Man VTA User manual

Table of contents

1 Adjustable turbine nozzle ring (VTA) .................................................................................................... 3

1.1 Range of applications .................................................................................................................3

1.2 Application Examples .................................................................................................................8

1.3 Low-speed propulsion engines from MAN B&W ......................................................................11

2 Overview of series ............................................................................................................................... 14

2.1 VTA on TCA turbocharger .........................................................................................................14

2.2 Dimensions ................................................................................................................................14

2.3 Weights ......................................................................................................................................14

2.4 Casing Positions ........................................................................................................................15

3 Design .................................................................................................................................................. 16

3.1 Characteristics of the Assemblies ...........................................................................................16

3.2 Operation Method of the Adjusting Device ..............................................................................17

4 Systems ............................................................................................................................................... 18

4.1 VTA Control (VCS) ......................................................................................................................18

4.2 Cooling Water System ...............................................................................................................20

4.3 Inflation Air ................................................................................................................................22

5 Engine room planning ......................................................................................................................... 24

5.1 Equipment .................................................................................................................................24

5.2 VTA Control System (VCS) ........................................................................................................24

5.3 Multi Purpose Controller (MPC) ................................................................................................25

5.4 Main Operating Panel (MOP) ....................................................................................................25

5.5 Cabling ......................................................................................................................................26

6 Operation ............................................................................................................................................. 27

6.1 Putting into Operation ...............................................................................................................27

6.2 VTA – Adjustment Ranges and Adjustment Speeds ................................................................27

6.3 Emergency Operation on Failure of the VTA Adjusting Device ...............................................27

7 Maintenance and inspection .............................................................................................................. 29

7.1 Introductory Remarks ...............................................................................................................29

7.2 Cleaning the Variable Turbine Area ..........................................................................................29

7.3 Maintenance of the Adjusting Device ......................................................................................29

7.4 Inspection of the Pipe Systems ................................................................................................29

7.5 Electronic Equipment ................................................................................................................29

8 Matching ............................................................................................................................................. 30

8.1 Matching Procedure ..................................................................................................................30

8.2 Adjusting the Charging Air Pressure ........................................................................................30

2013-12-04 - de

Table of contents

MAN Diesel & Turbo

1 (38)

8.3 Surge Tests ...............................................................................................................................31

9 Scope of supply ................................................................................................................................... 32

9.1 Delivery Scope, VTA and Equipment ........................................................................................32

9.2 Hardware ...................................................................................................................................32

9.3 Software ....................................................................................................................................33

9.4 Cable Sets ..................................................................................................................................33

10 Retrofits – worldwide turbocharger service ...................................................................................... 35

10.1 Retrofitting a Variable Turbine Area ........................................................................................35

10.2 MAN | PrimeServ .......................................................................................................................35

10.3 Worldwide service addresses ...................................................................................................36

Table of contents

2013-12-04 - de

MAN Diesel & Turbo

2 (38)

1 Adjustable turbine nozzle ring (VTA)

1.1 Range of applications

The VTA was designed for applications on turbocharged large diesel engines

with different load profiles. Due to its adjustability, the VTA adapts the turbo-

charging characteristics so that the engine works efficiently over a wide load

range.

In order to meet the requirements of modern large diesel engines, a variable

fresh air supply is required. One particularly efficient way of achieving this is

to use an adjustable turbine nozzle ring, or VTA. This modifies the pressure

level in the engine by adapting the narrowest nozzle ring cross section for the

air flow. The area through which the air flows is modified by adjusting the

guide vanes of the turbine nozzle ring.

If adjusting the guide vanes makes the air flow cross section narrower, this

increases the speed of the air flow to the turbine wheel. This increases the

turbocharger speed, thereby causing the charge pressure on the compres-

sor side to rise.

The VTA technology is available for all turbocharger sizes in the TCA Series

and can be used with both 2-stroke and 4-stroke engines. Both diesel

engine and gas-powered engine applications can be improved significantly

using a VTA.

Engine performance is optimised in accordance with customer requirements

by means of adapted control programs.

See table Overview – VTA range of applications.

