EngA CRD C-TRAC3 User manual

A

Jan 13 R5

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

C-TRAC3

COOLING CONTROLLER

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

Engineered Air for information and/or parts.

www.engineeredair.com

A

2 of 21 Jan 13 R5

C-TRAC3

If any errors or omissions are noted please contact Engineered Air –Calgary Service at

To ensure warranty is honored, only a qualified HVAC service person, who has received training on the

C-TRAC3, should be employed for service and troubleshooting. If further information is required please

contact the nearest Engineered Air office.

Under no conditions (except for temporary copying) should the unit function description be removed from

the unit. There are two copies provided with the unit. One is in an envelope for copying, then return it to

the unit or store in a safe place. The other is attached to the control panel door and should never be

removed. If a copy of the function for a particular unit is needed, contact Engineered Air with the unit

serial number, C-TRAC3 model number (ex model C-TRAC3.3.1) and the C-TRAC3’s program number noted

near the top right corner of the controller. The program number should also be noted on the electrical

drawing.

Warning:

This unit is connected to high voltages. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that may start

unexpectedly. All work should be performed by a qualified technician. Always

disconnect and lock out power before servicing. DO NOT bypass any interlock or

safety switches under any circumstances.

AC-TRAC3

3 of 21 Jan 13 R5

Table of Contents

INTRODUCTION ................................................................................................................................................................ 5

STARTUP AND SHUT DOWN ............................................................................................................................................. 5

SERVICE SWITCH............................................................................................................................................................... 5

TEMPERATURE CONTROL ................................................................................................................................................. 6

BASE SETPOINT ................................................................................................................................................................. 6

SETPOINT RESET ............................................................................................................................................................... 6

SETPOINT LIMITS .............................................................................................................................................................. 6

MODES OF OPERATION .................................................................................................................................................... 6

SENSOR #2 ........................................................................................................................................................................ 7

MEASURING TEMPERATURE AND SETPOINT ................................................................................................................... 7

OPERATION....................................................................................................................................................................... 7

AMBIENT SENSING............................................................................................................................................................ 8

BLOWER CONTROL ........................................................................................................................................................... 8

ECONOMIZER MODE ........................................................................................................................................................ 8

MINIMUM POSITION ........................................................................................................................................................ 9

Ambient Compensation.................................................................................................................................................. 10

HEATING MODE.............................................................................................................................................................. 10

COOLING MODE.............................................................................................................................................................. 10

DUAL MODE.................................................................................................................................................................... 10

OCCUPIED/UNOCCUPIED................................................................................................................................................ 11

INDICATION AND DIAGNOSTIC LIGHTS........................................................................................................................... 11

LOW LIMIT ...................................................................................................................................................................... 13

VARIABLE AIR VOLUME .................................................................................................................................................. 13

WIRING ........................................................................................................................................................................... 14

EMS Wiring ..................................................................................................................................................................... 15

TROUBLE SHOOTING ...................................................................................................................................................... 15

BASIC (MULTIMETER) ..................................................................................................................................................... 15

DIP Switches (C-TRAC 3.2 and higher) ............................................................................................................................ 15

SIMULATING A HEAT/COOL CALL ................................................................................................................................... 16

ENCHANCED (COMPUTER) ............................................................................................................................................. 16

Calibration ...................................................................................................................................................................... 17

SENSOR TABLES .............................................................................................................................................................. 18

SERVICE NOTES............................................................................................................................................................... 19

AC-TRAC3

4 of 21 Jan 13 R5

AC-TRAC3

5 of 21 Jan 13 R5

INTRODUCTION

The CTRAC-3 is designed to control the cooling, heating, mixing economizer and fan(s). Additionally, it

allows for independent control of other types of equipment operations such as multi-zone and

dehumidification.

The CTRAC-3 requires a 24Vac grounded power supply. The fuse is located on the back of the control, and

has a rating of 800mA (slow blow). Fuse failure can be checked by having 24Vac across terminals H and N,

but the small green light on the face of the C-TRAC3 is not illuminated. There should also be no Vdc

reading across V and Z.

This information in this manual should be used in conjunction with the unit function sheet(s) and the

terminal designation list that accompanied the equipment.

The C-TRAC3 configuration program number is noted on the face of the C-TRAC3. This number is

important when contacting the factory about the unit operation, or for replacement parts. This number

should accompany the unit serial and tag number, and model number.

The C-TRAC3 is designed to control Engineered Air equipment only. It is not designed to simulate or

copy other controllers on the market today, nor can it be modified to do so.

CAUTION:

All of the remote wiring must be complete and functional before attempting to start

the unit.

CAUTION:

It is important that the service technician understands the C-TRAC3 is a configurable

controller. While the terminal designation remains the same, the operation of the

terminal is dependent on the required function, and may differ from unit to unit.

The C-TRAC3 is not field programmable. If the C-TRAC3 program becomes damaged or corrupted, it

must be replaced or returned to Engineered Air for re-programming.

