EnerSys alpha Matrix C16 User manual

Matrix C16™

High Density Connectorized DC Distribution Breaker Panel

Technical Manual

Effective: January 2020

2C048-725-30 Rev. B (01/2020)

The following sections contain important safety information that must be followed during the installation and maintenance

of the equipment and batteries. Read all of the instructions before installing or operating the equipment, and save this

manual for future reference.

There may be multiple warnings associated with the call out. Example:

ATTENTION provides specic regulatory/code requirements that may aect the placement of equipment and /or

installation procedures.

ATTENTION:

NOTICE provides additional information to help complete a specic task or procedure.

NOTICE:

ELECTRICAL HAZARD WARNING provides electrical safety information to PREVENT INJURY OR DEATH

to the technician or user.

WARNING! ELECTRICAL HAZARD

FUMES HAZARD WARNING provides fumes safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FUMES HAZARD

FIRE HAZARD WARNING provides ammability safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! FIRE HAZARD

This WARNING provides safety information for both Electrical AND Fire Hazards

WARNING! ELECTRICAL & FIRE HAZARD

CAUTION provides safety information intended to PREVENT DAMAGE to material or equipment.

CAUTION!

GENERAL HAZARD WARNING provides safety information to PREVENT INJURY OR DEATH to the

technician or user.

WARNING! GENERAL HAZARD

Safety Notes

Alpha Technologies Services, Inc. considers customer safety and satisfaction its most important priority. To reduce the

risk of injury or death and to ensure continual safe operation of this product, certain information is presented dierently in

this manual. Alpha®tries to adhere to ANSI Z535 and encourages special attention and care to information presented in

the following manner:

3C048-725-30 Rev. B (01/2020)

Matrix C16™

High Density Connectorized DC Distribution Breaker Panel

Technical Manual

C048-725-30 Rev. B

Eective: January 2020

©2020 by Alpha Technologies Services, Inc.

Disclaimer

Images contained in this manual are for illustrative purposes only. These images may not match your installation.

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If there are

questions regarding the safe operation of this powering system, please contact Alpha Technologies Services, Inc. or your

nearest Alpha representative.

Alpha®shall not be held liable for any damage or injury involving its enclosures, power supplies, generators, batteries or

other hardware if used or operated in any manner or subject to any condition not consistent with its intended purpose or is

installed or operated in an unapproved manner or improperly maintained.

Contact Information

Sales information and customer service in USA

(7AM to 5PM, Pacic Time): 1 800 322 5742

Complete Technical Support in USA

(7AM to 5PM, Pacic Time or 24/7 emergency support): 1 800 863 3364

Sales information and Technical Support in Canada: 1 888 462 7487

Website: www.alpha.com

4C048-725-30 Rev. B (01/2020)

Contents

1.0 Purpose and Applicability � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

1�1 Product Model � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

2.0 Theory of Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

2�1 Introduction� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

2�2 Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3.0 Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Package Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4.0 Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1 Installation Preparation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�1 Elevated Operating Ambient Temperature � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�2 Reduced Air Flow� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�3 Mechanical Loading � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�4 Circuit Overloading � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�5 Reliable Earthing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1�6 Disconnect Device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�2 Mechanical Mounting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�1 Rack Mount Ears � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�2 Cable Lacing Bar � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�3 Optional Rear Rack Support Kit (C750-284-10) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

4�3 Ground Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�4 Input Connections� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

4.4.1 Straight Lug Input Conguration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

4.4.2 Optional 90 Degree Lug Input Conguration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

4�5 Rear Plastic Safety Shields � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�5�1 Straight Isolators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�5�2 Optional 90 Degree Isolators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�6 Output Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

4�7 Alarm Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

4�8 Breaker Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

4�9 Installing the Network Cable� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5.0 Operation (Models with SmartSwitch) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �15

5�1 User Interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�2 Home Screen Information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�3 Initial Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�3�1 Breaker Inventory Process� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�3�2 Setting Breaker Ampacity � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�4 “VIEW BKR LOAD HOLD 3 S” � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5 “SETUP HOLD 3 S” – Setup Menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5�1 “SETUP BKR INV HOLD 3 S” – Breaker Inventory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5�2 “SETUP BUS ALMS” – Bus Alarm Menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5�3 “SETUP BKR ALMS HOLD 3 S” – Breaker Alarm Menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5�4 “SETUP VOLT CAL HOLD 3 S” – Voltage Calibration Menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�5�5 “SETUP ADVANCED HOLD 3 S” – Advanced Settings Menu� � � � � � � � � � � � � � � � � � � � � � � � � � � 18

5�6 Review System Status via the Embedded Web Server � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

