Engel HFI2230-S200 User manual

STO Safe Torque OFF

Document History

Operating Manual Rev. 1.3 www.engelantriebe.de page 2

Document History

Document

Date

(dd.mm.yyyy)

Rev

Changes

BA_STO_Entwurf_de_xxxxxx_de

xx.xx.xxxx

1.0

Erstellung Entwurf

BA_STO_Rev1.1_200518_de

18.05.2020

1.1

Installationsbeispiele 1-/2-kanalig OSSD, versch. Hinweise

ergänzt, div. Korrekturen, AC Anteil Versorgung

BA_STO_Rev1.2_200527_de

27.05.2020

1.2

Rework after Review

BA_STO_Rev1.3_210507_en

07.05.2021

1.3

First English edition

Copyright

The information and specifications in this document have been compiled with great care and to the best of our knowledge.

However, specifications differing between the document and the product cannot be eliminated with absolute certainty.

ENGEL assumes no liability whatsoever for errors or consequential damages resulting from these deviations. No liability is

assumed for damages which arise from the use of the device with the use of applications or defective circuits, either.

ENGEL reserves the right to change, supplement or improve the document or the product without prior notice. This docu-

ment may not, without the express authorization of the copyright holder, be reproduced in any way or be transmitted in

another natural or machine language or on data carrier, whether this would take place electronically, mechanically, visually

or in any other manner.

STO Safe Torque OFF

Table of Contents

Operating Manual Rev. 1.3 www.engelantriebe.de page 3

Table of Contents

DOCUMENT HISTORY.........................................................................................................................................2

TABLE OF CONTENTS..........................................................................................................................................3

1 INTRODUCTION ..............................................................................................................................................4

2 SYMBOLS USED IN THIS DOCUMENT .............................................................................................................4

3 LIST OF AVAILABLE INTEGRATED DRIVES WITH STO FUNCTION ................................................................4

4 ABBREVIATIONS USED IN THIS DOCUMENT .................................................................................................5

5 SAFETY INFORMATION ...................................................................................................................................5

5.1 General safety information ...........................................................................................................................5

5.2 Intended use ..............................................................................................................................................5

5.3 Non-intended use........................................................................................................................................6

5.4 Achievable safety level.................................................................................................................................6

5.5 Requirements for safe operation ...................................................................................................................6

5.6 Qualified personnel......................................................................................................................................7

6 FUNCTIONAL DESCRIPTION ...........................................................................................................................8

6.1 Inputs of the STO channels ..........................................................................................................................8

6.2 STO status signal ...................................................................................................................................... 10

6.2.1 Functionality of the status signal and the status output ...................................................................... 10

6.2.2 Diagnostic test................................................................................................................................ 11

6.2.3 Switch-off time of the safety function ............................................................................................... 12

6.2.4 Firmware ....................................................................................................................................... 13

6.3 Error messages ......................................................................................................................................... 14

7 TECHNICAL DATA ......................................................................................................................................... 15

7.1 System data.............................................................................................................................................. 15

7.2 Safety parameters ..................................................................................................................................... 16

7.3 Certification .............................................................................................................................................. 16

7.4 Maintenance ............................................................................................................................................. 16

8 PIN ASSIGNMENT / INSTALLATION / COMMISSIONING........................................................................... 17

8.1 X3 –STO signal plug ................................................................................................................................. 17

8.2 STO connection cable ................................................................................................................................ 17

8.3 Installation diagrams ................................................................................................................................. 18

8.3.1 Examples for dual-channel STO connection ....................................................................................... 18

8.3.2 Examples for single-channel STO connection..................................................................................... 19

8.4 Commissioning information ........................................................................................................................ 20

BA_STO_Rev1.3_210507_en

Technical changes reserved

STO –Safe Torque OFF

Introduction

Operating Manual Rev. 1.3 www.engelantriebe.de page 4

1Introduction

This document is intended solely for the description and intended use of the Safe Torque Off (STO) safety function in

accordance with EN 61800-5-2, which is available via an optional "STO module" in the integrated drives of the HFI series.

The separately available operating manual for the HFI series of integrated drives further describes their complete features

and functionalities.

2Symbols used in this document

Symbol

Signal Word

Meaning

Attention!

This symbol highlights safety and warning notices.

Non-observance can result in personal injury and/or damage to property.

Note!

This symbol highlights notes to be observed.

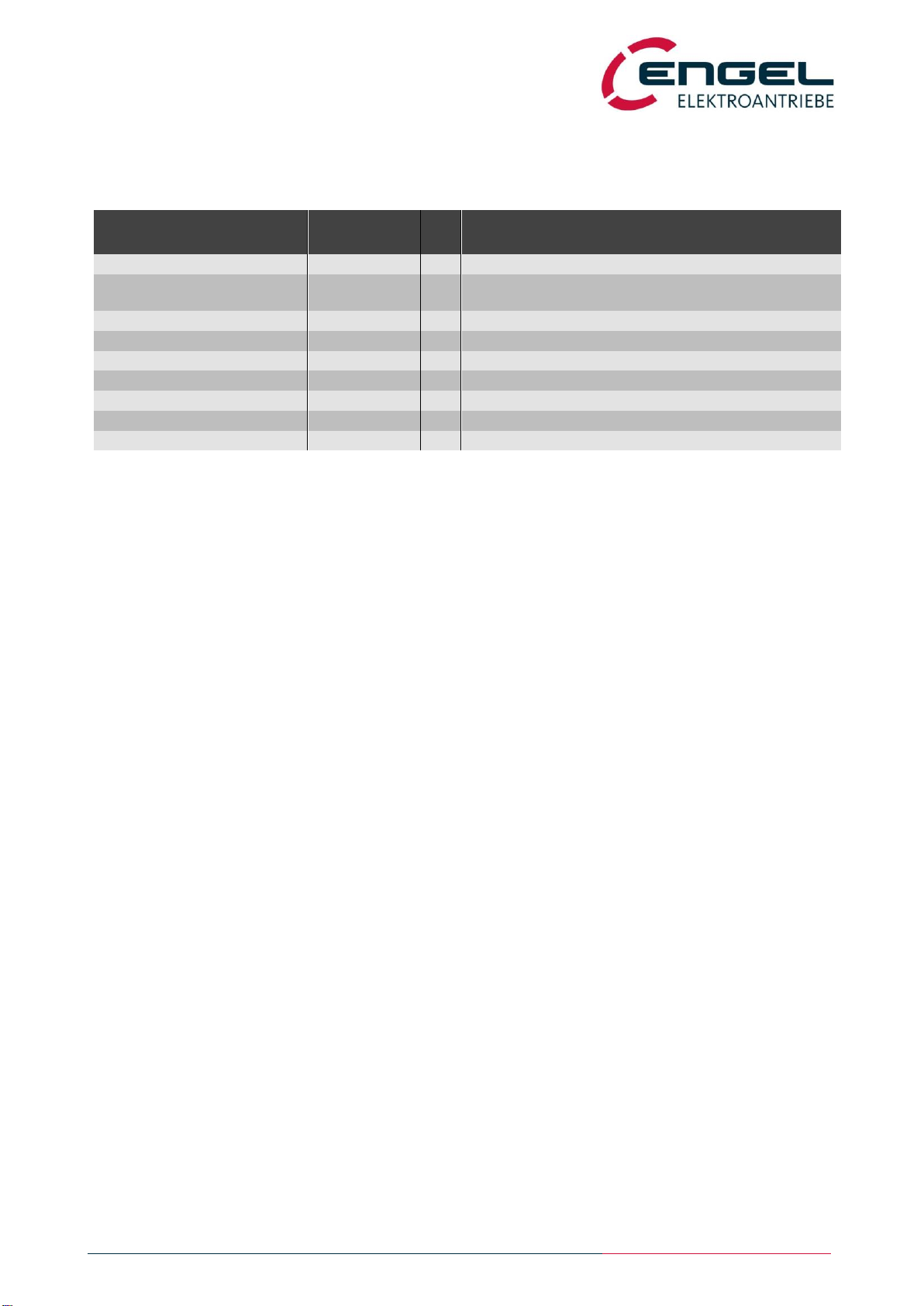

3List of available integrated drives with STO function

The Safe Torque Off (STO) safety function is certified and available for the integrated drives of the HFI series from ENGEL

Elektroantriebe GmbH. The STO models are equipped with an additional hardware module for this purpose and bear the

„S‟ in their type designation.