STARTUP AND SHUT DOWN

Startup and shutdown should always be accomplished by the use of the remote start contacts and/or

switches, or the unit on/off switch or an EMS control signal. This will allow the C-TRAC3 to disable unit

operation in sequence, protecting the unit components from damage.

SERVICE SWITCH

The service switch, located in the main electrical control panel, is designed for service and maintenance

use only, and should not be used to regularly enable or disable normal operation. Once the unit has

AC-TRAC3

6 of 21 Jan 13 R5

completely shut down, turn the main disconnect switch off prior to attempting any service or

maintenance.

Additional details regarding startup and shutdown are noted in the unit function and in the Installation,

Operation and Maintenance manual.

TEMPERATURE CONTROL

BASE SETPOINT

The C-TRAC3 is designed to be a discharge air temperature controller. The base discharge air temperature

setpoint is typically set from the setpoint 1 control knob located on the face of the

C-TRAC3. Optionally, this setpoint may be replaced by a remote mounted potentiometer, directly set from

a remote BMS signal (0-10Vdc), preset from a computer, or commanded from an EMS signal. If not used,

set this knob to maximum (fully clockwise), as noted on the face of the C-TRAC3.

The C-TRAC3 has the ability to perform 2 independent operations at the same time, such as a

dehumidification system (pre-cool and reheat) or a multizone system (hot deck, and cold deck). These

types of systems normally incorporate both face-mounted setpoint dials, but the optional setpoints noted

above can still apply to both or either setpoint. As above, if setpoint 2 is not used, set to maximum, as

indicated on the face of the C-TRAC3.

SETPOINT RESET

The base discharge air temperature is normally modified from a remote signal to maintain the desired

temperature of the supplied space. This is called reset. The C-TRAC3 discharge temperature can be reset

from a variety of sources such as ambient air temperature, modulating or staged room thermostats, return

air temperature, or a BMS signal (0-10Vdc).

The resulting change in the discharge temperature setpoint from reset is the actual, or calculated,

discharge air temperature setpoint. This is normally referred to as the SPC.

SETPOINT LIMITS

The discharge air setpoint range is set, and limited to, a specified temperature range programmed prior to

shipment. For example, if the minimum discharge temperature is programmed at 60°F, then that is the

minimum possible temperature setting. Even though the setpoint dial may go as low as 50°F, the

calculated, or actual, setpoint can never go below 60°F.

MODES OF OPERATION

The C-TRAC3 has 3 distinct sequential modes of operation: heating, economizer and cooling. Depending

on ambient conditions the C-TRAC3 may start in any of the three modes. Mode change time is five

minutes (six minutes from heat to mechanical cooling if there is no economizer). If the C-TRAC3 is unable

AC-TRAC3

7 of 21 Jan 13 R5

to satisfy the SPC in its present mode and the discharge temperature slips outside of the discharge

temperature dead band then it will begin timing for a mode change. Once the timing is completed, it can

change modes. If the timer is active and the discharge temperature slides back into the dead band, the

mode change timer is reset. If the current operating mode becomes disabled the C-TRAC3 will immediately

move into the next mode. A preprogrammed option can disable the unit operation if no modes are

available. The table below indicates which 24Vac input terminal can enable or disable its corresponding

mode.

Table 1

Mode

Terminal

Operation

Heat

HS

Heating is allowed with 24Vac at the terminal.

Economizer

E

Economizer is disabled to minimum with 24Vac.

Cool

A

Cooling is allowed with 24Vac at the terminal.

The C-TRAC3 will not always be able to exactly maintain the SPC. Enabling a cooling compressor, for

example, may cause the discharge temperature to fall below the SPC. When the compressor is disabled

the temperature may rise above the setpoint. On average, however, the discharge temperature will

closely match the SPC.

The C-TRAC3 controls to a +/-2°F dead band of the SPC when in heating and economizer mode. The

cooling dead band is based on the dry bulb temperature drop of each stage of mechanical cooling.

SENSOR #2

The C-TRAC3 is has the option of using, and controlling to, two sensors. Some equipment may incorporate

2 discharge air sensors for improved temperature control. Multi-zone equipment use sensor #1 for the

hot deck, and sensor #2 for the cold deck. Dehumidification equipment use sensor #1 for the reheat

(leaving) section, and sensor #2 for the pre-cool section.

MEASURING TEMPERATURE AND SETPOINT

The calculated setpoint (SPC) and the actual temperature can be monitored using a DC voltmeter and the

temperature test points and a DIP switch block mounted on the face of the C-TRAC3 (located near the

RS232 serial connection). Note that the calculated setpoint includes any resets to the setpoint. Refer to

Table 4 on page 14.

OPERATION

As the C-TRAC3 is configurable and will vary in its operation unit to unit, it is imperative that the unit

function, terminal designation sheet and wiring diagram be reviewed to understand how the control is

operating for each particular application.

