entegris AERONEX H Series User manual

AERONEX® H SERIES

GAS PURIFICATION SYSTEM

Continuous ultrapure H2gas at a low cost of ownership

Overview

The Aeronex®HSeries removes gaseous contami-

nants such as H2O, CO, CO2, O2and nonmethane

hydrocarbons to sub-ppb levels in hydrogen gas. The

systems utilize ambient temperaturepurification

technology, have a low pressure drop and offer a

low cost of ownership.

With the Aeronex®HSeries systems, all purifiers

used in a process areintegrated into a single,

microprocessor-controlled cabinet with a touch

screen interface. Systems use two purifier beds in

order to maintain a continuous flow of puregas.

One purifier bed is on line while the other is in

regeneration or is ready for use. Contaminants

are removed to sub-ppb (part-per-billion) and

ppt (part-per-trillion) levels.

All functions such as conditioning and purging

arecompletely automated, requiring minimal user

interface and providing maximum reliability and

cost of ownership. The system offers improved

safety by placing all purifiers in a single location

and, because the purifiers are regenerable, there

areno environmental concerns.

Panel-mounted subsystems are offered specifically

to Original Equipment Manufacturers (OEMs) and

are designed for integration into a process tool.

Applications

• Photolithography

•Metallorganic Chemical Vapor Deposition

(MOVCD)

•Atomic Layer Deposition (ALD)

•Low Temperature Epitaxy (LTE)

•Other applications that require ultrapure

hydrogen gas

Features and Benefits

• Power failure will not damage the

purification system

• Complete automatic operation saves time,

increases reliability

• Purifies to sub-ppb (part-per-billion) and ppt

(part-per-trillion) levels

• Low pressure drop means no changes to inlet

pressure are required

• Self-regenerating purifiers provide the lowest

cost of ownership

•Ambient temperaturepurification means lower

energy costs and resource conservation

• CE and SEMI®S2 certified

• Start-up service is provided, making it easy to

integrate the unit

•The system is designed for easy field mainte-

nance and upgrades

• Available worldwide through Entegris’ global

infrastructure

Models Available

Model Description

PGPS4H Panel-mounted model for OEM use and for

applications requiring a flow rate up to 120 SLM

EGPS4H Enclosed model for use with applications

requiring a flow rate up to 120 SLM

EGPS8H Enclosed model for use with applications

requiring a flow rate up to 300 SLM

EGPS12H Enclosed model for use with applications

requiring a flow rate up to 1000 SLM

AERONEX® H SERIES GAS PURIFICATION SYSTEM

continuous ultrapure H2gas at

a low cost of ownership

Regen vent

Rotameter

Optional

V1A

V1B

V8

(optional)

Process out

System Process and Instrumentation Diagram

Models PGPS4H, EGPS4H, EGPS8H

Process in

R1

V2A

V2B

Purifier A

Purifier B

Moisture

Sensor

Process in Process out

Purifier A

Purifier B

Regen vent

Rotameter

Optional

Moisture

Sensor

Regen input

V8

(optional)