The following basic devices, optionally expandable with fieldbus interfaces, gearboxes and parking brakes, are available

with the STO safety function:

Basic Device

Part Number*1)

Description

HFI2230-S200

8822312

xxx

Basic Device HFI2230, 24V Version

HFI2230-S400

8822314

xxx

Basic Device HFI2230, 48V Version

HFI2260-S200

8822612

xxx

Basic Device HFI2260, 24V Version

HFI2260-S400

8822614

xxx

Basic Device HFI2260, 48V Version

HFI2630-S200

8826312

xxx

Basic Device HFI2630, 24V Version

HFI2630-S400

8826314

xxx

Basic Device HFI2630, 48V Version

HFI2660-S200

8826612

xxx

Basic Device HFI2660, 24V Version

HFI2660-S400

8826614

xxx

Basic Device HFI2660, 48V Version

HFI3260-S200

8832612

xxx

Basic Device HFI3260, 24V Version

HFI3260-S400

8832614

xxx

Basic Device HFI3260, 48V Version

HFI3290-S400

8832914

xxx

Basic Device HFI3290, 48V Version

HFI3760-S400

8837614

xxx

Basic Device HFI3760, 48V Version

HFI3790-S400

8837914

xxx

Basic Device HFI3790, 48V Version

*1)

"xxx"

is a placeholder for the expansion options that a basic device is equipped with.

STO –Safe Torque OFF

Abbreviations used in this document

Operating Manual Rev. 1.3 www.engelantriebe.de page 5

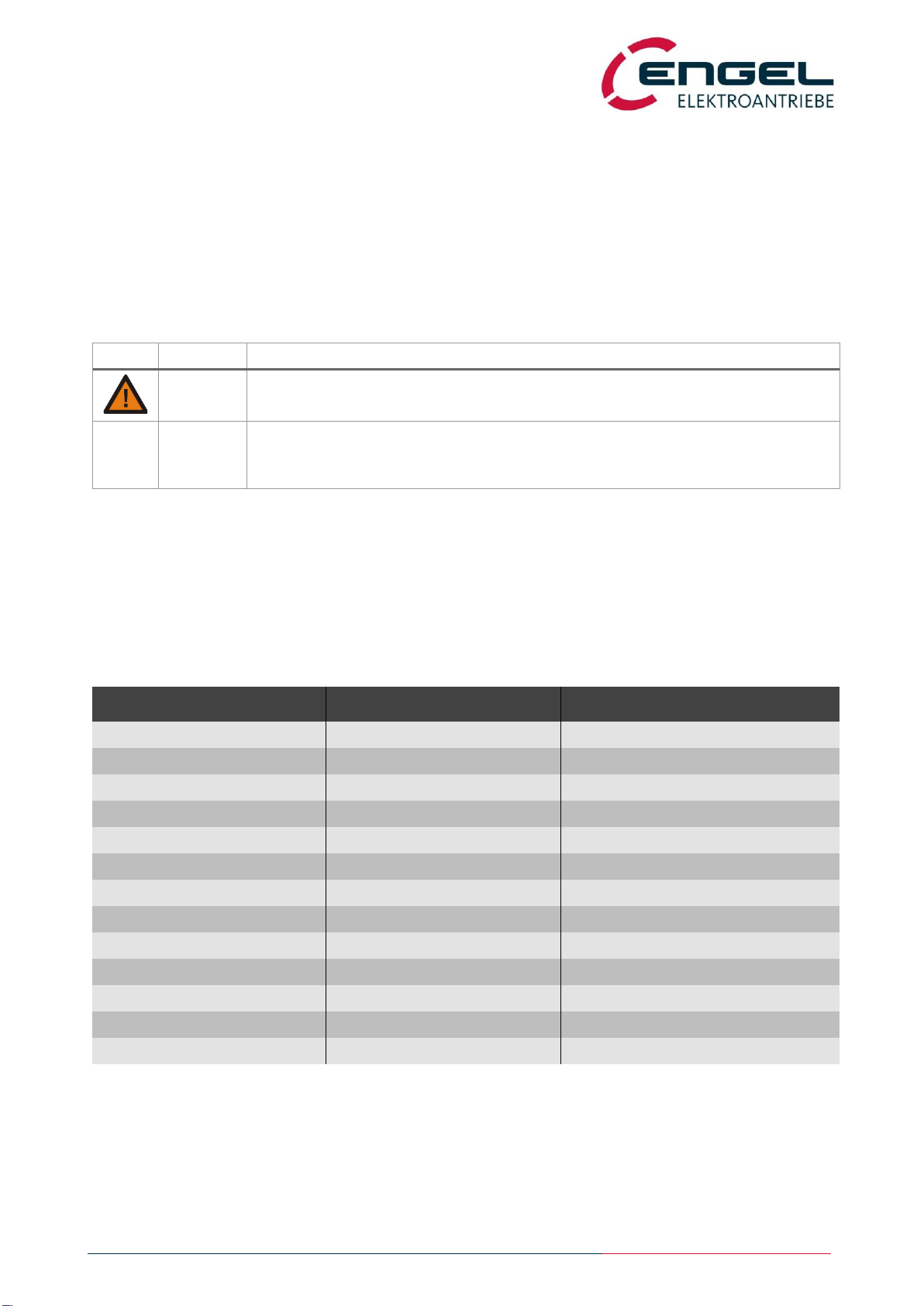

4Abbreviations used in this document

Abbreviation

Meaning

DCavg

Average Diagnostic Coverage

HFT

Hardware Fault Tolerance

MTTFd

Mean Time To Dangerous Failure

OSSD

Output Signal Switching Device

PELV

Protected Extra Low Voltage

PFD

Probability of dangerous Failure on Demand

PFH

Probability of dangerous Failure per Hour

PL

Performance Level

SELV

Safety Extra Low Voltage

SFF

Safe Failure Fraction

SIL (SC)

Safety Integrity Level (Systematic Capability)

STO

Safe Torque Off

5Safety information

5.1 General safety information

Always observe the safety information in the operating manual of the drive used.

5.2 Intended use

The drives of the HFI series with integrated STO module may only be used under the following conditions:

-The drive is in technically perfect condition.

-The drive is in its original condition without any unauthorised modifications.

-The limit values listed in the

Technical Data

chapters of the operating manual and in this STO document

(see chapter 7 Technical data) are complied with.

-Use in the industrial sector.

Attention!

Potential danger of the safety function becoming ineffective:

•Observe the ambient and installation conditions! (see chapter 7.1 System data)

•Never bypass the safety function!

•Do not open the housing!

•Never carry out unauthorised repairs on the device!

Attention!

In the event of damage resulting from unauthorised modification or non-intended use,

the warranty and liability claim against the manufacturer shall expire.