CAUTION:

All of the remote wiring must be complete and functional before attempting to start

the unit.

AC-TRAC3

8 of 21 Jan 13 R5

AMBIENT SENSING

The C-TRAC3 constantly monitors the ambient temperature using an Engineered Air TE6000EA3 sensor. On

initial start up the C-TRAC3 pre-determines which mode to start in: heating, cooling, or economizer. The

load requirements, ambient temperature and digital inputs determine which mode the C-TRAC3 can start

in. Note that some applications will involve dual modes, such as dehumidification and multi-zone

equipment.

The C-TRAC3 must have an ambient sensor installed to operate, or it will lockout on ‘open sensor’ failure.

BLOWER CONTROL

When 24Vac is applied to terminal FS the C-TRAC3 is considered to be in occupied mode. After a time

delay, that allows the damper actuators to respond, the blower(s) will be enabled by closing the output

contact between terminals C and SA. The time delay is variable depending on the equipment and the

function.

Control of occupied and unoccupied time may be accomplished with an EMS controller. If used, and

enabled by the SMC programming software, the 24Vac input into terminal K is not required.

Fan start timing will vary depending on the unit configuration. Make up air equipment has a base delay

time of 90 seconds, while equipment with mixing dampers have a 10 second base delay time. Additionally,

there may be delays for morning warm up, cool down, and pump down, which may vary depending on the

ambient and discharge air temperature. Always refer to the unit function for specific application time

values. The fan delay off time can vary from 10s to 2.5 minutes.

ECONOMIZER MODE

When in economizer mode the C-TRAC3 will mix the warm return air with the cool outside air to try and

achieve the required discharge SPC. The C-TRAC3 will modulate the mixing dampers (return, outside and if

equipped, exhaust) from fully open to the minimum position setting (expressed as a percentage of outside

air).

The C-TRAC3 has 2 independent outputs for damper control. One is a 24Vac output from terminal DM for

on/off control or a 2 position damper actuator. The other is a modulating Vdc output from terminal ED for

modulating (economizer) actuator control. Flat mixing boxes are set to output a 0-7Vdc range, while angle

mixing boxes use a 0-10Vdc range.

The C-TRAC3 will drive the actuator to minimum position when in heating mode. Optionally, the

C-TRAC3 can be programmed to either drive the damper actuator to minimum position when in cooling

mode or continue to modulate to 100% outside air. If set to modulate, the dampers will decrease the

amount of outside air as the mechanical cooling is enabled to ensure that there is sufficient startup load to

avoid damaging the compressor. Once the compressor has started, the dampers will slowly modulate

open, as required.

AC-TRAC3

9 of 21 Jan 13 R5

If input terminal E is powered (24Vac), the modulating output signal will drop to the minimum outside air

position setting. An optional enthalpy control is normally connected to this terminal.

Unoccupied mode will disable the mixing dampers to 100% return air.

MINIMUM POSITION

The normal setting for the minimum amount of outside air is 15%, although there are many situations

where this number could vary substantially. Refer to the unit function sheet to determine the required

amount.

The mixed air minimum position setpoint is typically adjusted at the C-TRAC3 using the face mounted

minimum position potentiometer; however a variety of methods could be employed. Input terminal MP

may be used to set the minimum position from a remote 0-10Vdc signal (10Vdc = 100% outside air). The

minimum position can also be programmed into the C-TRAC3 through the RS232 communication port from

a computer or directly controlled from an EMS signal. If the minimum position potentiometer is not used

it should be set to zero (turned fully CCW) as it remains in the hardware control circuit.

The mixed air minimum position may overridden from another device, such as a building static pressure

sensor or CO sensor. Refer to the unit function and wiring diagram to clarify. If used, this is normally a

“flow through” device that would input to the MP terminal on the C-TRAC3 first. The C-TRAC3 would then

output the appropriate signal to the damper actuator(s), rather than the minimum position signal directly

feeding into the damper actuator.

Variable Frequency Drives

If the equipment is employing variable frequency drives to control the fan speed (and program options are

selected), a feedback signal of actual speed (10Vdc = 60Hz) is connected to the C-TRAC3. This is to ensure

the airflow is adequate to correctly operate and safeguard the equipment.

As the total air volume drops when the VFD speed decreases, the amount of minimum outside air also

decreases. To compensate for this, the C-TRAC3 will automatically increase the minimum outside air

signal to the damper actuator(s) to allow for more outside air.

Under low air volume conditions the C-TRAC3 will limit the maximum amount of heating and cooling

output for improved temperature control and to safeguard the equipment. This is referred to as ‘load

shedding’. This feature has been removed in versions 3.6 and later.

Refer to the variable air volume section of this manual for additional information.

Mixed Air Low Limit Override

To avoid low limit failure, if the discharge air temperature approaches the low limit setpoint (typically

40°F) the C-TRAC3 will try and keep the unit operational by decreasing the minimum outside air position

down to ½ of its setpoint.

