EnerSys alpha SE41-2722 Quick start guide

SE41-2722/2730

Multipurpose Enclosure Series

Technical Guide: 0290002-J0

Effective:07/2020

SE41-2722/2730

Multipurpose Enclosure Series

For technical support, contact Alpha Technologies:

Canada and USA: 1-888-462-7487

International: +1-604-436-5547

Alpha shall not be held liable for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware if used or operated in any manner or

subject to any condition inconsistent with its intended purpose, or if installed or oper-

ated in an unapproved manner, or improperly maintained.

Photographs contained in this manual are for illustrative purposes only. These photo-

graphs may not match your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe operation of this powering

system, contact Alpha Technologies or your nearest Alpha representative.

NOTE:

NOTE:

Copyright

Copyright © 2020 Alpha Technologies Ltd. All rights reserved. Alpha is a registered trademark of Alpha Technologies

Services, Inc.

No part of this documentation shall be reproduced, stored in a retrieval system, translated, transcribed, or transmit-

ted in any form or by any means manual, electric, electronic, electromechanical, chemical, optical, or otherwise

without prior explicit written permission from Alpha Technologies.

This document, the software it describes, and the information and know-how they contain constitute the proprietary,

confidential and valuable trade secret information of Alpha Technologies, and may not be used for any unauthorized

purpose, or disclosed to others without the prior written permission of Alpha Technologies.

The material contained in this document is for information only and is subject to change without notice. While

reasonable efforts have been made in the preparation of this document to assure its accuracy, Alpha Technologies

assumes no liability resulting from errors or omissions in this document, or from the use of the information contained

herein. Alpha Technologies reserves the right to make changes in the product design without reservation and with-

out notification to its users.

0290002-J0 Rev G

2

Table of Contents

1. Safety....................................................................................................................................4

1.1 Safety Symbols.......................................................................................................................... 4

1.2 General Warning and Cautions.................................................................................................. 4

1.3 Electrical Safety......................................................................................................................... 5

1.4 Battery Safety ............................................................................................................................ 5

2. Introduction...........................................................................................................................6

2.1 Product Overview....................................................................................................................... 6

3. Specications........................................................................................................................7

4. Features................................................................................................................................8

4.1 AC and DC Power Options ........................................................................................................ 8

5. Site Evaluation and Pre-Installation......................................................................................9

5.1 Site Selection............................................................................................................................. 9

5.2 Tools Required........................................................................................................................... 9

6. Installation...........................................................................................................................10

6.1 Safety Precautions................................................................................................................... 10

6.2 Plinth Mount Kit for Concrete Pad ........................................................................................... 10

6.3 Wall Mounting the Enclosure ................................................................................................... 12

6.4 Pole Mounting the Enclosure................................................................................................... 13

7. Wiring..................................................................................................................................14

7.1 Grounding the Enclosure......................................................................................................... 14

7.2 AC Input Wiring to the Load Center......................................................................................... 15

8. Maintenance .......................................................................................................................17

8.1 Heat Exchanger Fan Test Procedure....................................................................................... 18

8.2 Heat Exchanger Fan Replacement Procedure........................................................................ 19

8.3 Cooling Fan Test Procedure .................................................................................................... 22

8.4 Cooling Fan Replacement Procedure...................................................................................... 22

9. Warranty Statement and Service Information.....................................................................25

9.1 Technical Support .................................................................................................................... 25

3

0290002-J0 Rev G

9.2 Warranty Statement................................................................................................................. 25

9.3 Product Warranty..................................................................................................................... 25

9.4 Battery Warranty...................................................................................................................... 25

9.5 Warranty Claims....................................................................................................................... 25

9.6 Service Information.................................................................................................................. 25

10. Acronyms and Denitions .................................................................................................26

11. Certication .......................................................................................................................27

List of Figures

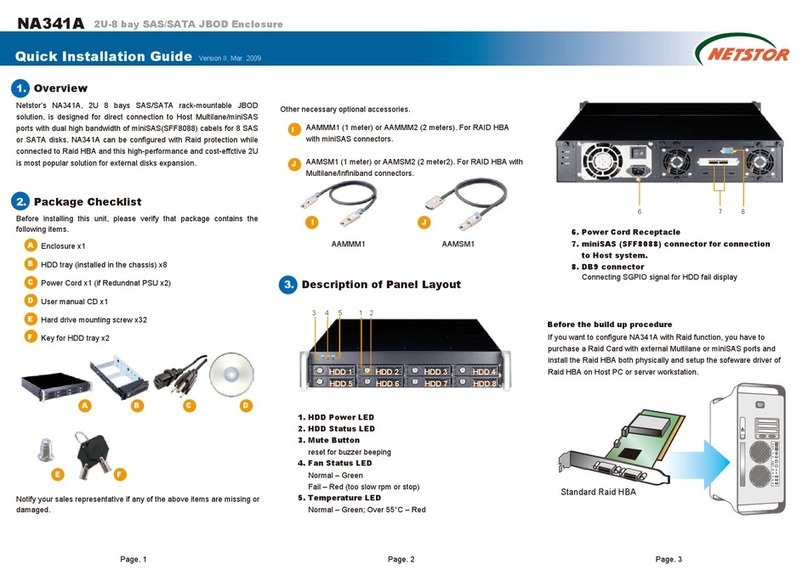

Figure 1 — Alpha SE41 Interior View ............................................................................................... 6

