ensto ARCTEQ AQ 100 Series User manual

A -102

Arc flash protection device

Instruction manual

Table of contents

1 Document inf1 Document informaormationtion .................................................................................................................................................................................................................................... 55

2 A2 Abbrbbreeviaviationstions .............................................................................................................................................................................................................................................................. 77

3 General3 General................................................................................................................................................................................................................................................................................ 88

4 De4 Devicevice ffeaeatturureses ........................................................................................................................................................................................................................................................ 99

5 Connections5 Connections.............................................................................................................................................................................................................................................................. 1010

5.1 Simpli_ed block diagram ...................................................................................................... 10

5.2 Inputs .................................................................................................................................. 12

5.2.1 Arc sensor channels.................................................................................................. 12

5.2.2 inary inputs ............................................................................................................. 12

5.3 Outputs ............................................................................................................................... 13

5.3.1 inary outputs ........................................................................................................... 13

5.3.2 Trip relays.................................................................................................................. 13

5.3.3 System failure relay.................................................................................................... 14

5.4 Auxiliary voltage................................................................................................................... 14

6 Ar6 Arc sensorsc sensors................................................................................................................................................................................................................................................................ 1515

6.1 Arc light _ber optic loop sensor AQ-06 ................................................................................ 15

6.2 Arc light _ber optic loop sensor AQ-07 ................................................................................ 15

6.3 Arc light _ber optic loop sensor AQ-08 ................................................................................ 15

6.4 Sensor dependencies .......................................................................................................... 15

6.5 Connecting sensors............................................................................................................. 16

6.5.1 Fiber loop sensors ..................................................................................................... 16

7 Opera7 Operation and con_gtion and con_guraurationtion .............................................................................................................................................................................................................. 1818

7.1 DIP switch settings .............................................................................................................. 18

7.1.1 Scheme selection ...................................................................................................... 19

7.1.2 Available logic schemes............................................................................................. 19

7.2 Push button (SET) ............................................................................................................... 21

7.2.1 System setup (auto-con_guration) ............................................................................. 22

7.2.2 Reset......................................................................................................................... 22

7.2.3 Input connection check ............................................................................................. 22

7.3 Circuit breaker failure protection .......................................................................................... 22

7.4 LED indicator functions........................................................................................................ 22

7.5 LED operations guide .......................................................................................................... 23

7.6 Non-volatile memory............................................................................................................ 23

8 S8 Syyststem self-superem self-supervisionvision............................................................................................................................................................................................................................ 2525

9 Applic9 Applicaation examplestion examples .................................................................................................................................................................................................................................. 2626

9.1 Application with overcurrent and arc light conditions (LV and MV) ........................................ 26

10 W10 Wiring exampleiring example.................................................................................................................................................................................................................................................. 2828

11 D11 Dimensions and installaimensions and installationtion ............................................................................................................................................................................................................ 2929

12 T12 Testingesting .......................................................................................................................................................................................................................................................................... 3131

12.1 Testing the light-only mode ................................................................................................ 31

12.2 Testing the light and current mode ..................................................................................... 31

12.3 Testing the C FP function.................................................................................................. 32

12.4 Testing the operation time.................................................................................................. 32

12.5 Test plan example .............................................................................................................. 32

13 T13 Trroubleshoooubleshootingting................................................................................................................................................................................................................................................ 3434

14 T14 Technicechnical daal datata.................................................................................................................................................................................................................................................... 3535

14.1 Mounting and installation ................................................................................................... 35

14.2 Operating times ................................................................................................................. 35

14.3 Auxiliary voltage................................................................................................................. 35

14.4 inary inputs...................................................................................................................... 35

14.5 Trip relays .......................................................................................................................... 36

14.6 inary output(s) ................................................................................................................. 36

14.7 System failure relay............................................................................................................ 36

14.8 Fiber optic loop sensors ..................................................................................................... 37

14.9 Disturbance tests............................................................................................................... 37

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

1

14.10 Voltage tests.................................................................................................................... 38

14.11 Mechanical tests.............................................................................................................. 38

14.12 Environmental conditions ................................................................................................. 38

14.13 Casing............................................................................................................................. 38

15 Or15 Ordering infdering informaormationtion ................................................................................................................................................................................................................................ 3939