STO –Safe Torque OFF

Safety information

Operating Manual Rev. 1.3 www.engelantriebe.de page 6

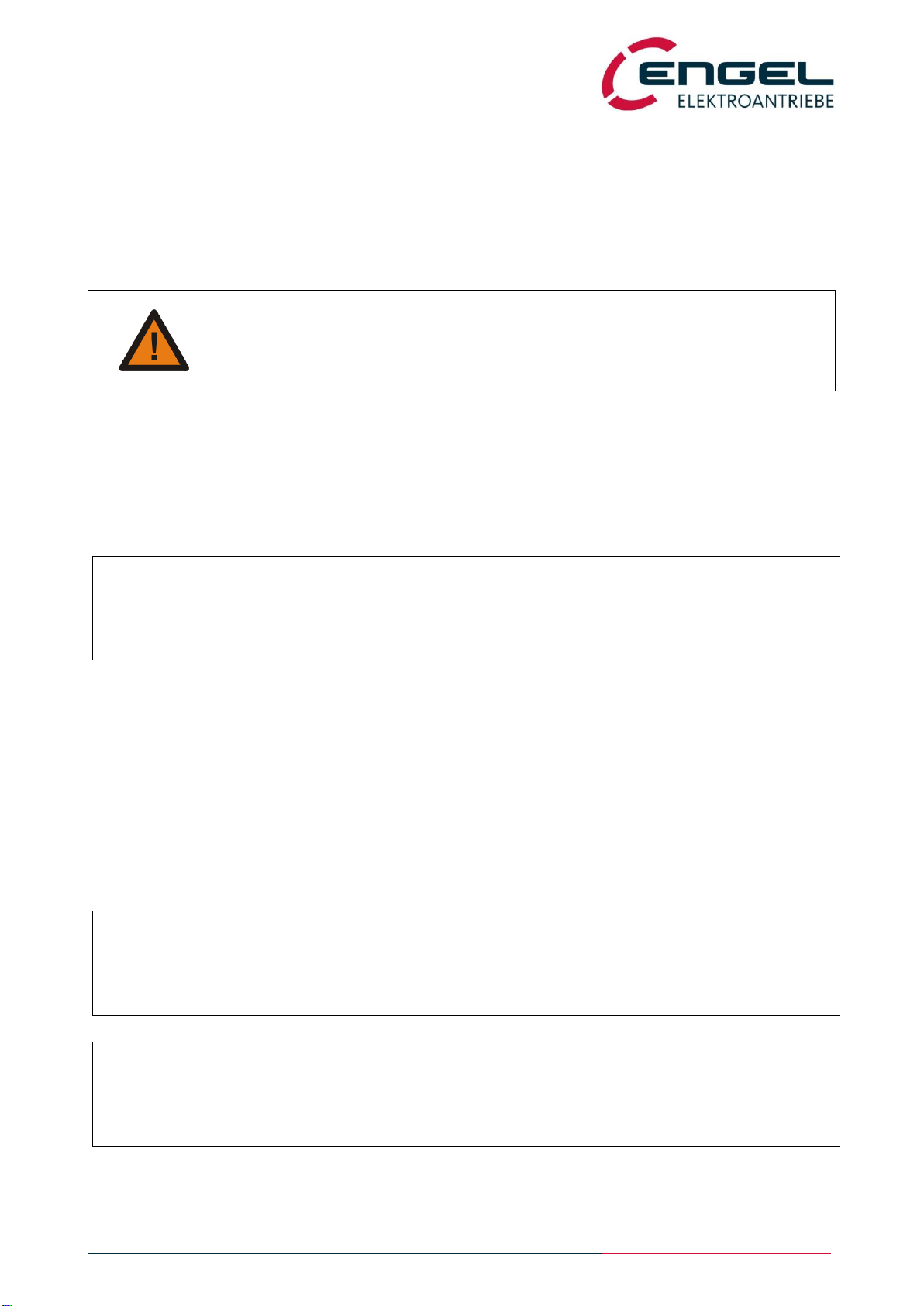

5.3 Non-intended use

The non-intended use of the HFI integrated drives includes, among other things:

-Use outdoors.

-Use in non-industrial areas (residential areas).

-Use in applications where switching off can lead to dangerous movements or conditions.

5.4 Achievable safety level

The drives of the HFI series with integrated STO function meet the requirements of the test specifications:

-Category 3 / PL e according to EN ISO 13849-1/-2

-SIL 3 according to EN61508, IEC 61800-5-2, EN62061

Note!

The achievable safety level depends on the other components used to implement a safety

function.

5.5 Requirements for safe operation

The requirements for safe operation are:

-The correct integration of the safety function of the device into the overall system. The system/machine manufacturer

must always carry out a system/machine-specific risk assessment in accordance with DIN EN 60204-1.

-Compliance with the specifications in this STO document and in the operating manual of the entire drive.

-Consideration of the legal regulations for the place of destination.

-For emergency stop applications, protection against automatic restart must be provided according to the required

safety category.

Note!

Depending on the application, measures may be required to prevent the drive from restarting

immediately upon deactivation of the STO safety function.

Note!

Depending on the application of the drive and irrespective of its STO safety function, measures

in accordance with DIN EN 60204-1 may become necessary to prevent unexpected start-up.

Attention!

Suspended loads or externally acting load forces must be secured by means of additional

measures!

STO –Safe Torque OFF

Safety information

Operating Manual Rev. 1.3 www.engelantriebe.de page 7

5.6 Qualified personnel

The device may only be commissioned and operated by personnel who are trained in:

-the installation and operation of electrical control systems

-the applicable regulations for the operation of safety-related installations

-the applicable regulations for accident prevention and occupational safety

-the available documentation on the drives with STO functionality

Note!

The design of a system according to safety aspects requires expert knowledge. A safe system

can only be achieved after expert, normative assessment.

The mere use of safety components without further assessment is not sufficient!

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 8

6Functional description

The Safe Torque Off (STO) function is ensured by a redundant pulse inhibit. When the STO safety function is engaged,

the pulse inhibit disconnects the torque-determining pulse patterns (PWM) generated by the drive's microcontroller from

the power stage. Without suitable pulse patterns, the power stage is unable to develop a continuous torque in the motor

system, the motor is de-energised and torque-free.

6.1 Inputs of the STO channels

The safe pulse inhibit of the STO module has a dual-channel redundant design. Each channel has a digital input to control

its safety sub-function of the pulse inhibit.

When both STO channels are voltage-free (0 V), e.g. both inputs are open, the pulse inhibit is safely activated.

When both STO channels are supplied with voltage (24 V), the pulse inhibit is deactivated and the drive can be operated.

Activation of the STO function ➔Channel STO1 = 0 V AND Channel STO2 = 0 V

Normal operation of the drive ➔Channel STO1 = 24 V AND Channel STO2 = 24 V

Both STO channels must always be operated simultaneously and consistently, i.e. equivalently.

The STO inputs allow a direct connection to …

-safe switching contacts such as electromechanical safety relays,

-safe semiconductor outputs such as electronic safety relays,

-passive safety sensors such as position switches with forcibly guided contacts

(see Figure 6-1: STO function with emergency stop device),

-active safety sensors such as light grids with OSSD signals

(see Figure 6-2: STO function with OSSD signals).

Test pulses from OSSD switching devices type C with a pulse duration of ≤ 1.0 ms and a period duration ≥ 500 ms do not

affect the safety function. This means that the test pulses are safely blanked and that the STO function will not be activated.

Note!

No cross-circuit detection of STO channels 1 and 2 is performed, neither by the STO module

nor by the drive.

According to DIN EN 61800-5-2, a cyclical test must be carried out every 3 months at the

latest to ensure the specified PFH value (see chapter 6.2.2 Diagnostic test).

Attention!

Note the following systematic behaviour of the drive:

In the event of a fault, a possible movement of the motor shaft of 60° (mech.)

cannot be ruled out, even if the STO safety function is activated!

When the safety function is activated and a defect occurs at the internal power stage on at

least two of the three motor phases, i.e. a total of two defects, motor phases can be energised.

In this case, a torque and a limited movement of the motor shaft may occur despite the

activated safety function, whereby the maximum angle of rotation of the motor shaft is limited

to 180° of the electrical period of the motor. For the 6-pole motor systems of the HFI series,

this corresponds to a mechanical angle of rotation of 60°.

