Enginuity SIPP-600 User manual

SIPP-600, Feb 2012

001-01-000055 Rev. 000

©2012 Enginuity Communications, Inc. Page 1 of 7

Service Interface Protection Panel

Model SIPP-600

SECTION PAGE #

1. OVERVIEW..............................................................1

2. APPLICATION.........................................................1

3. DESCRIPTION........................................................2

4. INSTALLATION.......................................................3

5. TESTING & TROUBLESHOOTING ......................5

6. CUSTOMER SERVICE ..........................................5

7. WARRANTY AND REPAIRS.................................5

8. SPECIFICATIONS ..................................................6

9. ORDERING GUIDE................................................7

1. OVERVIEW

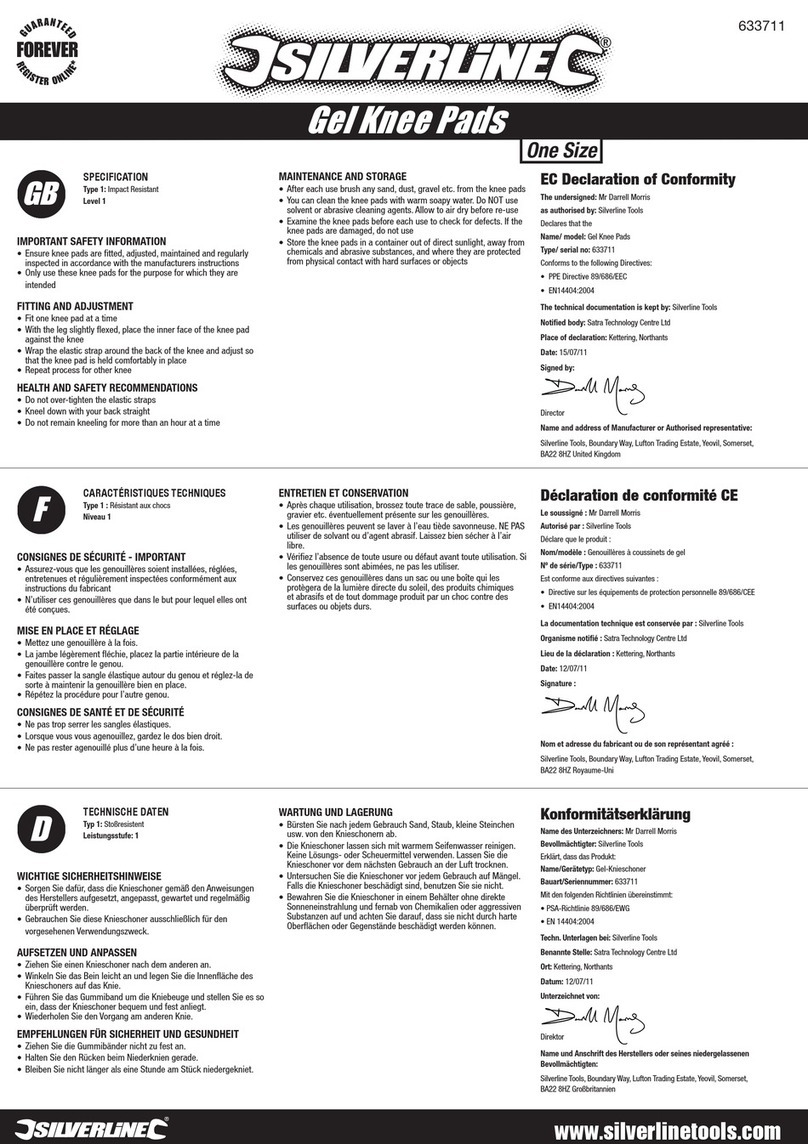

The Service Interface Protection Panel (SIPP), Model

SIPP-600, is a modular and easy to configure interface

that protects network transmission equipment exposed to

outside plant facilities. Advanced technology in the SIPP

provides greater protection to network equipment than

conventional methods. Applications include central

offices, CEVs, and outside plant cabinets - wherever

protection from lightningsurges and AC power faults is

needed.

The base SIPP-600 model is a 6-slot chassis that accepts

plug-in modules to terminate and protect dry-loop

Ethernet, T1/E1, or DS3 services. A fiber interface

module (without protection) is also available, allowing all

high-speed services to be groomed through a single

access panel. A choice of connector configurations

provides added flexibility and utility. The SIPP can be

installed in cabinet or wall mounted.

Document Status

This version of the document (Rev. 000) supersedes all

preliminary (Rev. Pxx) versions.

Product Features

Carrier-class interface for high-speed services:

oEthernet 10/100 or GigE (RJ45)

oT1/E1 (RJ48)

oDS3 (Coax)