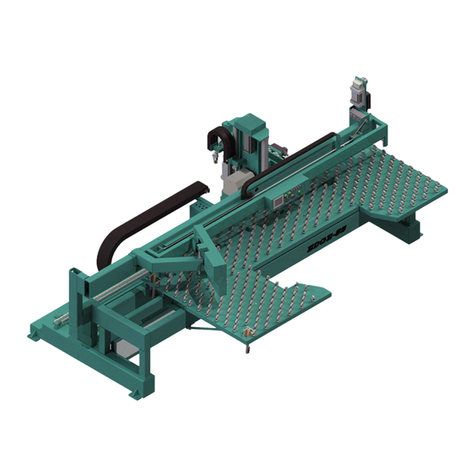

Figure 1: TCA turbocharger with adjustable turbine nozzle ring

Functional Principle

VTA for TCA Turbocharger

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.1 Range of applications

MAN Diesel & Turbo 1

EN-US 3 (38)

1 Adjustable turbine nozzle ring (VTA) 1.1 Range of applications

2013-12-04 - de

1MAN Diesel & Turbo

4 (38) EN-US

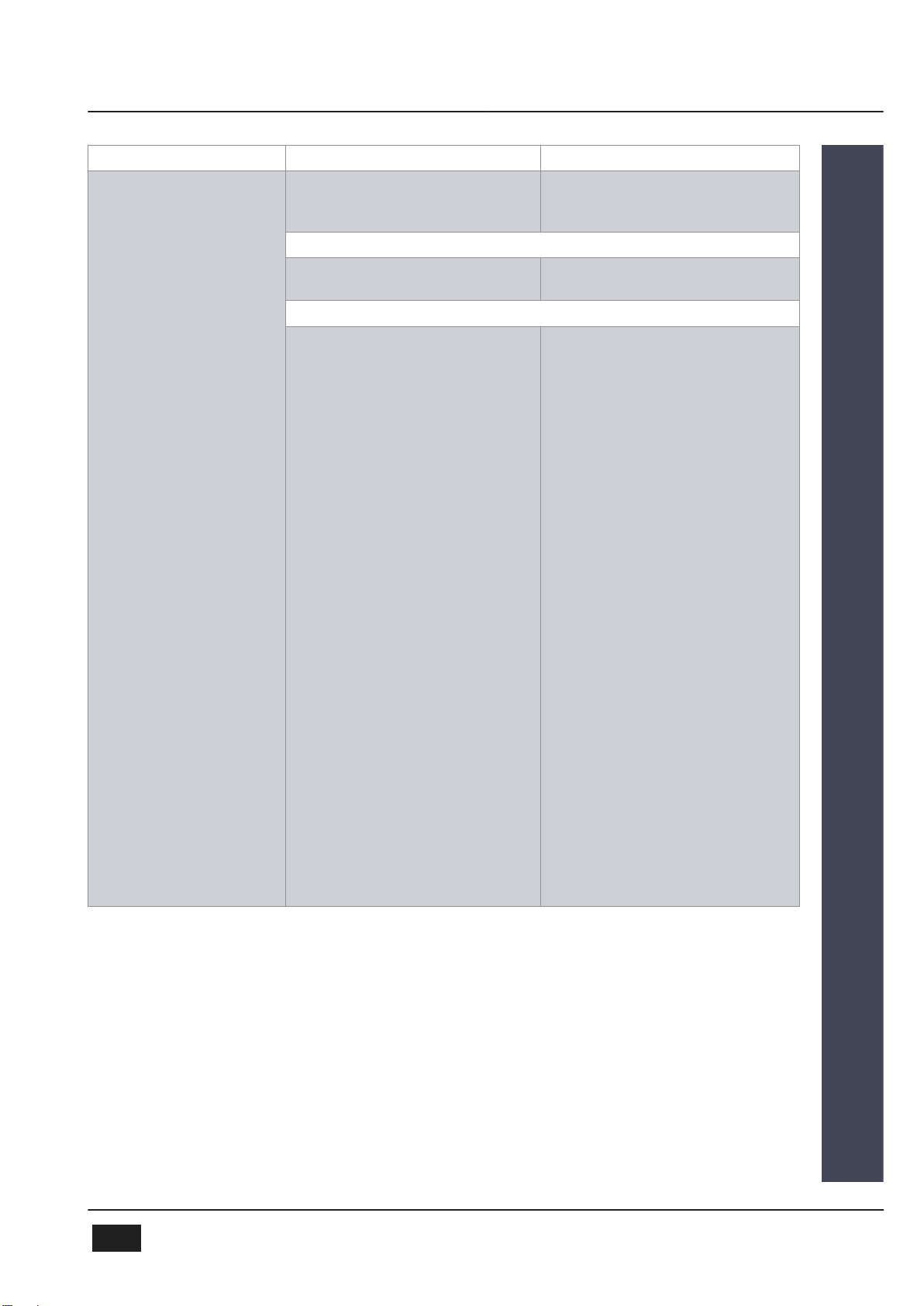

Application Functional principle Effect

2-stroke diesel engine

▪Scavenge air pressure at partial

load is increased by closing the

VTA:

▪At partial load either

Economy Mode (Mode 1.)

Increased ignition pressure for reduction

of SFOC 3)

Reduced fuel consumption

(NOx increased) or

Emission Mode (Mode 2.)

Ignition pressure is kept constant by

ignition retard.

