ENOCHS POWER 4000 User manual

SERVICE MANUAL

FOR POWER 4000

ENOCHS

Examining Room Furniture

TABLE OF CONTENTS

2

Item

Page

IMPORTANT Safety Blocking Procedure

3

System Overview

4

Important Safety Information

5

Troubleshooting Problems

6

Access to Table Components

7

Back Cylinder Replacement

8

Lift Cylinder Replacement

9

External Solenoid Replacement

10

Hydraulic Hose Replacement

11

Pump Unit Replacement

12

Installation of Access Panels

14

Electrical System Wiring Diagram

15

Electrical System Schematic

16

Hydraulic System Schematic

17

Foot Pedal Wiring Diagram

18

Maintenance Checklist

19

Parts List

20

Service Log

22

SAFETY BLOCKING PROCEDURE

for ENOCHS Power 4000

3

W A R N I N G

Follow SAFETY BLOCKING PROCEDURE before any hydraulic

maintenance work is initiated.

F a i l u r e t o f o l l o w t h i s i n s t r u c t i o n c o u l d r e s u l t

i n s e r i o u s b o d i l y i n j u r y

D A N G E R

Loosening or disconnecting the hose running from the base of the

lift cylinder to the external solenoid (reference Hydraulic Schematic,

part number 116-42BH1B) will release hydraulic pressure in the lift cylinder

and will cause sudden downward collapse of table.

NEVER work inside pedestal column without safety blocking in place.

SAFETY BLOCKING PROCEDURE:

Required: External Blocking (A)2 - 2x4s cut to 18¾" for use if lift cylinder not working

Internal Blocking (B)2 - ¾" hardwood dowel rod (or equal blocking) cut to 29" length

1. Raise table to maximum height, lower back to flat position and skip to Step 4. If table can not be hydraulically raised, raise back to full

chair position and unplug table. Remove side drawer, free front of right drawer track mount channel and lower for access to the lift

cylinder clevis. Locate and remove clevis key and pin.

2. Locate and remove the bolt connecting the support arm to the couch frame. Allow support arm to lower into table base and lower back of

table to flat position. Lift up seat section to locate and remove the four bolts securing couch to table base. Carefully lift upholstered couch

top off and set safely aside.

3. With assistance, manually raise moveable table section to maximum height and support it between floor and outside shell as shown

above with External Blocking (A)

4. If lift cylinder or hose # 116-42BH2R is being replaced, locate and remove only the top two screws (1-L & 1-R) holding headend sliding

access panel channels in place (see Installation of Access Panels on page 14).

5. Remove the two sliding access panels from footend of table (C) (see Installation of Access Panels on page 14).

6. Place Internal Blocking (B) between lower foot end corners of the pedestal housing and upper cylinder support weldment (see above).

7. Raise moveable section of table and remove external blocking then lower the section so that it is fully supported by the Internal Blocking.

Verify table is firmly supported on Internal Blocking before proceeding with any maintenance or repair.

8. UNPLUG POWER CORD to eliminate possible electrical shock and proceed with specific repair.

(B) Internal Blocking

Place two correct length 3/4” dowel

(or other blocking), inside the housing

between the lower foot end corners of

the pedestal housing and UPPER

cylinder support weldment.

HEYCO® strain relief

Moveable section of table

(A) Exterior Blocking

2x4 cut to 18¾"

Upholstered couch

(D) Remove footend squaring panel.

(C) Remove sliding access panels from table

FOOTEND VIEW OF POWER 4000

(A) Exterior Blocking

2x4 cut to 18¾"

SYSTEM OVERVIEW

4

This manual covers service and repair of the ENOCHS Power 4000 High-Low Examination Table. If you

encounter questions or concerns that are not covered in this manual, contact ENOCHS Examination

Room Furniture - Customer Service at 1-800-428-2305 or Technical Support at 1-800-322-6416, FAX to

317-580-2944 or e-mail to enochs@enochsmed.com.

MAINTENANCE PROCEDURE

WARNING

Follow SAFETY BLOCKING PROCEDURE on page 3

before

any hydraulic maintenance work is initiated.

Failure to follow these instruction could result in serious bodily injury.

OPERATING OVERVIEW

The table height adjustment range is 24" to 40". Back adjustment is from flat to full chair position.

Adjustment is made by operating the appropriate foot control treadle. Other table features include

overload protected dual electrical outlets, storage drawer, warming drawer, pelvic tilt, stirrups, paper roll

holder, irrigation basin and a pull out leg extension.

SYSTEM OVERVIEW

The electro-hydraulic system includes: a 1/3 hp, 120 VAC, bi-directional hydraulic pump unit consisting of

a pump/motor/reservoir assembly, one double acting cylinder with external solenoid low control valve to

adjust table height and one double acting cylinder with internal solenoid valve to adjust back position.

The pump/motor has a built in thermal protection and will temporarily interrupt operation if overheating

occurs.

RECOMMENDED OIL: Manufacturer of system recommends using an ISO 32 or a 10 weight hydraulic

oil. Oil must be industrial grade, non-detergent and mineral based.

Manufacturer of system recommends Mobil DTE 24 (10 wt) or Valvoline 10.

IMPORTANT: DO NOT USE MEDICINAL MINERAL OIL

FILL LEVEL: Oil should be ½"–¾" below fill hole to allow for expansion of oil during system operation.

ELECTRICAL RATING: 115 VAC, 60 Hz, 12 A. DO NOT CONNECT TO OTHER VOLTAGES

MAINTENANCE

Periodically check:

inside of table to make sure no objects have fallen into base of table

hydraulic fluid levels –confirm hydraulic oil level is ½" from fill hole

Every 6 months:

Complete MAINTENANCE CHECKLIST on page 19

Every 12 months:

Lubricate gear bushings and shaft of upper chain drive

If a problem develops, DISCONTINUE USE of the table until a service technician can make repairs.

Keep this manual in a location for access by service technician as reference for correct maintenance and

repair of this product.

IMPORTANT SAFETY INFORMATION

5

Special safety considerations for the maintenance and repair of the Power 4000 are for the protection and safety

of service technician. BEFORE performing any maintenance or repair, carefully read and understand all

instructions and procedure requirements. It is technician’s responsibility to follow maintenance/repair

instructions in this manual.

Failure to follow these instructions could result in bodily injury and/or

product damage.

MAI NTENA NCE PR O C ED URE W A RNIN G

Maintenance personnel must properly secure table with SAFETY BLOCKING before any hydraulic

maintenance work is initiated. Failure to follow this instruction could result in serious bodily injury.