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 9

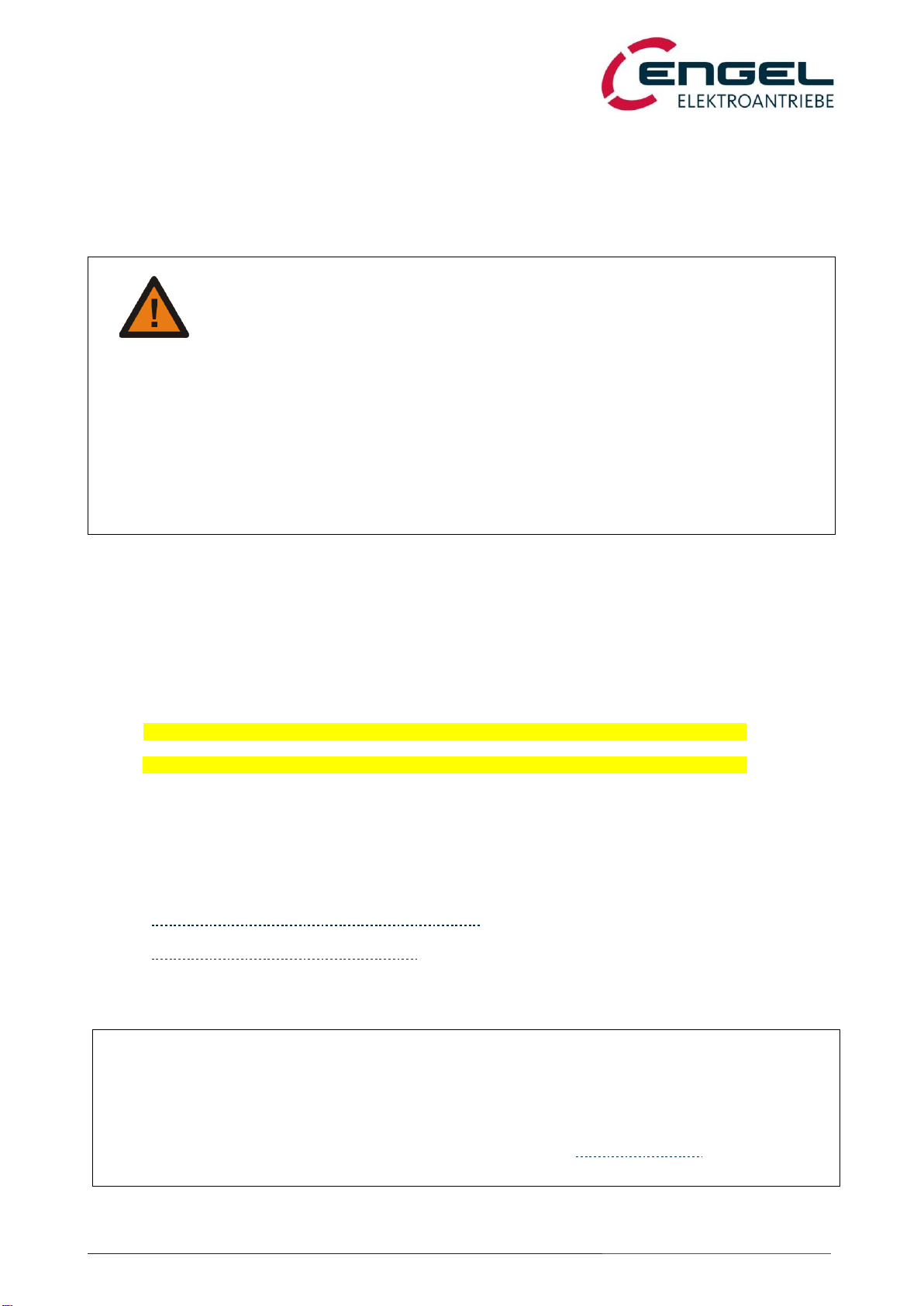

Figure 6-1: STO function with emergency stop device

Figure 6-2: STO function with OSSD signals

The integrated drive can be supplied by either a PELV or SELV power source.

The safety circuit, i.e. the STO channels, can as well be supplied by either a PELV or SELV power source.

For drives with a supply voltage of 24 V, it is permissible to supply the STO channels from the 24 V power supply of the

integrated drive.

Each STO input and the status output are galvanically isolated from each other and from the control electronics of the

integrated drive.

Note!

An incorrect wiring of the STO inputs can result in a lower safety level. By connecting input

„a‟to „c‟, for example, the external dual-channel structure of the system is lost.

STO Input 1

STO Input 2

STO Status

Controller

Pulse

Inhibit

Power

Stage

and

Motor

a

b

c

d

S

Emergency Stop

Device

GND

24 VDC

SELV/PELV Power Supply

HFI-Sx00

STO Input 1

STO Input 2

STO Status

Controller

Pulse

Inhibit

Power

Stage

and

Motor

a

b

c

d

S

OSSD

Switching Device

GND

24 VDC

SELV/PELV Power Supply

Output 1

Output 2

HFI-Sx00

Test Pulses

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 10

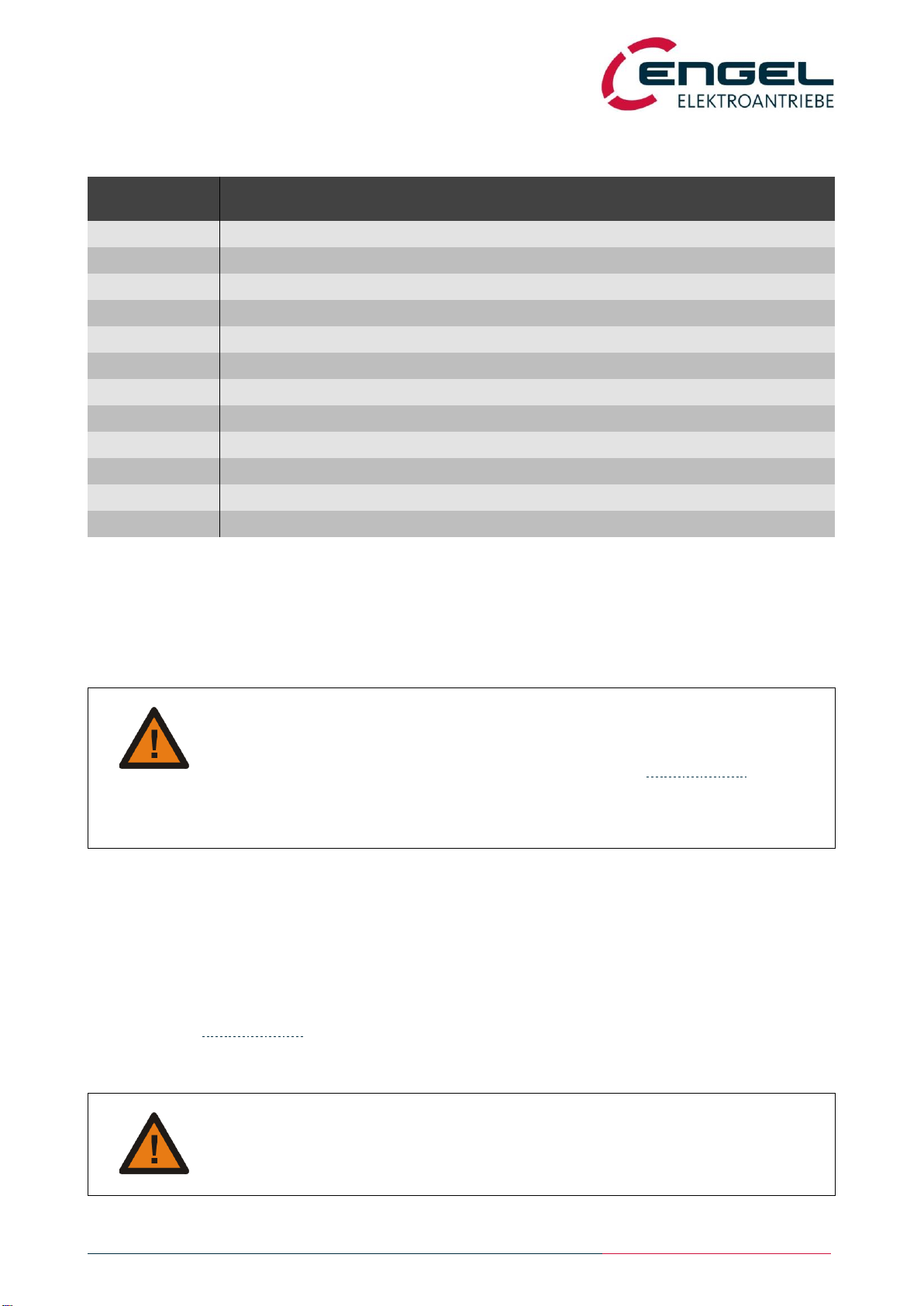

6.2 STO status signal

6.2.1 Functionality of the status signal and the status output

The status of the STO safety function is signalled via a potential-free semiconductor output. Only when the safety function

is activated the semiconductor output is closed, i.e. conductive.

The status output can be used to signal the status of the safety function to a higher-level control unit.

The status output has reverse polarity protection and is protected against overload and short circuit by a resettable fuse.

Channel1

VSTO1

Channel2

VSTO2

Status Output

Note

0 …5 V

(OFF)

0 …5 V

(OFF)

closed / conductive

Both STO channels voltage-free, unsupplied:

STO active = safe state

24 V

(ON)

0 …5 V

(OFF)

open / non-conductive

Invalid state:

STO channels inconsistently driven

0 …5 V

(OFF)

24 V

(ON)

open / non-conductive

Invalid state:

STO channels inconsistently driven

24 V

(ON)

24 V

(ON)

open / non-conductive

Both STO channels supplied with voltage:

Safety function deactivated,

normal operation of the drive available

Figure 6-3: Circuit diagram of the status output

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 11

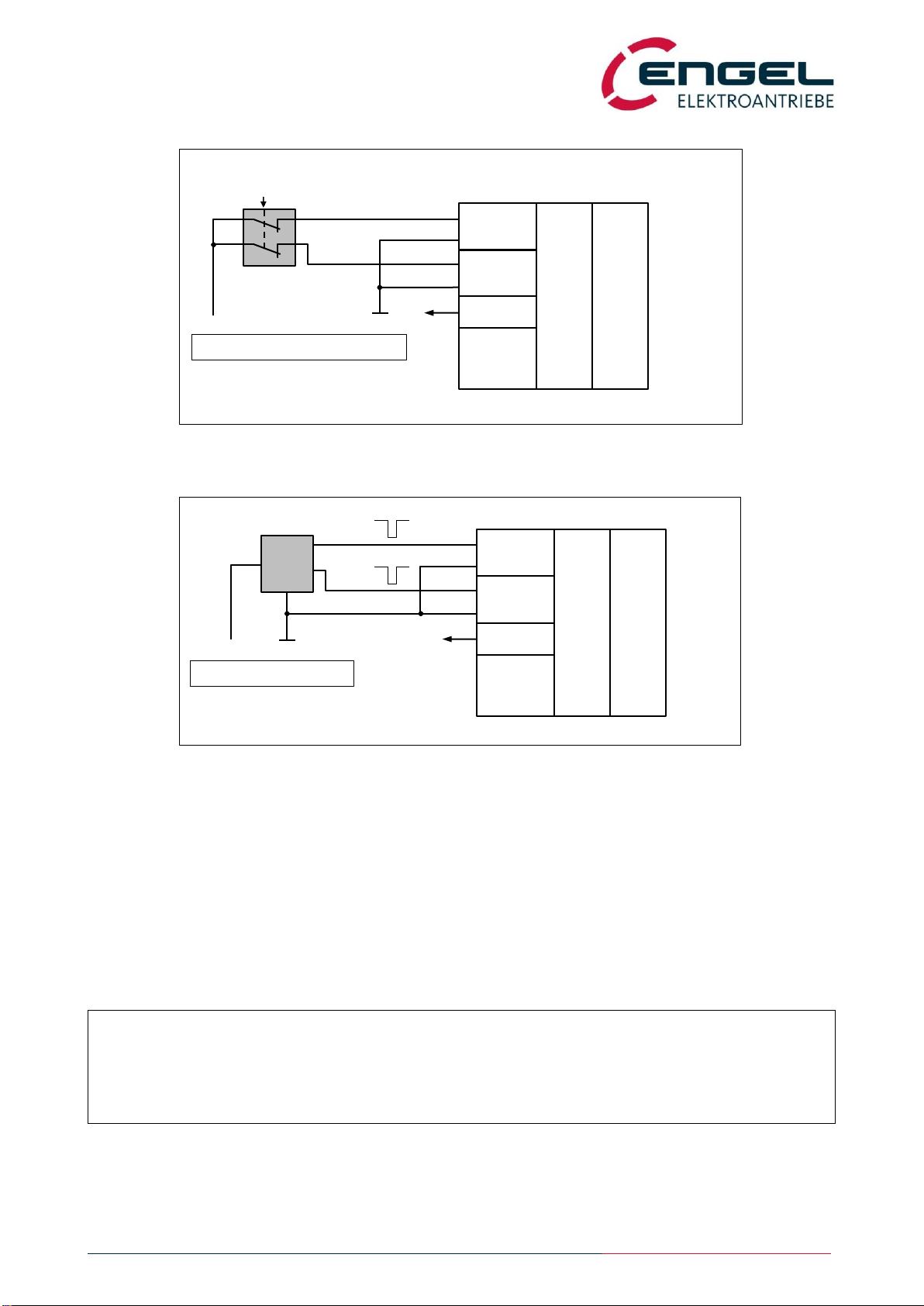

6.2.2 Diagnostic test

According to DIN EN 61800-5-2, a cyclical test of the proper function of the status output must be carried out at least

every 3 months to ensure the specified PFH value.

For this purpose, the two STO channels are stimulated in a test sequence with different input states (test steps 1 –6).

In each test step, the state of the status output is compared to its target state specified in the table below. The correct

function of the status output is only fulfilled, when the status output reacts according to the target states in all 6 test steps

in succession.

The test sequence can be carried out manually or automatically by means of a control unit.

Test

Step

Channel1

VSTO1

Channel2

VSTO2

Status Output

Target State

Note

1

0 …5 V

(OFF)

0 …5 V

(OFF)

closed

conductive

Both STO channels voltage-free, unsupplied:

STO active = safe state

2

24 V

(ON)

0 …5 V

(OFF)

open

non-conductive

Invalid state:

STO channels inconsistently driven

3

0 …5 V

(OFF)

0 …5 V

(OFF)

closed

conductive

Both STO channels voltage-free, unsupplied:

STO active = safe state

4

0 …5 V

(OFF)

24 V

(ON)

open

non-conductive

Invalid state:

STO channels inconsistently driven

5

0 …5 V

(OFF)

0 …5 V

(OFF)

closed

conductive

Both STO channels voltage-free, unsupplied:

STO active = safe state

6

24 V

(ON)

24 V

(ON)

open

non-conductive

Both STO channels supplied with voltage:

Safety function deactivated,

normal operation of the drive available

Note!

The status signal / status output is for diagnostic purposes only and has no safety rele-

vance. It must not be used in the safety circuit!

Note!

Measuring and contact points should be provided (in the control cabinet, for example) to make

a manual diagnostic test possible and practicable.

A software aided diagnostic test is permissible.

Note!

The values listed under Safety parameters are valid on condition that the specifications of this

diagnostic test are observed. Therefore, the diagnostic test must be carried out for dual-chan-

nel systems as well as for single-channel systems.

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 12

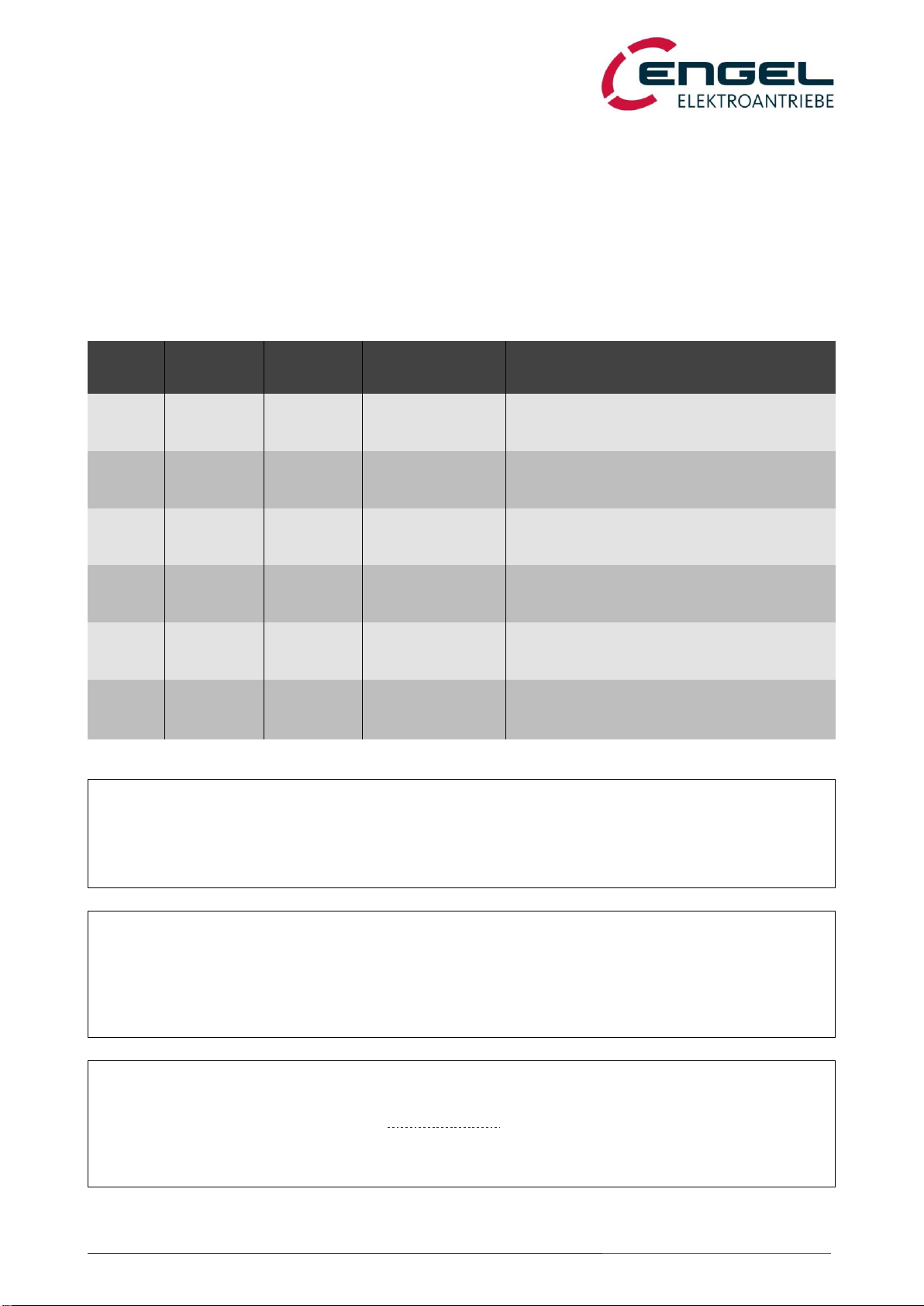

6.2.3 Switch-off time of the safety function

After both STO channels are de-energised (0 V …VSTO1/2 …5.0 V), the safety function (disconnection of the PWM pulse

patterns) is guaranteed after a switch-off time of 20 ms max.

