ENGGA EVC800i Guide

EVC800i AUTOMATIC VOLTAGE REGULATOR

SPECIFICATIONS

The EVC800i is a 3 Phase full wave, pulse width modulated type of Automatic Voltage Regulator for regulating the voltage

of Brushless Generator.

Excitation power can be derived from a shaff mounted 3 Phase premanent generator (PMG) or stator winding or Auxillary

winding. Internal electrical isolation is created between the PMG inputs and sensing inputs of AVR. This isolation with the

PMG assures the performance of the AVR against Non linear loads and reduces the Radio frequency interference on the

generator terminals. The PMG supply enables the generator to maintain current into a short circuit.

Sensing to AVR is directly from main winding. This signal is used to control the power fed to the exciter stator (and hence

to the main rotor) to maintain the generator output voltage within the specified limits. Provision is made for the connection

of remote potentiometer allowing the user to find control generator output voltage.

Built up of generator output voltage is fully under control manner keeping excitation current within limits and with soft start.

A frequency measuring circuits continually monitors the speed of the generator to provide low speed protection to the

excitation system. It reduces generator output voltage proportionally with speed below an adjustable threshold as per volt

per hertz slope. This slope is provided adjustable and adjusted by DIP adjustment trimmer. In addition to DIP, an delayed

voltage recovery (DWELL) is provided to improve speed recovery time when generator is used in conjunction with Turbo

charge engines. Generator overload circuit cuts off the excitation power in the event of excessive load on generator or

malfunctions. AVR observe overload condition for 20 seconds and after that cuts off the field voltage.

This condition remains latched until the generator has stopped.

For connecting 2 or more generators in parallel, quadrature droop and analog inputs provide reactive power sharing

controls.

Specification, Installation & Adjustment Manual

DESCRIPTIONS

Sensing Input

Power Input

Output

Built up Voltage

Voltage Regulation

Response Time

V - V for 220 Vac,

V - V for 400 Vac, 350 to 480Vac, 50/60Hz

PMG : 160 to 250 V, 3 Ph, 50 to 400 Hz.

Main Winding : 160 to 250 V, 1 Ph

Auxillary : 160 to 250 V, 1 Ph

Voltage : 180 Vdc on Input of 200 Vac

Current : Continuous 8 Amps

Residual Voltage : >4 Vac at AVR terminal

: < 1 % RMS

: < 20 mSec

0 200

380

180 to 250Vac, 50/60Hz

±

7 to 18 Ohms.

Maximum Input : ± 5Vdc

Sensitivity : 1 Volt for 2 % generator Volts

0

Field Resistance

Analog Input

Burden : 0.25 Ohms

Maximum Sensitivity : 1 Amp for 10 % Droop

Maximum Input : 2 Amps

Factory setting : 47 Hz with Switch 2 OFF

57 Hz with Switch 2 ON

Slope : 100 - 300 % down to 25 Hz

: 1%Hz = 1%Volts to 1%Hz=3%Volts

: Adjustable from 0 to 45 V in 4 Sec Max.

Operating Temperature : -40 to +70 C

Storage Temperature : -40 to +90 °C

Relative Humidity : Max. 95%

Vibration : 3.3Gs @ 100-2K Hz

175 mm L x 129 mm W x 37.5 mm H

XXXX

External Volts Adjustment

Atleast ± 10 % with 100 K Ohms 1 Watt trimmer

°

Droop Input

Under frequency protection

DIP

DWELL

Environment

Dimension and Weight

AVR CONTROL FUNCTION

CONTROL:

VOLT

STAB

UFRO

TRIM

DROOP

EXC TRIP

DIP

DWELL

SW1-ON

SW1-OFF

SW2-ON

SW2-OFF

FUNCTION:

To adjust generator output voltage

To prevent voltage hunting

To set under frequency Roll Off knee point

To match AVR input to Accessory Input

To set voltage Droop to 10% at 0.8 PF

To set the over-excitation protection Trip level

To adjust frequency related voltage Dip

To set the rate of voltage recovery time

To add fix response time

Response time as per STAB Pot

To set UFRO knee point at higher frequency

To set UFRO knee point at lower frequency

DIRECTION:

Clockwise increases output voltage

Clockwise increase in response

Clockwise increases knee point frequency

Clockwise increases AVR sensitivity

Clockwise increases the Droop

Clockwise increases the Trip level

Clockwise increases the Dip

Clockwise lengthens the recovery time.