Enhanced protection against lightning and AC

power faults

Up to 6 circuits in a compact 1RU chassis

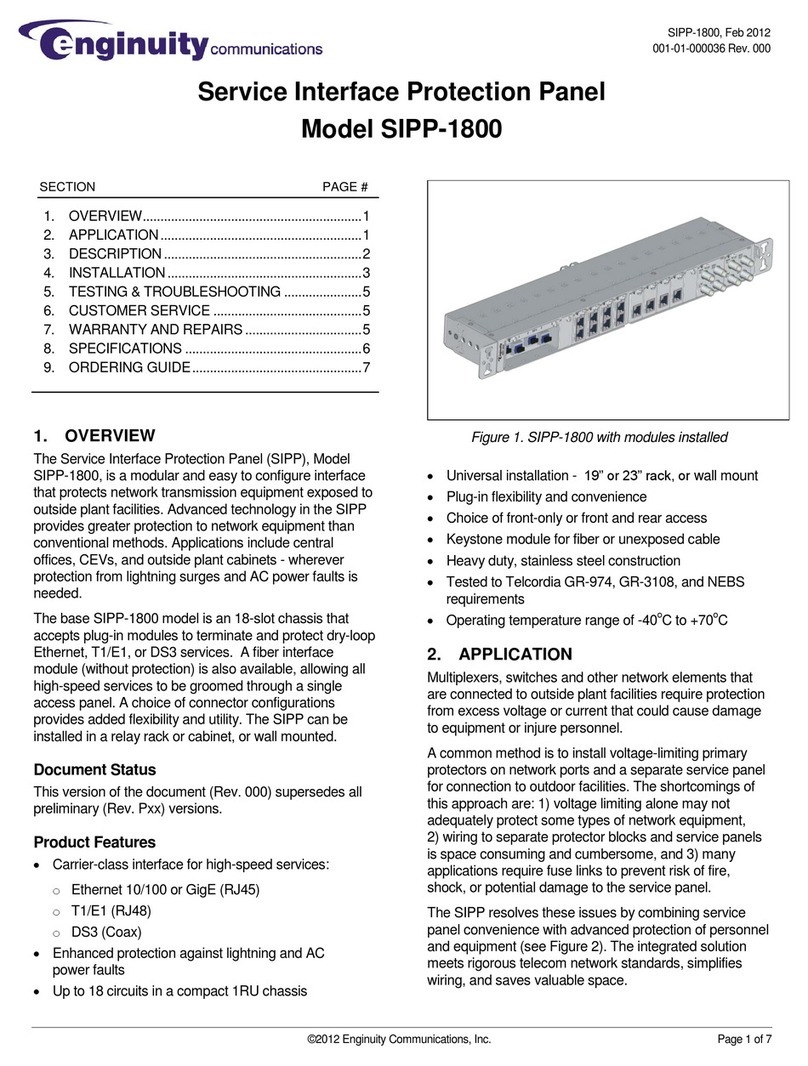

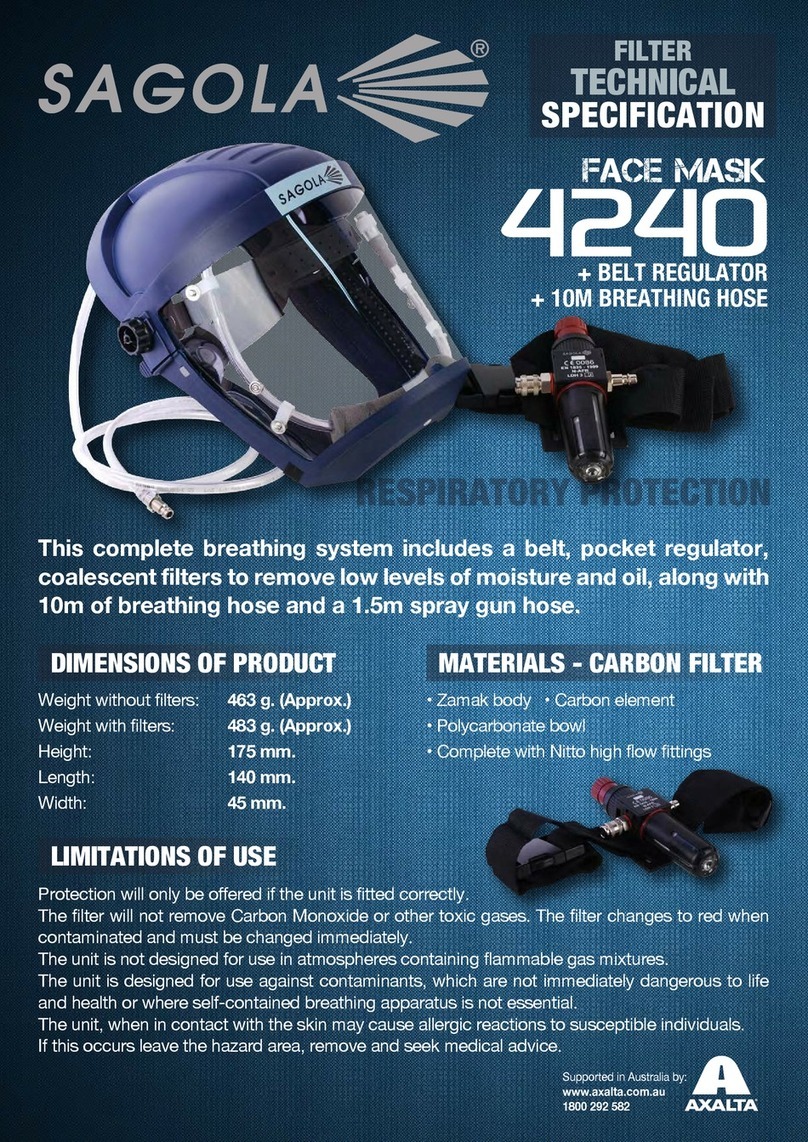

Figure 1. SIPP-600 with modules installed

Supports multiple wall mount configurations

Plug-in flexibility and convenience

Choice of front-only or front and rear access

Keystone module for fiber or unexposed cable

Heavy duty, stainless steel construction

Tested to TelcordiaGR-974, GR-3108, and NEBS

requirements

Operating temperature range of -40oC to +70oC

2. APPLICATION

Multiplexers, switches and other network elements that

are connected to outside plant facilities require protection

from excess voltage or current that could cause damage

to equipment or injure personnel.

A common method is to install voltage-limiting primary

protectors on network ports and a separate service panel

for connection to outdoor facilities. The shortcomings of

this approach are: 1) voltage limiting alone may not

adequatelyprotect some types of network equipment,

2) wiring to separate protector blocks and service panels

is space consuming and cumbersome, and 3)many

applications require fuse links to prevent risk of fire,

shock, or potential damage to the service panel.

