Enertex ProxyTouch KNX Quick guide

2018-04-11 Page 2 of 18

Note

The contents of this document may not be wholly or partially, reproduced, transferred,

distributed or stored in any form without prior written approval by Enertex® Bayern GmbH.

Enertex® is a registered trademark of Enertex® Bayern GmbH. Other product- and company

names mentioned herein can be names of trademark or registered trademarks of their

respective owners.

This manual may be changed without notifications or notice and makes no claim to

completeness or accuracy.

Contents

Notes.............................................................................................................................................................. 2

Help function................................................................................................................................................. 2

Overview........................................................................................................................................................ 3

Co issioning............................................................................................................................................ 3

Supply....................................................................................................................................................... 3

Connection diagram................................................................................................................................. 4

Application................................................................................................................................................ 4

Fitting & installing instructions..................................................................................................................5

Default -

no waterproofing required........................................................................................................................5

ith waterproofing -

e.g. in showers......................................................................................................................................... 7

Software description....................................................................................................................................8

Programming............................................................................................................................................ 8

Button partitioning.................................................................................................................................... 8

Lock object............................................................................................................................................... 9

Specification............................................................................................................................................. 9

ETS Application - Para eter....................................................................................................................... 9

General.....................................................................................................................................................................

Buttons...................................................................................................................................................................10

Configuration of buttons.........................................................................................................................................10

Group objects.........................................................................................................................................................11

Revision History......................................................................................................................................... 18

Notes

•Installation and mounting of electrical equipment must be carried out by qualified

electricians. Please note here the section Fitting & installing instructions.

•When connecting KNX/EIB devices specialist skills provided by KNX™ trainings are

required.

•Ignoring the instructions can damage the device, as well a fire or other hazards can

arise.

•These instructions are part of the product and must be left with the end user.

•The manufacturer is not liable for costs or damages incurred by the user or third parties

through the use of the device, misuse or malfunction of the connection, malfunction of

the device or user equipment.

•Opening the housing, other unauthorized alterations and or modifications to the device

will invalidate the warranty!

•The manufacturer is not liable for improper use.

•During installation, pay attention to maintenance access. Claims for damages for

consequential damages due to removing is not granted and is excluded.

Help function

This pdf document uses the division into sections of the Acrobat Reader, which are also called

as “bookmark”. Click on the left edge on the bookmarks tab to view this.

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 3 of 18

Overview

The Enertex®-ProxyTouch KNX is a capacitive touch sensor that can be installed behind

surfaces such as ceramic, wood and glass. It has three sensor areas (see Figure 7) that can be

flexibly adapted to the preferences of the user:

Basic features

•The sensors can be addressed together,

•individually,

•or by slide gestures.

•For individual sensors also a double click is applicable for each sensor area.

•If the slide gesture is set, the 3 sensor areas can be additionally addressed by a double

click and as a single common button.

Feedback

If you touch the tile, behind which the device was mounted, at the desired sensor area (A, B or

C), so a message is written to the bus. After contact (parametrizable) an audible feedback is

given, which at each panel has a different pitch (A=high, B=medium, C=low). If the back of the

device is available, a light up of orange LEDs below the respective sensor area can be seen

when touching the control panel. If the device is in programming mode, a red LED is visible and

an acoustic signal is given. The volume of the acoustic signal can be changed in three stages.

Cleaning operation

In the device a cleaning operation mode can be activated via the group object (KNX message).

When this is active and an operation/trigger of the sensors is done by the user, so no messages

are triggered and parametrizable an acoustic signal is generated. The cleaning operation mode

can be canceled by itself parametrized via a time constant up to max. 3h.

Application

Since the sensors react to changes in the surrounding electric field, the functionality of the

ProxyTouch KNX is better given at a rapid approach than at a slow. In addition, the surface of

the material has to be really touched to excite the sensor. Wiping or approaching without contact

does not lead to tripping. By using double click it has to be ensured that the complete gesture

was really led away from the sensor and back to it again. A simple quick tap with your finger, as

usual from the computer mouse operation, is not sufficient.

Co issioning

Supply

For the operation of the Enertex® ProxyTouch KNX an external voltage supply is not needed.

The device gets the supply voltage from the bus.