Figure 2 — Plinth Template for Mounting Bolts............................................................................... 10

Figure 3 — Preparing Enclosure for Wall Mounting........................................................................ 12

Figure 4 — Bolting the Pole Mount Rail to the Cabinet Brackets ................................................... 13

Figure 5 — Mounting the Bracket/Rail to the Pole.......................................................................... 13

Figure 6 — Enclosure MGB and Chassis Ground.......................................................................... 14

Figure 7 — Main Breaker Load Center Wiring................................................................................ 15

Figure 8 — Main Lug Load Center Wiring ...................................................................................... 15

Figure 9 — Enclosure Alarm Block Wiring...................................................................................... 16

0290002-J0 Rev G

4

1. Safety

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions that must

be followed during the installation, servicing, and maintenance of the product. Keep it in a safe place. Review the

drawings and illustrations contained in this manual before proceeding. If there are any questions regarding the safe

installation or operation of this product, contact Alpha Technologies or the nearest Alpha representative.

1.1 Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following sym-

bols have been placed throughout this manual. Where these symbols appear, use extra care and attention.

The use of ATTENTION indicates specic regulatory/code requirements that may aect the

placement of equipment and /or installation procedures.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to personnel.

Warnings are indicated by a shock hazard icon, the word WARNING, and a rule beneath

which the information appears.

WARNING!

You must read and understand the following warnings before installing the enclosure

and its component. Failure to do so could result in personal injury or death.

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or equipment.

Cautions are designated with a yellow warning triangle, the word CAUTION, and a rule beneath

which the information appears.

NOTE:

A NOTE provides additional information to help complete a specific task or procedure. Notes

are designated with a checkmark, the word NOTE, and a rule beneath which the information ap-

pears

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician or

user.

1.2 General Warning and Cautions

• Read and follow all instructions included in this manual.

• Only trained personnel are qualified to install or replace this equipment and its components.

• Use proper lifting techniques whenever handling equipment, parts, or batteries.

5

0290002-J0 Rev G

1.3 Electrical Safety

Before working with any live battery or power system, follow these precautions:

a. Remove all metallic jewelry, such as watches, rings, metal rimmed glasses, or necklaces.

b. Wear safety glasses with side shields at all times during the installation.

c. Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

WARNING!

Lethal voltages are present within the power system. Always assume that an electrical

connection or conductor is energized. Check the circuit with a voltmeter with respect to the

grounded portion of the enclosure (both AC and DC) before performing any installation or

removal procedure.

WARNING!

Follow battery manufacturer’s safety recommendations when working around battery systems.

Do not smoke or introduce an open flame when batteries (especially vented batteries) are

charging. When charging, batteries vent hydrogen gas, which can explode.

WARNING!

Hazardous voltages and/or energy levels can be present at the input of power systems. The DC

output from rectifiers and batteries, though not dangerous in voltage, has a high short-circuit

current capacity that may cause severe burns and electrical arcing.

• Do not work alone under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment. Input voltages can range up to

240 Vac. Ensure that the utility power is disconnected and locked out before performing any installation or

removal procedure.

• Ensure that no liquids or wet clothes come into contact with internal components.

• Hazardous electrically live parts inside this unit are energized from the batteries even when the AC input

power is disconnected.

• The enclosure which contains the DC or AC power system along with customer installed radios must remain

locked at all times, except when authorized service personnel are present.

• Always assume electrical connections or conductors are live. Turn off all circuit breakers and double-check

with a voltmeter before performing installation or maintenance.

• Place a warning label on the utility panel to warn emergency personnel that a reserve battery source is pres-

ent which will power the loads in a power outage condition or if the AC disconnect breaker is turned off.

• At high ambient temperature conditions, the internal temperature can be hot so use caution when touching

the equipment.

1.4 Battery Safety

• Never transport an enclosure with batteries installed. Batteries must ONLY be installed after the enclosure

has been securely set in place at its permanent installation location. Transporting the unit with batteries in-

stalled may cause a short circuit, fire, explosion, and/or damage to the battery pack, enclosure and installed

equipment.

• Servicing and connection of batteries must be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

• Batteries contain or emit chemicals known to cause cancer and birth defects or other reproductive harm.

