Engler Piezo-Mate User manual

Piezo-Mate

Piezo-Mate

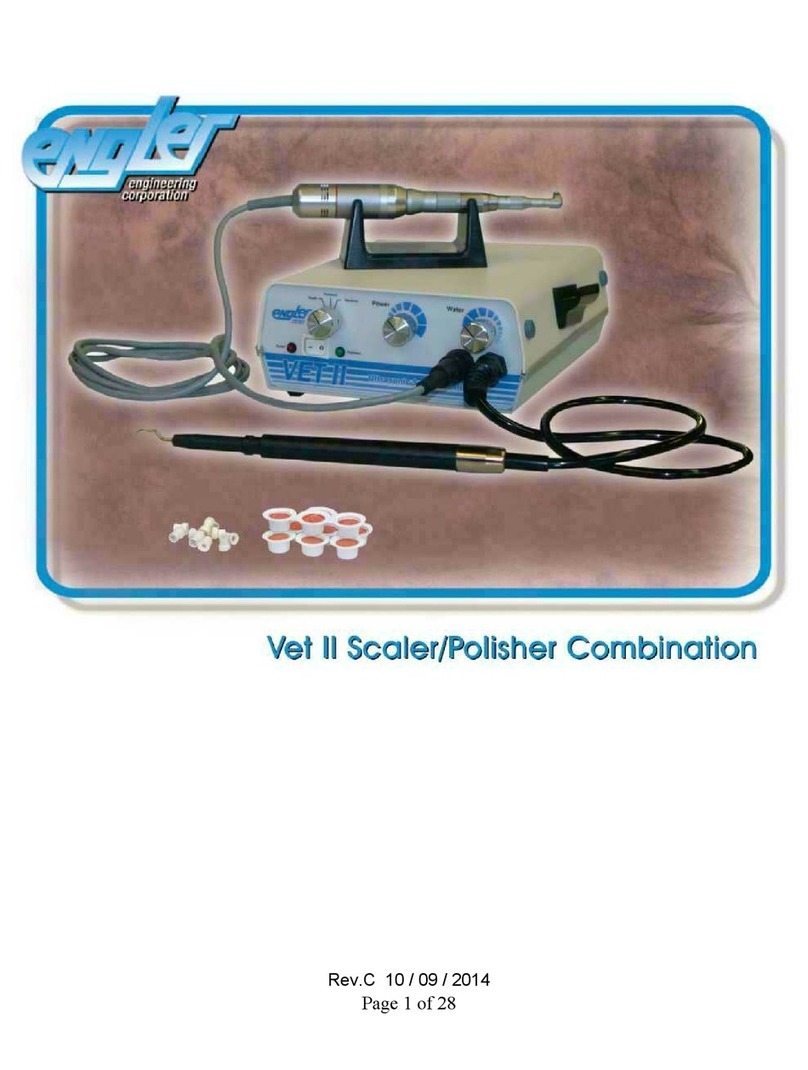

Veterinary Ultrasonic Dental Scaler / Polisher

Veterinary Ultrasonic Dental Scaler / Polisher

Instruction Manual

Instruction Manual

Engler Engineering Corporation

Engler Engineering Corporation

1099 East 47th Street, Hialeah, Florida 33013

1099 East 47th Street, Hialeah, Florida 33013

800-445-8581 – 305-688-8581 – F X 305-685-7671

800-445-8581 – 305-688-8581 – F X 305-685-7671

Web site:

Web site: www.englerusa.com

www.englerusa.com Support site:

Support site: www.engler411.com

www.engler411.com

REV. B 11 / 22 / 2019

Page 1 of 35

Table of Contents

READ BEFORE YOU START..............................................................................................................

COMPANY PROFILE...........................................................................................................................5

INTRODUCTION..................................................................................................................................7

INSTALLATION INSTRUCTIONS.......................................................................................................9

SCALER OPERATING INSTRUCTIONS..........................................................................................12

SCALER MAINTENANCE..................................................................................................................1

POLISHER INSTALLATION..............................................................................................................15

POLISHER OPERATION...................................................................................................................16

POLISHER MAINTENANCE: PROPHY ANGLE ..............................................................................17

STRAIGHT HANDPIECE MAINTENANCE........................................................................................18

CLEANING and STERILIZATION OF HANDPIECE .........................................................................19

MICROMOTOR MAINTENANCE......................................................................................................20

SCALER TROUBLESHOOTING.......................................................................................................21

POLISHER TROUBLESHOOTING....................................................................................................23

PROPHY ANGLE CLEANING AND MAINTENANCE INSTRUCTIONS...........................................25

WATER FILTER CLEANING INSTRUCTIONS.................................................................................26

SADDLE VALVE ASSEMBLY ...........................................................................................................27

Installation Instructions.......................................................................................................................27

To mount the female quick disconnect, there are two options..........................................................29

WATER TANK INSTRUCTIONS.......................................................................................................30

WATER TANK CARE & MAINTENANCE..........................................................................................31

OPTIONAL Piezo-Mate ACCESSORIES...........................................................................................33

TECHNICAL DATA............................................................................................................................35

DIMENSIONS.....................................................................................................................................36

Page 2 of 35

RE D BEFORE YOU ST RT

The handpiece and tip are water cooled and must always have adequate water flow to function properly. The amount of

water delivered to the handpiece must be regulated according to the power level. If the power level is increased, the

amount of water must also be increased. Not having enough water flow through the scaling handpiece may

permanently damage the handpiece, will cause the handpiece to get hot, and void the warranty. For more information,

please turn to the Scaler Operating Instructions page.