DANGER

The weight of the table’s upper section is supported entirely by hydraulic oil captured in the

bottom section of the lift cylinder and the hose connecting it to the external solenoid cylinder.

Loosening or disconnecting the hose running from the base of the lift cylinder to the

external solenoid (part number 116-42BH1B - see Hydraulic System Schematic page 17)

will release the hydraulic pressure in the lift cylinder and will cause sudden downward

collapse of table.

Follow SAFETY BLOCKING PROCEDURES instructions on page 3 of this manual before proceeding with

any maintenance or repair procedures.

DANGER: ELECTRICAL SHOCK HAZARD

Shock hazard exists when working on table. Unplug power cord from power source when

working on table during all repair procedures to eliminate shock hazard. Replace all covers

upon completion of repair and before power is restored.

CHECK GROUNDING CONTINUITY periodically to ensure safe operation.

Failure to follow this instruction could result in bodily injury and/or product damage

Electrical Rating: 115VAC, 60 Hz, 12 A.

DO NOT CONNECT TABLE to other voltages. Irreversible damage to the electrical

components will occur and bodily injury may result.

USE ONLY a Hospital Grade 115 V receptacle for proper electrical connection.

UNDER NO CIRCUMSTANCES SHOULD HOSPITAL GRADE 115 VOLT CORD PLUG BE

REPLACED WITH OTHER TYPE.

DO NOT USE table if electrical cord is cut, worn, frayed or otherwise damaged.

DO NOT USE table if abnormal sounds are heard during any adjustment.

DO NOT USE extension cord unless NEMA approved for required electrical specifications.

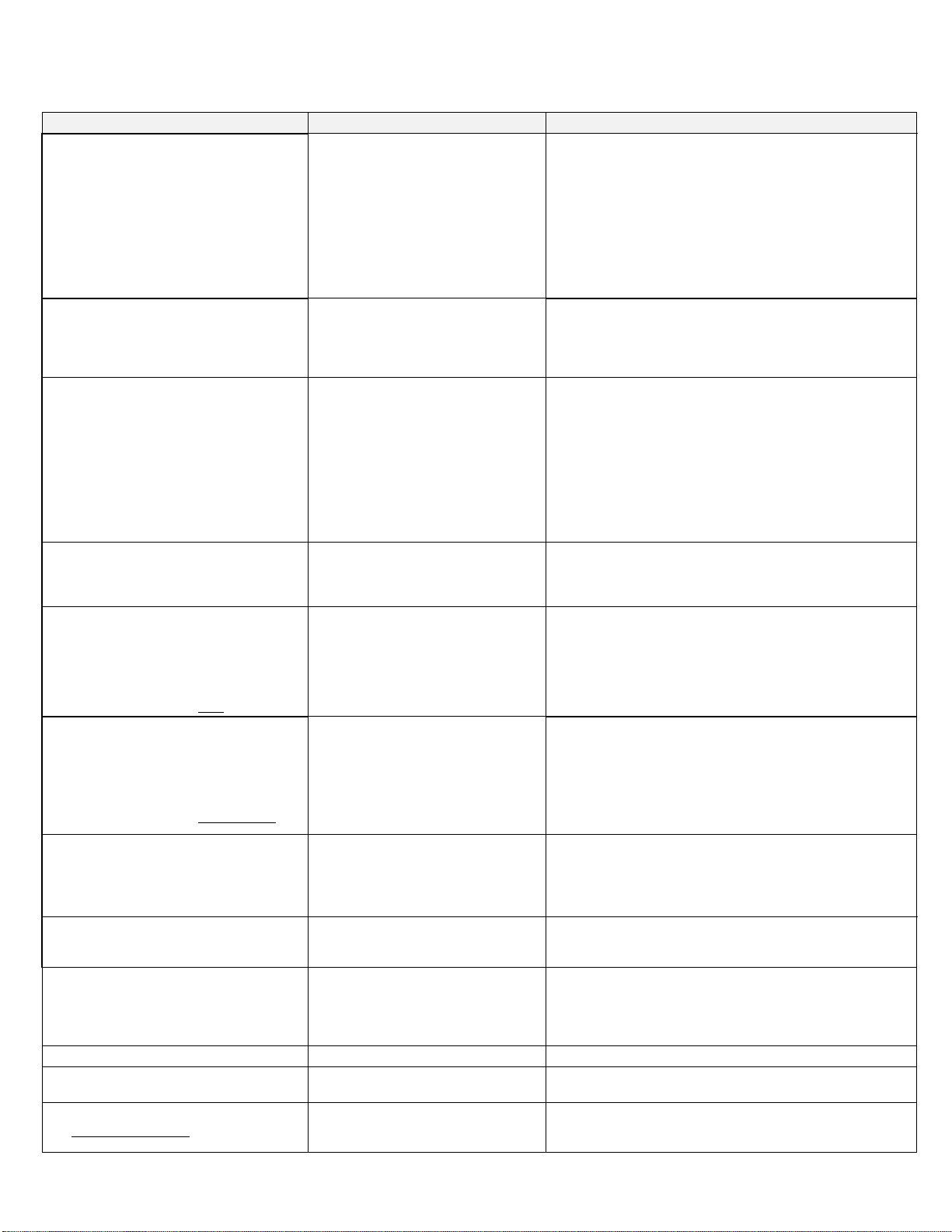

TROUBLE SHOOTING PROBLEMS

6

DESCRIPTION OF PROBLEM

POSSIBLE CAUSE

SOLUTION

Table height will not go up or down but:

motor turns on

back functions up & down

no hydraulic leak noted

foot treadle movement restricted

by debris or damage

OR

external solenoid not working

OR

problem with foot control cord wire or

micro switch

1. re-establish free movement of the treadles

2. confirm treadles making solid contact with micro-switches

1. reference Electrical System Schematic on page 16

2. check continuity of solenoid coil

3. replace bad external solenoid

1. reference Electrical System Schematic on page 16

2. check continuity of white wire in foot control cord

3. confirm micro-switch is activating solenoid

4. replace parts as required

Table is in full down position and will not

go up but:

motor turns on

back moves slowly or not at all

hydraulic leak noted

cylinder, hose or hose

connection leaking hydraulic oil

1. locate leak and replace required part

Back not responding to foot control but:

motor turns on

table height works up and down

no hydraulic leak noted

movement of foot switch treadle

restricted by debris or damage

OR

cylinder solenoid not working

OR

problem with foot control cord wire or

micro switch

1. re-establish free movement of the switch treadles

2. confirm foot pedal is making solid contact micro-switch

1. reference Electrical System Schematic on page 16

2. check continuity of solenoid coil

3. replace cylinder

1. reference Electrical System Schematic on page 16

2. check continuity of black-on-white wire in foot control cord

3. confirm micro-switch is activating solenoid

4. replace parts as required

Back will not go up or down but:

motor turns on

height will not work or is sluggish

hydraulic leaks noted

cylinder, hose or hose

connection leaking hydraulic oil

1. locate leak point

2. replace required part

Table’s height & back will not go up or

down but:

foot control micro switches clicking

when foot switches are activated

motor not turning on

no hydraulic leak noted

electrical outlets work

motor has overheated due to

prolonged continuous operation

OR

foot control cord wire problem

OR

Motor problem

1. wait for unit to cool down

2. motor protection re-sets automatically

1. reference Electrical System Schematic on page 16

2. trace circuit to isolate problem

3. repair as required

Table’s height & back will not go up or

down but:

foot control micro switches clicking

when foot switches are activated

motor not turning on

no hydraulic leak noted

electrical outlets DO NOT work

power source failure

OR

power cord damaged

1. check building power source

1. replace cord

Table will not lift patient but:

motor turns on

table acts like it wants to work

back functions up & down

no hydraulic leak noted

patient to heavy

OR

oil supply may be low

1. don’t use table with this size patient

1. check oil level in reservoir.

2. refill with recommended hydraulic oil to correct level

Table running slow or functions incomplete

oil supply low due to leak in cylinder,

hose or hose connection

1. check oil level in reservoir

2. if level is low, locate and repair any oil leaks

3. refill with recommended hydraulic oil to recommended level

Height and back moves in only one direction

–up or down.

motor/pump not changing direction flow

OR

Wire in foot control cord damaged or

disconnected

1. replace pump unit

1. reference Electrical System Schematic on page 16

2. check continuity of blue or red foot control wires

3. repair as needed

Cylinder drifts down , won’t hold position

bad solenoid valve

1. replace back cylinder or external solenoid for lift cylinder

110 V. outlet not working but:

all other table functions work

damaged outlet or loose wire

1. tighten connections or replace duplex receptacle

Hydraulic system makes squealing noise at

the end of cylinder stroke but:

no hydraulic leak noted

leaving foot to long on pedal after unit

reaches maximum stroke

1. take foot off pedal as soon as stroke is complete

TROUBLE SHOOTING PROBLEMS

7

DESCRIPTION OF PROBLEM

POSSIBLE CAUSE

SOLUTION

Hydraulic system makes squealing noise

during adjustment but:

no hydraulic leak noted

oil supply may be low

1. check oil level in reservoir.

2. refill with recommended hydraulic oil to correct level.

Clunking sounds are heard during table’s

height adjustment but:

all other tables functions working

sliding side access panels are not

positioned correctly

1. remove footend access panels, check to make sure Nylatron

edging is securely in place and reinsert panels into slides

2. reference Installation of Access Panels on page 14

Table makes scraping or grinding noises

during height adjustment but:

back does not make noise

no hydraulic leak noted

lift chains and shaft bearings require

lubrication

1. remove side drawer, locate chains and shaft

2. spray roller chains and shaft bushings with silicone lubricant

Table functions are erratic and noisy but

no hydraulic leak noted

air in hydraulic system

1. run table through all functions several times

2. loosen fill hole cap on reservoir to release air

Table wobbles or jiggles

table leveling glides not properly

adjusted

1. adjust leveling glides located at each corner of the base until

all four levelers set firmly on the floor surface.

For Diagnostic Help Call ENOCHS Technical Support at 1-800-322-6416

ACCESS TO TABLE COMPONETS

ACCESS TO TERMINAL BLOCK 1 (TB1)

Terminal block is accessible from the footend table base through the sliding access panels. Before continuing, read

and follow all instruction for SAFETY BLOCKING PROCEDURES on page 3.

ACCESS TO CAPACITORS

Capacitors are accessible from the footend table base through the sliding access panels. Before continuing, read

and follow all instruction for SAFETY BLOCKING PROCEDURES on page 3.

ACCESS TO HYDRAULIC PUMP UNIT

Pump unit is accessible from the footend table base through the sliding access panels. Before continuing, read and

follow all instruction for SAFETY BLOCKING PROCEDURES on page 3.

ACCESS TO FOOT CONTROL MICRO-SWITCHES

The foot operated function control switches are of modular construction. Each module is held in place by three (3)

Phillips screws accessible from the bottom of assembly. Once module is freed, the screw at the treadle foot plate’s

lower pivot point can be removed to free the treadle foot plate. CAUTION: Be sure the Nylatron pivot bearing is in

place on the pivot screw when reinstalling the treadle foot plate.

ACCESS TO BACK CYLINDER

If cylinder is functional, raise back to full up position and remove access panel on table base. If back cylinder is not

functional: UNPLUG TABLE FROM POWER SOURCE. Locate bolt connecting the support arm to the couch

frame. Using a 7/16" socket with 12" extension remove the nut, tap bolt out approx. 1" and remove with pliers. Lift

couch and secure in forward-most position. Then remove access panel on table base.

ACCESS TO LIFT CYLINDER

Cylinder is accessible from the headend of the table base after table has been blocked per the SAFETY

BLOCKING PROCEDURES on page 3 and headend squaring panel has been removed.

ACCESS TO EXTERNAL SOLENOID

This part is accessible from the footend table base through the sliding access panels. Before continuing, read and

follow all instruction for SAFETY BLOCKING PROCEDURES on page 3.

ACCESS TO HOSES

Reference Hydraulic Hose Replacement on page 11 for access of specific hose. Before continuing, read and follow

all instruction for SAFETY BLOCKING PROCEDURES on page 3.

ACCESS TO WARMER BULB

Pull footend drawer out to full extension, lift slightly and remove drawer from table. Warming bulb is accessible

through the drawer opening.

BACK CYLINDER REPLACEMENT

8

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working on this table so

unplug power cord from power source during all repair procedures. Replace all covers upon completion of repair.

BEFORE BEGINNING: It is important to duplicate exact hose routing, plastic cable tie placement, clevis adjustment and

vinyl cylinder cover attachment to assure a correct installation. Note each detail before removal.

1. Adjust table to a comfortable working height.

2. Bring couch top to full chair position and UNPLUG TABLE. Remove bolt connecting the support arm to the couch frame

and allow support arm to lower down into table. Secure upholstered couch in a full forward position. If back cylinder is not

functional: UNPLUG TABLE FROM POWER SOURCE. Locate bolt connecting the support arm to the couch frame.

