Figaro EC01 User manual

取扱説明書

Instruction Manual

EC01

(Test chamber for gas sensor evaluation)

Instruction Manual

1. Safety instructions

2. Precautions for use

3. Parts names and functions

4. Measurement preparation

5. Measuring procedure

6. Specifications

Table of contents

Thank you very much for purchasing EC01 (Test chamber for gas

sensor evaluation). Please read this instruction manual carefully to use

the product correctly.

Page

1

1

2

4

6

8

Figaro Engineering Inc.

取扱説明書

Instruction Manual

(1)

(2)

(3)

(4)

1. Safety instructions Make sure to follow

2. Precautions for use

This product is a simplified test chamber. Make sure to close the lid firmly without any gaps.

For highly accurate gas testing, use more airtight test chambers than this product.

Placing large-volume equipment such as gas detectors in the test chamber reduces the

effective volume of the test chamber, and may lead to errors in the gas concentration.

Highly adsorbent gases such as ammonia, VOCs and organic solvent vapors attach to the

inner surface of the test chamber easily, and are therefore not suitable for such applications.

If the gas is adsorbed in the chamber and liquefied, the concentration of the gas in a

gaseous state may decrease. If you need to test with highly adsorbent gases, use a test

chamber made of a material resistant to gas adsorption or with an internal coating.

If highly adsorbent gases are injected into the test chamber, remove adsorbed gases by

appropriate measures such as cleaning the inside of the test chamber with alcohol and

venting the inside with clean air for a long time.

Measurements in high / low temperature or in extremely high / low humidity in indoor

environments may affect the measurement values of the gas sensor. Check the

specification of each sensor.

- 1 -

This test chamber is not explosion-proof. Do not use it for measurements when using

flammable gases with greater than 50% concentration of the Lower Explosive Limit (LEL).

The test chamber does not guarantee a completely sealed condition. Do not use it for

measurements with high concentrations of toxic gases hazardous to the human body.

When measuring with flammable gas, make sure to handle flames with caution, and only

exhaust gas from the test chamber in an area with adequate ventilation. Also be sure to take

necessary safety precautions such as installing gas detectors.

Perform measurements in a well-ventilated area, especially when using toxic gases. Also,

be careful not to inhale gases when venting them from the test chamber. Make sure to

ventilate gases outdoors or in fume hoods for safety.

(1)

(2)

(3)

(4)

(5)

取扱説明書

Instruction Manual

* Make sure that the test chamber for gas sensor evaluation itself and the following accessories

are included in the package

Test chamber for gas

sensor evaluation

(with signal cable)

Lid Syringe (5ml)Test board for

evaluation modules

③

①Test chamber body

②Control box

③AC power cable

④Power switch

⑤Switch of mixing fan

⑥Mixing fan

⑦Power supply cable

⑧Ribbon cable for measuring sensor output

(50-core)

⑨Supply voltage adjustment hole

(not used normally)

⑩Test chamber lid

⑪Gas inlet

* Adhesive tape is affixed to the syringe insertion rubber.

Do not remove this tape, because it is used to prevent the

insertion rubber from coming off when removing the syringe

during measurement.

⑫Test board for gas sensor evaluation modules

⑬Connectors for module measurement (CH1 to CH12)

⑭Connector for ribbon cable connection (CN1)

⑮Connector for power supply (CN2)

⑥

④

⑫

⑧

⑩

⑬

⑭

⑮

⑨

⑦

⑤

Instruction Manual

(this document)

②⑪

3. Parts names and functions

Products and accessories

- 2 -

①

Parts names

取扱説明書

Instruction Manual

CN1

Pin

number

Evaluation

module

Connector pin

number

Evaluation

module

CH number

1 to 6 1 Common

VC (5.0 V DC)

7 2 CH18 3

9 4

10 2 CH211 3

12 4

13 2 CH314 3

15 4

16 2 CH417 3

18 4

19 2 CH520 3

21 4

22 2 CH623 3

24 4

25 2 CH726 3

27 4

Connector pin layout for power supply (CN2)

Signal from the test board for evaluation modules (CN1)

CN1

Pin

number

Evaluation

module

Connector pin

number

Evaluation

module

CH number

28 2 CH829 3

30 4

31 2 CH932 3

33 4

34 2 CH1035 3

36 4

37 2 CH1138 3

39 4

40 2 CH1241 3

42 4

43 NC

44 NC

45 to

50 5 Common

GND

Pin number

Name Function

1 VC

Power input

2 GND Ground

* The red line on the ribbon cable line (50-core)

corresponds to number "1" of the CN1 pin.