When active, ultrasonic tips vibrate at over a million cycles per minute, if it touches soft tissue, gums or skin, it will

cause burns due the friction of the vibration. The tip does not get hot but the ultrasonic vibration will burn if it makes

contact with soft tissue. This is due to the friction between the skin and the vibrating tip. This is normal for all

ultrasonic scalers. Never let the scaling tip touch soft tissue / skin. Engler Engineering Corporation is not

responsible for any damage caused by improper use of this device or its accessories.

When using a water bottle, it must be kept pumped to at least 30 PSI. The pressure relief valve (if equipped) will slightly

move out showing the yellow interior when pressure builds up. As water is used the pressure will decrease and the

bottle must be pumped to keep adequate pressure. The bottle should be maintained at ½ to ¾ full. Always use distilled

water.

It is recommended to remove the tip and clean / disinfect the handpiece after every use to prevent the spread of germs,

bacteria and disease.

Handpieces, tips, prophy angles, rubber cups, straight handpieces, burrs, and water filters, are normal wear and tear

items. In order to achieve optimal performance they should be replaced regularly.

The power switch is on the left side of the unit.

Page 3 of 35

COMP NY PROFILE

Engler Engineering Corporation has been in business since 196 and occupies an 8000 square

foot facility in Hialeah, Florida (USA). Engler manufactures high speed and table top ultrasonic

dental scalers, polishers and combination units. Other devices include electrosurgery equipment

and ultrasonic instruments for the veterinary market as well as a microprocessor controlled

anesthesia delivery system and a respiratory monitor for veterinary use.

Engler Engineering Corp. acquired the exclusive manufacturing and marketing rights of Dynax

products, including stretchers, gurneys, The Cat Grabber, comfort cots, warm water heater /

circulator with pads, and other products. We also acquired the Alpha-Sonic, Ora-Sonic, and Pro-

Sonic line of piezo scalers.

Engler manufactures all of the inserts and tips used in the Engler products as well as many others

on the market today in the 18K and 25K frequency range.

Our repair department has the technical knowledge to repair and maintain a number of dental

devices manufactured by other companies including Shorline.

Engler Engineering Corporation’s foreign sales are handled through a large and growing network

of veterinary distributors. At the present time we are represented throughout the Middle East,

Europe, Central and South America, Canada, Asia, New Zealand, Australia, and most other

countries.

If you have any questions or comments, please contact:

Engler Engineering Corporation

1099 East 47th Street, Hialeah, Florida 33013

800-445-8581 – 305-688-8581 – F X 305-685-7671

Web site: www.englerusa.com Help site: www.engler411.com

Page 4 of 35

Engler Engineering Corporation’s brand name veterinary products proudly include:

•DS 2000, microprocessor controlled anesthesia delivery system / ventilator,

•Excelsior, high speed dental air unit with vacuum / electrosurgery / ultrasonic scaler / high

speed drill / low speed polisher / air - water syringe, and on demand compressor,

•Scale - ire, high speed dental air unit with ultrasonic scaler / high speed drill / low speed

polisher / air - water syringe and on demand compressor,

•Scale - ire Mini, high speed dental air unit with ultrasonic scaler / high speed drill / low

speed polisher / air - water syringe,

•Drill – ire Plus, high speed dental air unit, high speed drill / low speed polisher / air - water

syringe,

•Drill – ire, high speed dental air unit, high speed drill / air - water syringe,

•Son - Mate II, ultrasonic scaler / 35,000 RPM drill / low speed polisher,

•Sonus II, ultrasonic dental scaler,

•Tri - Mate, ultrasonic scaler / 35,000 RPM drill / low speed polisher / electrosurge,

•Electro – Son, touch screen, mono / bi-polar electrosurgical unit,

•Poli - X, 35,000 RPM drill / low speed polisher,

•Sentinel V.R.M., respiratory monitor,

•Engler Veterinary Respiratory Monitor (EVRM)

•More coming soon!

If you have any questions or comments, please contact us!

Engler Engineering Corporation

1099 East 7th Street, Hialeah, Florida 33013

800- 5-8581 – 305-688-8581 – FAX 305-685-7671

Web site: www.englerusa.com Help site: www.engler 11.com

Page 5 of 35

Table of contents

Other Engler Dental Equipment manuals