16 Contact and r16 Contact and reeffererence infence informaormationtion........................................................................................................................................................................................ 4141

AA -102-102

Instruction manual

Version: 2.02

2© Arcteq Relays Ltd

IM00008

Disclaimer

Please read these instructions carefully before using the equipment or taking any other actions with

respect to the equipment. Only trained and quali_ed persons are allowed to perform installation,

operation, service or maintenance of the equipment. Such quali_ed persons have the responsibility to

take all appropriate measures, including e.g. use of authentication, encryption, anti-virus programs,

safe switching programs etc. necessary to ensure a safe and secure environment and usability of the

equipment. The warranty granted to the equipment remains in force only provided that the instructions

contained in this document have been strictly complied with.

Nothing contained in this document shall increase the liability or extend the warranty obligations of the

manufacturer Arcteq Relays Ltd. The manufacturer expressly disclaims any and all liability for any

damages and/or losses caused due to a failure to comply with the instructions contained herein or

caused by persons who do not ful_l the aforementioned requirements. Furthermore, the manufacturer

shall not be liable for possible errors in this document.

Please note that you must always comply with applicable local legislation and regulations. The

manufacturer gives no warranties that the content of this document is in all respects in line with local

laws and regulations and assumes no liability for such possible deviations.

You are advised to notify the manufacturer in case you become aware of any errors in this document or

of defects in the equipment.

The manufacturer reserves the right to update or amend this document at any time.

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

3

Copyright

Copyright © Arcteq Relays Ltd. 2023. All rights reserved.

AA -102-102

Instruction manual

Version: 2.02

4© Arcteq Relays Ltd

IM00008

1 Document information

Table. 1 - 1. History of Revision 1.

RReevisionvision 1.001.00

Date October 2011

Changes - The _rst revision of the manual.

RReevisionvision 1.011.01

Date October 2011

Changes - Product image added.

RReevisionvision 1.021.02

Date November 2011

Changes

- Chapter 3.3.1 revised: e.g. a DIP switch forward-and-back feature is added to system

con_guration.

- Chapter 3.3.5 revised: e.g. the scheme selection by DIP switching is added. One selective

and one non-selective scheme added.

RReevisionvision 1.031.03

Date May 2019

Changes - Input connection check added.

- Technical data updated.

Table. 1 - 2. History of Revision 2.

RReevisionvision 2.002.00

Date October 2020

Changes

- Content completely rewritten to improve grammar and readability.

- The "Available logic schemes" chapter updated.

- The AQ-02 point sensor chapter added to the "Arc sensors" chapter, and AQ-02's technical

data added to the "Technical data" chapter.

- The sensor–unit type dependency list updated.

- The "Connecting sensors" chapter added.

- All technical data checked and updated where necessary.

- Ordering information updated.

- Images updated where necessary.

RReevisionvision 2.012.01

Date November 2021

Changes

- Cut-out panel installation image added.

- Dimension measurements updated in images and in technical data.

- Wiring diagram, simpli_ed block diagram, DIP switch diagram & application image(s)

updated.

- Push button image added.

- End covering description added to AQ-07, removed from AQ-08.

- Cut-and-slice text removed from all _ber descriptions.

- Connections image updated.

- The test plan example updated.

- All table layouts uni_ed in "Technical data".

- The IP classi_cation of point sensors updated.

- The AWG value of sensor cable corrected.

- "Disturbance tests" table reformatted.

- Order code images updated.

- The number for Arcteq's technical support added to the reference information.

RReevisionvision 2.022.02

Date January 2023

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

5

Changes

- Updated the Arcteq logo on the cover.

- Updated the distance between the flash and the sensor in the "Testing the operation time"

chapter.

- Uni_ed terminology used througout the manual (e.g. unit and device means the same thing.

Now all AQ 100 series relays are called "devices").

- Improved many existing drawings.

- Rearranged topics into a more logical order.

- Added connection drawings to input and output descriptions under "Connections" chapter.

- Added hyperlinks to chapters. (e.g. "See Device features chapter for more information")

- Listed more features in Device features chapter.

- T3 is now considered to be normally open by default and normally closed as an order option.

- Added information about binary output pulse messages.