SW1-ON : Increase in response time for 60 Hz

SW1-OFF : Response time for 50 Hz

SW2-ON : UFRO set at higher frequency

SW2-OFF : UFRO set at lower frequency

10/02/2015Page 1 of 9

EVC800i AUTOMATIC VOLTAGE REGULATOR

AVR SETTING

Before installing, adjusting or using this product it is important that you read the content of this manual and also become

familiar with the equipment.

Observe all cautions and warning notices

Caution Caution refers to a hazard or unsafe method or practice which can result in product damage.

Warning refers to a hazard or unsafe method or practice which can result in injury or death.

*

Warning This AVR has capacitors which have stored charge present even after stopping the generator and

can remain charge for upto 5 minutes. Terminal F+, F-, P1, P2 and P3 are linked to this charged

capacitor, so do not work on the wiring of AVR or machine until this time has elapsed.

Warning

Do not operate the equipment with the protective generator terminal cover removed.

* All work and adjustment must be carried out by skill technician using instruments and equipments which are regularly

checked for safety.

* Before carrying out any maintenance work, disable engine system, automatic closure circuit and turn off anti

condensation heaters.

* Never expose Live connections unless you have created safe working area around you.

Specification, Installation & Adjustment Manual

SAFETY PRECAUTIONS

Most of the AVR adjusments are factory set in positions which will give satisfactory performance during installation of

generator. But to achieve optimum performance under operating conditions, adjustment of some setting is required and

details are as below :-

The generator output voltage is set to 400 V at the factory but can be altered by adjusting Volt control or by external

trimmer

If a replacement AVR has been fitted or voltage setting is not known then proceed as below:-

1. Before running the generator ensure that the suitable voltmeter is available to measure generator output voltage.

2. Turn the VOLTS control fully anti-clockwise and turn the external hand trimmer (if fitted) to its Midway position.

3. Turn the STAB control to its Midway position.

4. Start the generator set, and run at no load condition at nominal frequency e.g. 50 or 60 Hz.

5. If UFRO LED is ON refer to the UFRO setting.

6. If O/L LED is ON refer to the O/L setting.

7. Carefully turn the capital VOLTS controls clockwise until rated voltage is reached.

8. If voltage instability is present refer to STAB adjustment and then re-adjust the generator voltage if necessary.

Warning During testing it is required to adjust controls which are very near to Live terminals or components.

Only personnel qualified to perform Live electrical service should carried out the testing or

adjustment.

Voltage [VOLTS] Adjustment :

Caution Do not increase the voltage above the rated voltage of the generator.

Stability [STAB] Adjustment :

The AVR Stability circuit ensure good steady state and transient

performance of the generator. In addition to STAB adjustment pot,

SW1 is also provided to quickly change the response of the stability

circuit to suit 50 or 60 Hz application.

The correct setting of the stability control can be achieved as

follows:-

1. Before running the generator select appropriate Sw1 position as

per the frequency of the generator.

2. Turn the STAB control to its mid-way position.

3. Run the generator at no load.

4. Slowly turn STAB control clockwise until the generator voltage

become unstable.

5. Slowly return the STAB control anti-clockwise until the voltage

is again stable.

6. Continue to rotate 2 more point anti-clockwise and this is the

correct running position.

10/02/2015Page 2 of 9

1 to 2 Points More Anti-Clockwise

From The Most Stable Point

Stable Point

Voltage

0 50 100

Clock Wise End

Anti Clockwise End Rotations

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 3 of 9

Voltage

37 38 39 40 41 42 43 44 45 46 47 48 49 50

Knee Point

Frequency

Under Frequency Roll Off [UFRO]

V/Hz slope [DIP] Adjustment

Dwell [DWELL] Adjustment

Droop [DROOP] Adjustment.