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 4 of 18

Connection diagra

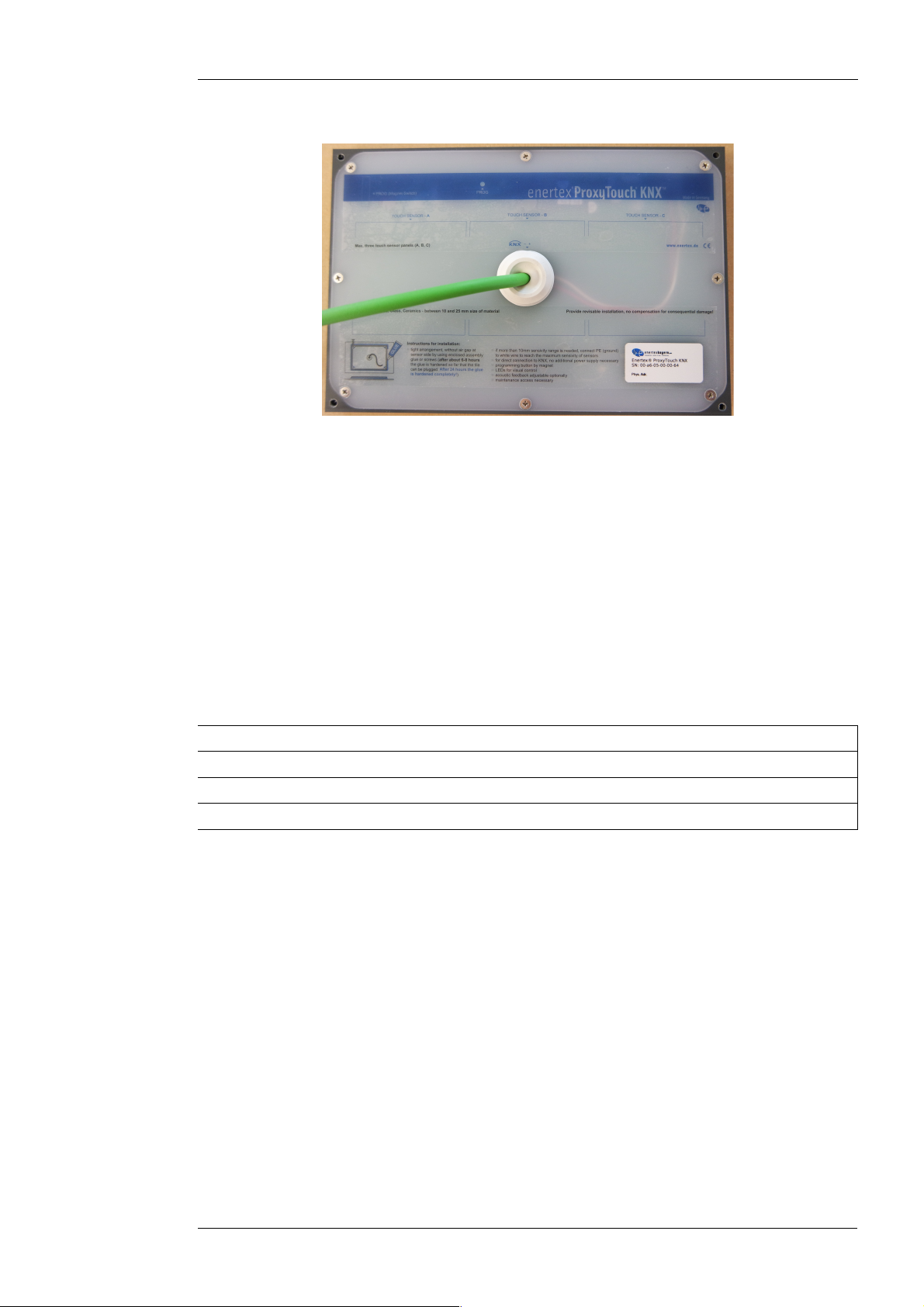

Figure 1: Connections Front view

•Before installing the ProxyTouch in the wall the KNX cable must be connected to the

KNX bus.

•Especially in case of an installation behind thicker wall coverings the white conductor in

the KNX connection cable of the sensor may be connected to the protective earth of the

building to increase the sensitivity. Thereby, the KNX bus is capacitively coupled to the

protective earth.

•The magnetic switch button at the bottom right sets the ProxyTouch into the

programming mode.

Application

The Enertex® ProxyTouch KNX can be mounted behind several materials with different

thicknesses.

Material Max. reco ended aterial thickness

Tile 25 mm

Wood 20 mm

Glass 25 mm

To ensure the functionality completely, the maximum material thicknesses must be noted. It may

be also necessary to connect the white conductor in the KNX connection cable of the sensor to

the protective ground of the building. Thereby, the KNX bus is capacitively coupled to the

protective earth.

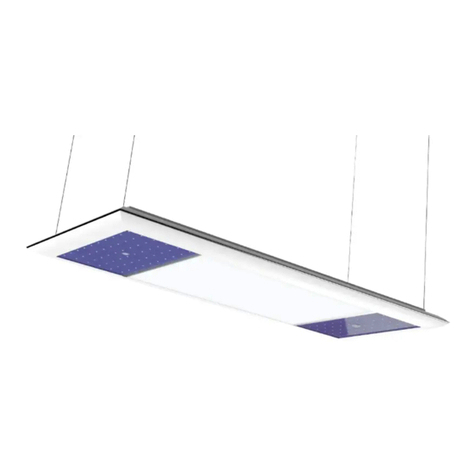

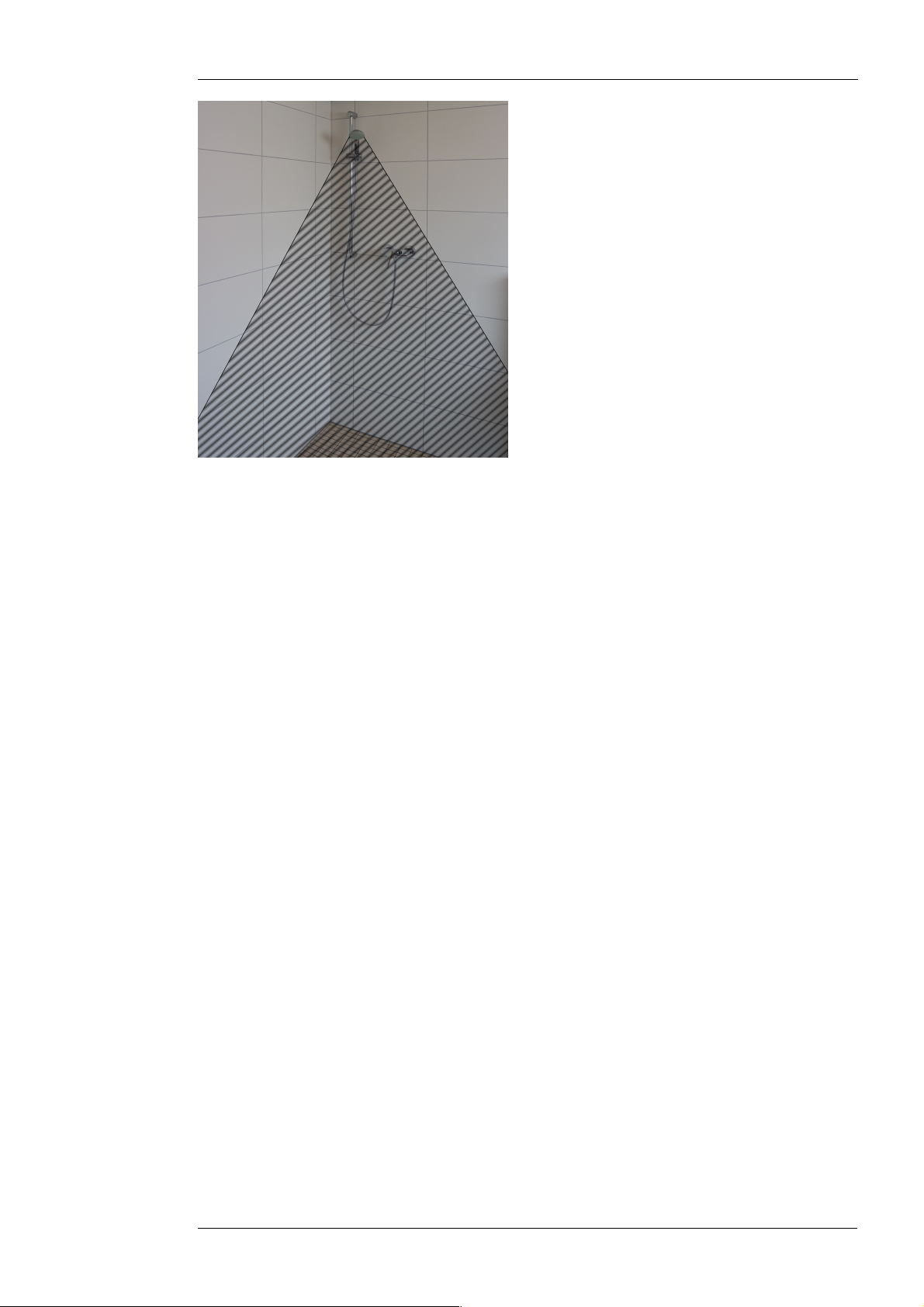

The Enertex®-ProxyTouch can be installed in wet rooms. Direct water jet is to be avoided. It is