Battery post terminals and related accessories contain lead and lead compounds. Wash your hands after

handling batteries.

• Batteries are hazardous to the environment and should be disposed at a recycling facility. Consult the battery

manufacturer for recommended local authorized recyclers.

0290002-J0 Rev G

6

Door mounted fan

Convenience

receptacle

Adjustable 19/23"

equipment rails

(front-to-back)

Insulation

Master Ground

Bar (MGB)

1.2kW rectier shelf

2. Introduction

2.1 Product Overview

The Alpha SE41 is a NEMA 3R multipurpose outdoor enclosure. The SE41 is available with the following options:

• AC, DC, or line power system

• 22" or 30" depth

• Expansion battery enclosure

• Generator inlet and manual transfer switch

• TVSS

• One or two battery trays

• Battery heater mats

• Thermal management options: fan, heat exchanger or air conditioner

• Enclosure heater

Figure 1 — Alpha SE41 Interior View

Battery tray

7

0290002-J0 Rev G

3. Specifications

Table A — Specications

Electrical

AC Input AC load center option: 120/240V, 100A maximum, 60Hz, 1PH, 3W+PE

Generator supply option: 120/240V, 30A maximum, 60Hz, 1PH, 3W+PE

Internal power options: CXRF 48-1.2kW rectier shelf:

CXPS-E3 system:

FXM 650-24:

FXM 650-48:

FXM 1100:

FXM 2000:

120/240V, 57A maximum, 60Hz, 1PH

120/240V, 75A maximum, 60Hz, 1PH

8.7/4.5 @120/230 Vac

10.5 @120 Vac

15.5/8 @120/230 Vac

20/12 @120/230 Vac

Internal cooling options: 2000 BTU air conditioner: 120V, 7A maximum, 60Hz, 1PH

4000 BTU air conditioner: 120V, 13.8A maximum, 60Hz, 1PH

Internal heating options: Enclosure fan heater: 120V, 3.5A maximum, 60Hz, 1PH

Enclosure heater mat: 120V, 1.5A maximum, 60Hz, 1PH

Output DC options: CXRF 48-1.2kW rectier shelf:

CXPS-E3 system:

LPS36 converter shelf:

42-58V (48V nominal), 4.8kW maximum

42-58V, (48V nominal), 14.4kW maximum

±190V, 3.6kW maximum (per shelf)

Convenience receptacle: 120V, 15A, 60Hz, 1PH

UPS: FXM650, FXM1100, FXM2000: 120V, 60Hz, 1PH

Mechanical

Dimensions (H x W x D): SE41-2722 (footprint) 1041mm x 686mm x 559mm (41in x 27in x 22in)

SE41-2730 (footprint) 1041mm x 686mm x 762mm (41in x 27in x 30in)

Weight: Fan Heat

Exchanger 2000BTU Air

Conditioner 4000BTU Air

Conditioner

63.5kg (140lbs) 78kg (172lbs) 87kg (192lbs) 110kg (243lbs)

SE41-2722

SE41-2730 71kg (155lbs) 85kg (187lbs) 94kg (207lbs) 117kg (258lbs)

Mounting: Plinth/Pad/Wall/Pole

Construction / Finish: 5052-H32 aluminum / Powder coat

Insulation: Standard

Equipment rails: 23" adjustable front to back (23" to 19" adapter plates available as option)

Equipment space: 20RU

Cable entrance: Knockouts located on sides, bottom and rear of enclosure

Hinge type: 3-position lift-o hinge

Door prop: Wind-stop with automatic lock

Door latch: 3-point latch with L-handle for padlocking

Installation access: Full front access as well as rear access with a removable gland plate

HVAC

Cooling options: •Thermostat-controlled ltered fan cooling

• 2000 BTU air conditioner

• 4000 BTU air conditioner

• 50W/°C heat exchanger

Heating options: 500W heater integrated with air conditioner

External 400W fan heater

Environmental

Operating temperature: -40 to 46°C (-40 to 115°F)

Storage temperature: -40 to 85°C (-40 to 185°F)

Compliance

NEMA rating: 3R

UPS Products: UL 1778 and CSAC22.2 107.3

DC Products: UL 60950-1 & CSA C22.2 No. 60950-1

Remote Power Feeding: UL 60950-21 & CSA C22.2 No. 60950-21

0290002-J0 Rev G

8

4. Features

4.1 AC and DC Power Options

The following options are available for the SE41-2722 and SE41-2730 enclosure. Contact your representative for

system configuration or part numbers.