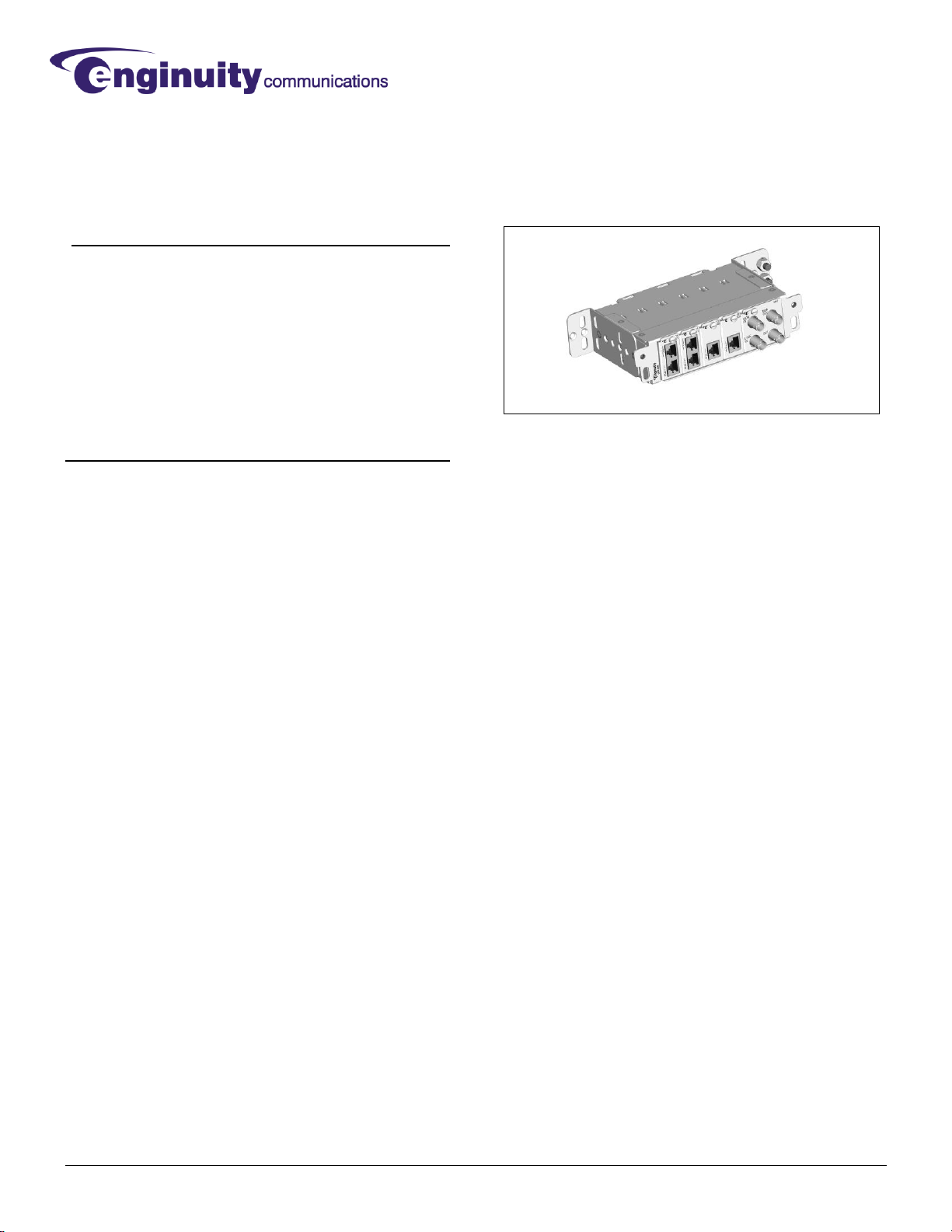

The SIPP resolves these issues by combining service

panel convenience with advanced protection of personnel

and equipment (seeFigure 2). The integrated solution

meetsrigorous telecom network standards, simplifies

wiring, and saves valuable space.

001-01-000055 Rev. 000 Page 2 of 7

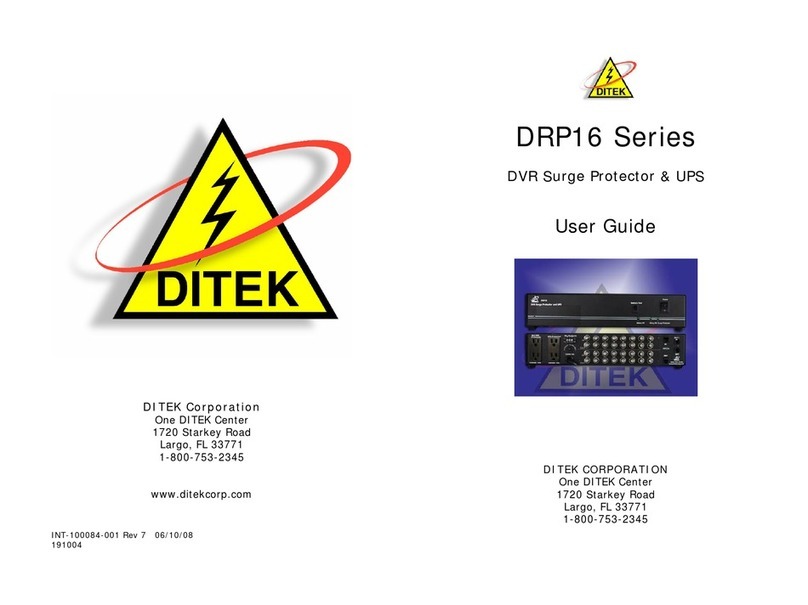

TWISTED PAIR

CAT5/CAT6

Network

Equipment

Customer

A

Customer

B

Customer

C

FIBER Customer

D

COAX

T1

DS3

Ethernet

Fiber

SIPP

Service

Interface

+

Primary

Protection

+

High-Speed

CurrentLimiter

BUILDING,HUT, ORCABINET

Figure 2. SIPP application

The versatility of the SIPP makes it suitable for any

combination of Ethernet, T1/E1, DS3, or fiber services in

central offices, CEVs, or outside plant cabinets.

Orderable options allow for front-only or front and rear

access to connectors.

NOTE: For dry-loop service only (no DC voltage).

3. DESCRIPTION

The base SIPP-600 model is a 6-slot chassis, 1RU high,

with adjustable brackets for a variety of wall mount

configurations. The chassis is constructed of heavy-

gauge stainless steel and accommodates up to six plug-

in modules, as described below. Model SIPP-600C

includes a removable cable cover to prevent tampering

with front-side network equipment connections.