recommended that the mounting position in wet rooms is so configured that splash from the

biggest person hits the sensors as little as possible. In the next Figure 2, the shower head is at

height of 1. 5 meters, thus the striped area due to the angle of radiation is not recommended

for mounting:

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 5 of 18

Figure 2: Installing position in wet rooms

The robustness of the ProxyTouch decreases with increasing water amount reacting on the

surface. In contrast to the direct reaction of a water jet, low splashing and water vapor do not

result to false tripping. The robustness of the ProxyTouch is substantially increased when in wet

rooms the button partitioning “Slide gestures” is applied and the sensor areas are only

configured as double click.

At this point it is again referenced to the application described above:

Since the sensors react to changes in the surrounding electric field, the functionality of the

ProxyTouch is better at a rapid approach than at a slow. Furthermore the surface of the material

has to be really touched to excite the sensor. Wiping without contact does not lead to tripping. At

double click it has to be ensured that the complete gesture was led away from the sensor and

back to it again. A simple quick tap with your finger, as usual from the computer mouse

operation, is not sufficient.

Fitting & installing instructions

A correct installation is fundamental for Enertex® ProxyTouch KNX to work as designed, and

depends on its operation area. It must also be ensured that the ProxyTouch KNX lies as flat as

possible on the back, that is it should be avoided, that an “air” distance is formed between the

back of the desired surface and the ProxyTouch KNX. A possible distance between the

mounting material and the sensor reduce the sensor range. In particular, “air” between the two

dampens the range by factor by factor 3 to 4 which means that 2mm air between sensor and

back side of mounting location corresponds to a 6 to 8 mm range shortening.

During installation, pay attention to aintenance access. Clai s for da ages for

consequential da ages due to dis ounting is not granted and is excluded.

Default -

No waterproofing

The Enertex® ProxyTouch KNX is each aligned and fixed on the back of the desired surface. In

case of tiles, plastic and glass the housing is glued to the edges using the enclosed adhesive.

For wood the housing has additional holes at the corners, through which the housing can be

screwed together with screws. With the use of the mounting adhesive the housing must be

placed and fixed on the intended place of the material to prevent slippage during the bonding

operation (Figure 3). It must be ensured that the adhesive surface is clean, dry and free of dust

and grease.

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 6 of 18

Figure 3: Fixing the housing

If so, the mounting adhesive can laterally be applied 5mm high in the corner between housing

and material.

Figure 4: Applying the adhesive mounting

To obtain a clean glue line, the applied mounting adhesive is spread.

Figure 5: Spreading the mounting adhesive

After the three easily accessible sides have been glued, the fixing can be untightened and the

last side can be bonded. While curing, the mounting should be weighted down to ensure a very

dense contact pressure at the surface. After about 6-8 hours the adhesive is so far cured that

the tile can be plugged. After 24 hours the adhesive is fully cured.

