EngA CenCon User manual

IOM68 June 2019

Technical Manual

Manual Revision 1.08

m c

g k

These instructions

are intended as an aid to qualified, licensed installers and

service personnel for proper installation, adjustment and operation of this unit.

Read and understand these instructions thoroughly before attempting installation or

operation. Failure to follow these instructions may result in improper installation,

adjustment, service or maintenance possibly resulting in fire, electrical shock,

carbon monoxide poisoning, explosion, personal injury or property damage.

www.engineeredair.com

CenCon

2

INTRODUCTION

This technical manual is intended for technicians and factory personnel already familiar with the operation of

Engineered Air equipment, control strategies and combustion setup.

The CenCon and expansion modules have been certified by Intertek (ETL) for use with Engineered Air

appliances only, evaluated to CSA 22.2 No. 24 Temperature Indicating and Regulating Equipment and UL873

Standard for Safety Temperature Indicating and Regulating Equipment.

If any errors or omissions are noted please contact the nearest Engineered Air Technical Service Department.

To ensure warranty is honored, only qualified personnel should be employed for service or troubleshooting. If

further information is required please contact the nearest Engineered Air sales office.

Copyright

This document and the information in it are the property of Engineered Air, and may not be used or reproduced

in whole or in part without written permission. Engineered Air reserves the right to revise this publication at

any time, and to make changes to its content without obligation to notify any person of such revision or

change.

CenCon

3

CONTACT INFORMATION

Canadian Head Office and Factory

1401 Hastings Cres. SE

Calgary, Alberta, Canada

T2G 4C8

PH: (403) 287 2590

FX: 1 888 364 2727

Email: service@engineeredair.com

USA Head Office and Factory

32050 W. 83rd Street

De Soto, Kansas, USA

66018

PH: (913) 583 3181

FX: (913) 583 1406

Canadian Eastern Factory

1175 Twinney Drive

Newmarket, Ontario, Canada

L3Y 5V7

PH: (905) 898 1114

FX: (905) 898 7244

WARNINGS, CAUTIONS AND

NOTICES

Warning, Caution and Notice statements are used

throughout this manual to emphasize important and

critical information. You must read these

statements to help ensure safety and to prevent

damage.

m

WARNING:

Indicates a hazardous situation that, if not

avoided, could result in death or serious injury.

m

CAUTION:

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate injury.

m

NOTICE:

Indicates information considered important but not

hazard related.

m

WARNING:

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operation and maintenance instructions

thoroughly before installing or servicing this

equipment.

m

c

WARNING:

This unit is connected to high voltages. Electrical

shock could occur if instructions are not

followed. This equipment contains moving parts

that can start unexpectedly. Injury or death

could occur if instructions are not followed. All

work must be performed by a qualified

technician. Always disconnect and lock out

power before servicing. DO NOT bypass any

interlock or safety switches under any

circumstances.

m

CAUTION:

All the remote wiring must be complete and

functional before attempting to start the

appliance.

m

CAUTION:

It is important that the service technician

understands the CenCon is a configurable

controller. Its operation on one appliance of

equipment may not mimic another.

m

CAUTION:

The CenCon is specifically programmed for this

specific appliance. Do not replace with another

controller without confirming its program

suitability with Engineered Air.

CenCon

4

TABLE OF CONTENTS

GENERAL OVERVIEW...................................... 6

HARDWARE INFORMATION ............................ 6

COMPUTER CONNECTION ............................. 7

KEYPAD ................................................. 10

DISPLAY SCREENS ..................................... 11

HOME SCREEN ....................................... 11

HEATING ............................................. 11

COOLING ............................................. 11

ECONOMIZER ........................................ 12

CENCON ANALOG I/O .............................. 12

CENCON DIGITAL I/O .............................. 12

HEATING ANALOG I/O ............................. 12

HEATING DIGITAL I/O ............................. 12

COMMUNICATION ................................... 13

SETTINGS ............................................ 13

ALARMS .............................................. 13

TERMINAL DESCRIPTION ............................. 14

OPERATION ............................................... 15

MODE SELECTION ..................................... 15

OCCUPIED / UNOCCUPIED ........................ 15

FAN CONTROL ......................................... 15

VARIABLE AIR VOLUME ............................ 15

AIR PROVING SWITCH .............................. 15

WARMUP/COOLDOWN ............................. 15

DAMPER CONTROL .................................... 16

MAKE UP AIR ........................................ 16

DAMPER END SWITCH .............................. 16

AMBIENT COMPENSATION ......................... 16

ECONOMIZER ........................................ 16

MINIMUM POSITION................................. 17

CALIFORNIA BUILDING ENERGY EFFICIENCY -

TITLE 24 ............................................. 17

HIGH AMBIENT LOCKOUT ......................... 17

INDOOR AIR QUALITY ...... Error! Bookmark not

defined.