- 3 -

Connector pin layout for gas sensor evaluation module

Pin

number

Model number of the gas sensor evaluation module

EM26 EM3870A EM5042A

EM5141A

EM-FECS (A)

1 VC VC VC VC VC

2 VOUT

V

OUT1

(CH4)

3

V

OUT2 (CO)

VOUT VOUT VOUT

4

5 GND GND GND GND GND

VC = Power input

VOUT = Sensor output

GND = Ground

* Refer to the Product Information

of each gas sensor evaluation

module for details.

Wiring specifications

取扱説明書

Instruction Manual

4. Measurement preparation

Prepare a measuring instrument (such as data logger

or digital multimeter) that can measure the voltage.

Wire the voltage measuring instrument.

・The measurement device on the right is an example.

Connecting a ribbon cable directly to a data logger or other voltage measuring instrument.

The signal wires coming out of the test chamber for gas sensor

evaluation correspond to connector pins 1 to 50, starting with the

red line. [Example of connection to a

data logger]

(2) Connecting a ribbon cable with a connector from the chamber to an extension ribbon cable

Ribbon cable: Cable with 2.54 pitch (50-core) compatible with a MIL

standard connector

- 4 -

Disconnect the connector by cutting the end of the ribbon cable coming out of the chamber body.

Check “Wiring specifications” on page 3, and connect the required lines to the voltage measuring device.

5V

GND

CH1

CH2

……

CH12

Wiring using recommended connectors prepared by the user

(1) Connecting a ribbon cable with a connector from the chamber to a printed circuit board, etc.

There are two methods for wiring:

Recommended connector: XG4A-5031 (Omron)

Recommended connector: XG4E-5031 (Omron)

1

B

.

A

.

取扱説明書

Instruction Manual

Attach the sensor to the gas sensor evaluation module, and attach it to the test board for

evaluation modules.

Match the pin number of the gas sensor evaluation

module and the terminal number of the connector on the

test board for evaluation modules, and insert it fully.

[Example of attachment of the test board for

evaluation modules]

Insert the terminal of the gas sensor

evaluation module into the larger

hole of the connector for the

module.

1 5

- 5 -

Open the lid of the test chamber and turn on the mixing fan for 2 to 3 minutes to remove

the contaminated air in the chamber.

①Connect the AC power cable of the test chamber to the

power outlet, and turn the power switch on the top of the

control box ("POWER") to "ON".

* The “green LED” in the control box lights up.

Green

LED

②Turn on the “FAN” switch and rotate the mixing fan for 2 to 3 minutes to remove the contaminated air

in the chamber, and stop it when it is done.

Connector for power supply

Connector for ribbon cable

(50-core)

Place the test board for evaluation modules attached with the gas sensor evaluation

modules in the test chamber. Connect the power supply cable and the ribbon cable to

their respective connectors on the test board.

③Set the power switch to “OFF”.

①Set the power switch to “ON”.

②Check if they are properly wired with data logger, for example, in advance.

* If the power supply voltage needs to be adjusted, see “How to adjust the power supply voltage” in page 7.

The factory setting of the supply voltage is 5 V. When testing with our gas sensor evaluation module, the

power supply voltage does not require adjustment.

Check the output voltage.

2

3

4

5

Make sure that the power switch is

“OFF” before connection.

取扱説明書

Instruction Manual

- 6 -

Close the lid of the test chamber.

5. Measuring procedure

The adhesive tape is affixed to the top surface to prevent the

"rubber for syringe insertion" from popping out. Replace it with a

new adhesive tape as it ages.

* Use standard mending tape.

After the measurement is complete, open the lid in a well ventilated area and turn the fan

to vent the gas in the chamber.

When opening the lid after the measurement, make sure to place the test

chamber in a well ventilated area, open the lid and turn the fan to remove the

gas in the chamber. Be careful not to inhale the gas from the test chamber or

spread it into the room.

* The lid should be closed by lightly pressing down to make it airtight.

Before injecting the gas, make sure to measure the output voltage from the evaluation

module in clean air, and confirm the voltage is stable.

Insert the syringe needle into the gas inlet on the lid and inject the gas.

* Calculate the required gas injection volume from the inner volume of the chamber and the gas

concentration to measure. (See below for calculation method)

After the injection, turn on the fan switch and mix the gas for approximately 30 seconds.

Then perform the measurement considering the operating conditions of the sensor.

The injection volume V (ml) of 100% concentration gas required to make a test gas of

concentration C (ppm) in the test chamber can be calculated from the following formula.

1

3

5

2

4

When diluting 100% concentration gas:

V = (chamber capacity) x C

1,000,000

* Chamber capacity = 10,300 ml

Example: Test gas

concentration 100% concentration

gas injection volume

1,000 ppm

5,000 ppm 10.3 ml

51.5 ml

Calculation of the injection volume of the gas

取扱説明書

Instruction Manual

Turn clockwise (+) 4.00V -> 5.50V

Turn counterclockwise (-) 5.50V -> 4.00V

The factory setting of the power supply voltage to the test board is set to 5V, and users do not need

to adjust it usually.