Figure 6-4: STO function switch-off time

Note!

There is no discrepancy time monitoring between the signals STO1 and STO2! This means

that there is no defined time interval within which both STO input signals must have reached

the same switching state.

STO1

0 V

24 V

STO2

0 V

24 V

Status

non-

conductive

conductive

STO active

Normal

operation

Normal

operation

Switch-off time

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 13

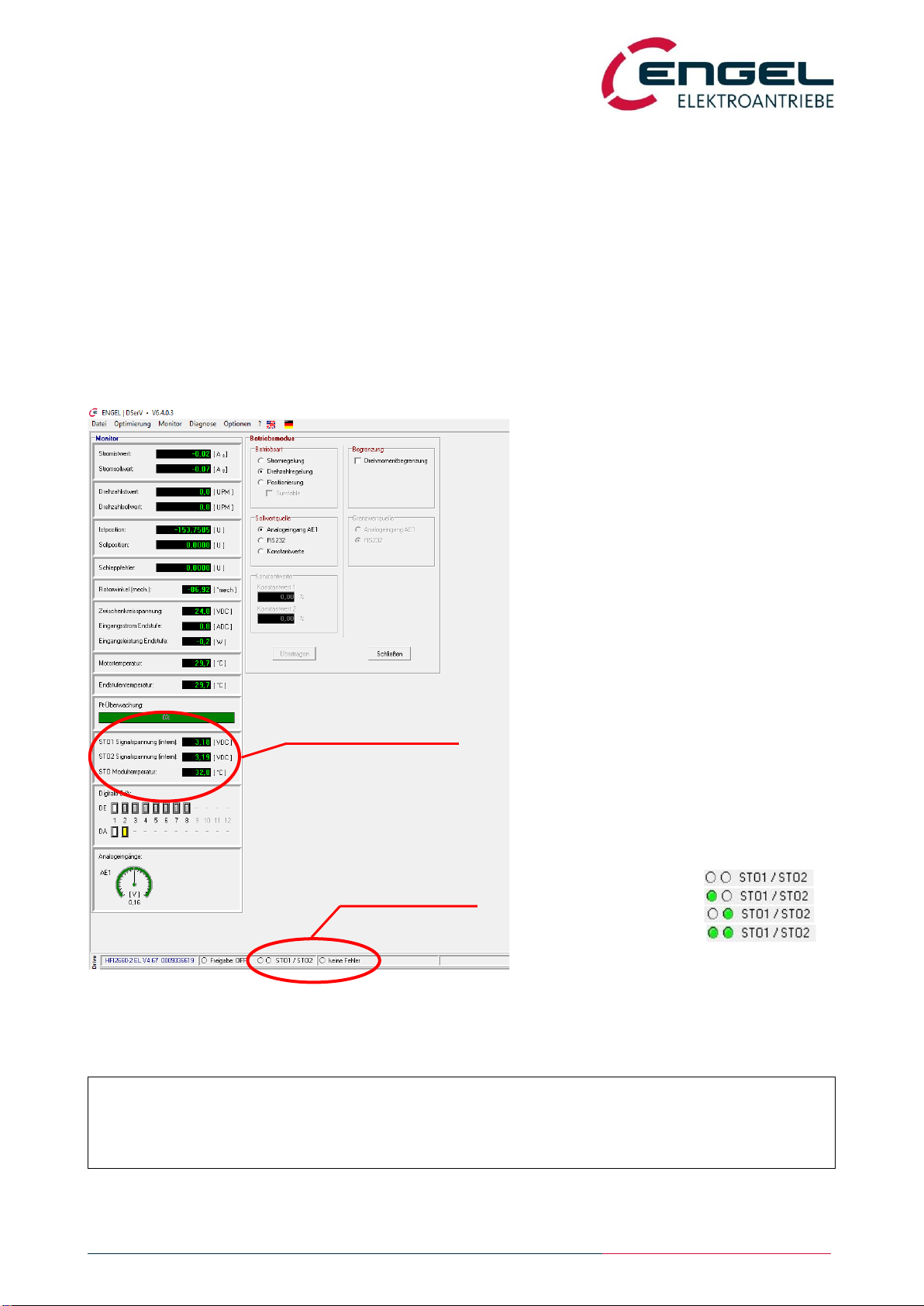

6.2.4 Firmware

The STO functionality is supported from firmware version V4.00 of the HFI series of integrated drives. The pulse inhibit of

the STO is hardware-based, i.e. the firmware of the integrated drives has no influence on the STO safety function. The

firmware is not safety-relevant.

The pulse inhibit is available at all times and works independently of other settings and operating modes of the integrated

drives.

The firmware monitors the internal signal voltages of the STO channels as well as the temperature of the STO module. In

the event of impermissible operating conditions, error messages are triggered that switch off the drive via its standard

functionality.

From version V6.403, the parameterisation software DSerV supports the STO functionality.

Figure 6-5: DSerV with STO visualisation

Note!

The parameterisation software DSerV is described in the operating manual of the HFI series.

STO status indication

and error indication

Internal signal voltages

and module temperature

STO STO

input signals status indication

STO1= 24 V / STO2= 24 V

STO1= 0 V / STO2= 24 V

STO1= 24 V / STO2= 0 V

STO1= 0 V / STO2= 0 V

STO –Safe Torque OFF

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de page 14

6.3 Error messages

The firmware of the integrated drive monitors various variables and conditions and triggers error messages (including STO

error messages) as soon as defined limit values or tolerance ranges are exceeded. In this case, the drive is deactivated,

but solely via its normal, non-safe function.

Some of the STO error messages are only triggered when the controller enable of the integrated drive is active, i.e. without

controller enable only the temperature monitoring of the STO module is active and no other STO error messages are

triggered. The following table lists the error messages resulting from the non-safety-relevant monitoring of the STO

module.

Error Code

(Fieldbus)

Error Code

(DSerV)

Error Description

Cause / Measure for error rectification

F080h

13.00000

Generic STO error

Internal error / No action

F081h

13.00002

Signal voltage STO1 ≤min

STO channel 1 voltage too low /

Operate STO channel with the specified voltage

F082h

13.00003

Signal voltage STO1 ≥max

Internal error / No action

F083h

13.00257

Temperature of STO > 115 °C

Overheat / Check operating conditions

F084h

13.00512

Signal voltage STO2 ≤min

STO channel 2 voltage too low /

Operate STO channel with the specified voltage

F085h

13.00514

Signal voltage STO1 ≤min

and

Signal voltage STO2 ≤min

STO channel 1+2 voltages too low /

Operate STO channels with the specified voltage

F086h

13.00515

Signal voltage STO1 ≥max

and

Signal voltage STO2 ≤min

Internal error / No action

F087h

13.00768

Signal voltage STO2 ≥max

Internal error / No action

F088h

13.00770

Signal voltage STO1 ≤min

and

Signal voltage STO2 ≥max

Internal error / No action

F089h

13.00771

Signal voltage STO1 ≥max

and

Signal voltage STO2 ≥max

Internal error / No action

Note!

For a safe deactivation of the drive, it is always required that the STO function is activated!

This also applies if the drive has already been deactivated due to an error message.

Note!

If internal errors occur, the unit must be replaced!

Repairs and interventions by the user are not permitted!