Using a 7/16" socket with 12" extension remove the nut, tap bolt out approximately 1" and remove with pliers. Lift couch

and secure in full forward position.

3. Remove four Philip-head screws that secure access panel on table base and remove panel to expose back cylinder.

4. Remove key and pin from cylinder rod-end clevis where it attaches to the support arm.

HELPFUL HINT: Before removing pin from clevis, note the position of the washer/spacers. These spacers are used to

center the cylinder within the support arm channel to allow adequate clearance for the top hose fitting of the cylinder.

Count exposed threads on cylinder rod, before removing clevis. New cylinder comes with a clevis that must be adjusted to

have the same number of exposed threads as the original to assure correct cylinder extension.

5. Cut the two large plastic cable ties securing vinyl cover to cylinder - do not cut the small plastic tie at top end of cover.

Remove cover. Note location and tension of ties for re-assembly.

6. Locate and cut the 8-10 small cable ties from the base of cylinder to the two large ties located where support arm enters

metal channel to free hoses and electrical cord - - DO NOT CUT LARGE TIES anchoring hoses and electrical cord to

channel. This process will allow splicing the electrical cord rather than replacing it all the way to the terminal point.

7. With hoses and cord still attached, remove base-end key and pin, carefully lift cylinder out and lay to the side, making

room for replacement.

8. Place new cylinder in position and secure with base-end pin and key. Transfer hoses to new cylinder. DO NOT OVER

TIGHTEN CONNECTIONS the cylinder fittings have internal "O"ring seals which can be damaged by excessive force

resulting in leaking at hose fitting.

9. Locate old cylinder’s electrical cord, measure 7-8" back from the metal channel and cut off cord at this point which will

allow ample cord to make splice. Strip outer cover to expose approx. 4" of insulated wire. Strip white and black wires

about 1/2", connect new cylinder wires and secure connections with "crimp on" wire joints (provided). Tape splices to

electrical cord in opposite directions to make splices secure and neat.

10. Plug table into power source and operate back cylinder several times to purge any air from system, confirm proper

operation and make sure there are no oil leaks at hose connections.

11. Clean up any hydraulic oil in the unit .

12. Once satisfied of successful replacement, place black vinyl cover on cylinder and secure with ties. Trim off excess tie

length. Install the rod-end clevis and leave the exact same number of threads exposed as was on old cylinder.

13. With extreme caution, depress foot pedal to extend clevis to support arm connection point. When installing new cylinder

make sure the top hose fitting on the cylinder is centered in channel with adequate clearance. This is accomplished by

using washer/spacers when installing clevis to support arm.

HELPFUL HINT: Support arm channel must be spread slightly in order to position the washers/spacers and pin for correct

alignment of the cylinder within the channel. Insert the handle of a ball pene hammer into channel and rotate using the

width of handle to spread the channel. This will allow the washer/spacers and the pin to be inserted easily.

14. Re-attach support arm to couch frame.

15. Place access panel in position on table base, but do not secure.

16. For correct clevis adjustment, place back in full down position and observe the bumpers attached to the underside of the

couch frame. At full down position, bumpers should make only gentle contact with the access panel. If back hits access

panel hard, clevis needs to be screwed out to expose more threads. If bumpers do not make contact with the access

panel, screw clevis in to reduce the number of exposed threads on the rod.

17. Confirm all adjustments are correct and hose connections are solid. Bind hydraulic hoses together with electrical cord

and secure with plastic ties. Trim off excess tie length. Secure access panel on table base with original four screws.

18. Raise table to full height, remove footend sliding access panels and insert blocking (see Safety Blocking Procedure page

3). Loosen fill cap on reservoir to release excess air from system and to check for correct oil level (see System Overview

page 4). When repair is completed install sliding access panels (see Installation of Access Panels on page 14).

LIFT CYLINDER REPLACEMENT

9

The weight of the table’s upper section is supported entirely by hydraulic oil captured in the

bottom section of the lift cylinder (116-42BC11) and the hose (116-42BH1B) connecting

it to the external solenoid (116-42BS).

Follow SAFETY BLOCKING PROCEDURE on page 3 of this manual before proceeding with this

maintenance or repair procedure.

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working

on this table so unplug power cord from power source during all repair procedures.

Replace all covers upon completion of repair.

BEFORE YOU BEGIN: It is important to duplicate the exact hose routing, plastic cable tie placement and clevis

adjustment attachment in order to assure a trouble free installation. Note each detail before removal.

1. IMPORTANT: You must complete the SAFETY BLOCKING PROCEDURE on page 3 and confirm table is

unplugged from power source before continuing with this repair.

2. Working at the headend of the table, remove sliding access panel, access panel channels, squaring panel and the

Heyco® strain relief. Note the top two screws of the access panel channels were removed in the Safety Blocking

Procedure. It is important to note the washer/ spacers placement between the channels and the base of table for

proper channel alignment during reassembly. Skip to Step 4.

3. For functional cylinder, remove side drawer and set aside. Reaching through the side drawer opening, locate top of

cylinder and remove key and pin from rod-end clevis. Plug table into power source and with extreme caution, lower lift

cylinder to full down position. Unplug table.

4. Cut the plastic cable ties to free hose from cylinder.

5. Remove hose at top of cylinder first by holding elbow with a ½" wrench while loosening fitting. Next remove hose at

bottom of cylinder using a 5/8" wrench to hold adapter and a ½" wrench to loosen hose fitting.

6. Remove base-end key and pin from cylinder and carefully remove cylinder from table. NOTE: Overall length of new

cylinder must match old cylinder’s. Helpful Hint: Place cylinders side-by-side to adjust new unit to correct length.

7. Place new cylinder in position and secure base-end with pin and key. Attach hoses to replacement cylinder. DO NOT

OVER TIGHTEN CONNECTIONS the cylinder fittings have internal "O" ring seals which can be damaged by excessive

force.

8. Plug table into power source and with extreme caution, depress foot pedal momentarily to extend cylinder until clevis

pin can be easily inserted. Secure with key. IMPORTANT NOTE: positioning of clevis pin key must be vertical)

9. Raise table and remove blocking. Run table through several cycles to purge air from system and to determine there are

no hydraulic fluid leaks. Upon successful repair, place table in highest position, clean up any hydraulic oil in the unit

and secure hose with ties, trimming off excess tie length. Following Installation of Access Panels on page 14, reinstall

headend squaring panel, access panel channels, sliding access panel and the HEYCO® strain relief.