Plug-in Modules

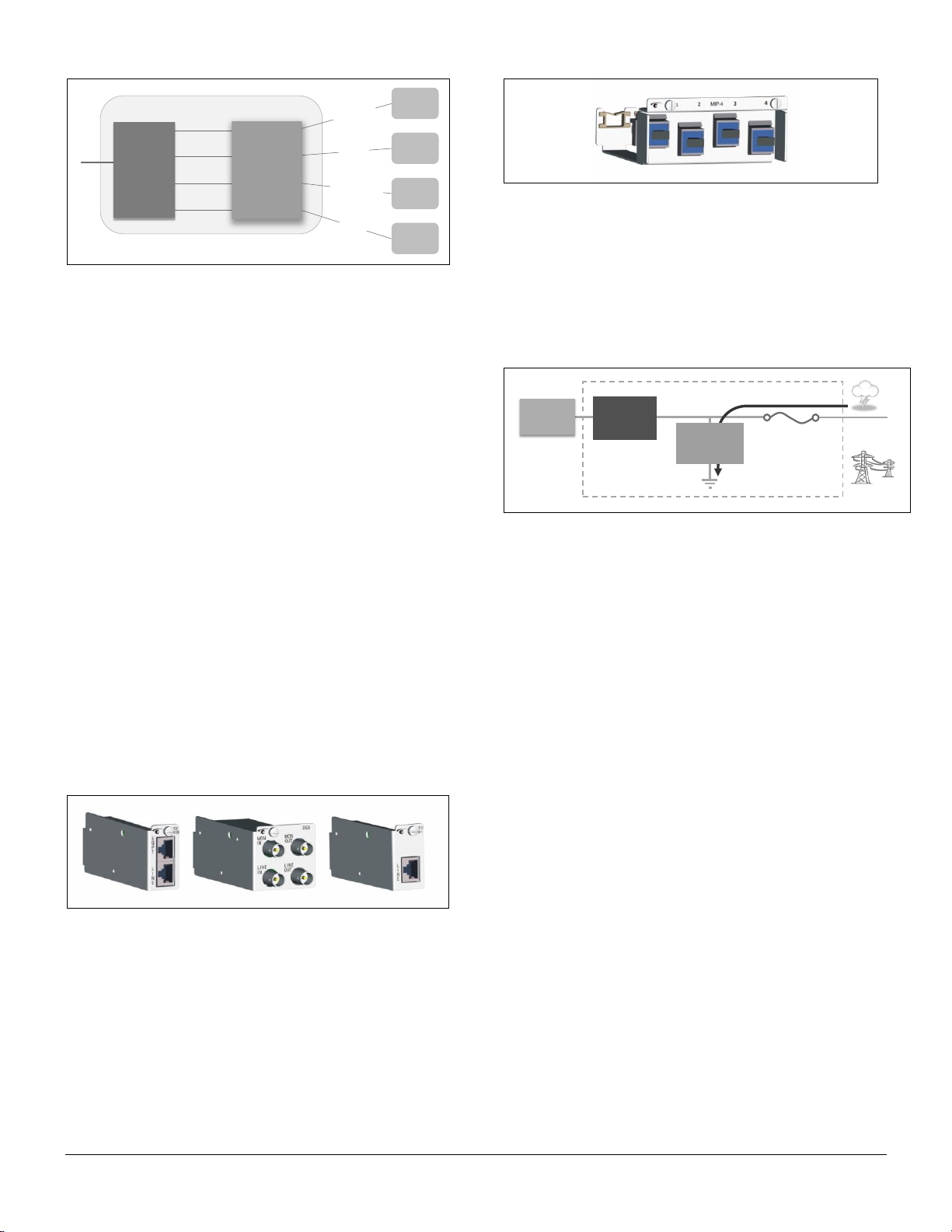

Service Protection Modules (SPM) connect to copper

facilities to protect Ethernet, DS3, or T1/E1 network

equipment against lightning surges and AC power faults.

Modules are available with front-only or front and rear

connectors, and optional monitor jacks. Each SPM

occupies one or two slots in a SIPP chassis, depending

on the chosen jack configuration.

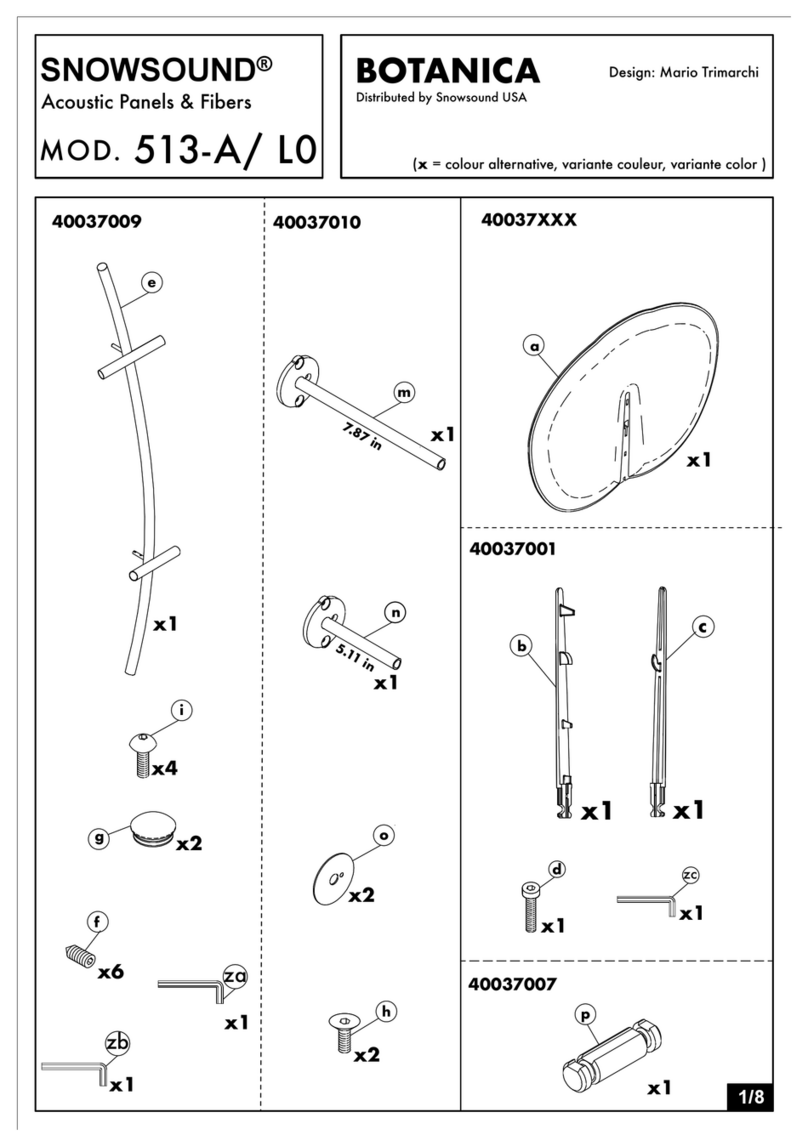

Figure 3. Example Service Protection Modules

Fiber services or copper services that do not require

protection can beconnected through a Modular Interface

Panel (MIP), shown in Figure 4. The MIP module

occupies four slots in a SIPP chassis and provides four

Keystone slots for snap-in couplers that connect network

equipment to facilities.