V1B

V2B

V1A

R1 PT2

PT1

V2A V7A

V7B

V5 V6

V3B

V4B

V3A

V4A

Model EGPS12H

AERONEX® H SERIES GAS PURIFICATION SYSTEM

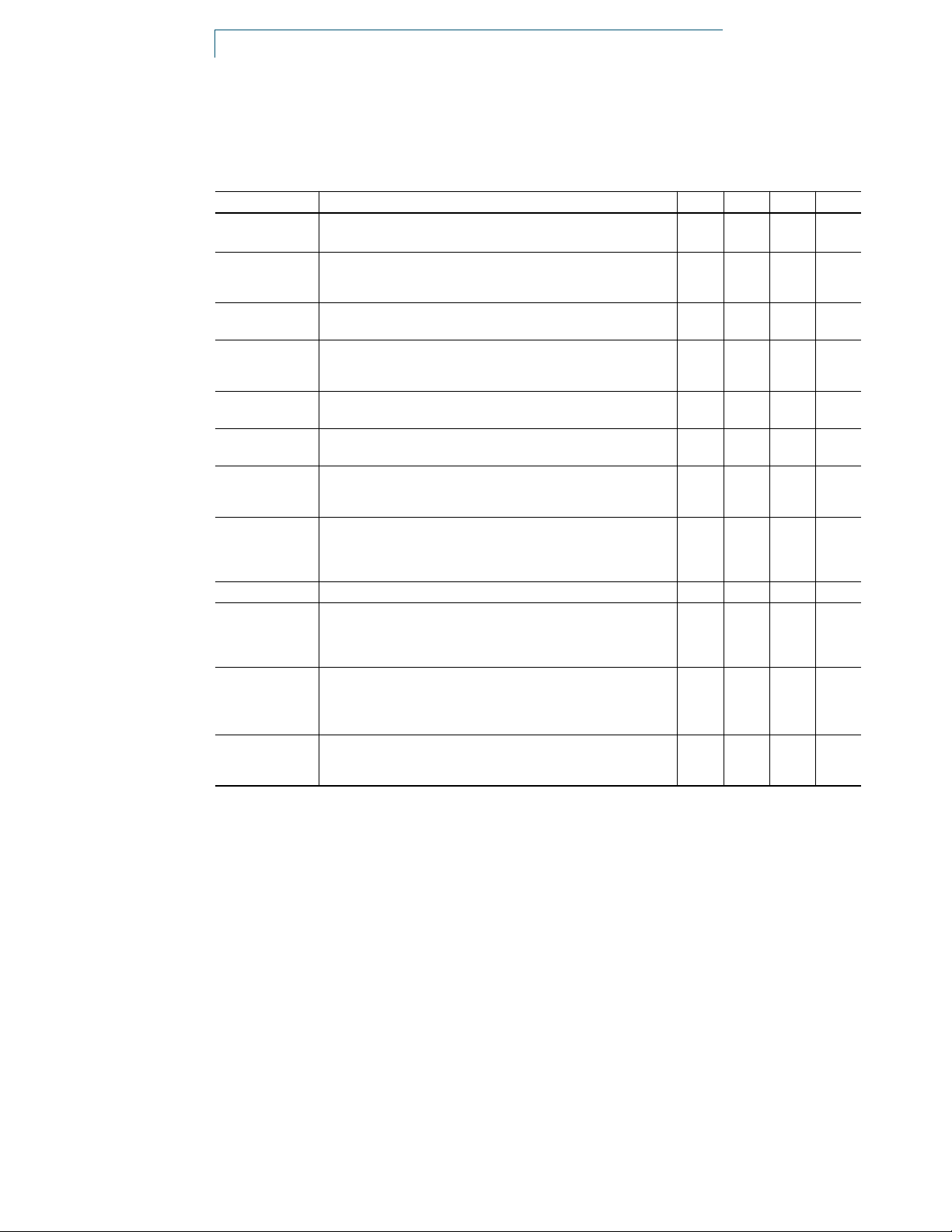

Safety Features

Feature Description PGPS4 EGPS4 EGPS8 EGPS12

Circuit breaker Provides additional electrical protection to the system and

includes a lock-out/tag-out.

N/A Yes Yes Yes

Over temperature

rise condition

Monitored via thermocouple. Heaters sized to prevent runaway

conditions. As a secondary precautionary device, a high-

temperature hardware interlock is included on the EGPS4.

Yes Yes Yes Yes

Hydrogen

detector

Triggers an EMO alarm and shuts down the system in the event

of a gas leak of hydrogen inside system enclosure.

N/A Yes Yes Yes

Rate-of-rise

detector

If the detector senses a rapid increase in temperature inside the

system enclosure, an EMO alarm with be activated and shut

down the system.

