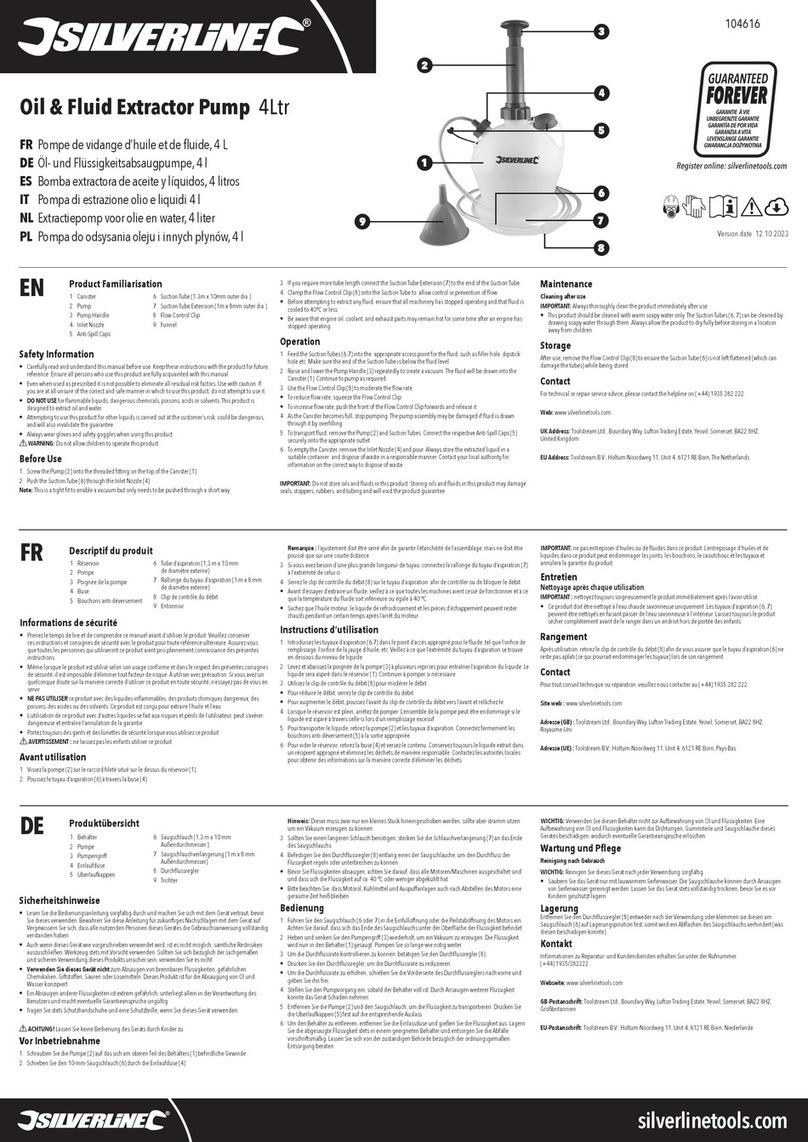

Silverline 104616 quick start guide