Basic Enclosure Options

• SE41-2722; Dimensions: H41" x W27" x D22"

• SE41-2730 Dimensions: H41" x W27" x D30"

Power System Options

• Cordex®HP 48-1.2kW Front Access Rectifier Shelf

• Line Power System; LPS 36

• AC UPS; FXM 650

• AC UPS; FXM 1100

• AC UPS; FXM 2000

Cooling and Heating Options

• Heat Exchanger, 50w / deg C, Thermostat Controlled

• 2000 BTU Air Conditioner

• 4000 BTU Air Conditioner

• Fan Cooled, Thermostat Controlled, MERV 6 Filter

• Heater; 400 Watt AC Powered Heater

AC Input Options

• AC Load Center, 100A 120/240Vac (L-N-L +G) with Main Lug

• AC Load Center, 100A 120/240Vac (L-N-L +G) with 100A 2P Main Circuit Breaker

• Transient Voltage Surge Suppressor: 120/240VAC Split Phase, 40k AIC

• Generator Receptacle: 30A AC Twist Lock, NEMA L14-30, Hubbel HBL2715SW

Battery Trays / Enclosure Options

• One Battery Tray

• Two Battery Tray

• Battery Base with One Battery Tray

Accessories

• Pole Mount Kit

• Wall Mount Kit

• Plinth, 4"

• Concrete Barrier

• Battery Heater Mat

9

0290002-J0 Rev G

5. Site Evaluation and Pre-Installation

5.1 Site Selection

Consider the following before selecting a mounting site:

• The Alpha SE41 enclosure is designed for front and rear access. Only front access is required for maintenance.

• Avoid areas that may be subjected to hot air exhaust from nearby equipment or buildings.

• Find out if your intended area is subjected to architectural controls or environmental restrictions.

• Avoid areas that are prone to flooding

The SE41 outdoor power enclosure has the following mounting options:

• Plinth, mounted on an at-grade concrete slab

• Pole mount

• Wall mount

• Pad mount spacer

• Refer to ordering guide for a list of mounting options and accessories.

5.2 Tools Required

Various insulated tools are essential for the installation. Use this list as a guide:

• Battery lifting apparatus if required

• Electric drill with hammer action, 1/2" capacity

• Various crimping tools and dies to match lugs used in installation

• Load bank of sufficient capacity to load largest rectifier to its current limit

• Digital voltmeter equipped with test leads

• Cable cutters

• Torque wrench: 1/4" drive, 0 - 150 in-lb.

• Torque wrench: 3/8" drive, 0 - 100 ft-lb.

• Insulating canvases as required (2' x 2', 1' x 1', 3' x 3', etc.)

• Various insulated hand tools including:

- Combination wrenches - Ratchet and socket set

- Various screwdrivers - Electricians knife

• Battery safety spill kit required for wet cells:

- Protective clothing - Face shields

- Gloves - Baking soda

- Eye wash equipment

• Cutters and wire strippers (#14 to #22 AWG) [2.5 to 0.34 mm²].

0290002-J0 Rev G

10

6. Installation

Only qualified personnel should install and connect the power components within the Alpha power system. For the

battery installation, refer primarily to the manufacturer’s manual.

6.1 Safety Precautions

Refer to the Safety section near the front of this manual.

6.2 Plinth Mount Kit for Concrete Pad

6.2 .1 Mounting the Plinth to the Concrete Floor

The mounting site must be built in accordance with local building practices and codes to handle the maximum

weight of the enclosure, equipment, and batteries.

Concrete pad installation requiring seismic compliance requires approval by the appropriate engineering discipline,

e.g., civil or structural. Cast-in-place or pre-cast concrete slabs can be used.