5�6�1 Default Static Network Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

5�6�2 Navigating the Web Server � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

5�6�3 Administration Settings � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

5�7 SmartSwitch User Interface Map � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

5C048-725-30 Rev. B (01/2020)

6.0 Operation (Models with LED Display) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �21

6�1 Layout and Function of Logic PCB Interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

6�2 To Inventory the Circuit Breakers � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

6�3 To Temporarily Silence Breaker Trip Alarm Beeper � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

6�4 To Disable/Re-Enable the Breaker Trip Alarm Beeper � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

6�5 To Perform a Factory Reset � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

7.0 Maintenance Operations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �23

7�1 Breaker Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

7�2 Output Connector Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

8.0 Product Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �24

9.0 Models and Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �25

Appendix A: Mechanical Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

A�1 Single-Input Matrix C16 (C016-1621-10)

w/o Safety Shields � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

A�2 Single-Input Matrix C16 (C016-1621-10)

w/ Straight and 90 Degree Safety Shields� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

A�3 Dual-Input Matrix C16 (C016-1622-10)

w/o Safety Shields � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

A�4 Dual-Input Matrix C16 (C016-1622-10)

w/Straight and 90 Degree Safety Shields � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

6C048-725-30 Rev. B (01/2020)

1.01.0 Purpose and ApplicabilityPurpose and Applicability

The purpose of this document is to detail the installation and

operation instructions for the Matrix C16™breaker panel�

1.11.1 Product ModelProduct Model

This document applies to the following congurations of the

Matrix C16 breaker panel:

Table 1. Matrix C16 Model Congurations

PART NUMBER DESCRIPTION

C016-1621-10 Matrix C16; Single Input; SmartSwitch

C016-1622-10 Matrix C16; Dual Input; SmartSwitch

C016-1623-10 Matrix C16; Single Input; LED Display, w/o Ethernet

C016-1624-10 Matrix C16; Dual Input; LED Display; w/o Ethernet

2.02.0 Theory of OperationTheory of Operation

2.12.1 IntroductionIntroduction

The Matrix C16 1RU High Power Density DC Distribution Center

provides high reliability, high power, DC distribution in a compact

1RU space to maximize rack space for signal equipment�

2.22.2 FeaturesFeatures

yCompact 1RU form factor

y400A total rating

y8A and 8B output circuits (dual input), 16 output circuits

(single Input)

yEnclosed breaker compartment to prevent nuisance trips

yRemote monitoring via Form-C dry alarm contacts

ySmartSwitch with per circuit current monitoring

yAvailable embedded web server for real time network

monitoring

3.03.0 Unpacking and InspectionUnpacking and Inspection

The Matrix C16 was carefully packaged at the factory to

withstand the normal rigors of shipping� However, you should

carefully inspect the box and contents to conrm that no damage

has occurred in transit. Most shipping carriers require notication

of shipping damage within twenty-four hours of delivery, and

it is the responsibility of the recipient to inspect the shipment

immediately upon receipt�

3.13.1 Package ContentsPackage Contents

yMatrix C16 1RU High Power Density DC Distribution Center

yInstallation kit

yRear plastic safety shields

7C048-725-30 Rev. B (01/2020)

4.04.0 InstallationInstallation

4.14.1 Installation PreparationInstallation Preparation

When selecting an installation location, ensure that all of the

following conditions are met before proceeding�

4.1.14.1.1 Elevated Operating Ambient TemperatureElevated Operating Ambient Temperature

If you install the panel in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be

greater than room ambient� Therefore, take care to install the

equipment in an environment compatible with the maximum ambient

temperature (TMA)�

4.1.24.1.2 Reduced Air FlowReduced Air Flow

Installation of the equipment in a rack should be such that the

amount of air ow required for safe operation of the equipment is not

compromised�

4.1.34.1.3 Mechanical LoadingMechanical Loading

Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical

loading�

4.1.44.1.4 Circuit OverloadingCircuit Overloading

Give consideration to the connection of the equipment to the

supply circuit and the eect that overloading of the circuits might

have on overcurrent protection and supply wiring� Use appropriate

consideration for equipment nameplate ratings when addressing this

concern�

4.1.54.1.5 Reliable EarthingReliable Earthing

Maintain reliable earthing of rack-mounted equipment� Pay particular

attention to supply connections other than direct connections to the

branch circuit (e�g�, use of power strips)�

4.1.64.1.6 Disconnect DeviceDisconnect Device

A readily accessible disconnect device must be incorporated in the

building installation wiring�

8C048-725-30 Rev. B (01/2020)