Please refer to the Ordering Guide at the end of this

documentfor a list of plug-in modules and their

descriptions.

Figure 4. MIP with SC fiber couplers installed

Coordinated Protection

The Service Protection Modules combine current limiting,

voltage limiting (gas discharge tube), and fusing to

prevent lightning and AC surges from damaging network

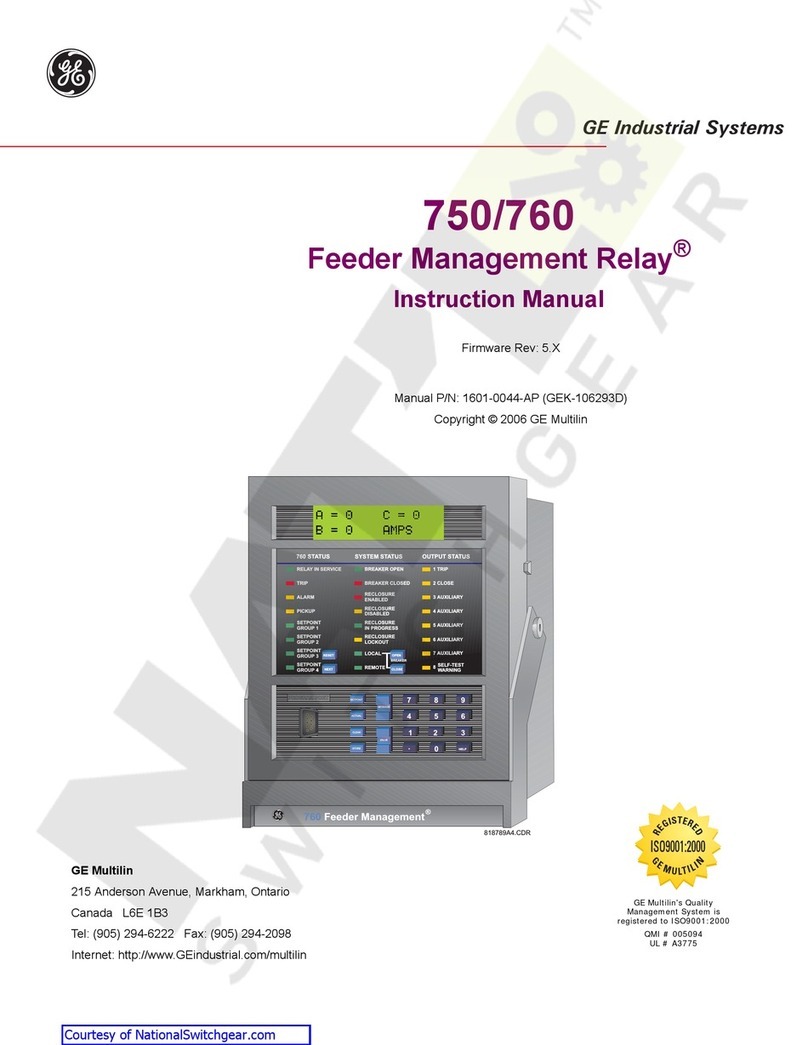

equipment.Figure 5 shows the placement of these

protection elements within the SPM.

EXPOSED

FACILITY

HIGH-SPEED

CURRENT

LIMITER

SURGEENERGY

NETWORK

EQUIPMENT

SPM

GAS

DISCHARGE

TUBE

SURGE

TOLERANT

FUSE

Figure 5. SPM block diagram

The fast-reacting current limiter blocks transients by

switching to a highresistance state, at which point the

gas tube diverts surge energy to ground. The

combination of current and voltage limiting blocks more

energy than can be achieved by voltage clamping alone.

Within one microsecond, the current let through toward

network equipment is reduced to less than 1 mA (0.1V

into a 100Ωload). After the surge clears, the current

limiter returns to a low series resistance and the gas tube

returns to high bridging resistance.

Fail Safe Operation

Fusing within the SPM provides an alternative to

installation of external fuse links. In the event of an

extreme lightning surge or high AC exposure, SPMfuses

opens to prevent hazardous damage to connectors or

cabling. The fuses are surge tolerant and remain

transparent to moderate strikes.

In addition, all SPM gas tubes include a fail-short

mechanism that prevents thermal overload under AC

conditions. The feature creates a mechanical short to

ground and only operates if prolonged AC energy exists

that could otherwise create a fire hazard.

Activation of a fuse or fail-short mechanism requires the

SPM to be replaced.