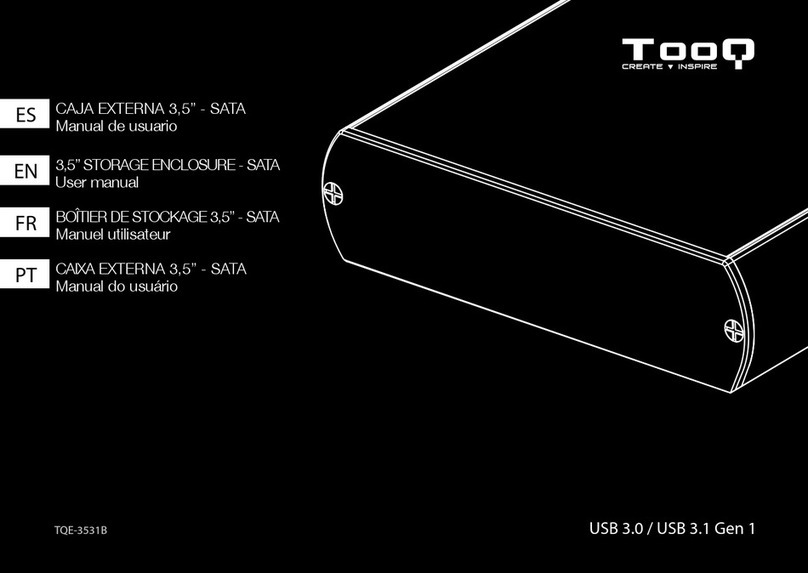

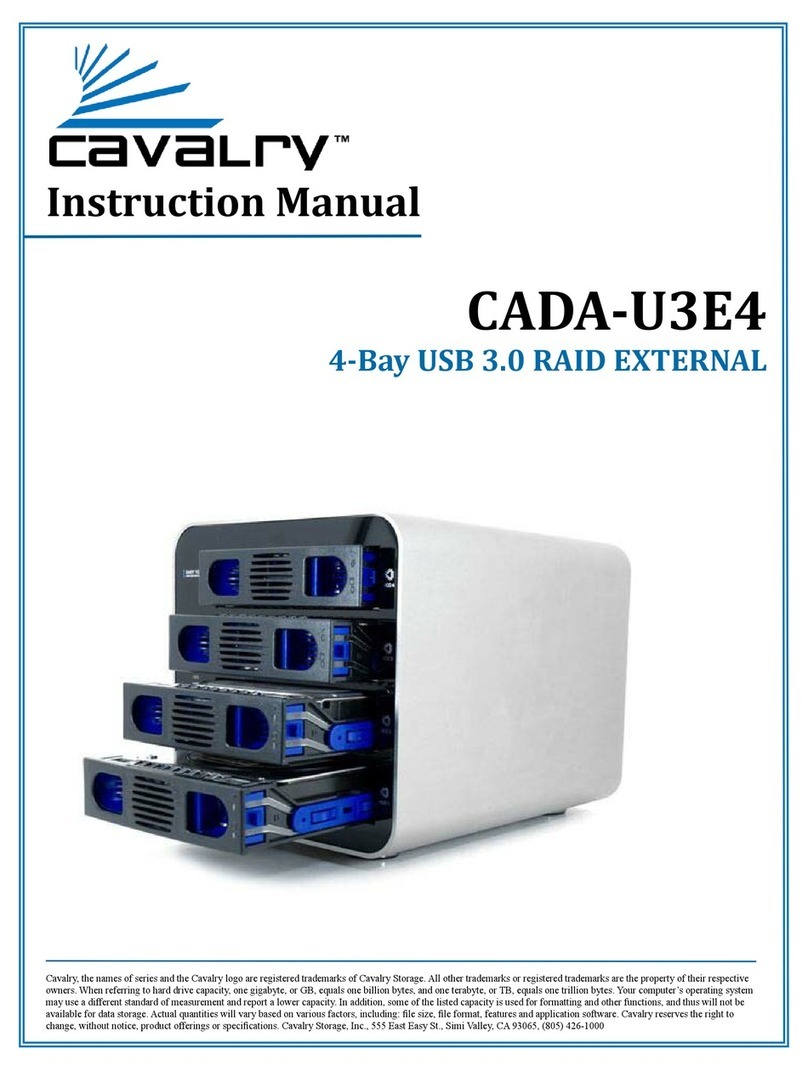

Use the template in Figure 2 to place the anchor bolts. Follow the specific recommendations from the fastener

manufacturer to ensure that the securing device achieves its full structural capacity.

2

18

2 23

22

27

4.5 18

3

16

4X 2"

TRADE SIZE

KNOCKOUT

4X

0.625

MOUNTING HOLES

6X 2"

TRADE SIZE

KNOCKOUT

23

27

2

2

2630

3

24

14.5

4.5 18

5.5 16

4X

0.625

MOUNTING HOLES

Figure 2 — Plinth Template for Mounting Bolts

22" Template 30" Template

NOTE:

If using a rubber isolation mat, place the mat onto the pad and orient the mat so the mounting

holes line up. If the rubber mat is ribbed the ribs should sit against the concrete.

1. Place the plinth in position over the anchor holes.

1. Install the anchoring hardware for each anchor FINGER TIGHT.

2. Check that the plinth is level front-to-back and side-to-side.

3. Add shims as needed under one or two of the corners of the plinth, placing the shims as close as possible to the bolts.

4. Once the plinth is level, tighten all bolts to the appropriate torque.

Recommended torque values

1/4" 8.8 ft-lbs

3/8" 32.5 ft-lbs

1/2" 73 ft-lbs

11

0290002-J0 Rev G

6.2.2 Unpacking the Enclosure

CAUTION!

Do not hoist/lift the enclosure with batteries installed.

1. Remove the protective covering from the system. The doors are designed to be locked with a padlock and are

secured with tie-wraps for shipping. Cut the tie-wraps and open the doors.

1. Inspect the packing slip to verify that you have received all the equipment that you ordered.

• All documentation is packed inside the equipment compartment.

• Inspect all moving parts, hardware, connectors, and other equipment.