10. Loosen fill cap on reservoir to release excess air from system and to check oil level (see System Overview page 4),

then reinstall footend sliding access panels, (see Installation of Access Panels on page 14)

11. To determine if clevis is adjusted correctly, fully extend footend drawer and lower table to full down position.

A. If drawer will not close cylinder clevis needs to be adjusted so cylinder has a longer extension.

1. Block table up as instructed in SAFETY BLOCKING PROCEDURE on page 3.

2. Remove clevis key and pin and carefully lower lift cylinder 3"–4"

3. Turn clevis counter clockwise two turns.

4. Position and carefully raise cylinder rod until clevis pin can be easily inserted

5. Secure with key making sure it is positioned vertically.

6. Remove all safety blocking and lower table.

7. If footend drawer still will not completely close, repeat steps 1 through 6.

B. If footend drawer closes completely adjustment of clevis is satisfactory.

EXTERNAL SOLENOID REPLACEMENT

10

The weight of the table’s upper section is supported entirely by hydraulic oil captured in the

bottom section of the lift cylinder (116-42BC11) and the hose (116-42BH1B) connecting

it to the external solenoid (116-42BS).

Follow SAFETY BLOCKING PROCEDURE on page 3 of this manual before proceeding with this

maintenance or repair procedure.

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working

on this table so unplug power cord from power source during all repair procedures.

Replace all covers upon completion of repair.

BEFORE YOU BEGIN: It is important to duplicate the exact hose and wire routing in order to assure a trouble free installation.

Observe and note each detail before removal.

1. IMPORTANT: You must complete the SAFETY BLOCKING PROCEDURE on page 3 and confirm table is

unplugged from power source before continuing with this repair.

2. SPECIAL SAFETY NOTE:The weight of the table’s upper section is supported entirely by hydraulic oil captured in the

bottom section of the lift cylinder (116-42BC11) and the hose (116-42BH1B) connecting it to the external solenoid (116-

42BS). DO NOT DO THIS REPAIR WITHOUT BLOCKING UP TABLE.

3. Remove the footend squaring panel and the HEYCO®strain relief. Note: on tables with Serial Numbers H00852 and

above, remove the black motor cover panel over pump unit and set aside.

4. Disconnect external solenoid cylinder’s two wire electrical cord from terminal block TB1 (see Electrical System Wiring

Diagram on page 15).

5. Remove hoses from external solenoid cylinder using a ½" wrench to hold adapter and a ½" wrench to loosen fitting.

HELPFUL HINT: To make cleanup easier have paper towels or shop rag handy to capture hydraulic oil from hose and

external solenoid cylinder.

6. Remove key and pin from external solenoid cylinder and carefully remove from table.

7. Place new external solenoid cylinder in position and secure with pin and key.

8. Reattach hoses to new external solenoid cylinder and secure. DO NOT OVER TIGHTEN CONNECTIONS the cylinder

fittings have internal "O" ring seals which can be damaged by excessive force.

9. Reconnect new external solenoid cylinder’s two wire electrical cord to terminal block TB1. (see Electrical System Wiring

Diagram on page 15)

10. Plug table into power source and with extreme caution raise table up slightly and look for leaks in hose and at hose

fittings. Leave blocking in place until no leaks have been confirmed.

11. Double check to make sure there are no leaks in hose or hose fittings between lift cylinder and external solenoid cylinder,

then remove blocking. Run table through several cycles to purge air from system and check again to make sure there are

no hydraulic fluid leaks.

12. Loosen fill cap on reservoir to release excess air from system and to check oil level (see System Overview page 4).

13. Once successful repair has been confirmed reinstall black motor cover, footend squaring panel, HEYCO®strain relief and

the footend sliding access panels (see Installation of Access Panels page 14).

HYDRAULIC HOSE REPLACEMENT

11

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working

on this table so unplug power cord from power source during all repair procedures.

Replace all covers upon completion of repair.

BEFORE YOU BEGIN: It is important to duplicate the exact hose routing and plastic cable tie positions in order to assure a

trouble free installation. It is also important to install new hoses to maintain original travel path of the hose and electrical

cord bundle when table height is adjusted. Observe and note each detail before removal.

FOR ALL HOSE REPLACEMENTS

1. For your safety you must complete the SAFETY BLOCKING PROCEDURE on page 3 of this manual and

confirm table is unplugged from power source before proceeding.

2. DO NOT OVER TIGHTEN HOSE CONNECTIONS the cylinder fittings have internal "O" ring seals which can be

damaged by excessive force.

3. The hoses must not be allowed to rub or chafe against table parts during movement or become damaged by moving

parts. The importance of this can not be over emphasized!

REPLACING HOSE # 116-42BH1B - 9-5" hose Routing: external solenoid base of lift cylinder

1. Block up table per instructions on page 3. SPECIAL SAFETY NOTE:

DO NOT DO THIS REPAIR WITHOUT BLOCKING UP TABLE. The

weight of the table’s upper section is supported entirely by hydraulic oil

captured in the bottom section of the lift cylinder (116-42BC11) and the hose

(116-42BH1B) connecting it to the external solenoid (116-42BS).

2. Disconnect old hose from base of lift cylinder and from external solenoid.

3. Connect new hydraulic hose to lift cylinder and to external solenoid cylinder. DO NOT OVER TIGHTEN HOSE

CONNECTIONS the cylinder fittings have internal "O" ring seals which can be damaged by excessive force.

4. Plug table into power source and with extreme caution raise table up slightly and look for leaks on hose or at hose

fittings. Leave blocking in place until you have confirmed there are no hydraulic oil leaks.

5. Go to: Finishing Hose Replacement below.

REPLACING HOSES

# 116-42BH2R - 75" hose Routing: motor top of lift cylinder top of back cylinder

# 116-42BH2B - 66" hose Routing: motor external solenoid base of back cylinder.

1. Using foot control, bring couch top to full chair position and UNPLUG TABLE. Remove bolt connecting the support

arm to the couch frame and allow support arm to lower down into table. Secure upholstered couch in a full forward

position. If back cylinder is not functional: UNPLUG TABLE FROM POWER SOURCE. Locate bolt connecting the

support arm to the couch frame. Using a 7/16" socket with 12" extension remove the nut, tap bolt out approximately

1" and remove with pliers. Lift couch and secure in the forward-most position.

2. Remove four Philip-head screws securing access panel on table base and set panel off to side.

3. When replacing hose #116-42BH2R remove headend sliding access panel, access panel channels, squaring panel

and the Heyco® strain relief. Note the top two screws of the access panel channels were removed in the Safety

Blocking Procedure. It is important to note the washer/ spacers placement between the channels and the base of

table for proper channel alignment during reassembly.