AC-TRAC3

10 of 21 Jan 13 R5

Ambient Compensation

Makeup air equipment normally uses a 2 position damper actuator. Equipment can be ordered with an

Ambient Compensation Package. Among other things, this package uses a modulating outside air damper

actuator. The modulating economizer output (ED) will control the actuator and vary the output signal

depending on the ambient temperature. As the ambient temperature falls, the output will decrease

proportionally, adding static pressure drop across the dampers and effectively reducing the outside air

volume. This compensates for the thermal expansion of the air as it passes over the heat exchanger.

HEATING MODE

Heating is allowed to operate if terminal HS is powered (24Vac). The heating is only activated when the C-

TRAC3 is in heat or dual mode. The C-TRAC3 has a set of contacts (terminals HE1 and HE2) that will close

to enable a heating source, as well as a modulating (0-10Vdc typically) output from terminal HD to control

an independent heating controller, SCR, or water/steam valve. Typically this output will drive one of the

Engineered Air heating controllers (G-TRAC, DJM, H-TRAC etc). Refer to the appropriate manual for

additional information on these controls.

COOLING MODE

Cooling mode is allowed if terminal A is powered (24Vac) and the ambient temperature exceeds the

minimum, pre-programmed low ambient setpoint. The cooling is only activated when the C-TRAC3 is in

cool or dual mode. The C-TRAC3 has 5 output contacts (1 to 5) to enable mechanical cooling stages.

Additionally, a modulating (0-10Vdc typical) output is available from terminal CD for control of a

modulating style of compressor or cooling valve actuator.

Terminal CF is an ambient based cooling output (24Vac). If the first cooling stage is enabled, and the

ambient temperature is above the pre-programmed setpoint, this contact will close. Typical applications

for this would be for an ambient based condenser fan or compressor.

Compressor inter-stage, and minimum on/off times range from 4 to 8 minutes depending on operating

conditions. When the C-TRAC3 first enters cooling mode the first compressor minimum delay is 2 ½

minutes, with the second compressor capable of starting 20 seconds later. These short compressor start

times occur only once whenever the C-TRAC3 initially enters the cooling mode.

Terminal AMB is wired to an externally mounted ambient sensor (Engineered Air TE6000-EA3). The

C-TRAC3 uses this sensor to perform multiple functions, such as low ambient compressor lockout, high

ambient set back, and mode control.

DUAL MODE

Dual control mode allows the cooling or economizer to operate at the same time as the heating. These

are for dehumidification and multi-zone equipment applications.

AC-TRAC3

11 of 21 Jan 13 R5

OCCUPIED/UNOCCUPIED

The C-TRAC3 is capable of a wide variety of control options for occupied/unoccupied control. Read the

unit function and wiring diagram carefully to understand the particular application. The mixing dampers

will set to 100% return air. This option is not available on make up air equipment.

The C-TRAC3 is capable of unoccupied heating and unoccupied cooling. Additionally, unoccupied fan

control may be continuous or intermittent.

An independent unoccupied setback thermostat is required if the unit does not have any method of

temperature reset. Normally the modulating room reset sensor is used, with the unoccupied setback

temperature pre-programmed. Systems using a remote 0-10Vdc discharge setpoint will trigger

unoccupied heating with an input signal greater than 6Vdc.

Switching input power (24Vac) from terminal ‘FS’ (fan switch or occupied mode) to terminal ‘K’ (knight or

unoccupied mode) puts the equipment into unoccupied mode. An EMS controller, connected to the C-

TRAC3 may enable occupied and unoccupied modes without the need of the FS and K input terminals.

INDICATION AND DIAGNOSTIC LIGHTS

On the face of the C-TRAC3 are 3 small LED lights, coloured green, yellow, and red. The green light is to

indicate the C-TRAC3 is powered and ready for operation. If power (24Vac) is applied to terminals H and

N, and the light is not on, the C-TRAC3 may be faulty and/or the fuse is blown. The yellow light indicates

mode and blower delay. The red light indicates problems and failures.

The yellow and red lights will flash on and off a number of times for indication. A noticeable pause occurs

between sets of flashes to avoid confusion. It is not the rate of flashes, but the number of flashes. Refer

to the table listed on the face of the C-TRAC3 or the table below.

Table 2

# of Flashes

Yellow LED

Red LED

1

Heat Mode

Temperature outside dead band

2

Economizer Mode

Mode change blocked

3

Cool Mode

Cooling mode blocked

4

Dual Mode

Low Limit

5

No Mode

Open Sensor

6

Blower Delay

Heat Fail

7

Unused

Auxiliary Alarm

8

Manual Control Mode

Low Air Flow

Heat Mode flashes when the C-TRAC3 is in this mode. The HE1 and HE2 contacts will be closed and the

modulating output will react based on the heating demand. It is possible to be in heat mode, with no

heating occurring.