LOW LIMIT............................................. 17

HEATING ............................................... 17

GAS FIRED HEATING............................... 18

COOLING .............................................. 18

GENERAL TIMING ..................................... 18

TEMPERATURE CONTROL ........................... 19

ROOM OR RETURN THERMOSTAT ............... 19

REMOTE SETPOINT ................................ 19

BMS SETPOINT ..................................... 19

ALARM DESCRIPTION ................................ 20

ALARM RESET ......................................... 20

EXPANSION MODULES (XM) ............................ 23

WIRING CONCERNS .................................. 21

MODULE GROUNDING ............................. 21

COMMUNICATION WIRING ........................ 21

COMMUNICATION WIRE GROUNDING ........... 22

J-XM ....................................................... 23

BASIC OPERATION .................................... 24

TERMINAL DESCRIPTION ............................ 25

J-XM / CD-XM TIMING ............................... 26

J-XM COMBUSTION SETUP .......................... 27

GAS ACTUATOR CALIBRATION ................... 27

COMBUSTION OFFSETS ........................... 27

ALARM DESCRIPTION ................................ 29

G-XM ...................................................... 30

BASIC OPERATION .................................... 30

G-XM TIMING.......................................... 31

TERMINAL DESCRIPTION ............................ 31

G-XM COMBUSTION SETUP ......................... 32

GAS AND AIR ACTUATOR CALIBRATION ....... 32

COMBUSTION OFFSETS ........................... 32

ALARM DESCRIPTION ................................ 34

M-XM ...................................................... 35

BASIC OPERATION .................................... 35

CenCon

5

M-XM / P-XM TIMING ................................. 35

TERMINAL DESCRIPTION ............................. 36

M-XM BURNER SETUP ................................. 37

MAXITROL VALVE ................................... 37

GAS ACTUATOR CALIBRATION .................... 37

ALARM DESCRIPTION ................................. 38

C-XM ....................................................... 39

BASIC OPERATION .................................... 39

C-XM TIMING ........................................... 39

TERMINAL DESCRIPTION ............................. 40

STAGED COMPRESSORS ............................ 41

AMBIENT CONDENSER FANS....................... 41

LOW AMBIENT LOCKOUT .......................... 41

H-XM ....................................................... 42

BASIC OPERATION .................................... 42

TERMINAL DESCRIPTION ............................. 42

HIGH AMBIENT LOCKOUT ......................... 43

S-XM ........................................................ 44

BASIC OPERATION .................................... 44

S-XM TIMING ........................................... 44

OPERATION NOTES ................................... 45

TERMINAL DESCRIPTION ............................. 45

ALARM DESCRIPTION ................................. 46

ER-XM ...................................................... 47

BASIC OPERATION .................................... 47

TERMINAL DESCRIPTION ............................. 48

ALARM DESCRIPTION ................................. 48

CD-XM ..................................................... 49

BASIC OPERATION .................................... 49

P-XM....................................................... 50

BASIC OPERATION .................................... 50

Appendix A - Thermistor Output Table ............. 52

Appendix B - Maxitrol Valve Adjustments .......... 53

Appendix C – Startup Checks ......................... 54

Appendix D - Service Issues ........................... 54

CenCon Specific ...................................... 54

READ AND SAVE FEATURES ...................... 54

COMMUNICATION ALARM ......................... 54

ERRATIC BEHAVIOR ............................... 54

HARD RESET BUTTON ............................. 54

Miscellaneous......................................... 55

COMBUSTION ANALYSIS .......................... 55

POOR PILOT SENSING ............................. 55

REGULATOR RESPONSE ........................... 55

WATER AND ICE FROM COMBUSTION ........... 55

MANIFOLD PRESSURE ............................. 55

CUSTOMER INSTALLED SENSORS ................ 55

SPEED SENSOR – DJ................................ 56

TOP LOADING ...................................... 56

AIR BALANCING .................................... 56

Appendix E – DJ/DG Fuel Curve Development ..... 57

Combustion Record - DJ ............................ 58

Combustion Record - DG ........................... 59

Combustion Record – HE ............................ 60

CenCon

6

GENERAL OVERVIEW

The Engineered Air CenCon controller is the primary operational component for the majority of custom

manufactured Engineered Air HVAC equipment. Expansion modules (-XM) may be added to extend the

operational capabilities to gas fired heating, cooling, humidification and energy recovery systems.

m

Notice:

There is approximately a 1 minute delay before operation can commence on initial power up. The CenCon has

to load parameters and configurations prior to operation. The time varies depending on the complexity of the

equipment it is controlling.