N/A Yes Yes Yes

EMO button When activated, power is removed from the cabinet. The system

shuts down. The front panel and controller remain powered.

N/A Yes Yes Yes

Remote EMO Provides input for remote EMO activation and an output for

remote signal of EMO condition.

Yes Yes Yes Yes

Remote alarm In the event of a minor alarm in the system not requiring an

EMO shutdown, the system will send a signal to an external

sensing device that alerts the facility of the alarm.

Yes Yes Yes Yes

Visual alarm In the event of an alarm, a detailed description of the alarm

will be displayed in red on systems that include a touch screen.

In the event of an alarm on a system with LEDs, a red LED

indicator will activate.

Yes Yes Yes Yes

Audible alarm Alarm conditions result in an audible alarm. N/A Yes Yes Yes

Static pressure

switch/door

interlock

Monitors system for adequate static pressure. If enclosure

ventilation falls below acceptable levels, an alarm is generated

in the system; also serves as a door interlock to prevent the

system from being used while the door is opened.

N/A Yes Yes Yes

Isolated

electrical

enclosure

Electronics are physically isolated from the main purifier cabinet in

an attached electrical enclosure in situations where high-voltage

lines are near potentially flammable gas. Low-voltage components

located inside the enclosure are SELV (safety extra low voltage).

N/A Yes Yes Yes

Single or dual

contained plumb-

ing interface

Allows end user to use either single or dual contained plumbing

for installation.

Yes Yes Yes Yes

Model PGPS4 EGPS4 EGPS8 EGPS12

Gases purified H2

Media type Inorganic

Contaminants removed H2O, CO, CO2, O2and nonmethane hydrocarbons

Outlet purity <1 part-per-billion (ppb)*

Operating pressure range 515–1825 kPa (60–250 PSIG) 1136 kPa

(60–150 PSIG)

Pressure drop <15 PSI @ 120 PSIG inlet and max rated flow <17 PSI @ 90 PSIG

and max rated flow

Maximum flow rate 120 SLM 300 SLM 1000 SLM

Gas operating temperature -40°C to +60°C (-40°F to +150°F)

Outlet filtration 0.003 micron @ 99.9999999% efficiency

Leak rating 1 ×10–9 atm cc/sec.

Product Specifications

*Outlet purity is significantly lower for some contaminants. Test data available upon request.

Facility Specifications

It is the customer’s responsibility to ensure that the equipment is installed according to local building code requirements.

Specifications PGPS4 EGPS4 EGPS8 EGPS12

Process gas input Mechanical connection 1⁄4″face seal 1⁄4″tube stub 1⁄2″tube stub 3⁄4″tube stub

Process gas output Mechanical connection 1⁄4″face seal 1⁄4″tube stub 1⁄2″tube stub 3⁄4″tube stub

Ventilation Mechanical connection N/A 4″duct

Exhaust flow N/A 50 CFM 100 CFM 65 CFM

Power requirements Mechanical connection Standard terminal

Power requirements 200–240 VAC

Power consumption 50W at idle and process mode;

300W during regen

50W at idle and

process mode;

800W during

regen

50W at idle and

process mode;

1000W during

regen

Regeneration Max regen frequency 3 days (May be configured per customer inlet gas purity)

Regen duration 48 hours

Regen gas input 1 Gas N/A N2 515–929 kPa

(60–120 PSIG)

Mechanical connection N/A 1⁄4″tube stub

Regen gas input 2 Gas N/A H2 515–929 kPa

(60–120 PSIG)

Mechanical connection N/A 1⁄4″tube stub

Regen gas output Pressure Atmospheric

Mechanical connection 1⁄4″tube stub

Instrument air Gas and pressure CDA or N2@ 653–791 kPa (80–100 PSIG)

Mechanical connection 1⁄4″compression fitting

Physical requirements Mounting Wall Floor

Shipping weight 32 kg (70 lbs) 39 kg (85 lbs) 113 kg (250 lbs) 205 kg (450 lbs)