STO –Safe Torque OFF

Technical data

Operating Manual Rev. 1.3 www.engelantriebe.de page 15

7Technical data

7.1 System data

Designation

Unit

Value

Additional information

min

typ

max

Permissible input voltage

STO channel 1/2 (VSTO1/VSTO2)

VDC

0

28.8

SELV/PELV

Overvoltage protection up to 60 V

Input voltage for deactivation

of STO channel 1/2

VDC

20.4

28.8

24 V -15 % / +20 % (≤ 5 % AC)

VSTO1 / VSTO2

Input voltage for activation of

STO channel 1/2

VDC

0

5.0

Current consumption

STO channel 1/2

mA

12

at VSTO1/2 = 24 V

Status output reverse voltage

VDC

24

30

Load current max. 50 mA

Voltage drop at 50 mA:

U ≤2 V

STO switch-off time

ms

20

Time between activation of the

STO function and the safe deacti-

vation of the power stage

Ambient temperature

°C

0

40

No condensation permissible

Storage temperature

°C

-25

75

No condensation permissible

Permissible altitude

m

2000

[m above sea level]

Max. cable length

m

20

Permissible max. cable length

of the STO inputs (M12 con-

nector)

OSSD pulse duration

ms

1.0

OSSD period duration

ms

500

Working life

years

20

due to design

Electromagnetic compatibility

Emission*1)

DIN EN 61800-3: 2019-04

According to category C2

Immunity

DIN EN 61800-3: 2019-04

DIN EN 61800-5-2: 2017-11 *2)

According to category C3

/ second environment

Insulation strength

Overvoltage Category III Surge Voltage 800 V

between each STO channel,

status output and control unit

*1) Conducted emissions towards the AC mains must be suppressed in the power supply unit of the device.

*2) Concerning the functional safety.

STO –Safe Torque OFF

Technical data

Operating Manual Rev. 1.3 www.engelantriebe.de page 16

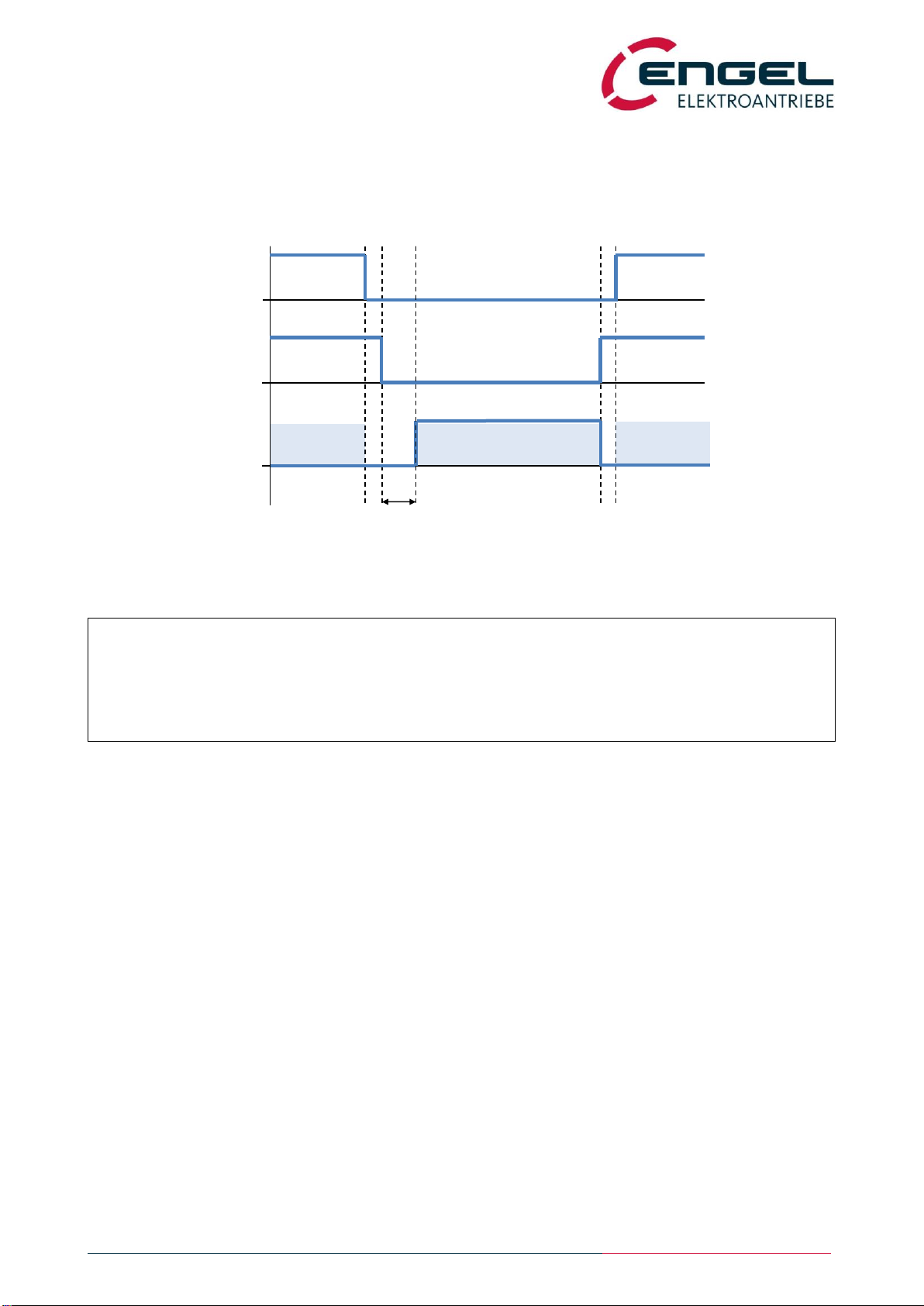

7.2 Safety parameters

Designation

Unit

Standard

Additional information

62061

61508

13849

HFT

1

1

Hardware fault tolerance

PFH

1/h

4.73 ∙ 10-11

9.12 ∙ 10-11

Probability of dangerous failure

per hour

PFD

1.04 ∙ 10-7

7.89 ∙ 10-6

Probability of dangerous failure

on demand

SFF

%

99.92

99.92

Safe failure fraction

(Percentage of failures that do

not affect the safety function)

SIL (SC)

3

3

Safety integrity level

DCavg

%

0.00

Average diagnostic coverage

MTTFd

years

25974

Mean time to dangerous failure

PL

e

Performance level

Cat

3

Category

7.3 Certification

Designation

Type examination

The functional safety technology of the product has been tested and certified as a

safety component to Annex IV of the European Machinery Directive 2006/42/EG.

Safety function „Safe Torque Off‟ (STO) according to DIN EN 61800-5-2 2017

Safety of machinery.

Certificate-issuing authority

TÜV Rheinland Industrie Service GmbH, Köln

7.4 Maintenance

The integrated drives from ENGEL Elektroantriebe GmbH do not require any special maintenance measures. A defective

drive must be completely replaced. Repairs are not permitted.