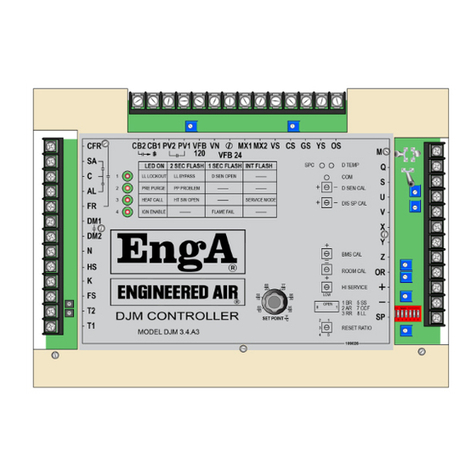

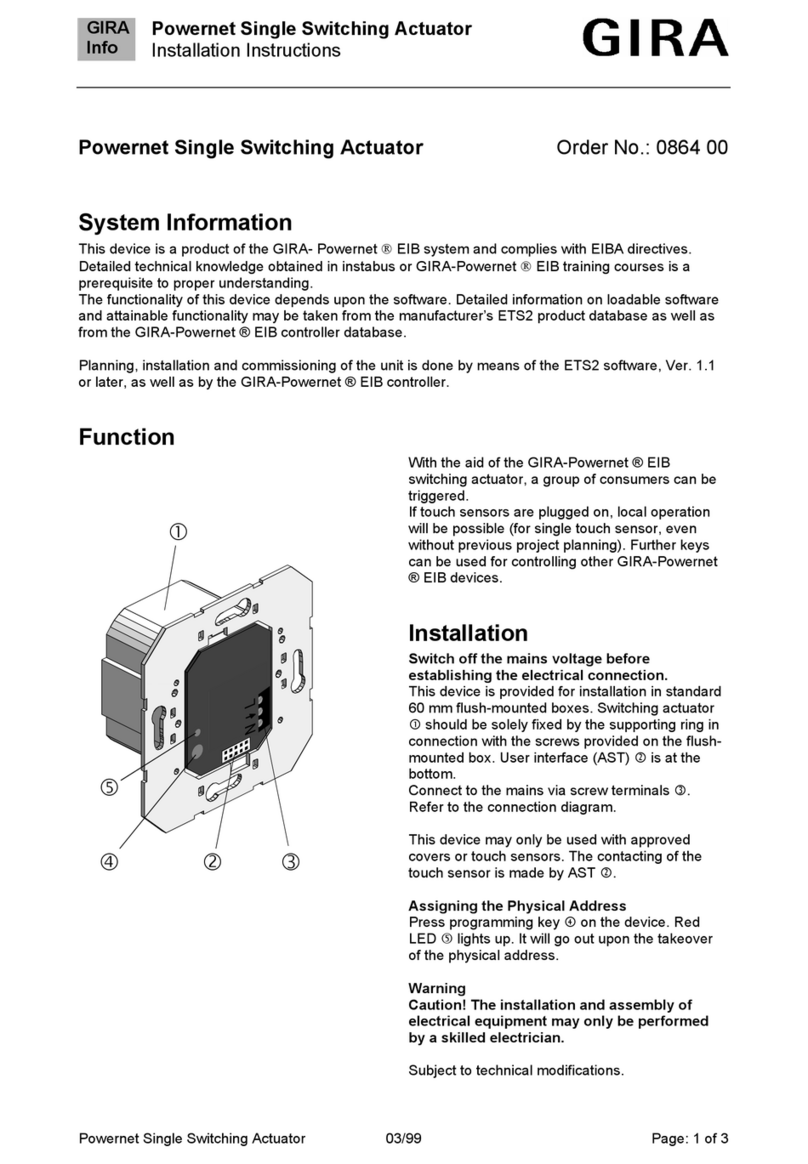

HARDWARE INFORMATION

Control Voltage

24Vac 60Hz

Apparent

Power

Ratings

Digital Output Rating

120V 10A

CenCon

10 VA

Digital Input

24Vac

1

J

-

XM, G

-

XM, M

-

XM

30 VA

Analog Output

0

-

10Vdc

C

-

XM

20 VA

Analog Input

0

-

10Vdc and 4

-

20mA

2

,3

CD

-

XM

5 VA

Analog In

Impedance

7.5k

Ω

P

-

XM

5 VA

Temperature Rating

-

40

–

150°F (65°C)

Temperature Sensor

10k Type 2 NTC

1 Digital input connection to the CenCon or any of the expansion modules cannot use Mosfet solid

state switches. Input switching must be mechanical.

2 If using 4-20mA, add a 500Ω resistor across the input terminals.

3 Analog inputs will trigger 10Vdc ‘high’ if using 24Vac input and a series Diode (1N400x).

Power indication light.

Slow Blink.

Internal Modbus network

light.

Fast Blink.

CenCon

7

COMPUTER CONNECTION

Direct connection may be made to a Windows 10 OS computer or tablet. To gain access to the CenCon testing

interface connect using a Cat.5 Ethernet cable to the CenCon, near the top right of the controller. Tablets

may require a USB to Ethernet adapter. Any Windows based web browser should work.

To set the correct IP address, click the Start button, then Settings, then Network and Internet. Then, click

Ethernet (on the left side), then Change Adapter Options. Click the Ethernet icon and a status page should

open. Press Properties, then Ethernet, then select Internet Protocol Version, and then Properties.