4. Position new hose next to the old hose/electrical cord bundle.

5. For either hose replacement, start at the motor connection and remove old hose and connect new hose. Then

systematically cut plastic cable tie, pull old hose out of bundle, replace with new hose and secure bundle with plastic

cable ties all the way to the cylinder. Cutting ties on cylinder, remove old hose from cylinder and connect new hose

then secure with cable ties. Continually check to make sure the same curve of the hose/cord bundle is being

maintained to assure a correct travel path of the hose when table height is adjusted. NOTE: DO NOT OVER

TIGHTEN HOSE CONNECTIONS the cylinder fittings have internal "O" ring seals which can be damaged by

excessive force.

6. Go to: Finishing Hose Replacement below.

FINISHING HOSE REPLACEMENT

1. Remove blocking. Run table through several cycles to purge air from system and check to make sure there are no

hydraulic fluid leaks from cylinders, hoses or hose connections.

2. Check travel path of hoses making sure they do not rub or chafe against table parts during movement which will

result in damage to hoses by moving parts.

3. Loosen fill cap on reservoir to release excess air from system and check oil level (see System Overview page 4).

4. Once successful repair has been confirmed, reinstall squaring panel, HEYCO®strain relief and sliding access

panels (see Installation of Access Panels on page 14).

PUMP UNIT REPLACEMENT

12

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working

on this table so unplug power cord from power source during all repair procedures.

Replace all covers upon completion of repair.

BEFORE YOU BEGIN: It is important to duplicate the exact hose, electrical cord and wire routings as

well as plastic cable ties placement to assure a trouble free installation. Observe and note location detail

before removal.

REPLACEMENT OF PUMP UNIT in tables with Serial Numbers H00851and below.

1. These tables have open top capacitors banded to a welded lug and do not need to be removed for the

installation of new pump unit

2. You must complete the SAFETY BLOCKING PROCEDURE on page 3 and confirm table is unplugged from

power source before proceeding.

3. Cut plastic cable ties on wires running from motor to capacitors. Disconnect the blue and red motor wires from

capacitors. Disconnect yellow motor wire from terminal block TB1 (see Electrical System Wiring Diagram page

15) DO NOT REMOVE capacitors from table but slightly lift them up for easier removal of motor pan.

4. Remove the six 1/4-20 Hex head bolts holding the motor pan to base of table.

5. Disconnect both hydraulic hoses from pump collar using a ½" wrench to hold adapter and a ½" wrench to loosen

fitting.

6. Pull out cords and wires tucked between the pan edge and the pump unit. Push them towards headend of table.

7. Lift entire pan with pump unit out of table and set on a clear work surface for installation of replacement.

8. Remove three bolts holding unit to the motor pan, carefully lift unit out and set aside.

9. Clean up any hydraulic oil in the motor pan and inside the table.

10. Place new pump unit in motor pan and secure with the three bolts.

11. Check oil level (see System Overview page 4).

12. Unfasten the terminal block TB1 from the table base and push all wires, electrical cords and hoses back towards

headend of table to keep them out of the way while installing new pump unit .

13. Place entire pump unit assembly back into table. Confirm no wires have been caught underneath motor pan.

14. Secure motor pan in place with the six 1/4-20 hex head bolts and lock washers.

15. Secure terminal block back into original position and confirm no wires have been caught under motor pan

assembly. Tuck wires and electrical cords securely between motor pan and pump unit.

16. Reconnect hoses to pump collar. DO NOT OVER TIGHTEN CONNECTIONS the cylinder fittings have internal

"O" ring seals which can be damaged by excessive force.

17. Reconnect blue and red motor wires to capacitors and the yellow wire to terminal block TB1. (see Electrical

System Wiring Diagram on page 15)

18. Plug table into power source and with extreme caution raise table slightly and remove blocking. Run table

through several cycles to purge any air from system and to confirm there are no hydraulic fluid leaks from the

hose connections.

19. Loosen fill cap on reservoir to release excess air from system and then secure cap.

20. Reinstall plastic cable ties, footend squaring panel, HEYCO®strain relief and sliding access panels (see

Installation of Access Panels on page 14).

PUMP UNIT REPLACEMENT

12

DANGER: ELECTRICAL SHOCK HAZARD

This repair should be done by a qualified service technician. Shock hazard exists when working

on this table so unplug power cord from power source during all repair procedures.

Replace all covers upon completion of repair.

REPLACEMENT OF PUMP UNIT in tables with Serial Numbers H00852 and above.

1. For your safety, you must complete the SAFETY BLOCKING PROCEDURE on page 3 and confirm table is

unplugged from power source before proceeding.

2. Locate the black motor cover panel over pump unit remove the two screws securing panel to assembly. Remove

panel and set aside.

3. Disconnect the blue and red capacitor wires and yellow motor wire from terminal block TB1 (see Electrical

System Wiring Diagram on page 15) DO NOT disconnect capacitors from pump unit assembly.

4. Remove the six 1/4-20 Hex head bolts holding the motor pan to base of table.

5. Disconnect both hydraulic hoses from pump collar using a ½" wrench to hold adapter and a ½" wrench to loosen

fitting.

6. Pull out cords and wires tucked between the pan edge and the pump unit and place towards headend of table.

7. Lift entire motor pan with pump unit and capacitors out of table and set on a clear work surface for installation of

replacement.

8. Cut the two small plastic cable ties holding the blue, red and yellow motor wires together on the pump unit

assembly.

9. Disconnect capacitors by slightly prying up on the spring clips holding capacitors in place. Once capacitors are

free, remove capacitor caps to gain access to wire connections.

10. Disconnect the blue and red motor wires only from the capacitors.

11. Remove three bolts holding pump unit to the motor pan and carefully lift pump unit out and set aside.

12. Clean up any hydraulic oil in the motor pan and inside the table.

13. Place new pump unit in motor pan and secure with the three bolts.

14. Reconnect the blue and red motor wires to capacitors - connect blue to blue side and red to red side.

15. Reassemble capacitors and clip back into place. Check to make sure spring clips are correctly aligned with the

groves in both the top and bottom caps of the capacitors.

16. Using plastic cable ties, secure all wires leading to capacitors.

17. Check oil level (see System Overview page 4).

18. Unfasten the terminal block from the table base and push all wires, electrical cords and hoses back towards

headend of table to keep them out of the way of reinstalling pump unit assembly.

19. Place entire pump unit assembly back into table making sure no wires have been caught underneath motor pan.

20. Secure motor pan with the six 1/4-20 Hex head bolts and lock washers.

21. Secure terminal block back into original position and tuck wires and electrical cords securely between pan and

pump unit.