Operating conditions 15°–40°C indoor (60°–104°F indoor)

Humidity 10–90% RH noncondensing

AERONEX® H SERIES GAS PURIFICATION SYSTEM

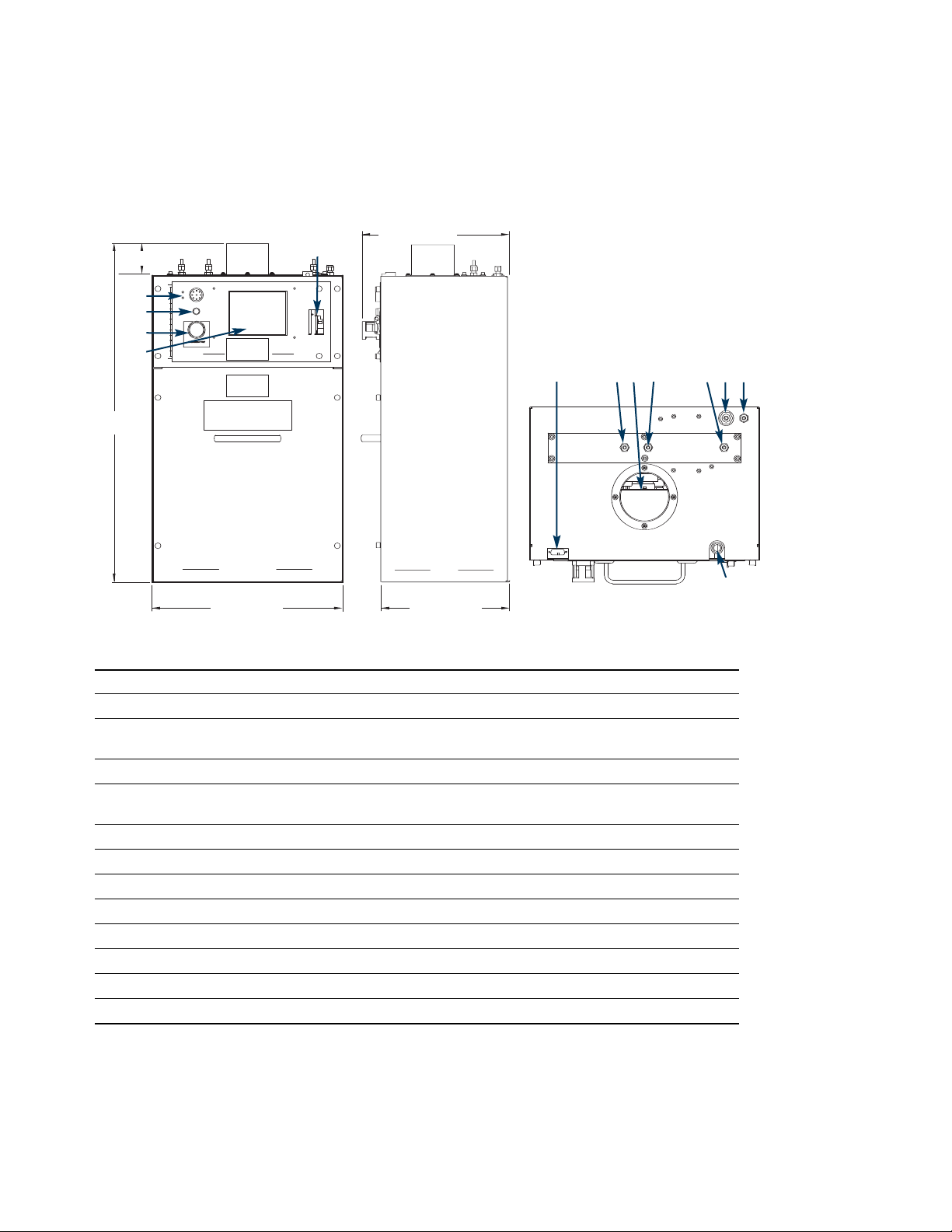

Model PGPS4

Dimensional Information

System Connections

1 Communications port For user interface via PC

2 LED indicators For main power, bed on line, bed regen, heaters and alarms

3 Start Used to begin system operations and to clear alarms

4 A/C terminal block Power connection

5 Gas exhaust/regen vent Exhausts regen gas

6 Process gas input Inlet gas (not purified)

7 Process gas output Outlet gas (purified)

Panel Information

This equipment is not enclosed. It is the user’s responsibility to ensure that it is installed in compliance with