Set a static IP address on the computer with the following settings:

Click OK to accept, and then open a web browser and type in the following address to gain access to the

testing interface:

192.168.0.10:8080/webvisu.htm

To simplify connections, make this a bookmark in the web browser for future connections.

CenCon

8

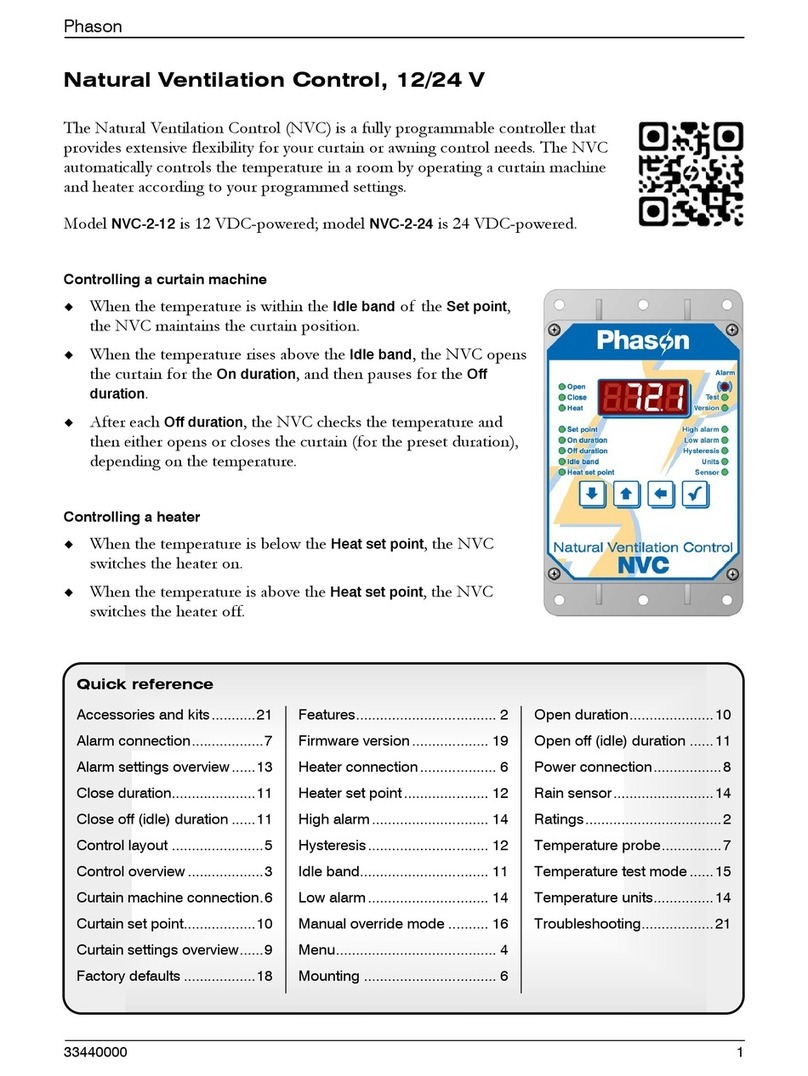

INTERFACE SCREENS

The layout of the display screen depends on the age and version of the CenCon.

The initial release interface display screen example:

A second release, similar to the following has been released. Note the tabs along the top bar:

CenCon

9

The third release screens have been improved for visibility and tablet use. Note the tabs along the top for

more screens. The background is black. This image is grey for printing purposes.