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 7 of 18

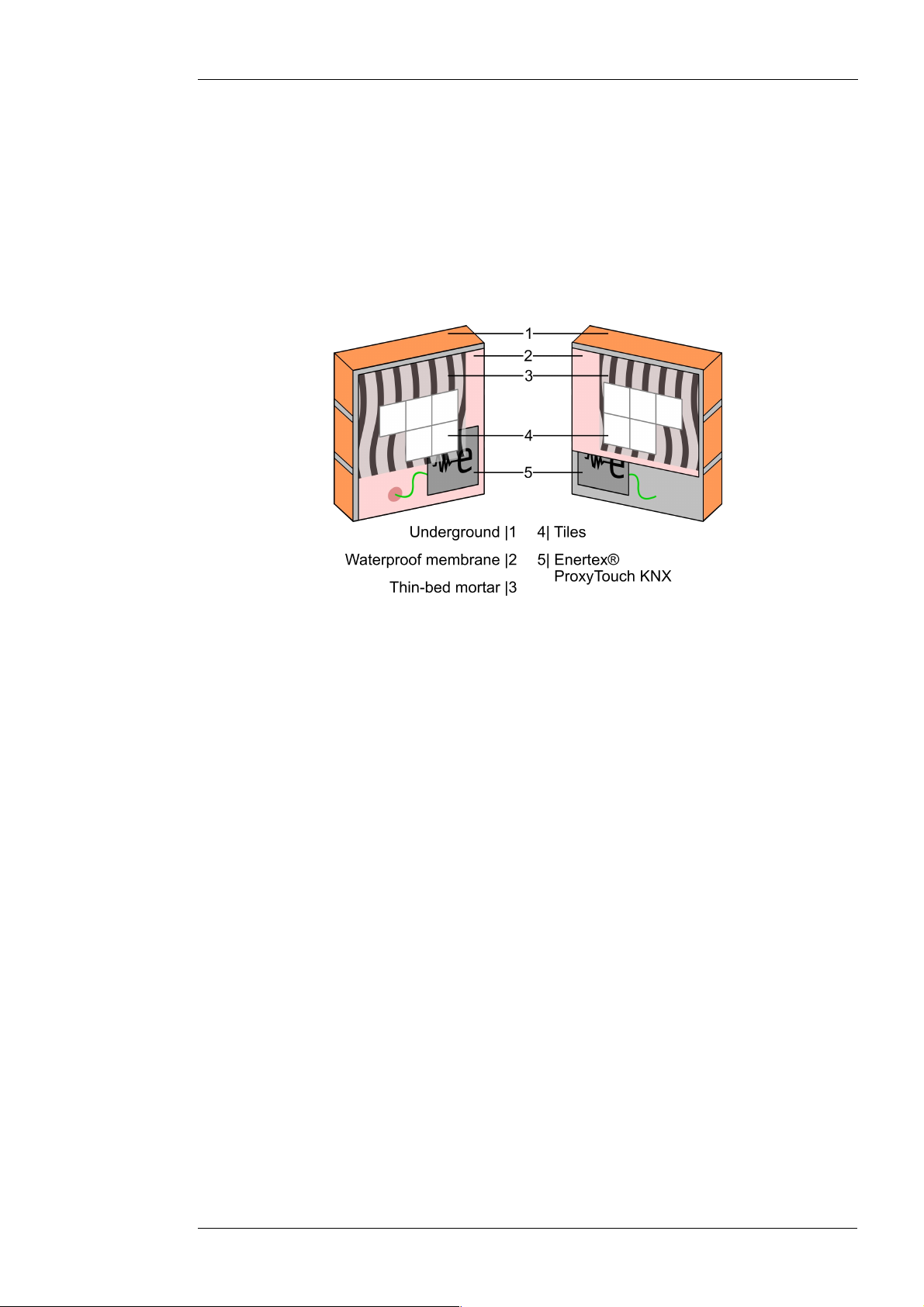

With waterproofing -

e.g. in showers

If the operation area is regularily exposed to water, waterproofing may be required. Please

consult IBC chapter 27 or Tile Council of North America (TCNA) publications, e.g., TCNA

Handbook for Ceramic, Glass, and Stone Tile Installation for detailed instructions. To maintain a

waterproof sealing of the underground construction, Figure 6 recommends two installation

options. The ProxyTouch KNX may be installed on or below the waterproof membrane. It

depends on the detailed conditions, which one is better suited. Please note the recommended

material thicknesses mentioned above is 25mm for tiles.

Figure 6: Waterproof installation

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 8 of 18

Software description

Progra ing

The device is programmed via the ETS. By the enclosed magnet the device can be set, even

after installation, into the programming mode. For this purpose the magnet is swept over the

surface behind which the device is located. The activation switch is located in the upper left

corner of the device and thus in the upper right corner of the surface. Once the device is in

programming mode an audible signal (buzz) can be clearly heard. If the device has not yet been

installed, a visual feedback (red LED) is also visible besides the audible signal.

Button partitioning

According to the parameterization up to four different messages can be transmitted to the KNX

bus via the touch panels. Each panel gives an audible feedback when touched. Thereby the

sound output varies from high (A) to deep (C). In the button partitioning “Slide gestures” and the

function double click an even higher tone than in single button is emitted in case of successful

operation.

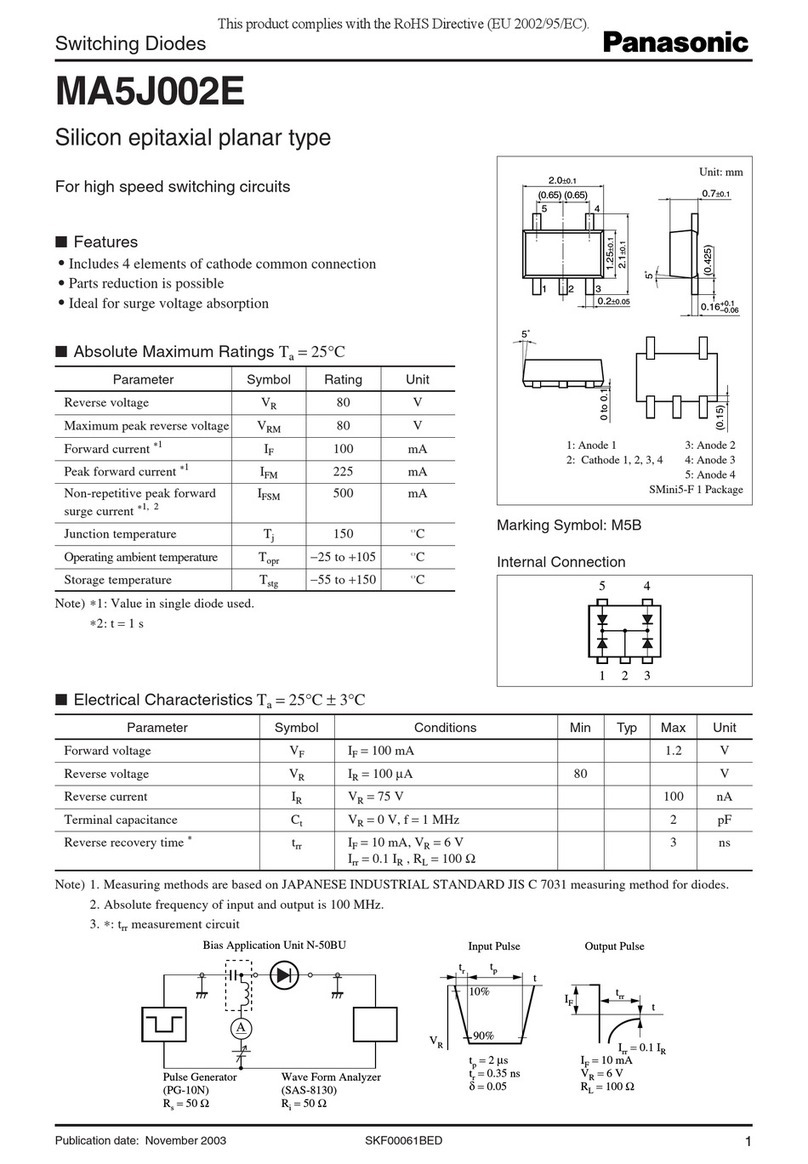

The panel is divided into a maximum of three different sensor areas:

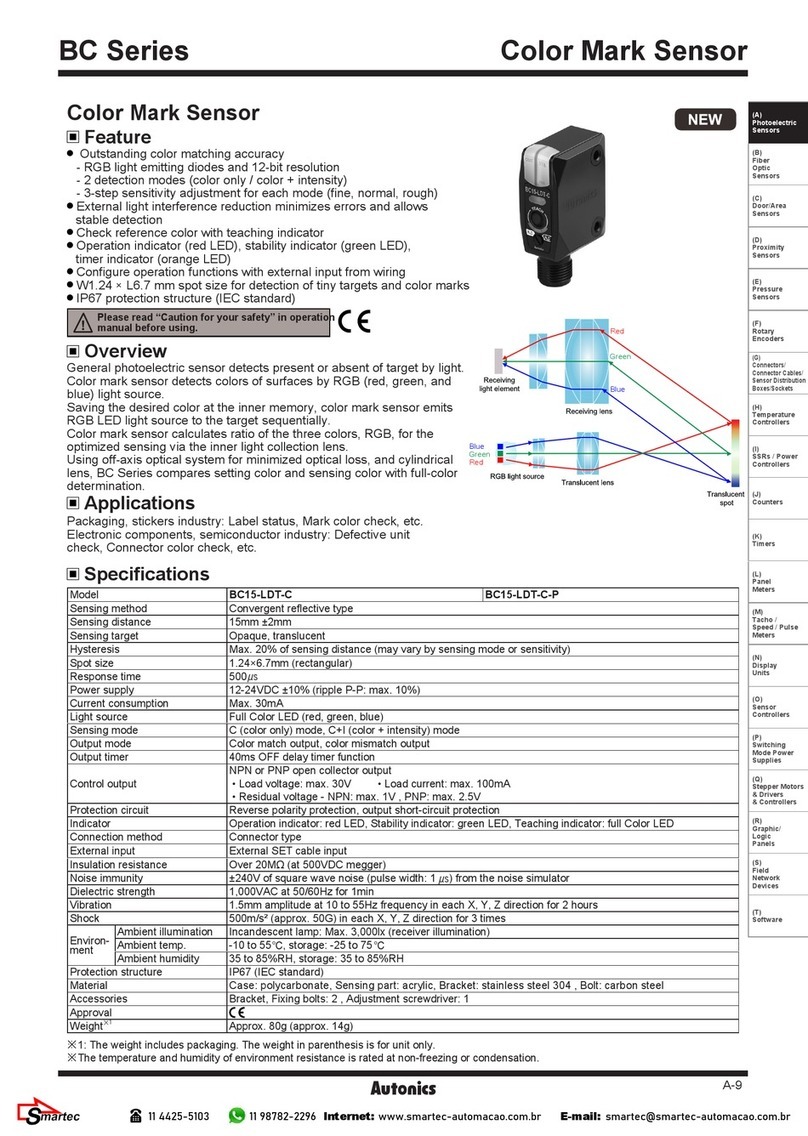

Figure 7: Panels Front view

By para etrization in the ETS the following button partitionings are available:

•Merged buttons

Here, the three sensor areas (A, B, C) are combined to form a one large panel. To carry

out the action programmed in the ETS, touch by hand the surface, behind which the

Enertex®-ProxyTouch is located.

•Single buttons

Here, each sensor area (A, B, C) represents a a control panel. To carry out the action

programmed in the ETS, touch by hand the point on the surface, behind which the

corresponding control panel is located. For all sensor areas a double click is possible.

The double click is triggered by two quick consecutive touches.

•Slide gestures

Here the slide gesture is assembled by the sensor areas (A→C) and (C→A). To carry

out the action programmed in the ETS, sweep with the open hand over the surface,

behind which the Enertex®-ProxyTouch is located. To detect a slide gesture the hand

movement must not be too slow. The sensor areas have two button functions, wherein

for all sensor areas a common single button and a double click is possible. The double

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page of 18

click is triggered by 2 quick consecutive touches.

Lock object

In each button partitioning the object function Lock object is available. With this object it is

possible to lock the sensor areas whereby no action can be carried out any more. This is

important for example for the cleaning operation to prevent unwanted triggering. If the object has

been set, it can be heard by an audible signal (buzz) during operation of the sensor.

Specification

ETS: from version 3.0d, patch A

ETS Application - Para eter

Note: Depending on the configuration some settings may not be available. They are not shown

in the ETS in these cases.