22. Reconnect hoses to pump collar. DO NOT OVER TIGHTEN CONNECTIONS (the cylinder fittings have internal

"O" ring seals which can be damaged by excessive force.

23. Reconnect the blue and red capacitor wires and yellow motor wire to terminal block TB1. (see Electrical System

Wiring Diagram on page 15).

24. Plug table into power source and with extreme caution, raise table slightly and remove blocking. Run table

through several cycles to purge any air from system and to confirm there are no hydraulic fluid leaks from the

hose connections.

25. Loosen fill cap on reservoir to release excess air from system and then secure cap.

26. Reinstall black motor cover panel, footend squaring panel, HEYCO®strain relief and sliding access panels (see

Installation of Access Panels on page 14).

INSTALLATION OF ACCESS PANELS

14

See Attachment

ELECTRICAL SYSTEM WIRING DIAGRAM

See Attachment

ELECTRICAL SYSTEM SCHEMATIC

See Attachment

HYDRAULIC SYSTEM SCHEMATIC

See Attachment

FOOT PEDAL WIRING DIAGRAM

See Attachment

Maintenance Checklist

19

Maintenance of the Power 4000 is responsibility of owner. Manufacturer recommends the following areas be inspected by

qualified service technician every six months to assure proper operation of table. Copy of this checklist should be used for each

inspection and maintained in table’s master file. Each inspection area is required to indicate a pass or fail status. ALL AREAS

failing inspection must be serviced/repaired immediately by qualified technician. See ENOCHS Service Manual for Power 4000

for repair/service advice and instructions. Direct all questions to ENOCHS at 1-800-322-6416.

Serial Number:

H

Inspection Date:

Inspection Agency:

Table Location:

Technician:

Area Supervisor:

PASS

FAIL

INSPECTION AREA

grounding continuity

outer rubber covering of power cord is free from all nicks, cuts, abrasions and/or

any fraying

electrical plug is free from all damage

power cord held firmly in place by strain relief at plug and table base

electrical outlet on table functional

warming drawer indicator light illuminates in ON position

warming drawer bulb is a 40 watt ( 11 ¾” long) and in working order

no hydraulic leaks

all foot control pedals move freely, returning to neutral position without sticking

outer rubber covering of foot control power cord firmly held in place by strain

relief at back of foot control and at table base

TABLE UP/DN functions exhibit smooth range of movement

BACK UP/DN functions exhibit smooth range of movement

pelvic tilt adjusts smoothly and easily

leg extension moves freely in and out of table

irrigation basin drawer moves freely in and out of table

stirrups slide smoothly in and out of table and lock into lateral position

upholstery is free from cuts, rips or punctures

POWER 4000 PARTS LIST

21

Part

Number

Category

Part Description

Unit

116-19B

base

base with shell, foot pedal & all internal parts (no top or padboard)

ea

116-19B1

base

base shell only

ea

116-19B8

base

lower sliding access panel

ea

116-19B9

base

upper sliding access panel (new style)

ea

116-19B91

base

upper sliding access panel (old style with galvanized panel)

ea

116-42BL

chain

chain with link assembly

ea

116-42BL1

chain

chain only

ea

116-42BL2

chain

connecting link

ea

116-42BGL

chain

single shaft assembly, lower gear (designate left or right side)