The AVR incorporation an under speed protection circuit for “Volts

per Hertz” characteristics when the generator speed falls below an

adjustable threshold. Under normal circumstance it would not be

necessary to adjust the factory setting of this control, but using

SW2, 47 or 57 Hz is quickly adjusted.

To re-adjust the UFRO knee point then proceed as follows:-

(It will be necessary to adjust the generator / engine speed during

this procedure)

1. Run the generator at no load and at nominal frequency (50 or

60 Hz)

2. Turn the UFRO control fully anti-clockwise (The red led should

be OFF)

3. Run the generator at required knee frequency (Typically 47 or 57 Hz)

4. Turn the UFRO clockwise until the led illuminates.

5. Return the UFRO control slowly anti-clockwise until the Led just turn off.

6. UFRO adjustment is now complete.

The DIP adjustment controls the amount of frequency related

voltage

dip. This feature is useful when the generator is coupled with the

turbo charged engines with limited step load acceptance capability.

This features only operate when the speed is below the UFRO

knee point and works by increasing the V/Hz slope to give greater

voltage dip in the proportion of falling speed. This also reduce KW

on the generator and helps recovering the falling speed.

With the DIP control fully anti-clockwise the generator voltage

characteristic will follow minimum V/Hz line as the frequency falls

below nominal. (1%Hz=1%V)

Turning the DIP clockwise creates a greater slope in the V/Hz

Characteristics thus aiding engine speed recovery.

The dwell function introduces a time delay between the recovery

of voltage and recovery of speed. The purpose of the time delay

is to reduce the generator KW below the available engine KW

during the recovery period, thus allowing the speed recovery.

Again this control is only functional below the “knee point”, i.e if

the speed stays above the knee point during load switching there

is no effect from the DWELL function setting. Thus function is

mostly used when the generator coupled to turbo charged

engines with limited block load acceptance.

When the DWELL control fully anti-clockwise the generator voltage

will follow the V/Hz line as per UFRO setting. Turning the DWELL

control increases the delay time between the speed recovery and

voltage recovery. The voltage recovery can be held back for several seconds using this switcher.

Generator intended for parallel operation are fitted with quadrature Droop current (CT) which provides a signal for AVR

allowing each generator to share reactive current. The CT is connected to S1 and S2 on the AVR. It is important to

match the generator no load voltage to within 1% of each other, to ensure good reactive load sharing. The Droop

adjustment is factory set to 0% so that during solo operation there is no voltage drop. With the control fully clockwise

is maximum Droop.

For synchronizing, Droop setting procedure is as below:-

1. Run the generator at 50% rated current at any power factor between 0.8 legging and 1.0, ensure that generator rated

current value gives a maximum rating for the frame size without any direct factor.

2. Adjust Droop control such that there is voltage drop of around 3 to 3.5% of the no load voltage.

3. Repeat above sets with the second generator also.

4. Now Droop adjustment is complete with both the set and can be synchronized.

Voltage

37 38 39 40 41 42 43 44 45 46 47 48 49 50

Knee Point

1%Hz = 1%V

1%Hz = 3%V

Voltage

Knee Point

Time

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 4 of 9

Trim [TRIM] Adjustment

Caution Any signal connected to this input must be fully floating and earth free.

Over Excitation [O/L] Adjustment

1. V0 - V200 - V380

2. Excitation Output F+, F- :

3. Power Input :

4. Current Compensation Input S1 and S2 :

5. External Voltage Adjustment VR1-VR2 :

6. Analog Input A+ and A- :

7. Dip Switch : SW1 - ON :

SW1 - OFF :

SW2 - ON :

SW2 - OFF :

An auxiliary input is provided to connect to power factor controller or any other type of PLC controller and is design to

accept DC signal upto +/-5 V.

The DC signal present to this input adds to or subtracts from the AVR reference circuit input and allows the external

controller to alter the generator excitation. The TRIM control allows the user to determine how much control the external

signal has over the AVR. With the Trim control fully clockwise the external signal has full control, with the trim control

fully anti-clockwise has no control.

The AVR includes the protection circuit to remove generator excitation in the event of over excitation, this condition is

usually a result of overload and can damage the rotor component within the generator. The excitation is cut of after a

delay of 20 seconds. During this time delay the overload condition should be continuous. Clockwise rotation of the O/L

control increases the excitation trip level. An over excitation trip condition is indicated by Red LED. The generator must be

stopped to reset the overload trip condition.