4.24.2 Mechanical MountingMechanical Mounting

THIS PRODUCT MUST BE INSTALLED WITHIN A

RESTRICTED ACCESS LOCATION WHERE ACCESS IS

THROUGH THE USE OF A TOOL, LOCK AND KEY, OR

OTHER MEANS OF SECURITY, AND IS CONTROLLED

BY THE AUTHORITY RESPONSIBLE FOR THE

LOCATION� THIS PRODUCT MUST BE INSTALLED AND

MAINTAINED ONLY BY QUALIFIED TECHNICIANS�

NOTICE:

4.2.14.2.1 Rack Mount EarsRack Mount Ears

The Matrix C16 can be mounted in a 19in or 23in rack conguration,

in a front ush or oset mid-mount orientation.

Step 1. Depending on the size of the rack, select one of the following

sets of mounting ears:

yFor 19” racks, use (2) C590-1936-10

yFor 23” racks, use (2) C590-1937-10

Step 2. Attach the two (2) front mounting ears in the appropriate

conguration using the included #10-32 hardware as shown

in Figure 1�

4.2.24.2.2 Cable Lacing BarCable Lacing Bar

NOTE: Installation of the rear cable lacing bar is optional but highly

recommended to provide strain relief for connected cables�

NOTE: If using optional rear rack support kit (C750-284-10), skip to

Section 4�2�3

Step 1. Attach the lacing bar to the rear of the panel using the

included #10-32 hardware as shown in Figure 2.

Step 2. Insert the panel into the rack and secure the front mounting

ears to the rack using the included #12-24 hardware.

Figure 1. Mounting Ears

Figure 2. Cable Lacing Bar

9C048-725-30 Rev. B (01/2020)

4.2.34.2.3 Optional Rear Rack Support KitOptional Rear Rack Support Kit (C750-284-10)(C750-284-10)

The optional rear rack support kit provides additional support to the rear of the panel by

mounting to the rear rack posts� An adjustable cable lacing bar is included�

Step 1. Attach the rear rack support brackets to each side of the Matrix C16 using the

included #10-32 hardware as shown in Figure 3 and Figure 4.

Step 2. Align each rear support rail as shown in Figure 5� Select a hole position for the

lacing bar and secure to each rear support rail using the included #10-32

hardware, then insert the rear support rail assembly into the rear support brackets

as shown in Figure 6� Secure the ears of the rear rack support assembly to a rack

using the included 1/4”-20 hardware�

Figure 3. A-Side Rear Support Bracket Figure 4. B-Side Rear Support Bracket

Figure 5. Rear Support Rail & Lacing Bar Figure 6. Insert Rear Support Rail & Lacing

Bar

Figure 7. Rear Rack Support Kit - Fully

Extended

10 C048-725-30 Rev. B (01/2020)

4.34.3 Ground InstallationGround Installation

DO NOT ENERGIZE THE PANEL BEFORE CHASSIS

GROUND IS CONNECTED�

CAUTION!

The chassis ground is located on each side of the panel� A two

hole lug landing position is provided per side� See table below

for termination information. A minimum of #6 AWG chassis

ground cable is required�

IMPORTANT: Grounding hardware not included� A properly-

sized grounding conductor must be installed per NEC

(250�122)�

Table 2. Ground Termination Summary

TWO HOLE

LANDING

TYPE

HOLE/

STUD SIZE

CENTER

TO

CENTER

RECOMMENDED

TORQUE VALUE

Threaded Insert 1/4in-20 5/8in 90in-lbs

Step 1. Connect the lug to the chassis (see Figure 8) with the

included 1/4in-20 hardware� Make sure heat shrink and

no-oxide compound are applied appropriately prior to

attachment�

Step 2. Torque the fasteners to 90in-lbs�

Figure 8. Chassis Ground Connection

11 C048-725-30 Rev. B (01/2020)

4.44.4 Input ConnectionsInput Connections

WARNING! ELECTRICAL HAZARD

TO PROTECT PERSONNEL AND EQUIPMENT,

ENSURE ALL INPUT POWER FEEDS ARE NOT

ENERGIZED BEFORE INSTALLING THEM�

ELECTRICAL INSTALLATION SHOULD ONLY BE

PERFORMED BY QUALIFIED PERSONNEL WITH

PROPER TOOLS AND PROTECTIVE SAFETY

EQUIPMENT�

MAKE SURE THAT ALL FEEDER CABLES HAVE

HEAT SHRINK APPLIED PRIOR TO TERMINATION,

AND THAT NO-OXIDE COMPOUND IS APPLIED

TO ALL COPPER-TO-COPPER CONNECTIONS�

USE ONLY COMPONENTS AND CRIMPING TOOLS

APPROVED BY AGENCIES OR CERTIFYING

BODIES RECOGNIZED IN YOUR COUNTRY OR

REGION�

NOTICE:

Table 3. Electrical Termination Summary

TWO HOLE

LANDING

TYPE

HOLE/

STUD SIZE

CENTER

TO

CENTER

RECOMMENDED

TORQUE VALUE

Through Hole 3/8in 5/8in - 1in 145in-lbs

4.4.14.4.1 Straight Lug Input CongurationStraight Lug Input Conguration

(See Figure 9)

Step 1. Secure the HOT input cables lug(s) to the HOT input bus

bar(s) with the included 3/8”-16 x 1” hardware� Torque

the bolts to 145 in-lbs�

Step 2. Secure the RTN cable lug(s) to the RTN input bus bar(s)

with the included 3/8”-16 x 1” hardware� Torque the bolts

to 145 in-lbs�

4.4.24.4.2 Optional 90 Degree Lug Input CongurationOptional 90 Degree Lug Input Conguration

(See Figure 10)

Step 1. Secure the 90 degree HOT input bus bar adaptor(s) to

the HOT input bus bar(s) with the included 3/8”-16 x 1”

hardware� Torque the bolts to 145 in-lbs�

Step 2. Secure the 90 degree RTN input bus bar adaptor(s) to

the RTN input bus bar(s) with the included 3/8”-16 x 1”

hardware� Torque the bolts to 145 in-lbs�

Figure 9. Straight Input Lug Installation

Figure 10. 90 Degree Input Lug Installation

12 C048-725-30 Rev. B (01/2020)

4.54.5 Rear Plastic Safety ShieldsRear Plastic Safety Shields

WARNING! ELECTRICAL HAZARD

FAILURE TO INSTALL THE PLASTIC SAFETY SHIELDS

PROPERLY MAY CREATE AN ELECTRICAL HAZARD�

THE PANEL MAY BE ENERGIZED WHEN INSTALLING

THE REAR PLASTIC SAFETY COVERS� USE INSULATED

TOOLS AND APPROPRIATE PERSONAL PROTECTIVE

EQUIPMENT WHEN INSTALLING OR REMOVING THE

REAR PLASTIC SAFETY COVERS� WHEN ALL REAR

ELECTRICAL CONNECTIONS HAVE BEEN COMPLETED,

THE REAR PLASTIC SAFETY COVERS MUST BE

INSTALLED� THE COVERS CAN BE REMOVED LATER TO

SERVICE THE PANEL�

When all input cables have been installed, attach the rear plastic safety

covers that go over each input landing position�

4.5.14.5.1 Straight IsolatorsStraight Isolators

Step 1. Pry the isolator open and place it around the cable� Ensure that it

is in the correct orientation (see Figure 11)�

Step 2. Slide the isolator forward until it covers the bus bars and its

corresponding isolator, against the metal chassis� It is held in

place by friction� Repeat these steps for all of the straight-

mounted input bus bars on the panel�

4.5.24.5.2 Optional 90 Degree IsolatorsOptional 90 Degree Isolators

Step 1. Place the bottom portion of the isolator on the bottom of the input

bus assembly and align with the top portion of the isolator as

shown in Figure 12�

Step 2. Install the two plastic snap-in clips at the top of the isolator

assembly to secure it in place� Repeat these steps for all 90

degree-mounted input bus bars on the panel�

4.64.6 Output ConnectionsOutput Connections

WARNING! ELECTRICAL HAZARD

ENSURE CIRCUIT BREAKERS ARE IN THE OFF POSITION

BEFORE PLUGGING IN OUTPUT CONNECTIONS�

NOTE: When viewing the connectors from the rear of the panel, ensure

that each RTN cable is oriented on the left position of each connector�

Step 1. Locate the connectorized output cable whips that were shipped

with your C16 panel�

Step 2. Insert the connector into the desired output position until it clicks

(see Figure 13)� The connector is keyed to prevent reverse

polarity� Refer to the output circuit map label for output circuit

mapping information�

Step 3. Lace the output cable to the previously installed lacing bar�

Repeat these steps for all desired output circuits to be installed�

Figure 11. Straight Isolators

Figure 12. 90 Degree Isolators

Figure 13. Output Connections

13 C048-725-30 Rev. B (01/2020)

4.74.7 Alarm InstallationAlarm Installation

The Matrix C16 has Form-C dry alarm contacts for remote

alarm monitoring� An 8p8c- (RJ-45) modular jack can be

found in the center of the panel when viewed from the rear� It

is the lower of the two jacks as shown in Figure 14� Plug a Cat

5/5e/6 UTP cable with a TIA/EIA T568B termination into the

alarm jack� Refer to Table 4 below for termination pinout�

Table 4. Alarm Contact PinOut

PIN 1 PIN 2 PIN 3 PINS 4-8

COM NC NO Reserved

4.84.8 Breaker InstallationBreaker Installation

SLIMLINE BREAKERS RATED GREATER THAN

65A DO NOT CARRY A UL 489 RATING AT THIS

TIME�

NOTICE:

MAKE SURE CIRCUIT BREAKERS ARE IN THE

OFF POSITION PRIOR TO INSTALLATION�

ENSURE CIRCUIT BREAKERS ARE COMPLETELY

INSERTED�

CAUTION!

There are 16 breaker positions in the Matrix C16 breaker panel�

Step 1. Remove the breaker compartment door from the panel

by loosening the two thumb screws on the door�

Step 2. Select a breaker of sucient ampacity and insert it into

the desired output circuit, making sure to seat the

breaker securely (see Figure 15)�

NOTE: A breaker legend is applied to the inside of the

compartment door to allow an installer to mark the use of each

breaker�

Step 3. Once all desired circuit breakers have been installed,

reinstall the breaker compartment door and secure it

with the thumb screws�

Figure 14. Alarm Jack

Figure 15. Breaker Installation

14 C048-725-30 Rev. B (01/2020)

4.94.9 Installing the Network CableInstalling the Network Cable

If remote monitoring over the network is required, complete

the following steps to connect the Ethernet module with

embedded web server�

NOTE: For initial conguration, it is recommended to use a

crossover Cat 5/5e/6 UTP cable to connect a laptop directly to

the Ethernet port of the Matrix panel. If the laptop is congured

for Auto MDI-X, a straight-through cable may be used�

Step 1. Connect a Cat 5/5e/6 UTP Ethernet cable from the local

network to the Ethernet port on the rear of the panel�

Refer to "Appendix A: Mechanical Drawings" on Page

27 for exact location� Use a TIA/EIA T-568B pinout for

the network connection�

Step 2. For information on conguring the web server, see "5.6

Review System Status via the Embedded Web server"

on Page 18�

Figure 16. Ethernet Jack

15 C048-725-30 Rev. B (01/2020)

5.05.0 OperationOperation (Models with SmartSwitch)(Models with SmartSwitch)

Operation instructions for models without the SmartSwitch

controller can be found in Section 6.0 “Operation (Models with

LED Display)” on Page 21.

If you are using the Ethernet based web server, see Section 5�6

“Review System Status via the Embedded Web Server" on Page 18

for setup and operation instructions� Refer to section 5�7 on Page 20

for a SmartSwitch user interface map�

5.15.1 User InterfaceUser Interface

To advance any item in the menu, tap the SmartSwitch screen (fully

depress the screen itself for less than one second)�

To select a value or enter a menu, press and hold the SmartSwitch for

at least 3 seconds�

5.25.2 Home Screen InformationHome Screen Information

The SmartSwitch home screen displays Input bus voltage, input bus

current, and alarm status� Under normal operation, the home screen

backlight will remain green�

The dual input Matrix C16 SmartSwitch home screen will

automatically cycle between the A and B bus displays� Tapping the

screen once will cycle through the home screens manually� The

available options from the home screen are Input A, Input B displays

as well VIEW BKR LOAD and SETUP menus�

The home screen also indicates the real time status of the panel

based on its backlight color� Refer to Table 2 below for status

information�

Table 5. Backlight Status

BACKLIGHT COLOR STATUS

INDICATED

ALARM TYPE

Green Normal Operation N/A

Orange Warning/Pre-Alarm Minor

Red Alarm Major

Bus B

48.0 VDC

0.0 AM

Figure 17. SmartSwitch Controller

16 C048-725-30 Rev. B (01/2020)

5.35.3 Initial OperationInitial Operation

Once all breakers are installed and power is present on

the inputs, remove the breaker compartment door and

slide the power switch to the on position� The power

switch is located on the front right side of the SmartSwitch�

The display will turn on and display the Alpha®logo

followed by the rmware version.