AC-TRAC3

12 of 21 Jan 13 R5

Economizer Mode flashes when the C-TRAC3 is in this mode. The modulating output from terminal ED can

rise above the minimum position to modulate the mixing dampers and maintain the required discharge air

temperature.

Cooling Mode indicates the mechanical cooling staged output contacts are available to begin enabling the

5 stages of mechanical cooling. All stages have minimum run time, minimum off time, and inter-stage

timing. As well, there may be an optional choice of a modulating cooling output signal if a modulating

compressor or other device such as a modulating chilled water coil is desired.

Dual Mode is a function used on equipment where the heating mode and the cooling or economizer

modes operate at the same time with independent set points.

Ex: multi-zone applications, or de-humidification functions.

No Mode will flash when the C-TRAC3 is not allowed to run the heating (HS not powered), cooling (A not

powered) or economizer (E powered). This generally occurs because of external controls, ambient

lockout, flame failure, etc. The C-TRAC3 can be preprogrammed to eliminate certain modes. For example

a makeup air unit does not have an economizer mode.

Blower Delay is to indicate the blower is preparing to start, but has internal timers to allow for the

dampers to open, or to warm up the heat exchanger.

Manual Control Mode indicates the C-TRAC3 is being controlled by SMC software directly.

Compressor Disabled refers to the mechanical cooling being disabled by the SMC software.

Temperature outside dead band means the temperature is no longer at setpoint and the C-TRAC3 is

attempting to resolve the error.

Mode Change Blocked indicates the C-TRAC3 wishes to change modes (ex economizer to cooling) but the

mode is blocked due to an external signal control, or no such mode exists.

Cooling Mode Blocked indicates the mechanical cooling mode is disabled from either low ambient

temperatures or terminal A not being powered.

Low Limit will flash when the unit has failed because of low discharge temperature, usually associated

with flame failure.

Open Sensor will blink and disable unit operation if the discharge or ambient sensor has failed (open

resistance). This is an optional setting, which may include sensor #2.

Heat Fail will flash if the gas fired heater has failed to ignite. The C-TRAC3 monitors the burner operation

with terminals PVE (pilot valve) and FRE (flame relay), and can be configured to shut down and lock out

the system on a flame failure. Some heaters may be configured for automatic re-light up to 3x before the

C-TRAC3 will go into heat fail. Electric heaters have a feedback, after the safety switches (high limits, air

switch and door switch), to terminal PVE which must prove within 1 minute, after the fan has started.

AC-TRAC3

13 of 21 Jan 13 R5

Auxiliary Alarm indicates a failure of an external binary input into one of the optional programmable C-

TRAC3 terminals. Refer to the unit function sheet and wiring diagram to determine what type of input and

which terminal. Typically, this input would be a filter switch or a current sensor.

Low Air Flow is a noted indication of either the VFD operating at too low of a speed, or an open air flow

switch (if used). Refer to the unit function sheet and wiring diagram to determine which type and

terminal.

LOW LIMIT

The C-TRAC3 control will have low limit (freeze) protection included as a standard option. To reset the

control after a low limit trip the C-TRAC3 must have the power removed and restored to terminals H and

N. This is usually done by turning the unit off at the service switch located inside of the control cabinet. A

computer or EMS can also command the C-TRAC3 to reset the air handler from a low limit alarm.

On initial start-up the C-TRAC3 will bypass low limit sensing for a pre-set amount of time, determined by

the size and type of heat exchanger, the ambient temperature and the discharge air sensor temperature.

The bypass timer is also reset if the minimum position is increased by more than 15% or the VFD feedback

signal increases by more than 10%. This is to avoid nuisance low limit tripping while the heat exchanger is

recovering from a sudden increase in air. The anti-nuisance time is set to 30 seconds for all applications,

and will automatically reset itself if the temperature rises above the low limit setpoint.

If the discharge air temperature approaches the low limit setpoint on equipment incorporating an

economizer mixing box function, the C-TRAC3 will automatically decrease the minimum position down to

½ of its original setting.

VARIABLE AIR VOLUME

Variable air volume and 2 speed systems change the amount of air being moved by the system using a

variety of means. The C-TRAC3 can accept the feedback signal of a variable frequency drive, connected to

input terminals on the C-TRAC3 (0-10Vdc). Refer to the wiring diagram to determine which terminals are

used. The C-TRAC3 is capable of adjusting the temperature control according to the change in the air

volume signal. For example, on a significant decrease in airflow, the C-TRAC3 will force unnecessary

compressors off to avoid possible damage to the refrigeration components. Reduced airflow would also

limit the number of cooling stages that could operate. A sudden volume change will also affect the heating

control. The heating ramp responds more quickly to increase the heating output on an increase in air

volume. Additionally, the internal low limit bypass time is reset on a sudden increase in air volume.