- Many tables have been simpli_ed and made easier to read.

- Scheme matrixes and simpli_ed logic diagrams have been made more detailed in "Available

schemes" chapter.

AA -102-102

Instruction manual

Version: 2.02

6© Arcteq Relays Ltd

IM00008

2 Abbreviations

AQD – arc quenching device

I – binary input

O – binary output

C – circuit breaker

C FP – circuit breaker failure protection

CT – current transformer

EPROM – erasable, programmable read-only memory

HSO – high-speed output

LED – light emitting diode

LV – low-voltage

MV – medium-voltage

NC – normally closed

NO – normally open

PC – printed circuit board

RF – radio frequency

Rx – receiver

SAS – standard arc scheme

SF – system failure

Tx – transceiver

μP - microprocessor

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

7

3 General

The AQ-102 is a sophisticated microprocessor-based arc flash protection device with _ber loops

sensor channels. The device is designed to minimize the damage caused by an arc fault. This is

done by tripping the circuit breaker which supplies current to the fault when _ber loops detect arc light.

The device includes a complete system self-supervision functionality which provides the highest level of

dependability as it continuously monitors all internal system functions as well as all external

connections.

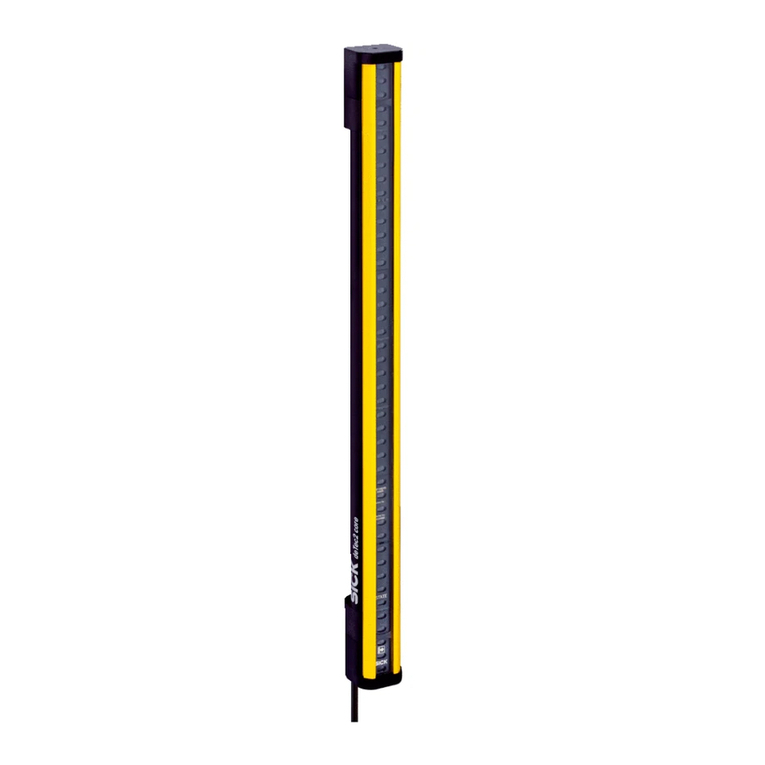

Figure. 3 - 1. Arc protection device AQ-102.

The AQ-102 is designed according to the latest protection relay standards and is therefore suitable for

installations in rough environments. These include utilities and power plants (both traditional and

renewable), various heavy industry applications (off-shore, marine, oil, gas, mining, steel, etc.) as well

as commercial and institutional electrical systems. AQ-102 is suitable for MV and LV switchgears as

well as for motor control center applications in both new and retro_tted installations.

AA -102-102

Instruction manual

Version: 2.02

8© Arcteq Relays Ltd

IM00008

4 Device features

AQ-102 is an arc flash protection device which can be applied to a variety of applications. It can be

used on its own as a stand-alone device, or it can be a part of a more complex arc protection system

by using binary inputs and outputs to connect multiple AQ 100 series devices together.