001-01-000055 Rev. 000 Page 3 of 7

4. INSTALLATION

Chassis Installation

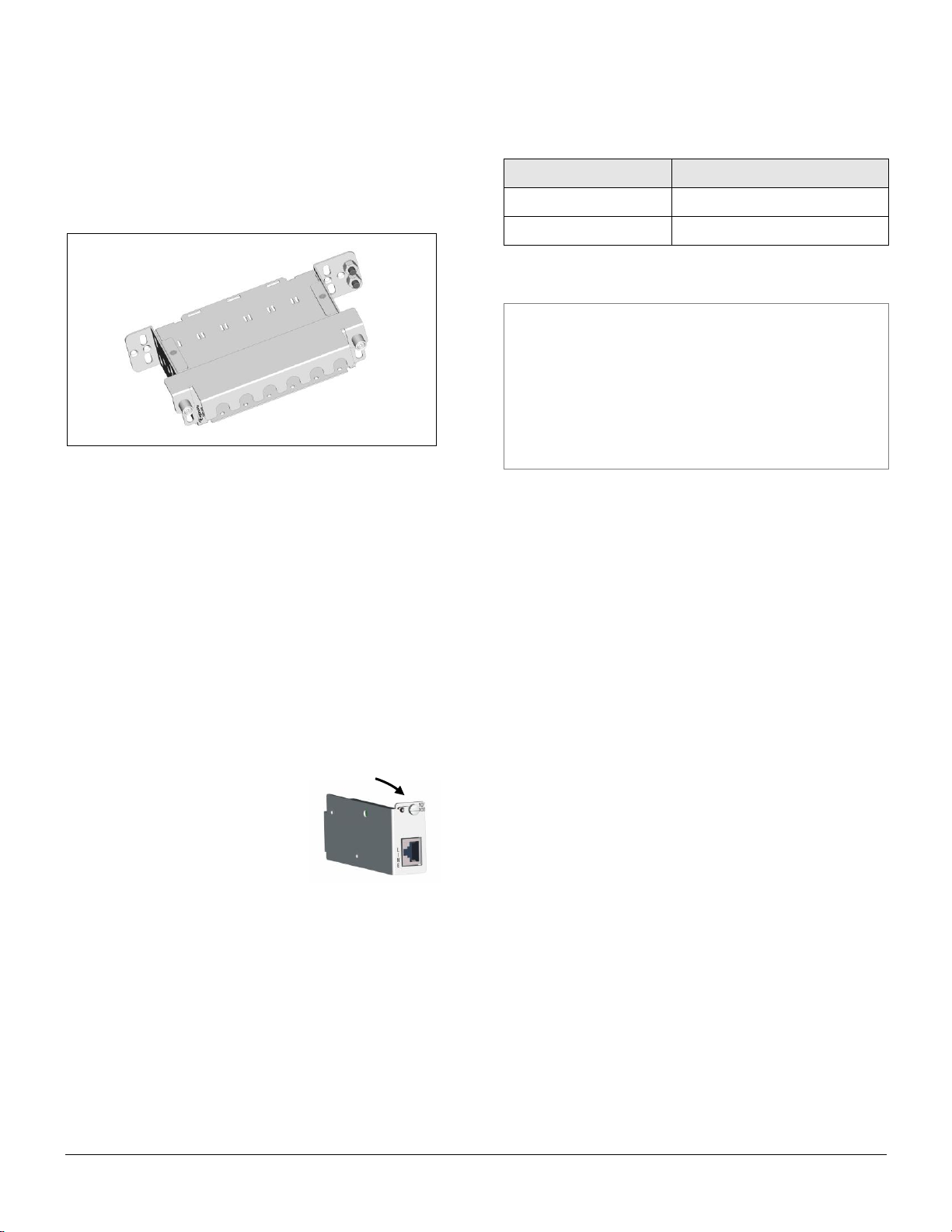

The SIPP-600 chassis is 1RU in height (1.75 inches) with

adjustable mounting brackets that support a variety of

wall mounted configurations (Figure 6).

Figure 6. Mounting configurations

To install the SIPP-600 on a wall or other surface:

1) Align the holes of a mounting bracket with holes on

the side of thechassis in the desired position. The

brackets can be positioned with the flanges toward

the rear, top, or bottom of the chassis.

2) Insert two (2) of the included 8-32 x 3/8” machine

screws through the round holes of the bracket and

tighten them firmly.

3) Repeat steps 1 and 2 with the second bracket on the

oppositeside of the chassis. Ensure that the

positions of the brackets are symmetrical.

4) Attach the panel assembly to a suitablesurface with

four (4) fasteners (not included), two for each bracket.

Besure to use the appropriate fastener type, and

anchors if necessary, to securely support the panel.

For outside plant applications, the SIPP assemblymust

be installed in a cabinet that complies with Telcordia

GR-487 requirements.

Chassis Grounding

CAUTION: Protection requires the use of appropriate

grounding practices in order to function properly. The SIPP

chassis and associated equipment should be connected to a

single common ground point. Wiring must conform to

applicable electrical codes and standards.

To ground the SIPP-600 chassis:

1) Choose an appropriatelysized ground lug to fit the

dual ground posts on the mounting bracket of the

chassis, shown in Figure 7. The studs are 1/4”

diameter with 5/8” center-to-center spacing.

2) Fasten the ground lugsecurely to thestuds with the

included lock washers and 1/4”–20 hex nuts.

3) Attach one end of a #6 AWG ground wire to the

ground lug.

4) Attach the other end of the #6 AWG ground wire to

the nearest qualified ground (impedance of 1 ohm or

less) via the shortest and most direct path, avoiding

sharp turns.

Figure 7. Chassis ground connector

WARNING

To avoid possible electric shock or personal injury,

follow these guidelines:

1) Do not install, troubleshoot, or conduct maintenance on

the SIPP-600 or associated SPM modules during

lightning or thunderstorm activity.

2) This equipment provides primary protection and

requires use of appropriate installation practices.

Only qualified and trained personnel should install or

maintain these products.

Complete the installation of the protection equipment

BEFORE connecting outside cable facilities.

A separate primary protector should not be installed

in conjunction with this equipment.

Suitable cabling must be used for all connections.

3) Protection requires the use of appropriate grounding

practices in order to function properly. The SIPP chassis

and associated equipment should be connected to a

single common ground point. Wiring must conform to

applicable electrical codes and standards.

Ground posts

001-01-000055 Rev. 000 Page 4 of 7

SIPP-600C Cable Cover

Model SIPP-600C includes a cable cover (Figure 8) that

needs to be removed in order to install or remove

modules. The cable cover prevents tampering with front-

side connections to network equipment after the modules

and cables are installed. The cover is fastened to the

chassis with two (2) spring-loaded Phillips screws.

Figure 8. SIPP-600C with cable cover

SPM Installation

NOTE: Primary protectors shall be installed in

accordance with the applicable requirements of National

Electric Code ANSI/NFPA-70, Article 800 Section 800.50.

Service Protection Modules can be placed in any order or

combination in available positions of the SIPP-600

chassis. Each SPM occupies one or two positions,

depending on its function.

To install a module, insert it into the front of the chassis

and slide it back slowly through the card guides. After fully

seating the module, tighten the screw on the front of the

unit to ensure proper grounding of its front panel to the

chassis frame.

SPM Network Connections

For SPM-XX-R modules, connect network equipment to

the jack(s) on the rear of the module.

NOTE: Installations with limited rear access may require

cables to be fed through the chassis, from back to front,

and attached to the module before inserting it into the

mounting. Be sure to provide adequate cable slack.

For SPM-XX-F modules, connect network equipment to

the EQPT jack(s) on the front of the module.