: When the generator output voltage required is 220Vac, connect the

sensing input to the terminal V0 and V200. When the generator output voltage requires 400Vac, connect the sensing

input terminal V0 and V380.

Connect Brushless exciter field to terminals F+ and F-, be sure to observe polarity.

AVR power input is on P1, P2 and P3. Input can be 1 Phase or 3 Phase. 3 Phase PMG can be

connected directly to P1, P2 and P3. Without PMG, Main Winding can be used as a power input. In that case for 400V

system connect U to P1 and N to P2. For 200V system connect U to P1 and W to P2. If auxiliary winding is there, then

that can also be used to power the AVR.

Current transformer of In:1A is connected to this terminal for parallel

operation.

If remote adjustment is required then connect a 100K/1W potentiometer to

terminal VR1 and VR2. VR1 and VR2 are left unconnected if remote pot not in use

5Vdc from external controller is connected to A+ and A-

Increases response time. Can be used for 60 Hz machine to increase the response time

(Slow response) or with 220V system when slow response is needed.

Response as per STAB pot set

60 Hz

50 Hz. As per STAB pot set

Sensing Input Terminal

±

WIRING

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 5 of 9

DRAWING

MECHANICAL SPECIFICATION

SW1: ON - Increase in Response Time.

OFF - Response as per STAB pot Set

SW2: ON - 60 HZ

OFF -50 HZ

175 mm

129 mm

143 mm

104 mm

VR

A2

A1

S2

S1

1

VR2

FUSE 8 Amps

4 X 4.4 mm

F-F+ V220 V380

38mm

H

V0

175 mm

129 mm

143 mm

104 mm

ENGGA

DROOP UFRO

TRIM STAB VOLT

www.engga.com.cn

Model EVC800i

Sensing Input V - V for 220 Vac , 180 to 250Vac, 50/60Hz

0 220

V - V for 400 Vac , 350 to 480Vac, 50/60Hz

Power Input 160 to 250Vac

Output 180Vdc , 8A

0 380

:

:

:

:

Outline Drawing

The Drawing For Trimmer

F-

F+ V220

V0V380

P3

P2

P1

1

2

ON

P1 P2 P3

O/L O/L

LED

DIP DWELL

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 6 of 9

P2

F- F+

V220

V380

VR

A2

A1

S2

S1

1

VR2

FUSE 8 Amps

Exciter

Field

+

-

Armature Stator Wire

W

N

V

U

+ 5 Vdc

-

CT

5A

IN :

100K/1W

V0

Connection Diagram with PMG Operation

Note : All doted lines are optional connections.

SW1: ON - Increase in Response Time.

OFF - Response as per STAB pot Set

SW2: ON - 60 HZ

OFF -50 HZ

P3 P1

1

2

ON

P3

P2

P1

PMG

O/L O/L

LED

DIP DWELL

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 7 of 9

AUX

P2

F- F+

V220

V380

VR

A2

A1

S2

S1

1

VR2

FUSE 8 Amps

Exciter

Field

+

-

Armature Stator Wire

W

N

V

U

+ 5 Vdc

-

CT

5A

IN :

100K/1W

V0

Connection Diagram with Auxiliary Winding

Note : All doted lines are optional connections.

SW1: ON - Increase in Response Time.

OFF - Response as per STAB pot Set

SW2: ON - 60 HZ

OFF -50 HZ

P3 P1

1

2

ON O/L O/L

LED

DIP DWELL

EVC800i AUTOMATIC VOLTAGE REGULATOR

Specification, Installation & Adjustment Manual

10/02/2015Page 8 of 9

P2

F- F+

V220

V380

VR

A2

A1

S2

S1

1

VR2

FUSE 8 Amps

Exciter

Field

+

-

Armature Stator Wire

W

N

V

U

+ 5 Vdc

-

CT

5A

IN :

100K/1W

V0

Connection Diagram with Main Winding

Note : All doted lines are optional connections.

SW1: ON - Increase in Response Time.