5.3.15.3.1 Breaker Inventory ProcessBreaker Inventory Process

Before the monitoring features of the Matrix panel can be

used, a breaker inventory must be taken�

Step 1. Upon rst power up, the system will prompt “TURN

ON THE BKRS HOLD 3S�”

Step 2. Turn on all breakers to be inventoried� Press and

hold the SmartSwitch as prompted�

Step 3. The SmartSwitch will now display the number of

breakers installed in the panel� If the number of

breakers displayed is incorrect, ensure that all

installed breakers are fully seated, in the correct

orientation, and turned on�

Step 4. If the number of breakers is correct, press and hold

the SmartSwitch for 3 seconds to continue�

Step 5. The SmartSwitch will now display “STORED

PRESS TO CONT�” Tap the SmartSwitch to

continue and set the breaker ampacity�

5.3.25.3.2 Setting Breaker AmpacitySetting Breaker Ampacity

The SmartSwitch will now display “SETUP BKR AMPS

HOLD 3S�”

Step 1. Hold the SmartSwitch for 3 seconds to enter the

menu to set breaker ampacity�

Step 2. The rst breaker in inventory will be shown, along

with its currently set ampacity� If the ampacity is

incorrect, press and hold the SmartSwitch for 3

seconds to enter the menu�

Step 3. Tap the SmartSwitch until the correct ampacity is

displayed (the display will advance through

standard Slimline breaker ampacities: 1, 3, 5, 10,

15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 80, 90,

and 100), then press and hold for 3 seconds to

save the value�

Step 4. The next breaker in inventory will now be displayed�

Repeat Steps 1-3 for each breaker in inventory�

Step 5. Once all of the breaker ampacities are set correctly,

advance to the screen that says “EXIT HOLD 3 S”

and hold the SmartSwitch for 3 seconds to exit the

menu and save the values�

This completes the initial SmartSwitch setup�

SETUP

BKR INV

HOLD 3 S

TURN ON

THE BKRS

HOLD 3 S

STORED

PRESS TO

CONT.

SETup

BKR AMPS

HOLD 3 S

17 C048-725-30 Rev. B (01/2020)

5.45.4 “VIEW BKR LOAD HOLD 3 S”“VIEW BKR LOAD HOLD 3 S”

Entering this menu will display voltage, current, and alarm status

information for each circuit that is stored in inventory� When the menu

is entered, the rst circuit in inventory will be displayed. Tapping the

SmartSwitch will advance to the next circuit in inventory�

5.55.5 “SETUP HOLD 3 S” – Setup Menu“SETUP HOLD 3 S” – Setup Menu

The setup menu is used to congure the SmartSwitch. The system will

prompt you with “SETUP HOLD 3 S” to enter the menu� This menu is

accessed by taping the home screen until the prompt appears, then

pressing and holding the SmartSwitch for 3 seconds�

5.5.15.5.1 “SETUP BKR INV HOLD 3 S” – Breaker Inventory“SETUP BKR INV HOLD 3 S” – Breaker Inventory

Press and hold the SmartSwitch for 3 seconds to enter the menu and

perform a breaker inventory. Follow the on-screen prompts to nish

inventorying circuits� A breaker inventory must be performed every

time a new circuit is added to the Matrix panel� Refer to "5�3�1 Breaker

Inventory Process" on Page 16 for instructions on how to complete

a breaker inventory�

5.5.25.5.2 “SETUP BUS ALMS” – Bus Alarm Menu“SETUP BUS ALMS” – Bus Alarm Menu

This menu is used to set the input bus rating to enable the panels over

current monitoring features�

Step 1. To set the bus A ampacity, select the option that says “SETUP

BUS A HOLD 3 S�” The SmartSwitch will then display “HOLD

TO EDIT, TAP TO SHIFT.” Tap to access the rst bus.

Step 2. Three digits will now appear on screen with an arrow under the

rst digit.

Step 3. To edit a digit, hold the SmartSwitch for 3 seconds, then tap to

change its value� Hold for 3 seconds to save the edits�

Step 4. Repeat these steps for each digit that needs to be edited�

Step 5. Repeat for bus B�

5.5.35.5.3 “SETUP BKR ALMS HOLD 3 S” – Breaker Alarm“SETUP BKR ALMS HOLD 3 S” – Breaker Alarm

MenuMenu

This menu is used to congure the alarm and warning threshold for

overcurrent alarms�

The alarm setting is used to set the threshold for the panel’s

overcurrent alarm� An alarm condition will annunciate locally with a red

display and an audible alarm� It will also cause a remote alarm via the

Form-C dry alarm contact and email alerts via the Ethernet web server�

The warning setting is used to set the threshold for the panel’s

overcurrent warning (pre-alarm)� The warning will only annunciate

locally�

5.5.45.5.4 “SETUP VOLT CAL HOLD 3 S” – Voltage“SETUP VOLT CAL HOLD 3 S” – Voltage

Calibration MenuCalibration Menu

This menu is used to calibrate displayed bus voltages� Voltage can only

be edited if within valid voltage range�

VIEW BKR

LOAD

HOLD 3 S

SETUP

HOLD 3 S

SETUP

BKR INV

HOLD 3 S

SETUP

BUS ALMS

HOLD 3 S

SETUP

BUS A

HOLD 3 S

SETUP

BKR ALMS

Hold 3 s

BUS a

299 AMPS

18 C048-725-30 Rev. B (01/2020)

5.5.55.5.5 “SETUP ADVANCED HOLD 3 S” –“SETUP ADVANCED HOLD 3 S” –

Advanced Settings MenuAdvanced Settings Menu

The advanced menu contains the following functions�

Changing these settings or using these functions may

aect the monitoring capabilities of the panel.