local safety requirements for gas equipment. The PGPS4 is designed using SEMI®S2 guidelines (for gas equip-

ment enclosures). Because it is a subsystem, it must be certified with the final product in which it is used.

381 mm (15.00″)

Top view

264 mm (10.40″)

711 mm

(28.0″)

5 6 7

4 5 6 7

123

Front view

Side view

Model EGPS4

Dimensional Information

System Connections

1 Audible alarm Audible warning informs of alarm condition

2 Start Used to begin system operations and to clear alarms

3 EMO When activated, power is removed from the cabinet. The system shuts down.

Front panel and controller remain powered.

4 Touch screen For system status and interface

5 Circuit breaker Provides additional electrical protection to the system and in some models

also acts as an ON/OFF switch for the system

6 Remote alarm interface Allows for remote alarm input and output with female 15 pin DB connector

7 Regen gas vent Exhausts regen gas

8 Exhaust vent Allows ventilation

9 Process gas input Inlet gas (not purified)

10 Process gas output Outlet gas (purified)

11 Reference Atmospheric reference for the internal enclosure flow sensor

12 Instrument air Supplies gas to the air-operated control valves

13 A/C power input Power connection

Enclosure Information

The ventilated enclosure is designed for indoor applications only. The enclosure has mounting locations on

the back surface. The front panel is removable.

457 mm (18.0″)

76 mm (3.0″)

305 mm (12.0″)

342 mm (13.46″)

813 mm

(32.0″)