2. Report any damage to the shipper and Alpha Technologies.

6.2.3 Mounting the Enclosure to the Plinth

1. Unbolt the enclosure from the shipping pallet.

2. Lift the enclosure onto the plinth.

3. Secure the enclosure to the plinth with the four 1/2" x 1-1/4" bolts included with the plinth.

6.2.4 Replacing the Lift Eyebolts

NOTE:

Depending on the internal system configuration, you may need to remove the rear panel to gain

access to the enclosure base rear mounting holes.

Remove the ten security screws and sealing washers of rear panel using a driver and the sup-

plied T-25 security bit.

When reinstalling the rear panel, ensure the panel edge with the gasket that runs the full width

of the panel is located at the top of the rear enclosure opening.

NOTE:

Theft of the eyebolts and solar shield is a common occurrence in some areas. It is recommend-

ed to replace them with stainless steel hex bolts.

1. Remove all four lift eyebolts.

2. Replace with the four 3/8-16 x 1" flange bolts provided with the enclosure.

3. Torque the bolts to a maximum of 32.5 ft-lbs.

Edge with gasket spanning full

width of rear panel

0290002-J0 Rev G

12

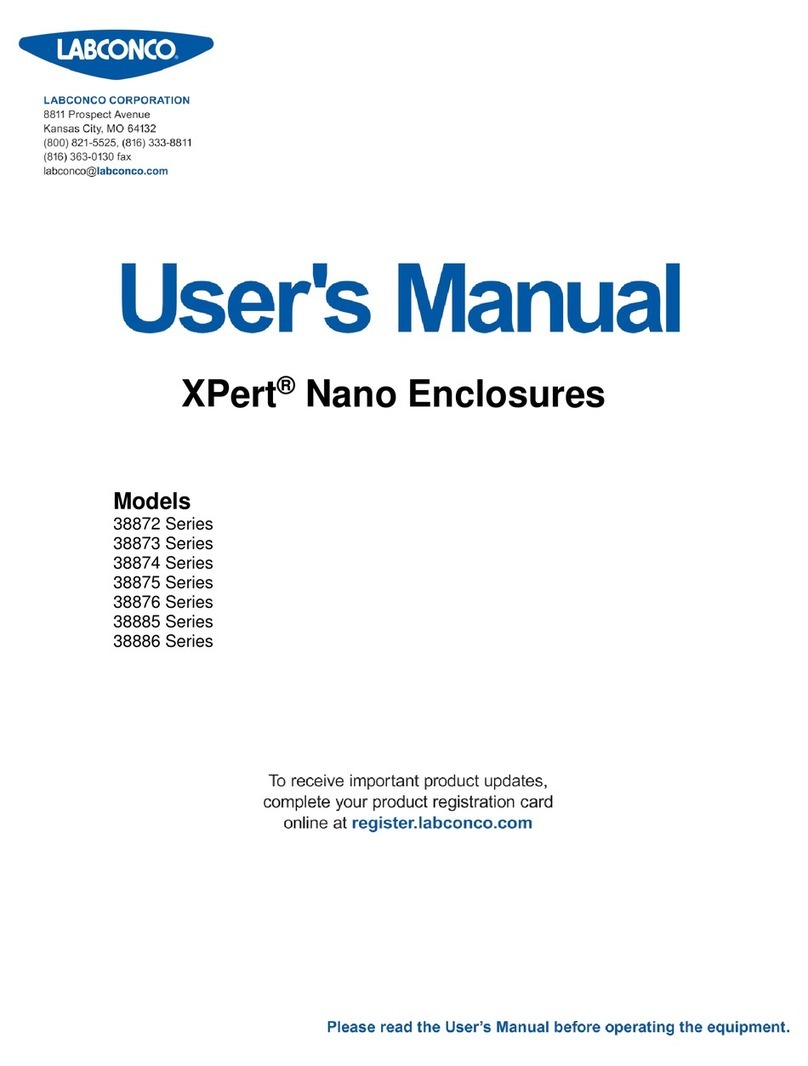

6.3 Wall Mounting the Enclosure

The wall mounting brackets facilitate easy mounting to walls. The SE41 enclosure can be mounted to metal or

concrete surfaces. The maximum total weight of the enclosure and equipment must be less than 833lbs.

1. Align the bottom holes in each bracket to the thread holes in the back of the enclosure (Figure 3).

2. Attach the brackets to the enclosure using the hardware in the mounting kit.

NOTE:

Ensure the wall construction can support the bracket and the weight.

Figure 3 — Preparing Enclosure for Wall Mounting

3. Mount horizontally on a vertical surface using fastening hardware that is appropriate for the chosen surface: four

3/8" screws in each bracket.

Recommended torque values

1/4" 8.8 ft-lbs

3/8" 32.5 ft-lbs

1/2" 73 ft-lbs

Use the bottom

pair of holes in

each bracket.