On units equipped with mixing dampers, the C-TRAC3 can increase the minimum position during a

decrease in air volume. This is to maintain the minimum required amount of outside air. For example, an

RTU delivering 10,000cfm at 10% minimum outside air should be moving 9000cfm return air and 1000cfm

outside air. If the VFD was reduced to 50% volume we would be delivering 4500cfm return air and 500cfm

outside air = 5000cfm total. The minimum fresh air required is still 1000cfm. To account for this, the

damper minimum position will be increased to allow 1000cfm of outside air and 4000cfm of return air.

AC-TRAC3

14 of 21 Jan 13 R5

This is a calculated increase meant to compensate for a reduction in total airflow, not a measured actual

value.

External controls are required to disable the mechanical cooling and heating if the VFD has been switched

to bypass mode, due to VFD failure.

If the C-TRAC3 is configured for variable airflow systems, the minimum position pot is factory sealed at the

fully counter-clockwise position, as the input will interfere with the VFD minimum speed setting.

CAUTION:

Adding a variable air volume system to equipment originally designed with

constant air flow will void warranty, unless approved and recorded by Engineered

Air.

WIRING

The C-TRAC3 terminals H and N require a minimum 24 Vac, 40 VA class 2 power supply that does not need

to be isolated from the rest of the systems components. The C-TRAC3 incorporates an internal ½ wave

rectified power supply that has the DC common virtually the same as the AC’s neutral supply (within

0.05Vdc).

Terminal N should be wired to the common of the same source supplying power to terminals E, A, and K.

All remote wiring attached to terminals Q, U, X, Y, V, Z, + and - should be installed in a clean (no electrical

noise) environment. Wire size should be a minimum of 24ga. twisted pair to reduce electrical noise

(shielded wire is recommended). For longer runs (over 50 ft. eq. length), the use of a minimum

20 gauge-shielded wire is recommended. The shield should be grounded at the unit end only, with the

other end taped.

It is important to ensure correct polarity when wiring into the system.

The modulating output signals from the C-TRAC3 can be programmed for other voltage ranges if needed

for operating other controls. The minimum load resistance is 500 Ohms. The possible variable voltage

ramps are:

0 –10 VDC

0 –7 VDC

0 –5 VDC

0 –2 VDC

As noted, these are configured values and the selected value is noted in the unit function sheet.

If the BMS input terminals (+ and -) are included as part of the unit function and are not field wired, the

signal is considered as being zero, therefore the control will operate as described when this signal is low

(ex maximum cooling).

AC-TRAC3

15 of 21 Jan 13 R5

EMS Wiring

The RS-485 communication cable to the C-TRAC3 is 24awg shielded twisted pair (STP) with a shunt

capacitance of 16pF per foot and 100 ohm characteristic impedance. Category 5 cable can be used as

defined by the EIA/TIA/ANSI 568 specification.

TROUBLE SHOOTING

The C-TRAC3 is designed to simplify service and troubleshooting. Most equipment failures and problems

occur due to sources external to the C-TRAC3, and can easily be traced with a digital multimeter.

Advanced troubleshooting may require the use of a computer.

BASIC (MULTIMETER)

The equipment has a function and terminal list attached to the electrical panel door. These explain how

the equipment is designed to operate. This information, along with the flashing patterns from the C-TRAC3

status lights and multimeter sensor and setpoint readings should allow for a majority of troubleshooting to

effectively take place.

Do not jumper or open circuit sensors. If necessary it is possible to substitute fixed or variable resistors in

place of the sensors for test purposes. Refer to the table later in this document for various sensor values at

various temperatures.

There is a test point and DIP switch block near the RS-232 connection for checking actual temperatures

and setpoints. Refer to the DIP switch settings to determine which of the 4 possible variables are being

read. Referenced to ground, measure a DC voltage that relates to temperature in °C. Refer to Table 3 and

Table 4 below.

Table 3

Vdc

0.5

1.0

1.3

1.5

1.8

2.1

2.4

2.7

2.9

3.2

°C

5

10

13

15

18

21

24

27

29

32

°F

40

50

55

60

65

70

75

80

85

90

Note the above actual temperature reading is the value at the Engineered Air sensor or setpoint. If there is

a building management system measuring temperature, its sensor should be located within one inch of

the Engineered Air sensor.

DIP Switches (C-TRAC 3.2 and higher)

A DIP switch block located to the left of the RS-232 connector will switch the multimeter test point to read

a variety of temperatures and setpoints. See the table below. Note that early versions of the

C-TRAC3 had selection jumpers.

AC-TRAC3

16 of 21 Jan 13 R5

Care must be taken to ensure static electricity does not damage the control’s central processor. When

working with any electronic control, discharge the static charge by touching ground before attempting to

service. (It is best to use an approved ground strap before servicing any electronic component).