5

1

2

3

4

Side view

Top view

Front view

6 7 98 121110

13

AERONEX® H SERIES GAS PURIFICATION SYSTEM

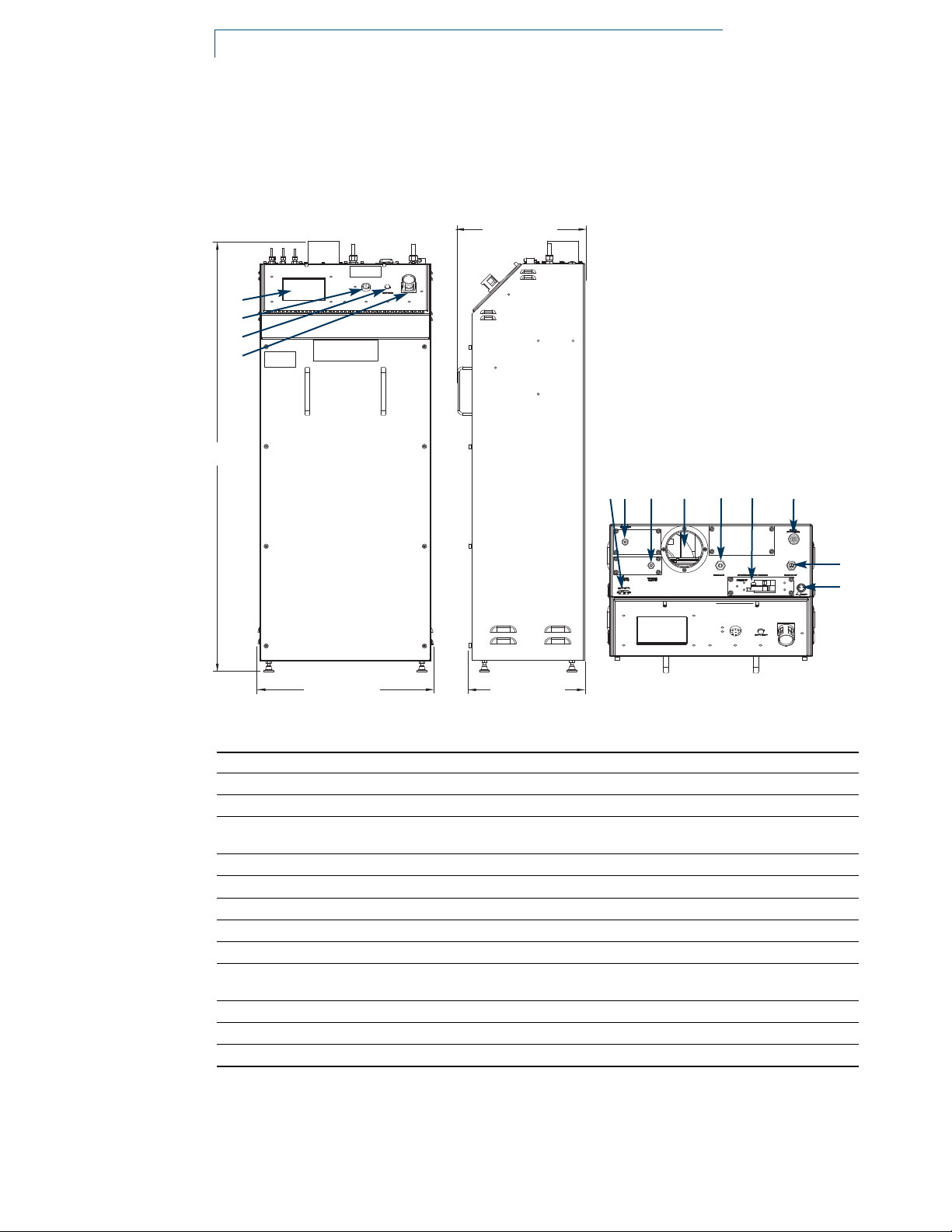

Model EGPS8

Dimensional Information

System Connections

Enclosure Information

The ventilated enclosure is designed for indoor applications only. The enclosure has bolt down locations on

the bottom surface. The front panel is removable.

572 mm (22.50″)

Top view

379 mm (14.92″)

416 mm (16.38″)

1421 mm

(55.94″)

Side view

1 Touch screen For system status and interface

2Audible alarm Audible warning informs of alarm condition

3 Start Used to begin system operations and to clear alarms

4 EMO When activated, power is removed from the cabinet. The system shuts down.

Front panel and controller remain powered.

5 Remote alarm interface Allows for remote alarm input and output with female 15 pin DB connector

6 Instrument air Supplies gas to the air-operated control valves

7 Regen gas vent Exhaust regen gas

8Exhaust vent Allows ventilation

9 Process gas input Inlet gas (not purified)

10 Circuit breaker Provides additional electrical protection to the system and in some models

also acts as an ON/OFF switch for the system.

11Reference Atmospheric reference for the internal enclosure flow sensor

12 Process gas output Outlet gas (purified)

13 A/C power input Power connection

1

2

3

4

12

13

Front view

65 7 8 9 1110

622 mm (24.50″)

Top view

454 mm (17.88″)

1831 mm

(72.08″)

Side view

System Connections

1 Touch screen For system status and interface

2 Audible alarm Audible warning informs of alarm condition

3 Start Used to begin system operations and to clear alarms

4 EMO When activated, power is removed from the cabinet. The system shuts down.

Front panel and controller remain powered.