13

0290002-J0 Rev G

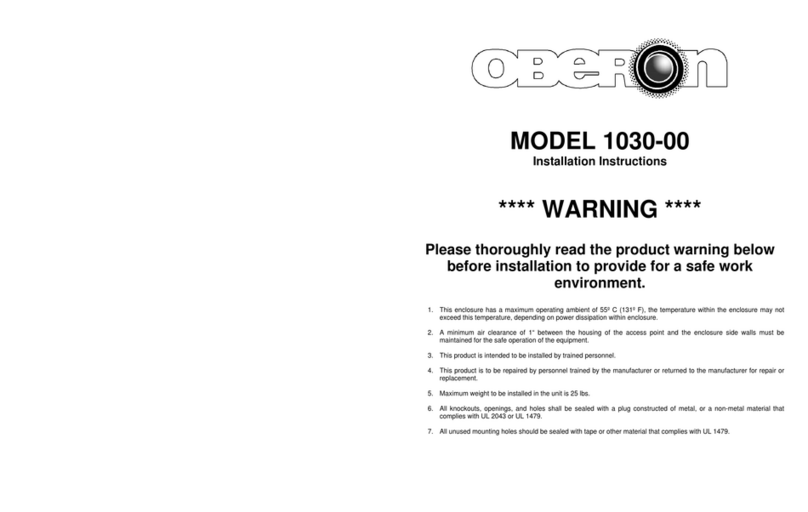

6.4 Pole Mounting the Enclosure

Pole mount kits are available in bolt or strap versions. Refer to the order-

ing guide for more information.

6.4.1 Attaching the Brackets to the Rail

1. Bolt the pole mount rail to the cabinet brackets as follows:

a. Orient the top cabinet bracket as shown in Figure 4.

b. Align the holes in the top bracket with the holes in the pole mount rail.

c. Bolt the bracket to the rail with the mounting hardware included with

the bracket. Torque to 32.5 ft-lbs.

2. Repeat for the bottom bracket reversing the orientation of the bracket.

6.4.2 Mounting the SE41 to the Pole - Strapping Method

Note: the bracket can support up to 1500lbs when strapped to the pole.

1. Mount the bracket/rail combination to the pole.

2. Use a total of six bands, two bands at each of the three slot locations on the bracket.

Straps must be stainless or galvanized – see below for specifications.

6.4.4 Mounting the SE41 to the Pole -

Bolt Through Method

Note: the bracket can support up to 1000lbs when

bolted to the pole.

1. Mark drilling locations of the upper and lower

mounting rail bolt-through holes on the utility pole.

2. Drill two 1" holes completely through the pole at

the marked locations.

3. Secure the bracket/rail combination to the pole

with 3/4" threaded rod, washers, and nuts (not

supplied). All hardware must be stainless.

Recommended strapping for

the SE41 pole mount:

• Maximum of two bands at

each of the three slots

• Strap size 3/4" x 0.023",

1,500lbs rating each Strapping location

Bolt-through location

Bolt-through location

Figure 4 — Bolting the Pole Mount Rail to

the Cabinet Brackets

Figure 5 — Mounting the Bracket/Rail to the Pole

6.4.3 Mounting the Cabinet to the Pole

1. Use the lift eyes to raise the cabinet to the pole.

2. Attach the upper and lower bracket to the cabinet with the mounting hardware. Torque to 32.5 ft-lbs.

0290002-J0 Rev G

14

7. Wiring

Only qualified personnel should install and connect the power components. For the battery installation, refer primar-

ily to the manufacturer’s manual.

7.1 Grounding the Enclosure

WARNING!

An enclosure that is not properly grounded presents an electrical hazard.

A proper grounding system that meets or exceeds the specifications of the equipment must be designed and in-

stalled prior to or in conjunction with the construction of the mounting method. The ground system must be bonded

to the enclosure to ensure a “common” or “single-point” ground. Refer to local building codes.

1. Locate the enclosure master ground bar at the front of the enclosure.

NOTE: Chassis ground is connected to the enclosure frame and is terminated at the master ground bar within the

enclosure.

1. Remove a suitable knockout for the external site ground wire connection. The knockouts are located on the

sides, bottom and rear of the enclosure.

2. Route the wire into the enclosure using the appropriate conduit and fittings.

3. Connect the site ground wire to an open position of the enclosure MGB. The master ground bar accepts lugs

with either 1/4" holes on 5/8" centers or 3/8" holes on 1" centers.

Figure 6 — Enclosure MGB and Chassis Ground

15

0290002-J0 Rev G

Figure 7 — Main Breaker Load Center Wiring

Figure 8 — Main Lug Load Center Wiring

7.2 AC Input Wiring to the Load Center

The enclosure AC load center is available with either a main circuit breaker or main lugs. The recommended wire

size is #2 AWG TYP.