This adjustment should only be made if any adjustment is required between 4.00 V and 5.50 V.

- 7 -

Screwdriver

The power supply voltage can be adjusted by inserting a + screwdriver into the supply voltage

adjustment hole on the side of the control box and turning the adjustment volume.

Check the voltages between ribbon cable connector pin numbers 1 to 6 (VC+) and 45 to 50

(GND).

Control box

How to adjust the power supply voltage

取扱説明書

Instruction Manual

Name Test chamber for gas sensor evaluation

Model number EC01

Product configuration Test chamber body and lid without opening

Test board for gas sensor evaluation modules (12 modules max.)

Syringe (5ml)

Main power AC 100 V to 240 VAC

Power consumption 2W (when fan is on)

* excluding power consumption required for gas sensor operation

Operating temperature

range 0 °C to 50 °C

Effective inner capacity 10,300 ml

External dimensions 340 (W) x 270 (D) x 202 (H) mm (excluding ribbon cable)

Weight Approx. 4 kg (including test board for evaluation modules)

Main material Chamber body: Polyvinyl chloride Lid: Acrylic

6. Specifications

Contact for inquiries about our products:

- 8 -

This manual is subject to change without notice to improve product

performance.

Connectors

Part number

Manufacturer

Standards

CN1 XG4A-5031 OMRON

MIL standard

MIL

-C-83503

UL standard

(File No. E103202) certified

CN2 B2P-VH-1 JST

UL standard

(File no. E60387) certified

CSA standard

LR20812

Evaluation

module

Connectors

(CH1 to CH12)

05JQ-BT JST

UL standard

(File no. E60387) certified

CSA standard

LR20812

Standards of connectors

(Model number: EC-P01)

The following parts are available separately.

Lid with air supply and exhaust openingsTest board for evaluation modules

Optional parts

Board size: 200 x 258 mm Air inlet and outlet, outer diameter:

32 mm Φ

(Model number: EC-P02)

Figaro USA, Inc.

121 S. Wilke Rd. Suite 300

Arlington Heights, IL 60005 USA

TEL.: (1) 847-832-1701

FAX.: (1) 847-832-1705

E-mail: figarousa@figarosensor.com

Table of contents

Other Figaro Gas Detector manuals

Popular Gas Detector manuals by other brands

BEINAT

BEINAT GSH900 Installation and user guide

Tecnocontrol

Tecnocontrol SE296KM quick start guide

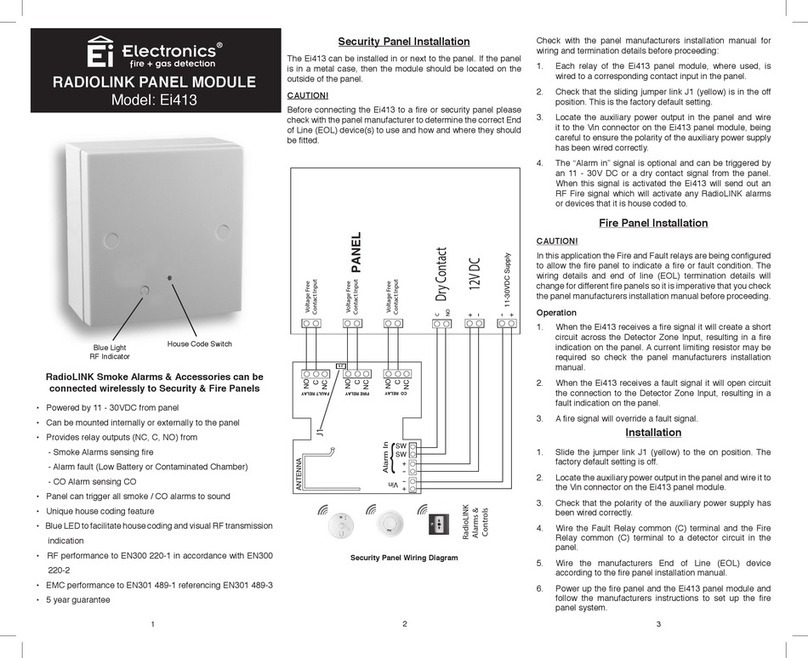

Electronics

Electronics Ei413 quick start guide

Blackline Safety

Blackline Safety G7 BRIDGE Getting started guide

Tecnocontrol

Tecnocontrol TS293P Series user manual

Tecnocontrol

Tecnocontrol TS293IM user manual

GASTRON

GASTRON GIR-3000 instruction manual

S&S Northern

S&S Northern Merlin GDP4 Installation, operating and maintenance

Foxcroft

Foxcroft FX-Mini operating manual

GASTRON

GASTRON GTD-3000ExW instruction manual

Consilium

Consilium Salwico ST400 H2S Calibration instructions

Hanwei

Hanwei JL269LED Operation manual