STO –Safe Torque OFF

Pin assignment / Installation / Commissioning

Operating Manual Rev. 1.3 www.engelantriebe.de page 17

8Pin assignment / Installation / Commissioning

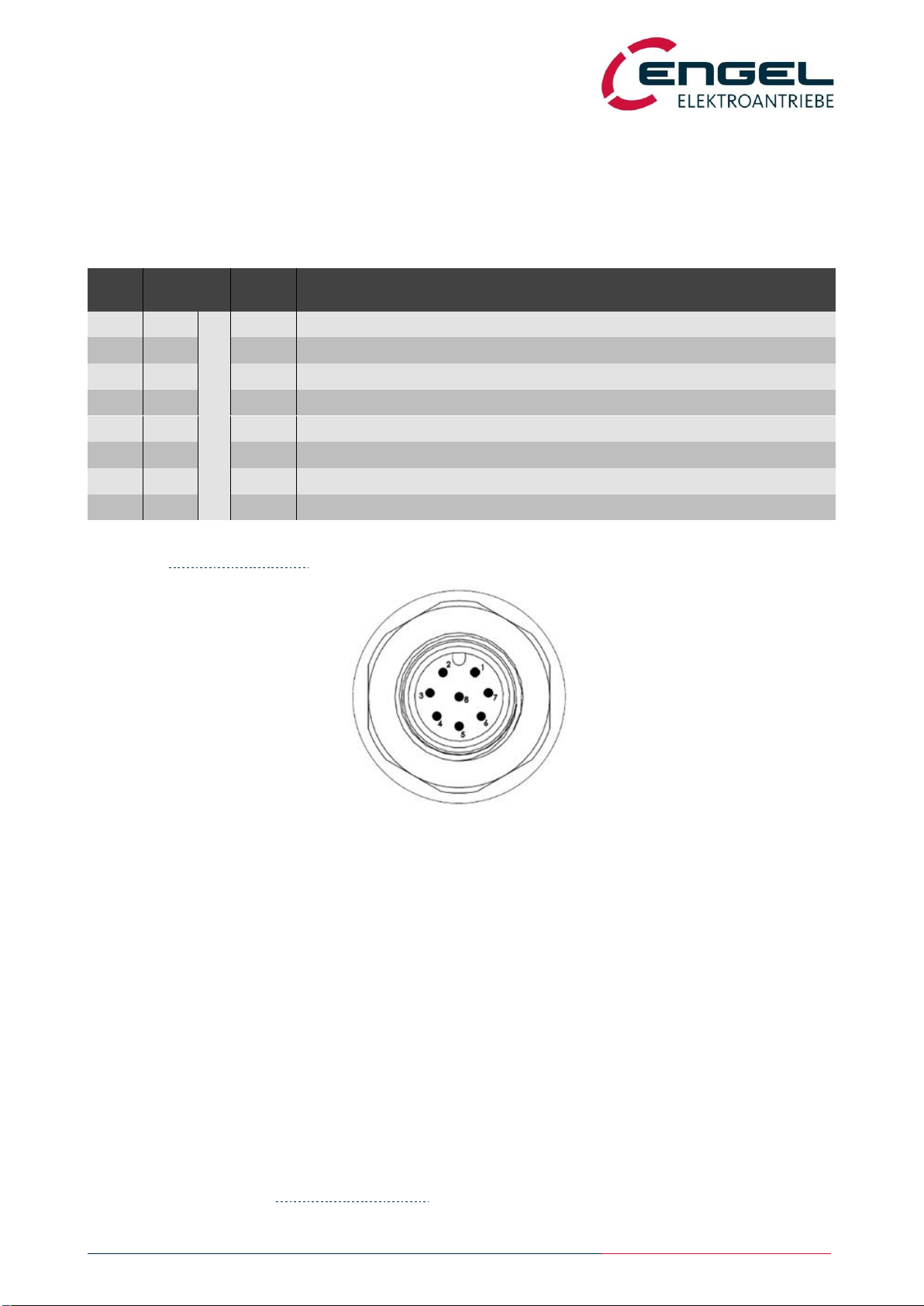

8.1 X3 –STO signal plug

Connector on the device: 8-pin M12 circular connector (male, A-coded)

Mating plug: 8-pin M12 circular connector (female, A-coded)

Pin-

No.

Wire 1

Name

Description

1

WH

8 x 0.25 mm2

Status+

Potential-free status output (positive potential, collector)

2

BN

Status-

Potential-free status output (negative potential, emitter)

3

GN

STO1-

STO channel 1 supply, reference potential, 0 V

4

YE

STO1+

STO channel 1 supply, positive potential, 24 V

5

GY

n.c.

6

PK

STO2+

STO channel 2 supply, positive potential, 24 V

7

BU

STO2-

STO channel 2 supply, reference potential, 0 V

8

RD

n.c.

1Wire colours and cross-sections apply to assembled STO connection cables from ENGEL Elektroantriebe GmbH

(see chapter 8.2 STO connection cable).

8.2 STO connection cable

Recommendations for the properties of the STO connection cable:

● recommended wire cross-section: 0.25 mm²

● overall shield

● suitable for drag chains, operating temperature min. +80 °C

● cable length max. 20 m

ENGEL original accessories:

Item-No.: 9900000650 SK_STO_M12_NC_5 signal cable STO | M12 | NC length 5 m

Item-No.: 9900000651 SK_STO_M12_NC_15 signal cable STO | M12 | NC length 15 m

Cable assembly with M12 connection plug, open on one end,

8 x 0.25 mm², overall shield, PUR, -30 °C … +90 °C, suitable for drag chains.

(For wire colours, see chapter 8.1 X3 –STO signal plug.)

Figure 8-1: Pin layout of the STO signal plug

View on the mating side of the receptacle on the drive

STO –Safe Torque OFF

Pin assignment / Installation / Commissioning

Operating Manual Rev. 1.3 www.engelantriebe.de page 18

8.3 Installation diagrams

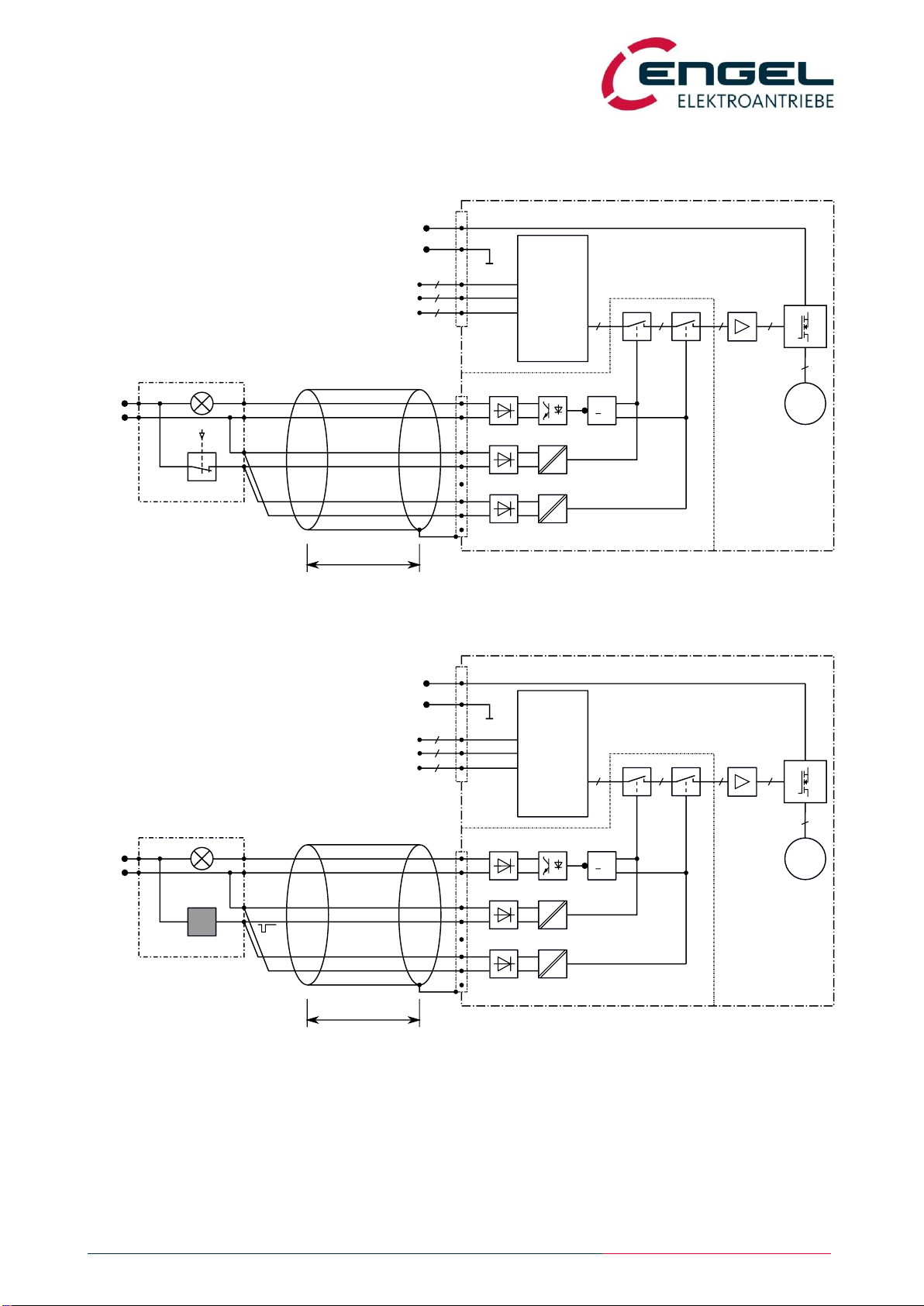

8.3.1 Examples for dual-channel STO connection

Figure 8-2: Dual-channel STO connection with emergency stop device

Figure 8-3: Dual-channel STO connection with OSSD switching device

The installation diagrams in the figures above show the dual-channel connection assignment of the STO function.

STO –Safe Torque OFF

Pin assignment / Installation / Commissioning

Operating Manual Rev. 1.3 www.engelantriebe.de page 19

8.3.2 Examples for single-channel STO connection

Figure 8-4: Single-channel STO connection with emergency stop device

Figure 8-5: Single-channel STO connection with OSSD switching device

The installation diagrams in the figures above show the single-channel connection assignment of the STO function.

STO –Safe Torque OFF

Pin assignment / Installation / Commissioning

Operating Manual Rev. 1.3 www.engelantriebe.de page 20

8.4 Commissioning information

In addition to the commissioning instructions described in the operating manual of the HFI series, the following steps have

to be executed:

Step 1: Wire the connections of the STO module properly according to the installation diagram.

Step 2: Check the wiring.

Step 3: Validate the functionality of the drive and the safety function.

Step 4: Perform a diagnostic test according to chapter 6.2.2 Diagnostic test.

This manual suits for next models

12

Table of contents

Other Engel Servo Drive manuals