The following list presents the main features of the device:

• 92…265 V AC/DC auxiliary power supply oror 18…72 V DC auxiliary power supply (optional)

• three (3) _ber loop channels for arc flash detection

• one (1) _ber connector for AQ-1000 arc quenching device control (optional)

• two (2) binary inputs with nominal operation voltage of 24, 110, or 220 V DC

• four (4) trip relay outputs

• one (1) binary output (with internal 24 V DC power supply)

• one (1) system failure output (change-over)

• eleven (11) indication LEDs

• eight (8) DIP switches for logic con_guration

• one (1) push button.

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

9

5 Connections

The _gure below depicts the connections of AQ-102. Please note that the SF relay is in the de-

energized position.

Figure. 5 - 2. Rear terminals of AQ-102.

5.1 Simpli=ed block diagram

The _gure below presents the main components of the AQ-102 device.

AA -102-102

Instruction manual

Version: 2.02

10 © Arcteq Relays Ltd

IM00008

Figure. 5.1 - 3. Simpli_ed block diagram of AQ-102.

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

11

5.2 Inputs

5.2.1 Arc sensor channels

Figure. 5.2.1 - 4. Arc _ber loop sensor connections

AQ-102 has three (3) _ber loop sensor channels: S1, S2 and S3. Each channel has a transmitter (Tx)

terminal and a receiver (Rx) terminal. When the _ber loop is connected to the device, one of its ends is

connected to "Tx" and the other to "Rx", both located at the rear of the device. This sensor loop is then

continuously monitored by a test light pulse that travels through the loop. If a discontinuity is detected,

the device goes into Error mode. See System self-supervision chapter for more information.

AQ-102 can be ordered with an additional transmitter (Tx) terminal for arc quenching device

(AQD) control. Device sends a test light pulse continuously to the arc quenching device to supervise

the _ber connection. If the arc quenching device doesn't receive the test pulses the device will go into

Error mode.

For more information on sensors, please refer to the Arc sensors chapter as well as to the AQ-0x

instruction booklet which can be found on Arcteq's website (https://www.arcteq._/downloads/). For

more information on AQ-1000 arc quenching device (AQD) please refer to the AQ-1000 Instruction

manual.

5.2.2 Binary inputs

Figure. 5.2.2 - 5. inary input connections

This device contains two (2) binary inputs. Typically, the binary inputs are used for receiving arc light

signals, master trip commands or overcurrent signals. Function of binary inputs are con_gured using

DIP switches. For more information, please refer to the DIP switch settings chapter.

AA -102-102

Instruction manual

Version: 2.02

12 © Arcteq Relays Ltd

IM00008

Please note that when this device receives an overcurrent signal from a non-AQ 100 series device, the

actual operating time depends on the operating time of the that device. Therefore, the total operating

time cannot be speci_ed in the technical data.

The binary inputs are activated when a connected DC signal reaches the speci_ed nominal voltage

level of the corresponding input. There are three (3) different nominal voltage levels available: 24, 110,

or 220 VDC. The threshold value must be chosen and speci_ed when ordering the unit. The actual

activation threshold of the binary input is at a lower voltage than the speci_ed nominal voltage value

(see Techical Data chapter).

AQ 100 series devices monitor health of wiring between binary inputs and binary outputs. If binary

input loses connection to any of the con_gured binary outputs, the device will go into Error mode. See

System self-supervision chapter for more information.

5.3 Outputs

5.3.1 Binary outputs

Figure. 5.3.1 - 6. inary output connection

The device has one (1) binary output: O1. AQ 100 series binary outputs have an internal 24 VDC

power supply. This binary output is used for sending overcurrent, light detection, master trip and other

signals to other AQ 100 series devices in the same system. The binary output function can be

con_gured with the DIP switches. For more information on the con_guration, please refer to the DIP

switch settings chapter.

AQ 100 series device's binary outputs send out a short pulse every second. inary inputs of the

receiving AQ 100 series devices use these pulses to count the number of connected binary outputs.

See System self-supervision chapter for more information.

NONOTE!TE!

Please note that the binary ouputs are polarity-sensitive.

5.3.2 Trip relays

Figure. 5.3.2 - 7. Trip relay connections

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

13

This device has four (4) normally open trip relay outputs. Trip relays T1 and T2 are used for tripping

circuit breakers. T4 is generally used for tripping one additional disconnecting device, or as a trip alarm

(local or remote) monitoring and alarming system.