5 Remote alarm interface Allows for remote alarm input and output with female 15 pin DB connector

6 Regen gas input 1 Nitrogen input

7 Regen gas input 2 Hydrogen input

8 Process gas input Inert gas (not purified)

9 Fire sensor located below cover

10 Exhaust vent Allows ventilation

1

1 Process gas output Outlet gas (purified)

12 Gas monitor located below cover

13 Regen gas vent Exhausts regen gas

14 Instrument air Supplies gas to the air-operated control valves

15 Reference Atmospheric reference for the internal enclosure flow sensor

16 Circuit breaker Provides additional electrical protection to the system and in some models

also acts as an ON/OFF switch for the system

17 A/C power input Power connection

Enclosure Information

The ventilated enclosure is designed for indoor applications only. The enclosure has bolt down locations on

the bottom surface. The front panel is removable.

65 87 9 10 11 13 1412

1

2

3

4

15

16

17

102 mm (4.03″)

Model EGPS12

Dimensional Information

Front view

AERONEX® H SERIES GAS PURIFICATION SYSTEM

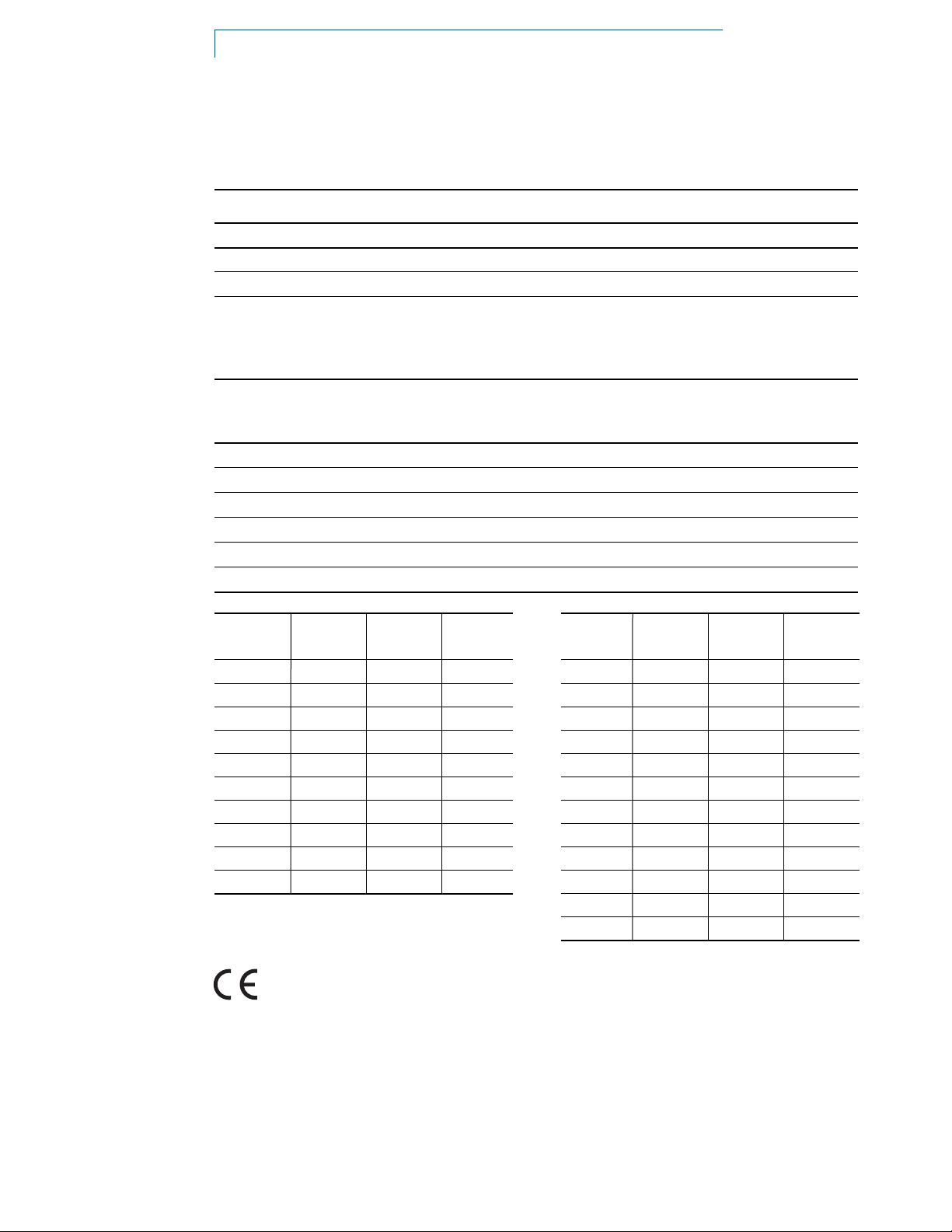

Options

Letter

Available Options (Designator) PGPS4 EGPS4 EGPS8 EGPS12

Automatic bypass manifold A Yes Yes Yes Yes

Manual bypass manifold M Yes N/A Yes Yes

Moisture indicator T Yes Yes Yes Yes

Ordering Information

Part Number

PGPS4 EGPS4 EGPS8 EGPS12

Panel-mounted model for OEM Use with applications Use with applications Use with applications

use and applications requiring requiring a flow rate requiring a flow rate requiring a flow rate

a flow rate up to 120 SLM up to 120 SLM up to 300 SLM up to 1000 SLM

PGPS4H EGPS4H EGPS8H EGPS12H

PGPS4HA EGPS4HA EGPS8HA EGPS12HA

PGPS4HAT EGPS4HAT EGPS8HAT EGPS12HAT

PGPS4HM EGPS4HT EGPS8HM EGPS12HM

PGPS4HMT EGPS8HMT EGPS12HMT

PGPS4HT EGPS8HT EGPS12HT

Automatic Manual

Part Bypass Bypass Moisture

Number Manifold Manifold Indicator

