FILTER TECHNICAL SPECIFICATION

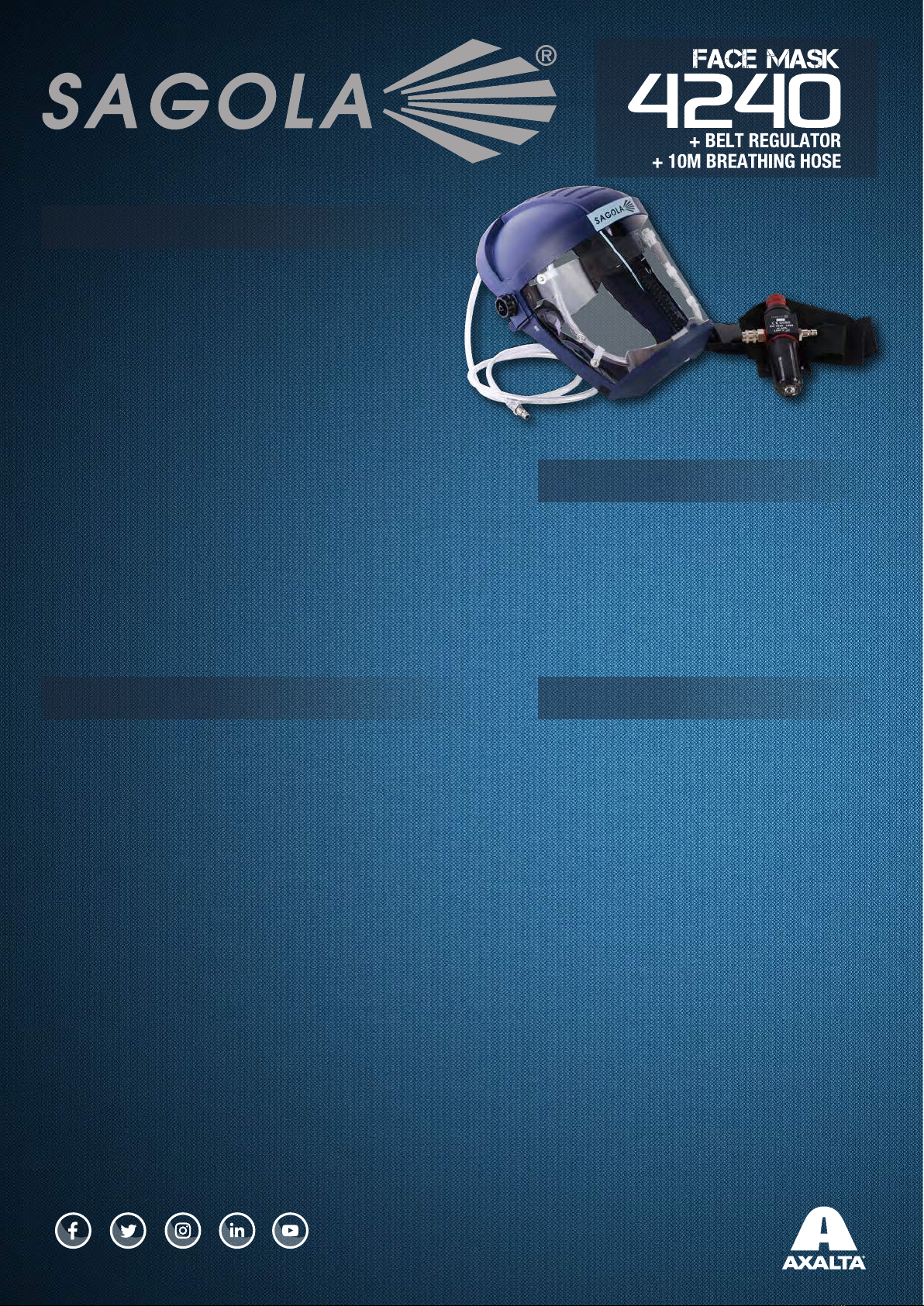

Fasten waistband around the waist with

the preset regulator situated above

the right hip.

Ensure that the faceshield fits comfortably

and securely on the head.

Connect the compressed air supply tube to the

preset regulator.

Should vibration occur upon connection, decouple

and reconnect slowly.

Ensure that the visor and skirt are in place before

entering the hazard area.

Where air contaminants are irritant to skin, eyes

or respiratory system, use the visor system.

The unit conforms to BS EN 1835, with

a protection factor of 40.

EC Certificate Number 58459, issued

by BSi Product Certification

CONFORMITY

The external surfaces of all

components may be cleaned using a

sponge and warm soapy water and

afterwards rinsed and allowed to dry

naturally.

Do not immerse any part of the

system in water, particulary the

regulator as this may damage it.

Do not use abrasive substances or

solvents.

Store in the packaging provided, out

of direct sunlight, away from chemical

and abrasive substances.

If the filter becomes damaged, it

should be replaced inmediately.

CLEANING &MAINTENANCE

INSTRUCTIONS FOR USE

Air supply pressure: max: 10 bar (145 psi)

min: 4 bar (60 psi)

Mask air supply rate: max: 232 L/min

min: 160 L/min

Mask hose length

(supply to regulator): 10m

Environmental working

temperature: 1.5 - 50oC

Nominal actual filter life: 400 operating hours

When used with a spray gun,

needs 620 L/min to 6 bar (60 psi)

Solid particle filtration: 0.01 um

Carbon filter to absorb vapour and odour.

SYSTEM PERFORMANCE

www.sagola.com

M19083

Supported in Australia by:

www.axalta.com.au

1800 292 582