CenCon

10

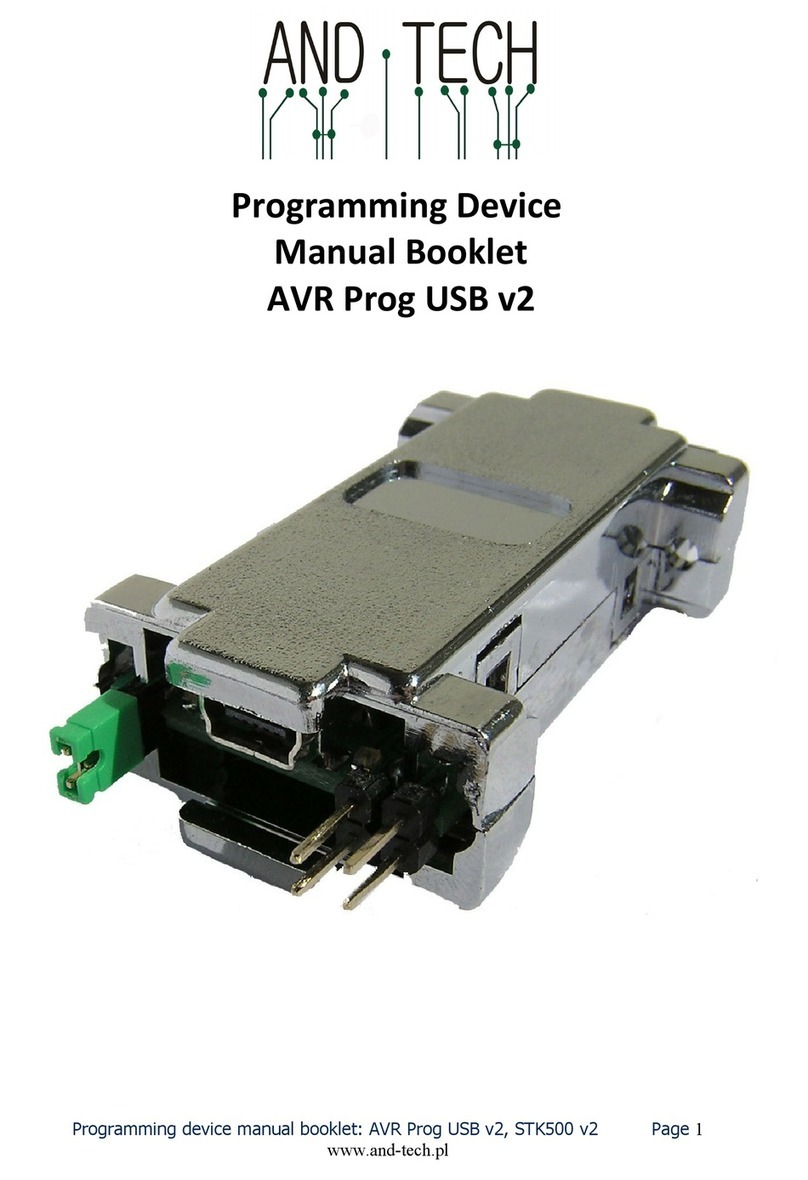

KEYPAD

The 9 button keypad has been configured to easily manipulate any user variables available for modification.

Typically, this would include the temperature setpoint(s) and outside air minimum position.

The home button displays the main page.

Pressing the alarm button changes the

display to the alarm page.

The left and right double arrow keys

increment the display to the next page.

Use the left and right arrows to navigate

the location of the cursor within each

page.

Press the enter key once the cursor is

located at the variable to be changed.

The up and down arrows change the

value of the indicated variable.*

*Changing a

variable is

‘live’

. Pressing enter is

not required to set the value.

CenCon

11

DISPLAY SCREENS

The CenCon display can show a variety of the input and output conditions, in addition to the current operating

variables. Additional screens become available as expansion modules (-XM) are added to the system. The

display screen saver will automatically go blank after 5 minutes. Pressing any key will reactivate the screen

and return to the home page.

HOME SCREEN

The Home screen displays the required setpoint, actual discharge temperature, and various active modes of

operation.

HOME

Setpoint 70°F

Discharge 70.3°F

Unit

ON

Mode HEATING

Damper ON

Blower ON

Alarm Display

Pressing the right page advance changes the display to the next status page(s). Note the top right corner

describes which module the variables relate to. The sample list that follows may or may not be present in the

particular appliance using the CenCon.

HEATING

G-XM sample shown, heating enabled, with the main valve enabled.

HEATING

G

-

XM

Setpoint 90 °F

Discharge 89.3 °F

Demand 16.9 %

Aux. Heat 0.0 %

Burner Sequence ①②③④➎⑥⑦

COOLING

Showing stages 1,2,3 enabled, out of 6 total.

COOLING

C

-

XM

Setpoint

55

°F

Discharge 57.1

°F

Demand 16.9 %

Aux. Cool

0.0 %

Compressors ➊➋➌④⑤⑥

Burner sequence

① Move to purge

② Purge

③ Move to ignition

④ Ignition / pilot

➎ Main valve

⑥ Post purge

⑦ Shutdown

Compressor Stages

➊ Stage #1 On

➋ Stage #2 On

➌ Stage #3 On

④ Stage #4 Off

⑤ Stage #5 Off

⑥ Stage #6 Off

CenCon

12

ECONOMIZER

CENCON ANALOG I/O

ANALOG I/O

CENCON

MEc

7.2 V

MHW

0.0 V

MCW

0.0

V

MSp

0.0 V

IAQ

0.0 V

RPM

0.0 V

HuO

0.0 V

HR +/

-

0.0 V

FbD

0.0 V

ASP

0.0 V

W +/

-

0.0 V

Y +/

-

0.0 V

CENCON DIGITAL I/O

DIGITAL

I/O

CENCON

SA

DM

AL

OLF

FbB

DES

FS

OCC

BAL

DhC

HEATING ANALOG I/O

ANALOG I/O

G

-

XM

MBV

4.41

V

CP

24.4 kΩ

FbG

4.39 V

MCA

3.74 V

FbA

3.71 V

HEATING DIGITAL I/O

DIGITAL I/O

G

-

XM

EnH

SR

CAS

FbV

FR

HL

PV

BFS

CB

ECONOMIZER

CENCON

Mixed Air

59.3 °F

Discharge

53.8 °F

Ambient Air

72.5 °F

Return Air

75.8 °F

Min. Position

20.0 %

Damper

34.5 %

CenCon

13

COMMUNICATION

COMMUNICATION

EMS Enabled: ( YES/NO )