OFF - Response as per STAB pot Set

SW2: ON - 60 HZ

OFF -50 HZ

P3 P1

1

2

ON O/L O/L

LED

DIP DWELL

Connection option for 400V system

Connection option for 200V system

Table of contents

Other ENGGA Controllers manuals

Popular Controllers manuals by other brands

Dover

Dover All-Flo PSG 72000-00 Installation operation & maintenance

Altronix

Altronix Maximal3FD installation guide

ENERGEN

ENERGEN P8 User manual and safety information

Holman

Holman CLXRGB60 user guide

Comnet

Comnet FVT109B Installation and operation manual

Honeywell

Honeywell S7014A Series quick start guide

Projecta

Projecta INTELLI-START IS3000 instructions

Dungs

Dungs GasMultiBloc MB-ZRD B07 Series Operation and assembly instructions

Johnson Controls

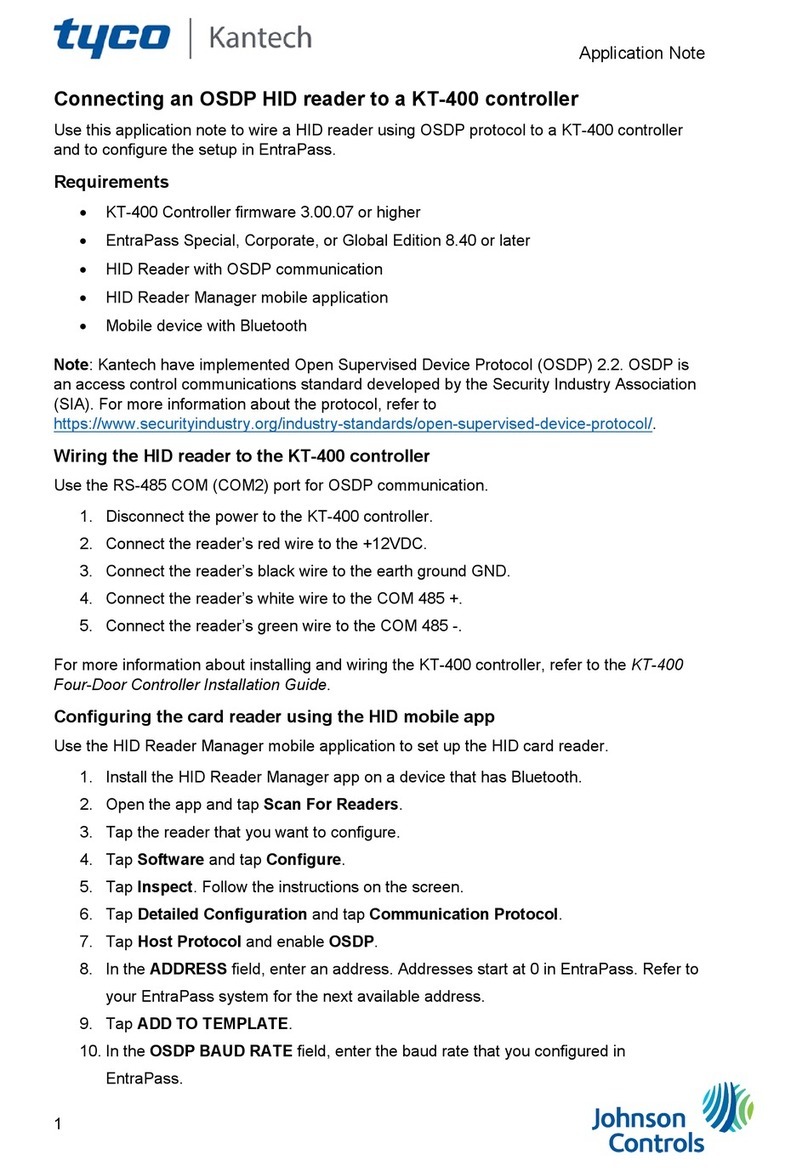

Johnson Controls Tyco Kantech KT-400 Connecting guide

THORLABS

THORLABS BPC301 user guide

SPINEA

SPINEA DRIVESPIN Series Operation manual

Emerson

Emerson FISHER FIELDVUE DLC3010 quick start guide