PGPS4H

PGPS4HA Yes

PGPS4HAT Yes Yes

PGPS4HM Yes

PGPS4HMT Yes Yes

PGPS4HT Yes

EGPS4H

EGPS4HA Yes

EGPS4HAT Yes Yes

EGPSHT Yes

Automatic Manual

Part Bypass Bypass Moisture

Number Manifold Manifold Indicator

EGPS8H

EGPS8HA Yes

EGPS8HAT Yes Yes

EGPS8HM Yes

EGPS8HMT Yes Yes

EGPS8HT Yes

EGPS12H

EGPS12HA Yes

EGPS12HAT Yes Yes

EGPS12HM Yes

EGPS12HMT Yes Yes

EGPS12HT Yes

Specifications are subject to change.

Please verify prior to order.

ENTEGRIS, INC.

Corporate Headquarters / 3500 Lyman Boulevard / Chaska, Minnesota 55318 USA

Customer Service Tel. 952-556-4181 / Customer Service Fax 952-556-8022

www.entegris.com

The materials integrity management company

Entegris®and Aeronex®are registered trademarks of Entegris, Inc.

SEMI®is a registered trademark of Semiconductor Equipment and Materials International.

U.S. Patent 6,361,696

©2004–2006 Entegris, Inc. All rights reserved Printed in USA 4507-2676ENT-1206

For More Information

Please call your Regional Customer Service Center

today to learn what Entegris can do for you. Visit

www.entegris.com and select “Regional Customer

Service Centers” for the center nearest you.

Terms and Conditions of Sale

All purchases are subject to Entegris’ “Terms

and Conditions of Sale.” To view and print

this information, visit Entegris’ website at

www.entegris.com and select the Legal Notices

link from the footer found on the home page.

This manual suits for next models

4

Table of contents

Other entegris Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Balluff

Balluff BTL PA0400 Series installation guide

CIAS Elettronica S.r.l.

CIAS Elettronica S.r.l. PYTHAGORAS3 manual

ABB

ABB HT567947 Operation manual

Purkeys

Purkeys STATUS 45 VOLT installation guide

INOXPA

INOXPA BCI Series Installation, service and maintenance instructions

WITTUR

WITTUR WRG200 Operating instruction