Protocol: ( IP / MSTP / NONE )

External MSTP Baud Rate : 38,400

Setpoint Location : ( KEYPAD / EMS )

SETTINGS

SETTINGS

Load From Factory

No

Load From Default User

No

Save to Default User

No

ALARMS

ALARMS

Unit: No alarms

Reset NO

Heating: No alarms

Cooling: No alarms

Communication: No alarms

CenCon

14

TERMINAL DESCRIPTION

Terminal

Type

Name

Description

Value

H N

Power Supply

24 Vac

GND

Ground

Connect to chassis.

LmA

B

Modbus

Internal

n

etwork

BmA,B

BACnet

BACnet

n

etwork

slave

(Future)

SmA,B

Modbus

Modbus

network slave (Future)

MCW

AO

Modulating cooling

Chilled water coil valve actuator. 0V=off.

0

-

10 Vdc

MEc

AO

Modulating economizer

Economizer / Mixbox actuator. 0V=closed.

0

-

10 Vdc

MHW

AO

Modulating heating

Hot water coil valve actuator.

0V=off.

0

-

10

Vdc

MSp

AO

VFD command speed

VFD control signal.

0

-

10 Vdc

RPM

AI

VFD feedback speed

Confirmation of VFD speed.

0

-

10 Vdc

DPr

AI

Supply duct pressure

Duct pressure sensor signal.

0

-

10 Vdc

IAQ

AI

Not used.

0

-

10 Vdc

HuO

AI

Outside humidity

Outside /

ambient air humidity sensor.

0

-

10 Vdc

CM

Relay common

Common power to output relays.

24 Vac

FbD

AI

Damper feedback

Damper actuator position feedback signal.

0

-

10 Vdc

OLF

DI

VFD fault

Motor overload or VFD fault input.

24 Vac

FbB

DI

Air proving switch

Supply blower air proving switch.

24 Vac

DES

DI

Damper end switch

Mechanical damper end switch.

24 Vac

AL

DO

Alarm

Alarm contact for annunciation.

24 Vac

SA

DO

Supply air

Blower enable contact.

24 Vac

DM

DO

Damper actuator enable

Two position

actuator control.

24 Vac

OCC

DI

Occupied / Unoccupied

Enable

occupied mode when powered.

24 Vac

TCB

DI

Time clock bypass

Momentary push button (future)

24 Vac

EnF

DI

Enable Fan

Occupied mode start

24 Vac

ALi

DI

Secondary Bacnet alarm

Spare al

arm input

for BACnet annunciation.

24 Vac

Y+- AI

Modulating cooling

thermostat Independent cooling demand signal. 0-10 Vdc

MA1,2

AI

Mixed air temperature

10k Type 2 thermistor

Ohms (Ω)

DA1,2

AI

Discharge temperature

10k Type 2 thermistor

Ohms (Ω)

A

A1,2

AI

Ambient

air temperature

10k Type 2 thermistor

Ohms (Ω)

RA1,2 AI

Return / room

temperature 10k Type 2 thermistor Ohms (Ω)

W+- AI

Modulating heating

thermostat Independent heating demand signal. 0-10 Vdc

ASP

AI

Remote VFD setpoint

VFD speed input demand

signal.

0

-

10 Vdc

H

r

+

-

AI

Modulating humidity

Independent humidity demand signal.

0

-

10 Vdc

DX1,2

AI

DX temperature

10k Type 2 thermistor

Ohms (Ω)

DhC

DI

Dehumidification.

Dehumidification call input.

24 Vac

Byp

DI

VFD Bypass

VFD bypass input.

24 Vac

RmA,B

Modbus Room

Modbus room thermostat (Future)

CenCon

15

OPERATION

MODE SELECTION

The CenCon can operate under up to 4 distinct modes; heating, economizer, ventilation and cooling, in

addition to combinations. There is a delay between changing from one mode to another in order to prevent

cycling of the equipment. Mode selection is determined by the demand call and the ambient temperature.

The CenCon must have an ambient sensor installed either within the appliance, or remotely located to measure

the ambient temperature.

OCCUPIED / UNOCCUPIED

During night, or unoccupied, operation, when the modulating room thermostat is calling for more than 60%

heating demand, the heater will operate at the maximum discharge setpoint until the room thermostat demand

falls below 20%.

FAN CONTROL

VARIABLE AIR VOLUME

On a blower start signal, and before the blower is started, the VFD feedback signal is checked for a false

signal. If a false feedback signal is detected the unit will go into alarm and not start. If the signal remains

above the trip set point for 30 seconds, the SA flow alarm is set. After the blower is started, the feedback

signal must rise above the low flow trip point. If it does not, after 30 seconds the SA flow alarm is set and the

equipment shuts down.