Table 4

Voltage Readout Function

DIP Switch #1

DIP Switch #2

Discharge temperature at sensor Q

Off

Off

SPC value for the main setpoint

On

Off

Discharge temperature at sensor X

Off

On

SPC for the auxiliary set point

On

On

SIMULATING A HEAT/COOL CALL

It is possible to simulate a call for full heating and cooling without using a computer. A resistor or

potentiometer can be temporarily installed to replace the discharge temperature sensor(s).

For heat, if the discharge sensor was replaced with a group of resistors (48°F=910 Ohms and 60°F=960

Ohms) and the SPC was at 70°F or warmer, the heat mode should be activated (through the mode timers).

As the discharge sensor does not send a signal to the C-TRAC3 that it is satisfied the heat will remain on.

(Note that if the resistor is less then about 880 ohms the C-TRAC3 will trip on low limit).

Similarly, for full cooling call, substitute the discharge sensor with a resistor (80°F=1050 Ohms –

100°F=1140 Ohms) with a SPC (calculated setpoint) of about 55°F, with acceptable ambient temperatures).

This should activate the mode timers and move the C-TRAC3 into cooling mode and start the cooling. Note

that fixed resistors should be 1 or 5 % tolerance for test purposes, though better yet would be a variable

resistor (pot) mounted on a scaleable fixture.

CAUTION:

Never leave the C-TRAC3 in normal operation with the sensors replaced with resistors.

ENCHANCED (COMPUTER)

The C-TRAC3 family is capable of communicating to a Microsoft Windows compatible computer. Connect

with a serial cable to the RS-232 port (15 pin serial port) located on the face of the C-TRAC3. Laptops and

computers require a standard null modem cable with both ends female.

For more detailed troubleshooting on how to access the C-TRAC3 from a computer contact Engineered Air.

AC-TRAC3

17 of 21 Jan 13 R5

Calibration

Calibration is factory set and cannot be done without a computer using Engineered Air SMC software.

Sensor calibration is normally not required, as there are typically external reasons why the sensor is not

operating properly, such as inadequate wire size or electrical noise and interference. Contact Engineered

Air for assistance.

The customer version of the SMC software has limited access to program variables,

and is primarily used for monitoring equipment operation.

AC-TRAC3

18 of 21 Jan 13 R5

SENSOR TABLES

Note sensor values on the table below. If the sensor is disconnected, placed at a fixed temperature and

the resistance measured, it should be close to the values below.

Table 5

SENSOR

(purple and blue)

Same resistance as TE 6000-960

Set-Point Dialled To

60°F

90°F

POT

(orange and grey)

2.725 K

3.272 K

(orange and blue)

3.184 K

2.702 K

(blue and grey)

970

OTHER

(purple and orange)

4.19 K

3.71 K

(purple and grey)

About 1.981 K (varies with element temp.)

Sensor Resistance Chart for TE6000EA3

Table 6

°C

°F

Resistance

°C

°F

Resistance

°C

°F

Resistance

-40

-40

602

18.3

65

983

48.9

120

1234

-34.4

-30

633

20

68

996

54.4

130

1269

-28.9

-20

665

20.6

69

1000.7

60

140

1333

-23.3

-10

698

21.1

70

1005

65.5

150

1365

-17.8

0

732

23.9

75

1026.5

71.1

160

1437

-12.2

10

768

26.7

80

1048

76.7

170

1491

-8.7

20

804

29.4

85

1070

82.2

180

1546

-1.1

30

842

32.2

90

1092

87.7

190

1602

4.4

40

881

35.6

95

1116

93.3

200

1659

10

50

921

37.8

100

1139

98.8

210

1718

12.8

55

942

43.3

110

1186

100

212

1778

Reference resistance is 1035 ohms at 77°F. Resistance tolerances are ±0.05 to 0.15% at 77°F. Temperature

range +32 to +104°F.

AC-TRAC3

19 of 21 Jan 13 R5

SERVICE NOTES

Dehumidification Mode

Any temperature reset methods used for normal operation are still active to affect the reheat temperature

if the equipment is enabled to dehumidification mode.

Room Sensor/Setpoint

The standard modulating room sensor is a Johnson Controls® TE-6100-960 that comes complete with a

setpoint dial. Optionally, the setpoint dial in the room can be disabled in favor of the second setpoint dial

on the face of the C-TRAC3.

Field Installed Discharge Air Sensor

The location of this sensor is critical to the performance of the equipment and is the most likely cause of

poor temperature control. If it is too close to the heat exchanger it may pick up radiant heat and cause the

equipment to discharge an actual temperature much lower than what is being read by the

C-TRAC3. If it is mounted too far downstream there will be too much lag in the response of the change in

temperature, and will cause the actual discharge temperature to hunt up and down. Refer to the

equipment Installation Operation and Maintenance manual for mounting location details.