Restore Defaults

Resets all of the panel settings back to factory default�

This will clear breaker inventory and set the breaker

ampacity, warning, and alarm thresholds back to their

default settings�

Setup Demo

This assigns fake values to current and breaker inventory

for demonstration purposes� It should not be used during

normal operation�

System Info

This displays the rmware version installed on the

controller�

5.65.6 Review System Status via theReview System Status via the

Embedded Web ServerEmbedded Web Server

This section applies to the Matrix family products with the

optional embedded web server installed� If a panel does

not have an Ethernet web server but you would like to add

one, or if you are unsure if this option is installed on your

panel, contact Alpha Support�

The optional embedded Ethernet module provides remote

monitoring via IP-based Ethernet networks and a web

browser� To view the system status, you will need to

connect the Ethernet port on the rear of your Matrix to

your network� See "4�9 Installing the Network Cable" on

Page 14 for information on installing the network cable�

By default, the Ethernet module is congured from the

factory with a static IP address and network settings, as

dened below.

5.6.15.6.1 Default Static Network SettingsDefault Static Network Settings

Set up a local network to communicate with the embedded

web server at the following network settings:

yIPV4 Address: 192�168�123�123

ySubnet Mask: 255�255�255�0

yDefault Gateway: 192�168�123�1

yPr imar y DN S: 192 �16 8�123 �1

ySecondary DNS: 8�8�8�8

Once you establish a connection to the embedded

Ethernet module, use the following credentials to gain

access to the protected data and administrative pages:

yUsername: root

yPassword: password

SETUP

ADVANCED

HOLD 3 S

19 C048-725-30 Rev. B (01/2020)

5.6.25.6.2 Navigating the Web ServerNavigating the Web Server

Upon loading the Matrix web server, the Realtime Status

page will be displayed� Click on the “Administration” tab to

view or modify settings�

5.6.35.6.3 Administration SettingsAdministration Settings

When accessing the web server for the rst time, it is

necessary to congure the administration settings. Click

on the "Administration" tab to access these settings�

Network Settings

See "5�6�1 Default Static Network Settings" on page 18 for

the default network settings for the Matrix web interface�

You can access and change any of the settings on this

page� After applying changes, you must reboot the Matrix

Ethernet web server using the link located at the bottom of

the Administration Settings page�

Notication Settings

Allows a user to edit settings for SNMP traps or email

alerts� All remote alarms are disabled by default�

E-mail and SNMP Settings

Used to congure SNMP trap destinations, SNMP

community string and alert email destinations� After

applying changes, you must reboot the Matrix Ethernet

web server using the link located at the bottom of the

Administration Settings page�

Site Settings

Settings for site name and location displayed on the

Ethernet web server and SNMP data�

Channel Settings

Allows a user to enter channel labels which can be

accessed via SNMP�

Upload Firmware

This menu is used to update the rmware for the Ethernet

web server� Contact Alpha support for further information�

Reboot Device

This allows the user to reboot the Ethernet web server

device remotely�

20 C048-725-30 Rev. B (01/2020)

5.75.7 SmartSwitch User Interface MapSmartSwitch User Interface Map

FROM STANDBY:

┣ (Input A Display)

┣ (Input B Display)**

┣ VIEW BKR LOAD HOLD 3S

┃ ┣ (A1 / 01*)

┃ ┣ (A2 / 02*)

┃ ┣ (A3 / 03*)

┃ ┣ (A4 / 04*)

┃ ┣ (A5 / 05*)

┃ ┣ (A6 / 06*)

┃ ┣ (A7 / 07*)

┃ ┣ (A8 / 08*)

┃ ┣ (B1 / 09*)

┃ ┣ (B2 / 10*)

┃ ┣ (B3 / 11*)

┃ ┣ (B4 / 12*)

┃ ┣ (B5 / 13*)

┃ ┣ (B6 / 14*)

┃ ┣ (B7 / 15*)

┃ ┣ (B8 / 16*)