Compressors, electric heat or direct fired burners are not allowed to run until the air flow is above minimum

feedback. While the blower is normally operating and the feedback drops 5% below the low air flow set point,

a low air flow warning is displayed and the 15 second alarm timer is started. If the air flow rises above the low

flow set point within 15 seconds, the low flow timer resets and the unit reverts to normal operation. During

this 15 sec time delay, compressors and heat exchanger style burners are allowed to stay running.

AIR PROVING SWITCH

On a blower start signal the air proving switch must be in the open position. If a closed position is detected,

the fan is not allowed to start and a 30 second alarm timer is initiated. The alarm will automatically clear if

the switch opens within 30 seconds.

If the flow proving switch is open, the blower can start normally. After the blower starts, the CenCon needs to

see the air switch close (prove) within 30 seconds. If the switch does not close, the low air flow alarm is

triggered. If during normal operation, the flow proving opens, a 15 second low air flow lock out timer is

started. During this time, compressors and heat exchanger style burners are allowed to stay running. Once

the 15 second timer has elapsed, the equipment will shut down on low air flow alarm.

WARMUP/COOLDOWN

A blower warmup/cooldown delay may be required to preheat or cool down the heat exchanger. For DG and

DJ style heat exchangers a full heat exchanger warm up delay is required when the ambient temperature is

below the low limit set point or when the ambient temperature is 8°F or more colder than the discharge set

point but above the full warmup required ambient.

CenCon

16

The base blower delay off time is automatically set according to the application and type of heating device,

according to the table below.

Application * Damper delay Exchanger Warm

up delay

Cool down delay

MUA On 90 sec

Off 20 sec

DJ: 75 sec

DG/DJX: 75 sec

Other: 0 sec

DJ: 90 sec

DG: 90 sec

DJX : 90 sec

HE: 8 sec

Other: 30 sec

Mixbox On 10 sec

Off 10 sec

DJ: 75 sec

DG: 75 sec

Other: 0 sec

*The damper off delay starts when the blower is shut off

DAMPER CONTROL

MAKE UP AIR

Make up air equipment will normally use a 2 position actuator to open or close the inlet dampers.

DAMPER END SWITCH

A damper end switch is a mechanical device used to prove the dampers have opened. The switch may be

independent, or an auxiliary contact from the damper actuator. If used, when the damper end switch ‘makes’

and inputs 24Vac to terminal DES, the fan delay timer truncates to zero, and the fan will start.

AMBIENT COMPENSATION

On blow through heat exchangers, the blower sees greatly varying inlet temperatures. As the air temperature

changes, so does the air density and volume. The blower delivers a constant volume of ‘cold’ air. As this air is

warmed by the heat exchanger, it expands causing the outlet air volume to increase. With the extra air

volume, the temperature rise falls and there may not be enough heat on a design day.

The ambient compensation attempts to correct this by partially closing the inlet damper enough to add enough

system static to compensate for the expansion effect. The compensation starts to reduce the damper opening

at 30°F and reaches maximum effect at -40°F. The low limit operation has no effect on the ambient

compensation package. This option requires a modulating damper actuator and opposed blade dampers.

ECONOMIZER

Economizer damper control will mix the return and outside air streams to achieve the required discharge air

temperature. The CenCon may also be configured to employ an additional mixed air sensor downstream of the

mixing dampers.

It is possible for the economizer to operate while in heating or cooling mode. While the display will show

either heating of cooling, the analog output to the economizer will be active and show a value greater than the

minimum position.

CenCon

17

Applications may require economizer damper control ‘by others’. This requires the CenCon to be programmed

as a MUA, and uses the FbD (Feedback Damper) input to allow the CenCon to adjust and reset the low limit

bypass timer if required during a significant increase in cold outside air.

MINIMUM POSITION

The minimum position setting is preset by design to the setting noted by sales, and may be adjusted using the

display keypad, a computer interface, Modbus or BACnet. This setting corresponds to the actuator output

signal, not the actual air volume.

CALIFORNIA BUILDING ENERGY EFFICIENCY - TITLE 24

This standard dictates that the economizer must be monitored and prove the mechanical operation of the

dampers. This is achieved by a number of methods. Whenever the economizer is in the full open position, a

damper end switch is activated to indicate that the dampers are operating correctly. A mixed air sensor must

be installed to give feedback on the effectiveness of the mixing section and to act as a mixed air low limit.

HIGH AMBIENT LOCKOUT

This feature is required in order to disable the economizer if there is no cooling available from the ambient air.

This can be performed by two different methods. Differential temperature is generally the method used and

compares the ambient temperature to the return temperature. A second method is differential enthalpy.

Humidity sensors are installed in the return and outside air, and enthalpy is calculated based on the humidity

and temperature readings.