ea

116-42BGU

chain

upper gear with shaft

ea

116-42BC2

cylinder

BACK cylinder with hoses

ea

116-42BC22

cylinder

BACK cylinder black cover

ea

116-42BC21

cylinder

BACK cylinder only

ea

116-42BS

cylinder

external solenoid

ea

116-42BC1

cylinder

LIFT cylinder with hoses

ea

116-42BC11

cylinder

LIFT cylinder only

ea

116-54B

drawer

side drawer with laminate front

ea

116-54B1

drawer

side drawer only

ea

116-54B2

drawer

side drawer front

ea

116-55B

drawer

footend drawer with heat sink & laminate front

ea

116-55B1

drawer

footend drawer with heat sink attached

ea

116-55B2

drawer

footend drawer laminate front

ea

116-55B3

drawer

footend drawer plastic rail & metal guide - right side

pr

116-55B5

drawer

footend metal heat sink only

ea

116-55B4

drawer

footend drawer plastic rail & metal guide - left side

pr

116-54B4

drawer

side drawer plastic rail & metal guide - left side

ea

116-54B3

drawer

side drawer plastic rail & metal guide - right side

ea

116-68

electrical

electrical plug, hospital grade NEMA plug

ea

116-69B

electrical

el-pac complete with Power 4000 faceplate

ea

116-69B2

electrical

el-pac without faceplate

ea

116-69B1

electrical

faceplate only

ea

116-68B2

electrical

HEYCO®strain relief at foot control

ea

116-68B1

electrical

HEYCO®strain relief for motor connection

pair

116-68B

electrical

hospital grade power cord and plug

ea

116-42BF

foot control

complete foot control with cord

ea

116-42BF1

foot control

complete foot control module

ea

116-42BF5

foot control

foot control outside metal casing only

ea

Table of contents

Popular Indoor Furnishing manuals by other brands

Mocka

Mocka Inca Console Table Assembly instructions

Furniture of America

Furniture of America CM6471-LV Assembly instructions

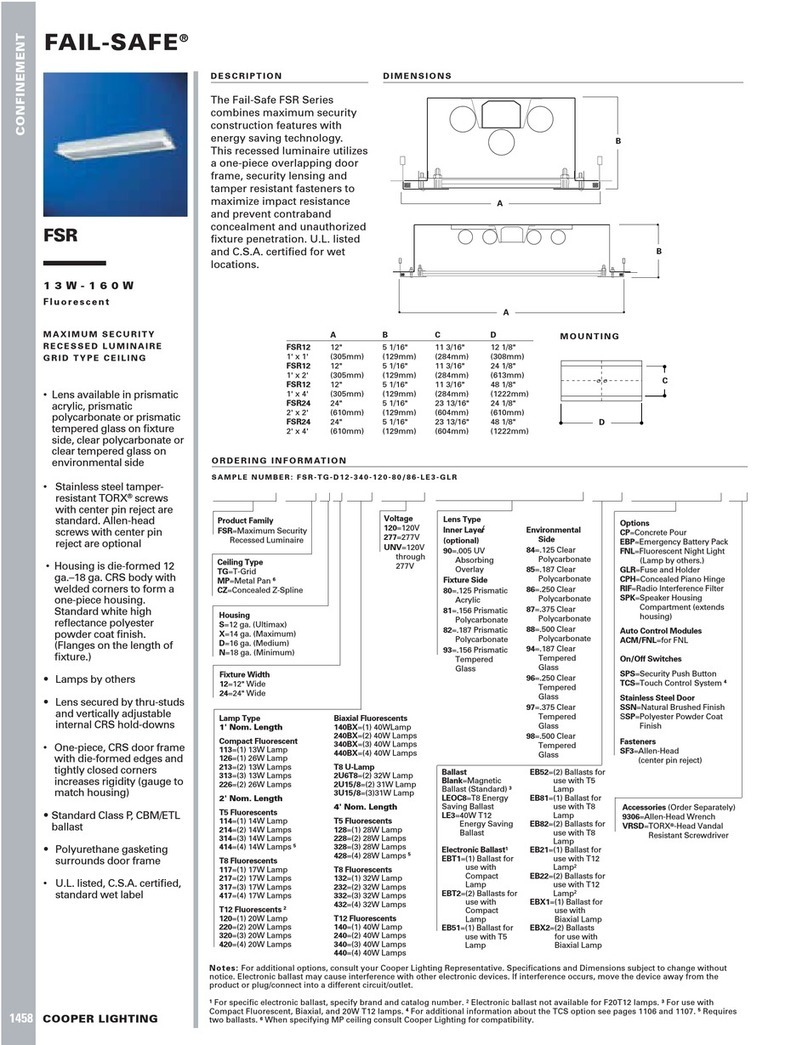

Cooper Lighting

Cooper Lighting FAIL-SAFE FSR Specification sheet

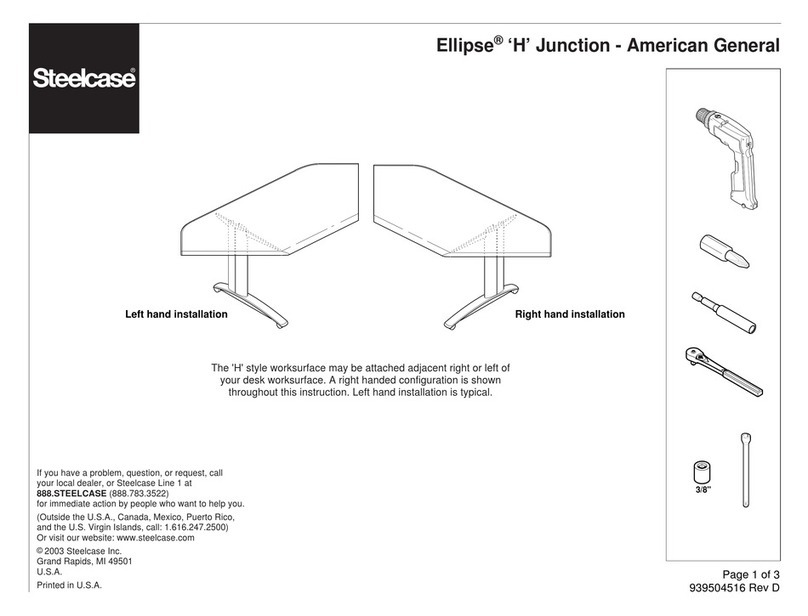

Steelcase

Steelcase Ellipse H Junction manual

Notável Móveis

Notável Móveis NT 1195 Assembly instructions

Coaster

Coaster 223652 Assembly instructions

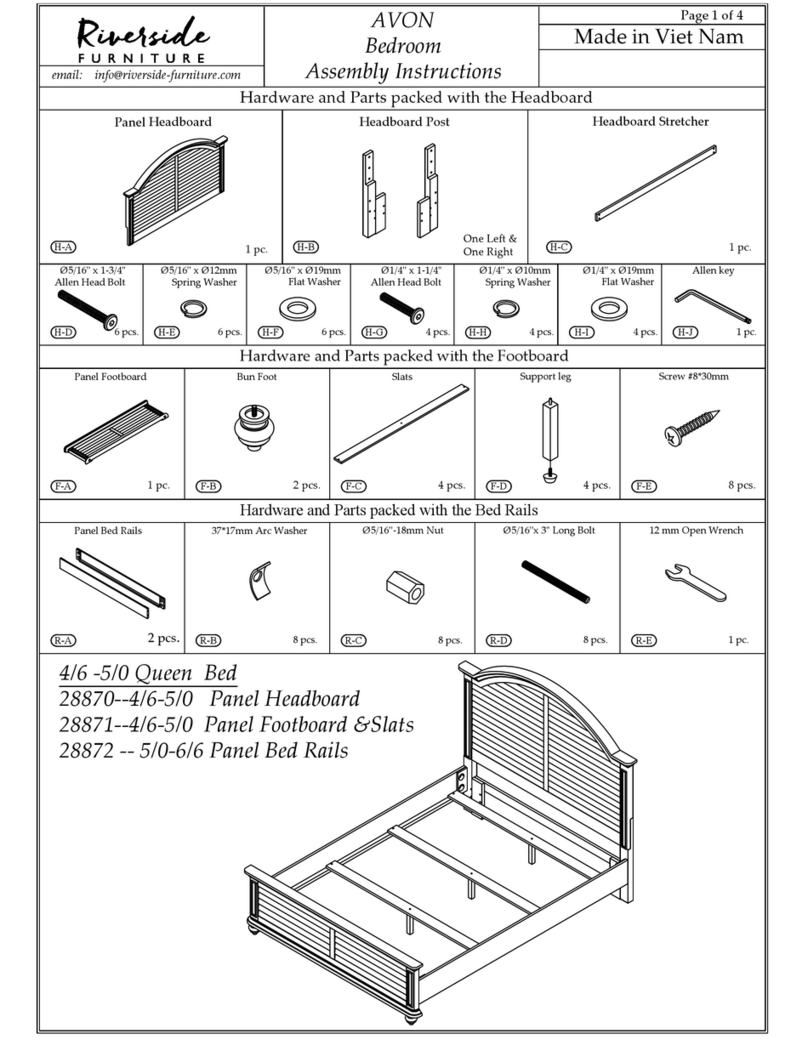

Riverside

Riverside AVON Assembly instructions

Haworth

Haworth Zody II Adjustment

Night & Day Furniture

Night & Day Furniture Murphy Cube Assembly instructions

Do+Able Products

Do+Able Products 12307 Assembly instructions

FMD Furniture

FMD Furniture BRISTOL 2 4020-002 Assembly instruction

JWA

JWA MARCELLUS 70888 Assembly instruction