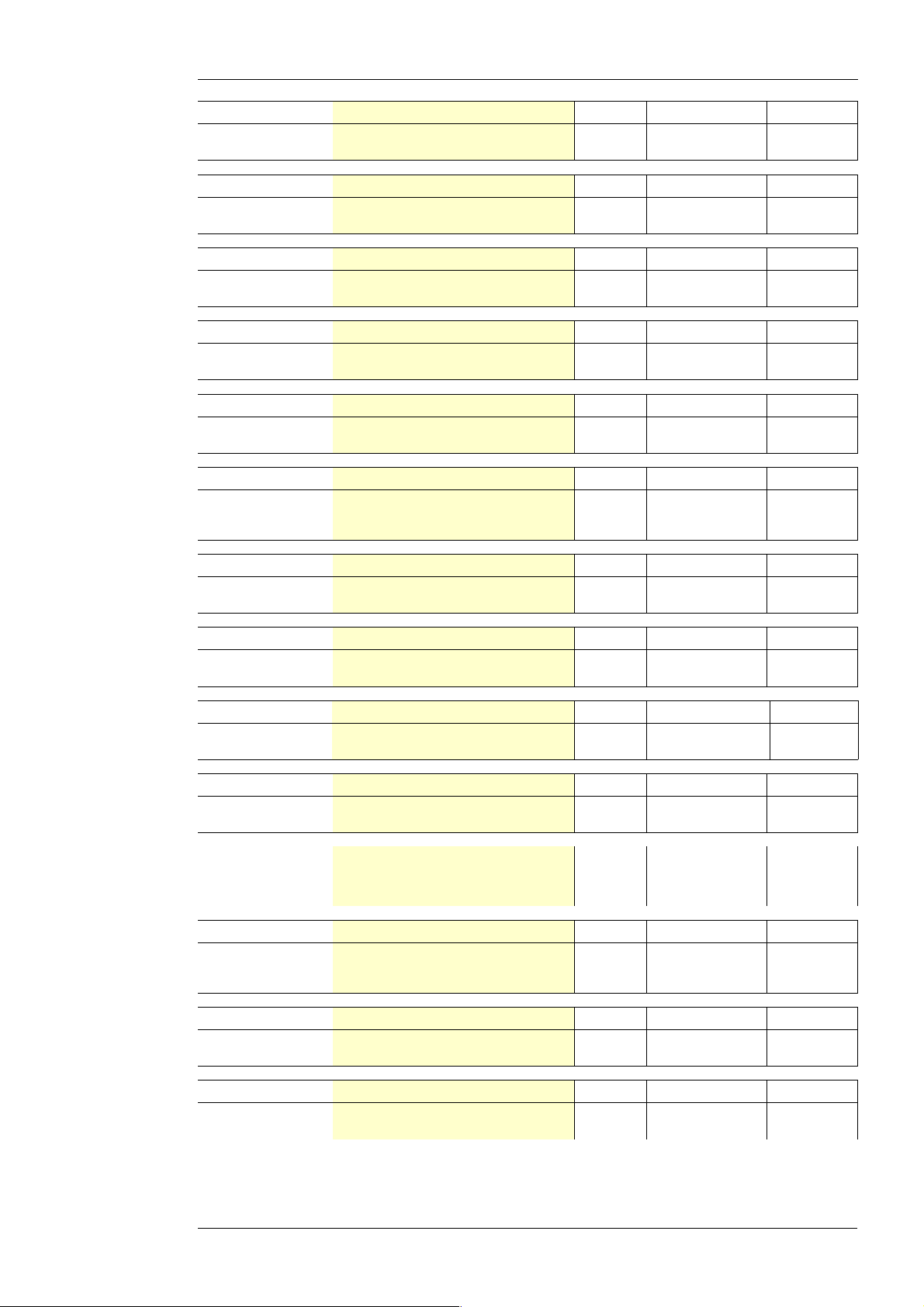

General

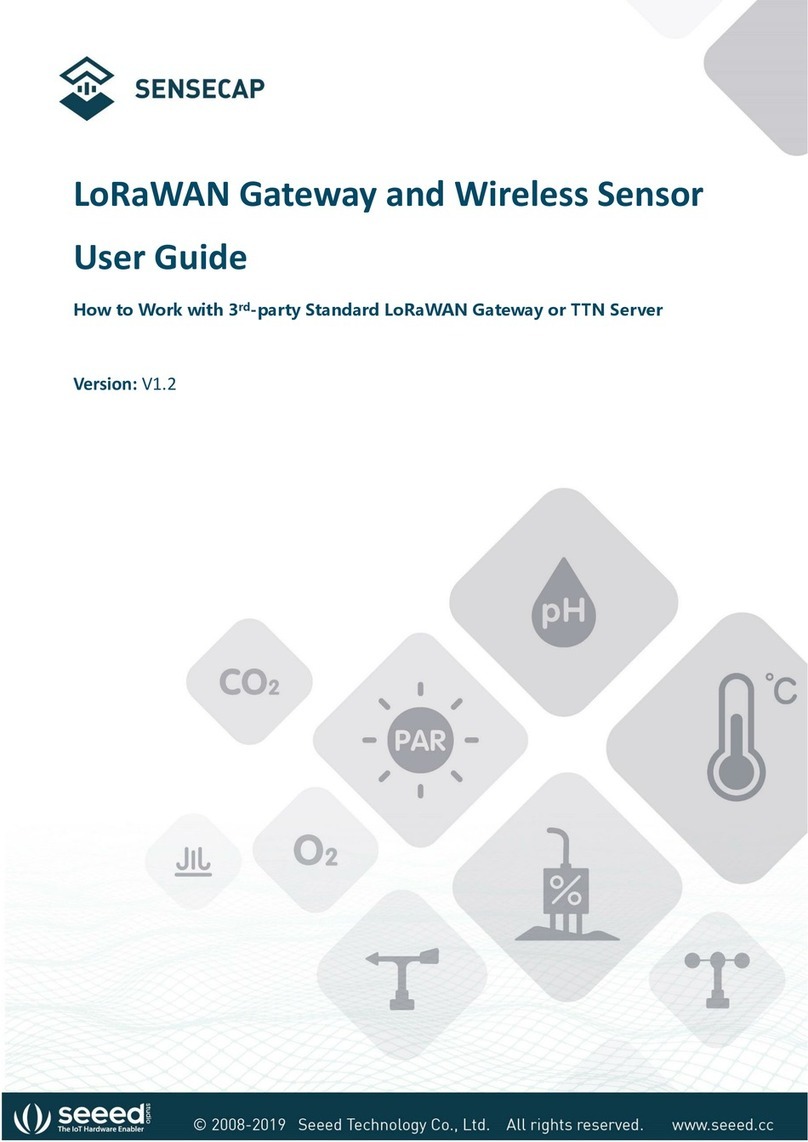

Under the tab “General” the following settings can be made:

Figure 8: General settings

Description of the para eters:

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 10 of 18

Na e Options Description

Acoustic feedback Off

Function

Key lock

Function/key lock

Mode in which an acoustic feedback

is given.

Volume 1 / 2 / 3 Volume of the audible feedback from

1 (low) to 3 (high)

Unlock keys after 5 min

10 min

15 min

...

3 h

-

Time, after which the key lock is to

be automatically turned off.