LOW LIMIT

Based on discharge air temperature sensing, the low limit will disable unit operation if the temperature falls

below 40°F (4°C). The setpoint is not adjustable. Low limit, or freeze protection, may be enabled or

disabled. The low limit bypass has 2 timers, the main bypass timer that occurs at initial startup of the supply

fan, and an anti-nuisance timer. The anti-nuisance timer has a duration of 30 seconds and resets once the

discharge temperature rises above the low limit setpoint. The main bypass time is 4 minutes for all types of

equipment.

On variable air volume systems the main low limit bypass time is reset if the economizer minimum position is

suddenly increased by over 15%, or if the VFD speed increases by over 20%, both within 10 seconds.

The bypass time is reduced to 2 minutes if the heating has been disabled. The low limit is not active in cooling

mode.

HEATING

The CenCon may control simple fluid based heating devices from the auxiliary heating 0-10Vdc output.

Expansion modules are necessary for gas fired heating to monitor and control the increased complexity and

safety requirements of gas fired equipment.

The MHW (Modulating Hot Water) output is a 0-10Vdc signal, with 0V=no heat and 10V=max heat, typically

associated with a hot water coil. Reversing function must be done at the actuator. A spring return actuator

would be required for applications desiring full open, closed or bypassed when the equipment is off.

CenCon

18

GAS FIRED HEATING

Commands to heating expansion modules are done via the internal Modbus network. Refer to the appropriate

expansion module section for more information.

COOLING

The CenCon may control simple fluid based cooling devices (chilled water or glycol) from the auxiliary cooling

0-10Vdc output. Expansion module(s) for mechanical cooling are necessary for staged or modulating

mechanical cooling. Refer to the C-XM cooling expansion module section.

The MCW (Modulating Chilled Water) output is a 0-10Vdc signal, with 0V=no cool and 10V=max cool, typically

associated with a chilled water coil. Reversing function must be done at the actuator. A spring return

actuator would be required for applications desiring full open, closed, or bypassed when the equipment is off.

GENERAL TIMING

Mode Change time

1 minute

Damper delay off

20 seconds

Supply low airflow alarm

30

seconds

Shorted Damper End Switch

1 second

Supply air shorted air switch alarm

30 seconds

Low limit bypass

4 minutes + 30 second anti

-

nuisance

CenCon

19

TEMPERATURE CONTROL

The CenCon is a discharge air temperature controller. The discharge setpoint is adjusted from the CenCon

display and keypad, between maximum and minimum limits determined by design.

There are a number of methods to change, or ‘reset’ the discharge temperature to what the space requires.

ROOM OR RETURN THERMOSTAT

The thermostat will have independent 0-10Vdc outputs for heating, cooling, or both.

The selected room thermostat is the Viconics VT7200F5000. This thermostat has (2) distinct 0-10Vdc analog

outputs, for heating (W+/-) and cooling (Y+/-). Refer to the field wiring diagram included with the appliance

for wiring connections.

A remote wall sensor (S3010W1000) is available for various single or averaging room sensor arrangements.

Further information can be found at www.viconics.com.

Mounting locations:

- Do not install on an exterior wall.

- Do not install near any heat source.

- Should not be installed near an air discharge opening.

- Should not be affected by direct sunlight.

- Must be open to air circulation around the thermostat.

REMOTE SETPOINT

A Belimo SGF24 (0-10Vdc) with a calibrated temperature dial may be used to directly change the discharge

temperature (W+/-).

BMS SETPOINT

This method uses a single 0-10Vdc input (W+/-) to modify the discharge temperature between the upper and

lower maximum temperature values.

CenCon

20

ALARM DESCRIPTION

The last alarm event will be shown on the main page of the CenCon display. A more detailed list can be found

by pressing the alarm keypad button . Additional alarms specific to the system are detailed by expansion

module type.

Low limit

The low limit setpoint is the lower of 40°F or 15°F below the discharge air

setpoint.

Air Proving Fault

VFD Feedback is greater than the minimum VFD speed for more than 30

seconds with the supply fan output off.

Shorted Air

Proving

Air Proving switch shorted

on startup.

Low airflow

Air Proving switch opens during operation for 30 seconds or the

VFD

feedback drops below the minimum speed for 30 seconds.

Discharge Air Sensor Failure

Discharge Air sensor is outside of its rang

e (

-

60°F to 220°F) for 10 seconds

or more.

Ambient Air Sensor Failure

Outdoor Ambient sensor is outside of range (

-

60°F to 220°F) for 10

seconds or more.

Damper End Switch Warning

Shorted damper end switch. Meaning the damper end switch is made

before energizing the damper output.

Damper Mechanical Alarm

End switch enabled codex is true and end switch is not made after

energizing damper output.

Communication Error

Triggered on loss of communication with application modules.

ALARM RESET

To reset from the computer screen, press the Alarm Reset button on the main screen. To reset from the

CenCon keypad, press the button, then to move the cursor to the reset area. Then press .

Table of contents

Other EngA Controllers manuals