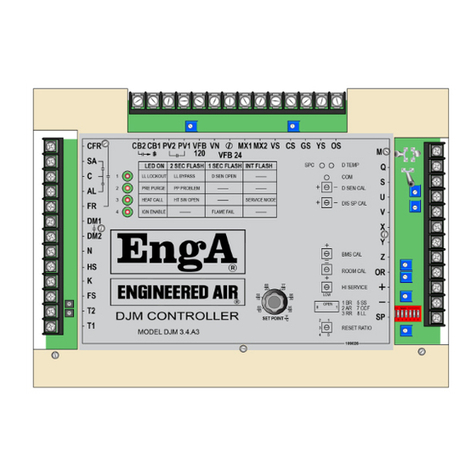

DJM2 Setup Notes

Set the DJM2 heating controller to be a fully proportional control by adjusting the CONT potentiometer to

the full counter clockwise position. Adjust the BMSS pot so that the burner comes on at 3.0Vdc and the

BMSZ pot so that the burner shuts off at 2.5Vdc. The precision of the BMSS and BMSZ pots is not overly

critical as the

C-TRAC3 will learn at what input the burner comes on and off, and will adjust its internal temperature

algorithms to compensate for any error.

G-TRAC2 Setup Notes

Add a 1k ohm resistor between G-TRAC2 terminals Q and U. Set block ‘C’ DIP switch 5 to disable the low

limit, and set 3 and 4 to the closed position. Block ‘A’ DIP switches 1, 2, 3, 4 and 5 must be off. With the

C-TRAC3 calling for maximum heat (10 Vdc into G-TRAC2 terminals + and -), adjust the BMS reset pot so

that the burner reaches full fire at 9.25Vdc (G-TRAC2 terminals PL and PG). The gas valve actuator will be

near fully open.

Two Speed Motors

Generally two speed motors do not present a problem to the stability of C-TRAC3 controller. It may,

however, be configured to operate similar to a VFD, using load shedding and minimum position

compensation. In this case, when the motor is turned to high speed, a contact between terminals V and

MP will close to notify the C-TRAC3 of high speed.

Tandem Compressors

If all the compressors are connected to the C-TRAC3 output contacts, there are no programming changes

required. However if the second compressor of the tandem set is operated from a pressure switch the

C-TRAC3 inter-stage time is increased to 8 minutes minimum.

AC-TRAC3

20 of 21 Jan 13 R5

Air Quality Sensors

Generally these sensors output a modulating 0-10Vdc signal based on the levels of impurities in the air.

The signal is connected to the MP terminal on the C-TRAC3 to override the base minimum position.

Normally the minimum position pot located on the face of the C-TRAC3 sets the base minimum. Note that

here are additional connection methods that can achieve the same result. Check with the wiring diagram,

terminal designation sheet and unit function sheet.

Damper Linearization Curve

As a set of dampers open, the amount of static pressure drop decreases. However it does not decrease

proportionally. Because of this the C-TRAC3 uses an output curve to the damper actuator(s) that tries to

match the actual airflow with the required airflow. For example, an input signal of 1.5Vdc (15%) will

output 1.9Vdc to the actuator. The actual air flow will be near 15%.

EMS Control

Energy Management Systems incorporating BACnet or Modbus communication protocols, or a nearby

computer using Engineered Air SMC software, may be connected to the C-TRAC3 for remote monitoring

and control of temperature setpoints, minimum damper positions and enabling operational modes and

control. Review the associated manual supplied with the equipment for additional information.

Face Mounted Setpoints

Some applications do not require the use of one or both of the setpoint knobs mounted on the face of the

C-TRAC3. If not required, the ‘Not Used’ check box will be ticked, with the note ‘Set at Max’ below it.

Setting the knob below maximum may cause the C-TRAC3 to have higher than expected setpoints.

Multizone Setpoint Calculation

Multizone program setpoints are configured somewhat differently from other programs. The SMC

software allows the user to input the minimum and maximum cold deck temperatures, and the maximum

hot deck temperature. The minimum hot deck temperature is based on an adder to the minimum cold

C-TRAC3 Damper Linearization Curve

0

10

20

30

40

50

60

70

80

90

100

0 1 2 3 4 5 6 7 8 9 10

Output to Actuator Vdc

Input %

C-TRAC3 Output

Linear Output

Other manuals for CRD C-TRAC3

1

Table of contents

Other EngA Controllers manuals

Popular Controllers manuals by other brands

Flowmeter

Flowmeter EASYVAC Service manual

ProMinent

ProMinent DULCOMETER D1CA operating instructions

Linde

Linde BOC 801325 operating instructions

Dramm

Dramm Rain Pro Expandable Installation and programming guide

KRIWAN

KRIWAN INT280 operating instructions

Motorola

Motorola MVME172 Programmer's reference guide

Vimar

Vimar by-me Eikon 20525 manual

Studio Technologies

Studio Technologies StudioComm 792 user guide

Kaysun

Kaysun KCCT-64 I (B) Owners & installation manual

LEGRAND

LEGRAND FSIR-100 user guide

ABB

ABB MS165 installation instructions

Siemens

Siemens RWF40 Series Installation, use and maintenance instructions