“-”=key lock is not turned off

automatically

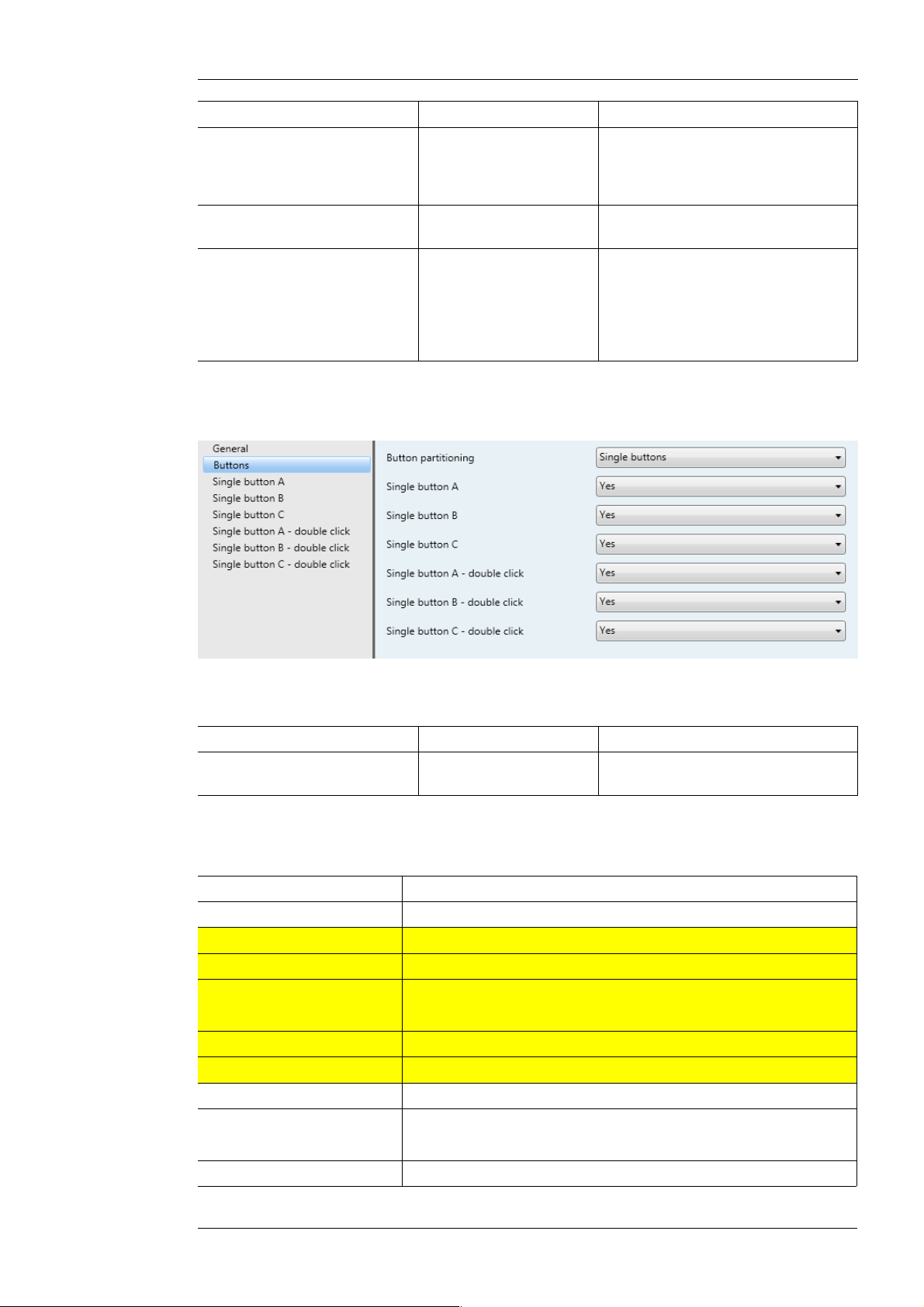

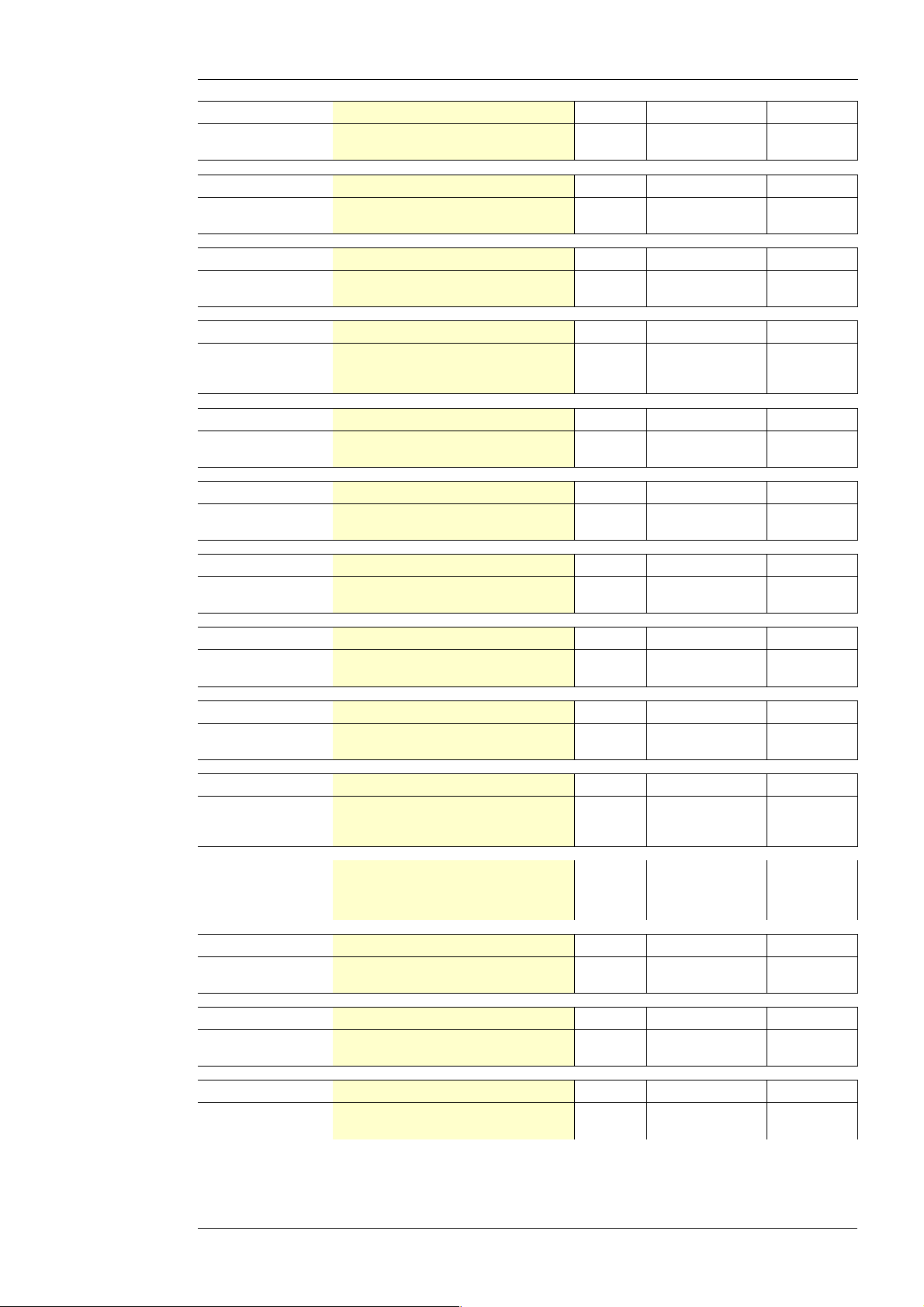

Buttons

Under the tab “Buttons” the following settings can be made:

Figure 9: Parameter Buttons

Description of the parameters:

Na e Options Description

Button partitioning Merged buttons / Single

buttons / Slide gestures

setting of the panels

Configuration of buttons

Description of the parameters:

Na e Options

Merged buttons Switch / Dim / Blinds / Start scene / Percentage

Single button A Switch / Dim / Blinds / Start scene / Percentage

Single button B Switch / Dim / Blinds / Start scene / Percentage

Single button C Switch / Dim / Blinds / Start scene / Percentage

Double click A Switch / Dim / Blinds / Start scene / Percentage

Double click B Switch / Dim / Blinds / Start scene / Percentage

Double click C Switch / Dim / Blinds / Start scene / Percentage

Slide gesture A→C Switch / Dim / Blinds / Start scene / Percentage

Slide gesture C→A Switch / Dim / Blinds / Start scene / Percentage

Single button Switch / Dim / Blinds / Start scene / Percentage

Double click A Switch / Dim / Blinds / Start scene / Percentage

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 11 of 18

Double click B Switch / Dim / Blinds / Start scene / Percentage

Double click C Switch / Dim / Blinds / Start scene / Percentage

1st order 2nd order 3rd order Options Description

Switch Value 0 / 1 / Toggle Value which is

transmitted on the bus

Dim Dim (relatively) Action Decreasing / Increasing Decreases or

increases to set stage

Step 0 - 7 0 = no change / 1 =

100 % / 2 = 50 % / 3 =

25 % / 4 = 12 % / 5 = 6

% / 6 = 3 % / 7 = 1 %

Switch Value 0 / 1 / Toggle Value to be transmitted

on the bus.