T3 can alternatively be ordered as a normally closed trip relay (electronic lock-out relay). Once opened

by fault detection it holds its open position until it receives a manual reset command or until auxiliary

power supply is lost. When re-applying the auxiliary power supply, the electronic lock-out relay returns

to the same contact condition it had prior to the power loss. This normally closed relay output can also

be used for tripping contactor-controlled devices.

T3 and T4 are always latching relays. Trip relays T1 and T2 can be set as latching relays by setting DIP

switch SW1:6 ("Latching / Non-latching") to "Latch" position. Latched relays can be reset by pressing

the "SET" button.

5.3.3 System failure relay

Figure. 5.3.3 - 8. System failure relay connection (de-energized position)

The system failure (SF) relay is of the change-over type (NO/NC) and it is energized when the device is

in a healthy condition and powered on. Whenever the device detects a system error or the auxiliary

power supply is disconnected, the SF relay changes its state. The state stays this way until the device

returns to a healthy condition. See the System self-supervision chapter for more information.

5.4 Auxiliary voltage

Figure. 5.4 - 9. Auxiliary power supply connection

The auxiliary power supply voltage is 92….265 V AC/DC. Alternatively, the optional auxiliary power

supply can be of 18…72 V DC. This choice must be speci_ed when ordering.

AA -102-102

Instruction manual

Version: 2.02

14 © Arcteq Relays Ltd

IM00008

6 Arc sensors

The AQ 100 series provides arc light point sensors and arc light _ber optic loop sensors. These

sensors can be used with different devices and different switchgear types according to speci_c

application requirements.

Arc light point sensors are typically installed in metal-clad compartments, and they provide a quick and

accurate location of the faulted area. Arc light _ber loop sensors typically cover a wider protected area

with one _ber, when there is no need to pinpoint the exact location for a fault.

6.1 Arc light =ber optic loop sensor A -06

AQ-06 is an arc light _ber optic loop sensor, which is a plastic _ber optic cable. Fiber sensors are

distributed through the protected switchgear cells. The _xed light intensity threshold of an AQ-06

sensor is 8,000 lux. The sensor's detection radius is 360 degrees.

AQ-06 sensors can be ordered in pre-manufactured lengths of 3…40 meters (3 m, 5 m, 10 m, 15 m,

20 m, 25 m, 30 m, 35 m, 40 m).

6.2 Arc light =ber optic loop sensor A -07

AQ-07 is an arc light _ber optic loop sensor, which is a robust _ber optic cable with a practically

unlimited bending radius. The sensor contains hundreds of glass _ber drains covered by a plastic tube,

thus making it extremely strong and durable. Fiber sensors are distributed through the protected

switchgear cells.

AQ-07 sensors can be ordered in pre-manufactured lengths of 3…50 meters (3 m, 5 m, 10 m, 15 m,

20 m, 25 m, 30 m, 35 m, 40 m, 45 m, 50 m).

The _xed light intensity threshold of an AQ-07 sensor is 8,000 lux. The sensor's detection radius is 360

degrees.

If necessary, the ends of an AQ-07 cable can be ordered with heat shrinking tubing to avoid light

detection outside the protected zone. The covered area can be one (1) or two (2) meters by default; if

other lengths are required, please consult the Arcteq sales team. You can _nd the Contact and

reference information page at the end of this manual.

6.3 Arc light =ber optic loop sensor A -08

AQ-08 is an arc light _ber optic loop sensor. It is designed to withstand temperatures up to 125 ºC,

which makes it suitable for e.g. wind turbine windings. AQ-08 is a robust _ber optic cable with a

practically unlimited bending radius. The sensor contains hundreds of glass _ber drains that are

covered by a plastic tube, thus making it extremely strong and durable. Fiber sensors are distributed

through the protected switchgear cells.

AQ-08 sensors can be ordered in pre-manufactured lengths of 3…15 meters (3 m, 5 m, 10 m, 15 m).

The _xed light intensity threshold of an AQ-08 sensor is 8,000 lux. The sensor's detection radius is 360

degrees.

6.4 Sensor dependencies

Compatibility of arc sensor types depend on the hardware available in the AQ 100 series device. The

table below describes those dependencies.

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

15

Table. 6.4 - 3. Sensor dependencies.