SPM Line Connections

Connect the exposed facility to the LINE jack(s) on the

front of the module.

MODULE CONNECTOR

CONNECT TO

Front (EQPT) or rear

Network equipment (protected)

Front (LINE)

Exposed facility (unprotected)

SPM Removal

To remove a protection module, first disconnect cables

from the unit. If access is limited, rear cables can be

disconnected after the module is removed from the

mounting. Loosen the screw on the module’s front panel

and slowly slide the unit forward out of thechassis, being

careful to guide anycables connected to the rear.

MIP-4 Couplers

The MIP-4 module accepts snap-in Keystone style

couplers for fiber, coaxial, or twisted pair terminations that

do not require protection.

NOTE: Couplers are installed or removed from the rear

of the MIP-4 with the module removed from the chassis.

Each coupler is held in place by angled tabs along the top

and bottom of the coupler body. To install a coupler, tilt it

back slightly while inserting it though therectangular

opening, until the lower tab clears thefront of the panel.

Then apply pressure to the upper tab and tilt the coupler

bodyforward until it snaps in place.

To remove a coupler from the MIP-4, apply pressure to

the upper tab while tilting the coupler bodybackward.

After the upper tab is freed, the coupler can be lifted and

removedfrom the opening.

MIP-4 Installation/Connection

The MIP-4 module occupies four slots in the SIPP-600

chassis.

Before installing the MIP-4 module, feed network cables

through the chassis, from back tofront, and connect them

to the rear of the couplers. Then insert the MIP-4 through

the front the chassis and slide it back slowly through the

card guides. After fully seating the module, tighten the

WARNING

When removing a module or its LINE connection:

Visuallyinspect the cable and equipment for damage or

exposed conductors BEFORE making contact.

Use appropriate detection equipment to ensure that no

hazardous voltages or currents are present.

Follow local guidelines for safety.

IMPORTANT: The module’s

front panel screw must be

tightened securely to ensure

proper grounding.

Recommended screw torque

is four (4) inch-pounds.

001-01-000055 Rev. 000 Page 5 of 7

screw on the front of the unit to ensure proper grounding

of its front panel to the chassis frame.

Connections can now be made to the front of the installed

couplers.

MIP-4 Removal

To remove the MIP-4 module, first disconnect cables

from the front of each coupler. Then loosen the screw on

the module’s front panel and slowly slide the unit forward

out of the chassis, being careful to guide anycables

connected to the rear. Cables can then be disconnected

from the rear of each coupler.

5. TESTING AND TROUBLESHOOTING

To test through a module toward the protected

equipment,connect test equipment to the LINE jack(s) on

the front of the unit. To test toward the exposed facility,

connect to the equipmentside jack(s)on the front or rear

of the unit(jack location depends on the specific model

being used).

Loss of signal, or more than 1.0 dB insertion loss through

an SPM, indicates that a fail-safe condition has occurred

and that the module needs to bereplaced.

6. CUSTOMER SERVICE

If technical or customer assistance is required, please

contact Enginuity at the following address or phone

number:

Enginuity Communications

1251 Nagel Blvd.

Batavia, Illinois 60510

Toll Free: 1-800-980-3266

Voice: (630) 761-1892

www.enginuitycom.com

7. WARRANTY & REPAIRS

Warranty

Enginuity warrants this product for ten (10) years from

date of purchase.

The Service Protection Modules contain fuses and fail-to-

ground mechanisms to safely protect personnel and

equipment. Operation of these fail-safe mechanisms due

to high voltage or current constitutes normal operation

and replacement under these conditions is not covered

by this warranty.

The warranty does not cover anylosses or damages

resulting from shipment, improper installation, abuse,

modification, or repair byother than Enginuity personnel.

Repair and Return

Enginuity equipment will be repaired or replaced without

cost during the warranty period if the product is defective

for any reason other than abuse, improper use, or

improper installation. Before returning defective

equipment,first request a Return Material Authorization

(RMA) number from Enginuity. Once an RMA number is

obtained, return the unit, freight prepaid, along with a brief

description of the problem, to:

Enginuity Communications

1251 Nagel Blvd.

Batavia, Illinois 60510

ATTN: Repair & Return Dept.

Replacements will be shipped in the fastest manner

consistent with the urgency of the situation. Repair or

replacement of faulty equipment beyond the warranty

period is available for a nominal charge. Contact

Enginuity for details.

IMPORTANT

Follow all instructions and safety warnings in the installation

section of this publication (Section 4) when testing or

troubleshooting this equipment.

001-01-000055 Rev. 000 Page 6 of 7

8. SPECIFICATIONS

Chassis (SIPP-600)

Dimensions

Height: 1.75” / Width: 6.1” (excluding mounting brackets) / Depth: 4.3”

Weight

1.6 pounds

Service Protection Modules

Ethernet 10/100 (SPM-100-XX)

Signal

10Base-T: Manchester Encoding, 10MHz or 100Base-T: MLT-3, 125MHz

Connector

Cat5e RJ45; gel coated contacts

Protected Leads

Pins 1, 2, 3, 6 (Pins 4, 5, 7, 8 grounded)

Ethernet GigE (SPM-1G-XX)

Signal

PAM-5 TC, 125 MHz, 1Gbit/s

Connector

Cat6 RJ45 (shielded); gel coated contacts

Protected Leads

Pins 1 through 8

T1/E1 (SPM-T1-XX)

Signal

T1: AMI B8ZS Encoding, 1.544 MHz, E1: HDB3 Encoding, 2.048 MHz

Connector

RJ48; gel coated contacts

Protected Leads

Pins 1, 2, 4, 5 (Pins 3, 6, 7, 8 grounded)

DS3 (SPM-DS3-XX)

Signal

AMI B3ZS Encoding, 44.736 MHz

Connector

75Ω BNC

Protected Leads

Center (signal)

Common Specifications (applicable to each of the above modules)

Standards

Tested to Telcordia GR-974, GR-1089, GR-3108, and GR-63 requirements

Application

Dry loop (No DC)

Impulse Life Characteristics

±10 A, 10/1000 µs:

> 1500 operations

±100 A, 10/1000 µs:

> 100 operations

AC Life Characteristics

1 A rms, 1 sec:

> 60 operations

10 A rms, 1 sec:

Fuse opens for protection

End of Life Characteristics

±10 A, 10/1000 µs:

> 3000 operations

±100 A, 10/1000 µs:

> 300 operations

Current Limiting

(toward equipment)

Protection turn-on threshold:

180 mA min., 360 mA max.