┃ ┗ EXIT HOLD 3S

┗ SETUP

┣ SETUP BKR INV

┃ ┗ TURN ON ALL BKRS HOLD 3S

┃ ┣ # OF BREAKERS CORRECT

┃ ┗ EXIT HOLD 3S

┣ SETUP BUS ALMS

┃ ┣ SETUP RATING HOLD 3S

┃ ┗ EXIT HOLD 3S

┣ SETUP BKR ALRMS

┃ ┣ ALARM %

┃ ┣ WARNING%

┃ ┗ EXIT HOLD 3S

┗ SETUP ADVANCED

┣ RESTORE DEFAULTS

┣ SETUP DEMO

┣ SYSTEM INFO

┗ EXIT HOLD 3S

About this map

yScreens in parentheses "( )" are information only�

There are no further menu items beyond these

screens�

yPress and hold SmartSwitch for 3 seconds to enter a

menu� Tap to advance between items�

* Dual Input Matrix / Single Input Matrix breaker display

** Does not display on single input Matrix (skips to

breaker menu)�

Table of contents

Other EnerSys Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Eaton

Eaton Cutler-Hammer Magnum Digitrip 220+ instructions

SELF

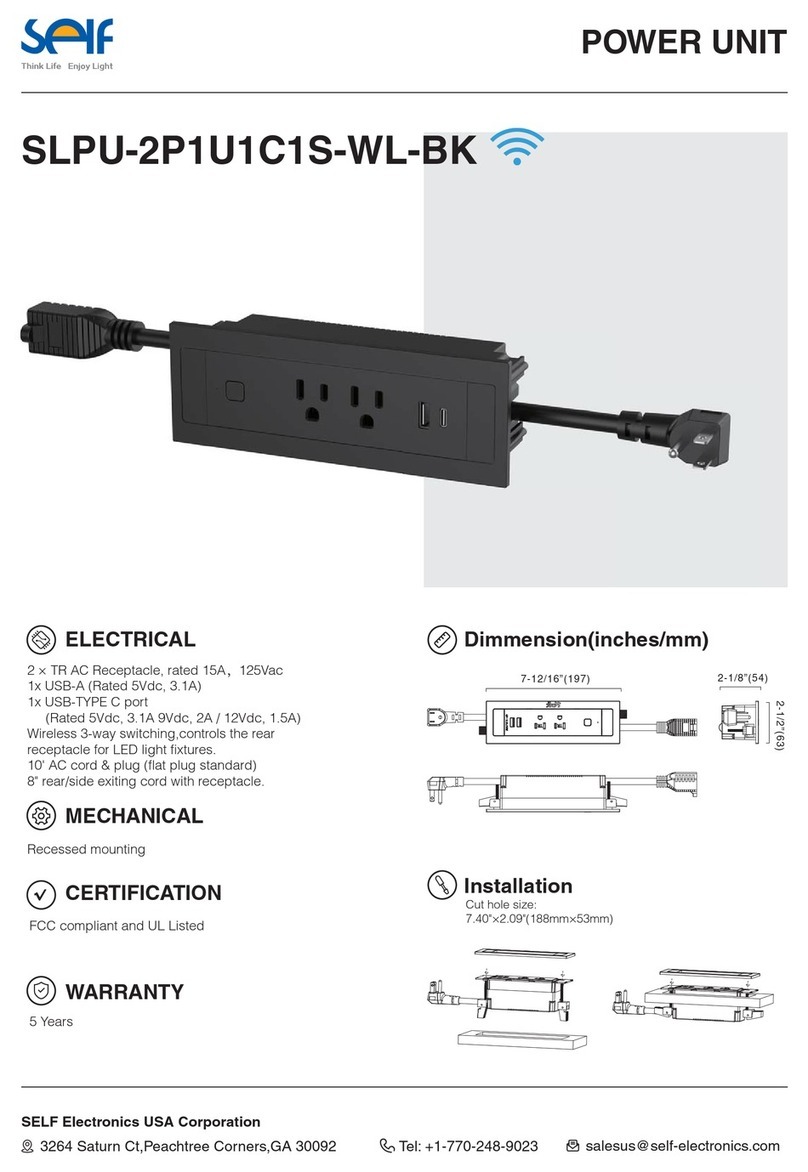

SELF SLPU-2P1U1C1S-WL-BK manual

Hitachi

Hitachi Relion 670 Series Communication protocol manual

LEGRAND

LEGRAND PLUGMOLD PM48TC installation instructions

ABB

ABB RELION REB670 Applications manual

Dataprobe

Dataprobe iBootBar iBB-N15 Installation and operations