Brightness Percentage 0 – 255 Percentage which is

written on the bus

Blinds Up/down - up Blinds move upwards

Up/down - down Blinds move

downwards

Step - increase/

STOP

Adjustment of the slat

or stop the blind

Step - decrease/

STOP

Adjustment of the slat

or stop the blind

Position Percentage 0 - 255 Blinds move to the

selected percentage

Start scene Scene number 1 – 64 Enables the scene with

the specified number

Percentage Percentage 0 – 255 Percentage is written

on the bus.

Group objects

Notes:

•Depending on the configuration some objects may not be available.

List of data point types (DPTs)

Typ Name Length Description Value

[1.1] DPT_Switch 1 Bit Switching 1, 0

[1.3] DPT_Enable 1 Bit Switching 1, 0

[1.7] DPT_Step 1 Bit Switching 1, 0

[1.8] DPT_UpDown 1 Bit Switching 1, 0

[3.7] DPT_Control_Dimming 4 Bit Relatively Dimming 0 = Stop

1 = 100 %

2 = 50 %

3 = 25 %

4 = 12 %

5 = 6 %

6 = 3 %

7 = 1 %

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 12 of 18

[5.1] DPT_Scaling 1 Byte Value Percentage

0% = 0......255 = 100%

[18.1] DPT_SceneControl 1 Byte Calling scene 0......63

ID Name Object function Length Type Flags

0 General Lock object 1 Bit [1.3]

DPT_Enable

RWCT--

ID Name Object function Length Type Flags

1 Merged buttons Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

2 Merged buttons Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

3 Merged buttons Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

4 Merged buttons Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

5 Merged buttons Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

6 Merged buttons Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

7 Single button A Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

8 Single button A Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

Single button A Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

10 Single button A Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

11 Single button A Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

12 Single button A Step 1 Bit [1.007]

DPT_Step

--CT--

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 13 of 18

ID Name Object function Length Type Flags

13 Single button B Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

14 Single button B Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

15 Single button B Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

16 Single button B Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

17 Single button B Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

18 Single button B Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

1 Single button C Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

20 Single button C Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

21 Single button C Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

22 Single button C Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

23 Single button C Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

24 Single button C Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

25 Slide gesture

from A to C

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

26 Slide gesture

from A to C

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 14 of 18

ID Name Object function Length Type Flags

27 Slide gesture

from A to C

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

28 Slide gesture

from A to C

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

2 Slide gesture

from A to C

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

30 Slide gesture

from A to C

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

31 Slide gesture

from C to A

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

32 Slide gesture

from C to A

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

33 Slide gesture

from C to A

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

34 Slide gesture

from C to A

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

35 Slide gesture

from C to A

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

36 Slide gesture

from C to A

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

37 Slide gesture

double click B

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

38 Slide gesture

double click B

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

3 Slide gesture

double click B

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

40 Slide gesture

double click B

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 15 of 18

ID Name Object function Length Type Flags

41 Slide gesture

double click B

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

42 Slide gesture

double click B

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

43 Slide gesture

single button B

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

44 Slide gesture

single button B

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

45 Slide gesture

single button B

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

46 Slide gesture

single button B

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

47 Slide gesture

single button B

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

48 Slide gesture

Single button B

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

4 Slide gesture

double click A

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

50 Slide gesture

double click A

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

51 Slide gesture

double click A

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

52 Slide gesture

double click A

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

53 Slide gesture

double click A

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

54 Slide gesture

double click A

Step 1 Bit [1.007]

DPT_Step

--CT--

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 16 of 18

ID Name Object function Length Type Flags

55 Slide gesture

double click C

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

56 Slide gesture

double click C

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

57 Slide gesture

double click C

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

58 Slide gesture

double click C

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

5 Slide gesture

double click C

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

60 Slide gesture

double click C

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

61 Single button

double click A

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

62 Single button

double click A

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

63 Single button

double click A

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

64 Single button

double click A

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

65 Single button

double click A

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

66 Single button

double click A

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

67 Single button

double click B

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

68 Single button

double click B

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

2018-04-11 Page 17 of 18

ID Name Object function Length Type Flags

6 Single button

double click B

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

70 Single button

double click B

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

71 Single button

double click B

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

72 Single button

double click B

Step 1 Bit [1.007]

DPT_Step

--CT--

ID Name Object function Length Type Flags

73 Single button

double click C

Switch 1 Bit [1.1]

DPT_Switch

--CT--

ID Name Object function Length Type Flags

74 Single button

double click C

Dimmer 4 Bit [3.7]

DPT_Control_Dimm

ing

--CT--

ID Name Object function Length Type Flags

75 Single button

double click C

Percentage 1 Byte [5.1]

DPT_Scaling

--CT--

ID Name Object function Length Type Flags

76 Single button

double click C

Scene 1 Byte [18.001]

DPT_SceneControl

--CT--

ID Name Object function Length Type Flags

77 Single button

double click C

Up/down 1 Bit [1.8]

DPT_UpDown

--CT--

ID Name Object function Length Type Flags

78 Single button

double click C

Step 1 Bit [1.007]

DPT_Step

--CT--

Communication flags according to the KNX specification with the following functions:

•R = Read: allows to read a value from group object

•W = Write: allows to write to the group object

•C = Communication: bus communication possible

•T = Transmit: allows a transmission of a value (usually indicates this flag the transmitting

GA)

•U = Update: allows to update a group object with any feedback ("listen and synchronize"

- functionality)

Enertex® Bayern GmbH – Ebermannstädter Straße 8 - 1301 Forchheim - Deutschland - mail@enertex.de

Table of contents