Time to trigger / Time to fully block

~ 10 nanoseconds / ~ 1 microsecond

Maximum let-through (blocked state):

1 mA (0.1V @ 100 Ω)

Insulation Resistance

> 100 MΩ@ ±50 VDC

Insertion Loss

< 1.0 dB

Series Resistance

< 14 Ω

Capacitance

< 20 pF

Operating Temperature

-40o C to +70o C

001-01-000055 Rev. 000 Page 7 of 7

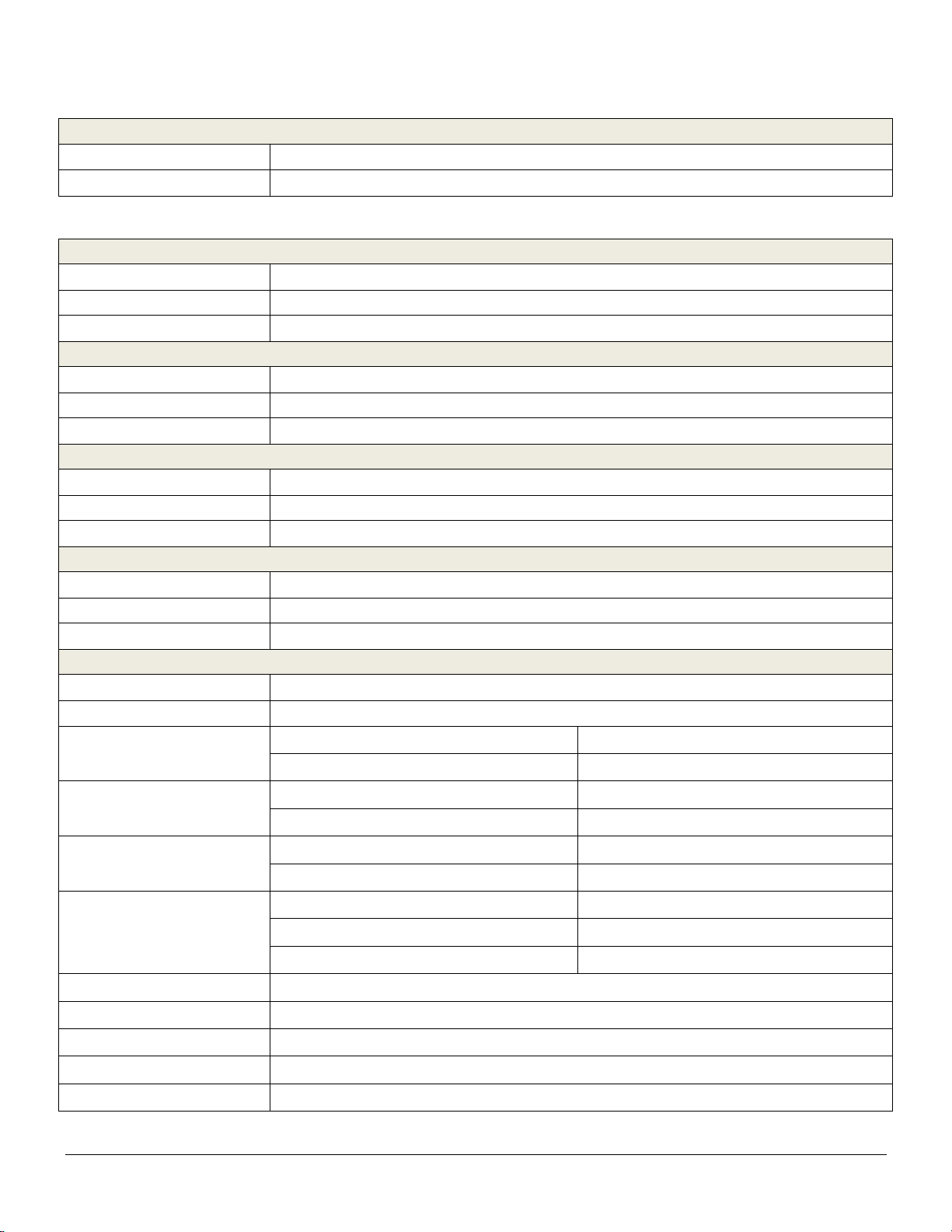

9. ORDERING GUIDE

Chassis

DESCRIPTION

PART NUMBER

SIPP chassis, 6-slot, wall mountable

SIPP-600

SIPPchassis, 6-slot, wallmountable, with removable cablecover

SIPP-600C

Service Protection Modules

SERVICE

CONNECTOR

TYPE

EQUIPMENT

CONNECTION

LINE

CONNECTION

MONITOR

CONNECTION

CHASSIS

SLOTS

PART NUMBER

10/100 Base-T

RJ45

(Cat5e)

REAR

FRONT

N/A

1

SPM-100-R

FRONT

FRONT

N/A

1

SPM-100-F

1G (GigE)

RJ45

(Cat6/shielded)

REAR

FRONT

N/A

1

SPM-1G-R

T1/E1

RJ48C

REAR

FRONT

N/A

1

SPM-T1-R

REAR

FRONT

FRONT

1

SPM-T1-RM

FRONT

FRONT

N/A

1

SPM-T1-F

FRONT

FRONT

FRONT

2

SPM-T1-FM

DS3

BNC Coax

REAR

FRONT

N/A

2

SPM-DS3-R

REAR

FRONT

FRONT

2

SPM-DS3-RM

FRONT

FRONT

N/A

2

SPM-DS3-F

Accessory Panels

DESCRIPTION

CHASSIS

SLOTS

PART NUMBER

Keystone coupler panel with (4) blank inserts installed

4

MIP-4

Keystone coupler panel with (4) SC fiber couplers installed

4

MIP-4SC

Blank cover for empty module slot

1

BP1-1

Cable Management Accessories

DESCRIPTION

PART NUMBER

Universal D-Ring, right or left rail mounted, 1RU

DRNG-U-1

Table of contents

Other Enginuity Protection Device manuals