Wire Color Connection Terminal

BLACK - Line 1 L1

RED - Line 2 L2

WHITE - Neutral N

GREEN - Ground Protective Earth

L2 L1

N

Protective

Earth

N

Protective

Earth

L1 L2

NOTE:

Service Rating Main Breaker: The main breaker is not provided as a service rated disconnect.

Please check with local codes to see if the unit may be used if a service rating is required.

0290002-J0 Rev G

16

7. 2 .1 Generator Connection (Option)

If equipped, the generator inlet receptacle is located below the AC load center and is wired to the generator circuit

breaker at the factory.

To connect a generator:

1. Connect the generator cable harness to the generator inlet receptacle.

2. Start the generator and allow to stabilize. Refer to the generator manufacturer's instructions.

3. Turn the main breaker on the AC load center to the OFF position.

4. Slide the interlock bracket to release the generator circuit breaker.

5. Turn the generator AC circuit breaker to the ON position.

CAUTION!

When using the generator inlet receptacle, the system loading must be limited to not exceed the

generator supply 30A rated circuit breaker.

Figure 9 — Enclosure Alarm Block Wiring

7.2.2 Power Enclosure Alarm Wiring Block

The alarm wiring block, located on the left side wall in the enclosure, uses Phoenix style blocks. Connect to the local

alarm-sending unit using wire gauges from #28 to #16 AWG (0.08 to 1.31 mm2). Wires do not need to be stripped

when the connections are made.

Refer to drawing 0290002-000-05 at the rear of this manual for the alarm schedule that corresponds to the enclo-

sure HVAC and power systems installed.

17

0290002-J0 Rev G

8. Maintenance

Routine checks and adjustments are recommended to ensure optimum system performance. Qualified service per-

sonnel should conduct.

The following table lists a few maintenance procedures for this system. These procedures should be performed at

least once a year.

Use extreme care when working inside the unit while the system is energized. Do not

make contact with live components or parts.

Circuit cards, including RAM chips, can be damaged by static electricity. Always wear a

grounded wrist strap when handling or installing circuit cards.

Ensure redundant modules or batteries are used to eliminate the threat of service inter-

ruptions while performing maintenance on the system’s alarms and control settings.

WARNING!

Table B — Sample maintenance log

Procedure Date Completed

Clean ventilation openings and rinse out the enclosure lters.

Inspect all system connections. Re-torque if necessary.

Verify alarm/control settings.

Verify alarm relay operation.

Verify HVAC operation

Check for rmware/software updates for the controller and power modules

Table C — Replacement Parts

Parts Part Number Description

Cooling system fan 7400144-001 Fan Assembly, w/Tach & Conn, Te45v2

Cooling system fan thermostat 171-002-10 Thermostat, Small, Bi-Metal, 0 to 60.C, NO

Cooling system GMT fuse

(1.2kW system option) 460-084-10 Fu, Alm Ind (Sprng),5A 125Vac 60VDC

Cooling fan door lter 6480111-001 Filter, Door, Fan Cooled, SE41-2722/2730

AC surge protection device 162-023-10 Surge Suppressor,120/240VAC, 3W, Spt Ph, 50/60Hz

AC surge protection device

circuit breaker 470-294-10 Circuit Breaker, 2 Pole, 15A 120Vac, Plug-on

Battery temperature

compensation probe 747-028-20-071 Temperature Sensor, 1/4" Lug, 6ft Cable Assembly

SE41-2722 battery heater mat 189-304-10 Battery Heater Mat,120Vac 160W,Te25/xh

SE41-2730 battery heater mat 1890056-001 Battery Heater Mat, Silicone, 120Vac, 180W, 20.5x21

Field replacement door 0380588-xxx

(refer to ordering

guide for

options) Assembly, Door, SE41-2722/2730

Air conditioner 171-020-19 2000BTU Air conditioner

Air conditioner 171-024-19 4000BTU Air conditioner

0290002-J0 Rev G

18

8.1 Heat Exchanger Fan Test Procedure

There are six heat exchanger fans. Three inner loop fans are located on the inside of the door and three outer loop

fans on the outside of the door. Perform the following procedure to test the fans.

1. Pull out the plunger of the heat exchanger power door switch.

2. If the fans do not turn on, carefully apply heat to the heat exchanger thermostat using a heat gun. The fans

should turn on above 30°C (86°F). If the fans still do not turn on, check the status of the cooling system breaker

or fuse.

3. Operation of the inner loop fans can be verified through visual inspection.

4. Unplug one of the outer loop fan connectors and listen for a noticeable drop in the sound level of the outside

fans. Plug the fan connector back in.

5. Repeat Step 4 for the two other outer loop fans.

Heat exchanger door switch

Heat exchanger thermostat

Outer loop fan

connectors

This manual suits for next models

1

Table of contents

Other EnerSys Enclosure manuals