PPoint sensorsoint sensors

(A(A -01 & A-01 & A -02)-02)

FFiber loopsiber loops

(A(A -06, A-06, A -07 & A-07 & A -08)-08)

AAQQ-101-101 Yes Order option

AAQQ-101D-101D Yes Order option

AAQQ-101S-101S Yes No

AAQQ-102-102 No Yes

AAQQ-103-103 Yes Order option

AAQQ-110P-110P Yes Order option

AAQQ-110F-110F No Yes

6.5 Connecting sensors

6.5.1 Fiber loop sensors

1. Drill holes on the wall for the sensor cable to enter the protected compartment.

2. Install protective covers in the holes to ensure the sensor cable remains unharmed by rough

edges.

AA -102-102

Instruction manual

Version: 2.02

16 © Arcteq Relays Ltd

IM00008

3. Run the sensor cable through the holes and along the protected area. Fasten it to the

compartment walls with cable clips or some other appropriate anchoring method.

4. Turn the black and blue receiver (“Rx”) and transceiver (“Tx”) screws counter-clockwise and

plug in the sensor cable terminals. Then turn the screws clockwise to secure the terminals in

their place.

AA -102-102

Instruction manual

Version: 2.02

© Arcteq Relays Ltd

IM00008

17

7 Operation and con=guration

7.1 DIP switch settings

The DIP switches are used to easily con_gure various tripping logics and other functionalities for the

device. The DIP switches are located at the back of the device. The _gure below presents the DIP

switch numbering, and the table below that gives a detailed description of the settings.

Protection logic can be de_ned by selecting a logic scheme with DIP switches 1 to 4. The scheme

selection is based on binary arithmetic. Logic schemes are described in the next chapter.

Tripping can be set with DIP switches 7 and 8 to require either just arc light or both arc light and

overcurrent simultaneously. Adding overcurrent criteria ensures the device trips when an arc fault

occurs but not when a strong natural light source hits the light sensor (e.g. sunlight). Overcurrent signal

comes from an external device (mainly AQ-110P or AQ-110F) and is connected to a binary input.

If the selected scheme uses C FP (circuit breaker failure protection) its time delay (100 ms or 150 ms)

can be set with DIP switch 5. C FP logic depends on the chosen logic scheme. See Circuit breaker

failure protection chapter for more information.

Figure. 7.1 - 10. DIP switch diagram.

Table. 7.1 - 4. DIP switch settings.

SwitSwitchch FFunction selectionunction selection ON (leON (left position)ft position) OFF (OFF (rigright position)ht position)

8 L> oror L> + I>

The tripping criterion for the S2, S3,

S4 (point sensor) and S5 (_ber loop)

channels. Tripping on light

only (L>).

Light detection only trips if

overcurrent is also detected at the

same time (L> + I>).

7 S1: L> oror L> + I> The tripping criterion for the S1 point

sensor channel.

6Latching oror Non-

latching

Enables or disables latching of T1 and

T2 trip relays.

T1 and T2 operate

as latching relays. T1 and T2 latching is disabled.

5100 ms oror 150

ms The setting for the C FP time. The C FP time is

set to 100 ms. The C FP time is set to 150 ms.

4–1 Scheme

selection Scheme selection.

Please refer to the

Scheme

selection chapter.

Switch 1: 1

Switch 2: 2

Switch 3: 4

Switch 4: 8

Please refer to the Scheme

selection chapter.

Switch 1: 0

Switch 2: 0

Switch 3: 0

Switch 4: 0

AA -102-102

Instruction manual

Version: 2.02

18 © Arcteq Relays Ltd

IM00008

This manual suits for next models

7

Table of contents

Other ensto Protection Device manuals

ensto

ensto Arcteq AQ-L3 7 Series User manual

ensto

ensto Arcteq AQ-M255 User manual

ensto

ensto Arcteq AQ-S215 User manual

ensto

ensto Arcteq AQ-T3 Series User manual

ensto

ensto ECO910 User manual

ensto

ensto Arcteq AQ-F213 User manual

ensto

ensto Arcteq AQ-L310 User manual

ensto

ensto Arcteq AQ-F205 User manual

ensto

ensto Arcteq AQ-C255 User manual

ensto

ensto Arcteq AQ-F210 User manual