▪Compensation of ambient tem-

perature influences on scavenge

pressure

▪Closing on acceleration

▪Compensation of extracted gas

flows (e.g. for power turbine

applications, see “Power tur-

bine” line)

▪Plants with EGR 4):

Scavenge air pressure kept con-

stant when EGR rate is modified

3) Specific fuel oil consumption

4) Exhaust gas recirculation

Reduced NOx emissions

(Fuel consumption slightly higher than

Mode 1.).

In conjunction with a variable injection

system and appropriate optimization, the

VTA enables reduced consumption and

flexible changing between Mode 1. and

Mode 2.

▪Slight increase in consumption at

full load

▪Shifting of auxiliary blower

switch-off point towards lower

outputs

▪Elimination of a bypass for scav-

enge pressure compensation at

extremely low intake tempera-

tures

(“Arctic conditions”)

▪Improved load application behav-

ior

▪Additional improvement of partial

load performance by shifting the

maximum efficiency towards a

lower engine load

▪Exhaust gas temperatures at

partial load reduced

NOTE!

In the dedicated “Economy Mode”

(Mode 1.), the VTA rating must be

adapted to the NOx limit values.

Table 1: VTA range of applications on 2-stroke diesel engine

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.1 Range of applications

MAN Diesel & Turbo 1

EN-US 5 (38)

Application Functional principle Effect

4-stroke diesel engine ▪VTA closes at partial load

▪Compensation of ambient tem-

perature influences on charge

pressure

▪Closing on acceleration

▪Compensation of extracted gas

flows (e.g. for power turbine

applications, see “Power tur-

bine” line)

▪Plants with EGR 4):

Charge air pressure kept con-

stant when EGR rate is modified

▪HAM 5) applications:

Increased water content at par-

tial load.

4) Exhaust gas recirculation

5) Humid air motor

▪Reduced fuel consumption at

partial load

▪Increased NOx emissions ⇨

With appropriate rating within the

limit values or constant cycle val-

ues, similar to 2-stroke

▪Reduction of exhaust gas tem-

peratures at partial load

▪Elimination of blow-off valves

▪Improved load application behav-

ior

▪Reduction of soot emissions in

the case of low load and load

application

▪Additional improvement of partial

load performance by shifting the

maximum efficiency towards a

lower engine load

Table 2: VTA range of applications on 4-stroke diesel engine

Application Functional principle Effect

Gas-powered engine ▪VTA opens at partial load

▪Compensation of ambient tem-

perature influences on charge

pressure

▪Closing on load application to

prevent overgreasing

▪Variation of the charge pressure

to adapt to changing gas quali-

ties

▪Reduced fuel consumption due

to increased turbocharging effi-

ciency compared with blow-off

valves or throttle

▪Elimination of blow-off valves/

throttle

Table 3: VTA range of applications on gas-powered engine

Application Functional principle Effect

Dual-fuel engine See gas-powered and diesel engine See gas-powered and diesel engine

Table 4: VTA range of applications on dual-fuel engine

Application Functional principle Effect

Test engine ▪Adaptation of the charge air

pressure to changing engine

parameters

▪Elimination of conversions

▪Infinitely adjustable setting of the

charge air pressure

Table 5: VTA range of applications on test engine

Application Functional principle Effect

Power turbine 1. VTA only on power turbine

▪“Closing” of the VTA to throttle

the power turbine output

▪Increased turbocharging effi-

ciency at a given power turbine

output, compared with power

turbine control by means of con-

trol flaps, due to elimination of

pressure losses

1 Adjustable turbine nozzle ring (VTA) 1.1 Range of applications

2013-12-04 - de

1MAN Diesel & Turbo

6 (38) EN-US

Application Functional principle Effect

2. VTA on every turbocharger and power turbine

▪“Closing” of all VTAs with con-

stant area factor (and thus con-

stant bypass ratio)

▪In full load range:

“Closing” of the VTA of the

power turbine to throttle the

power turbine output,

“opening” of the VTAs on the

turbochargers to limit the charge

pressure.

▪At partial load:

“Closing” of the VTA to throttle

the power turbine output, analo-

gous to 1.

▪Increased power turbine output

and reduced SFOC by increasing

the scavenge air pressure (see

“2-stroke engine” line) and

exhaust gas pressure

▪Increased turbocharging effi-

ciency at a given power turbine

output, compared with power

turbine control by means of

bypass

▪Increased turbocharging effi-

ciency at a given power turbine

output – see 1.

Table 6: VTA range of applications on power turbine

Application Functional principle Effect

Plant technology ▪Compensation of flow rate fluc-

tuations

▪Closing during a starting opera-

tion

▪Elimination of control flaps prone

to a high degree of loss

Table 7: VTA range of applications in plant technology

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.1 Range of applications

MAN Diesel & Turbo 1

EN-US 7 (38)

1.2 Application Examples

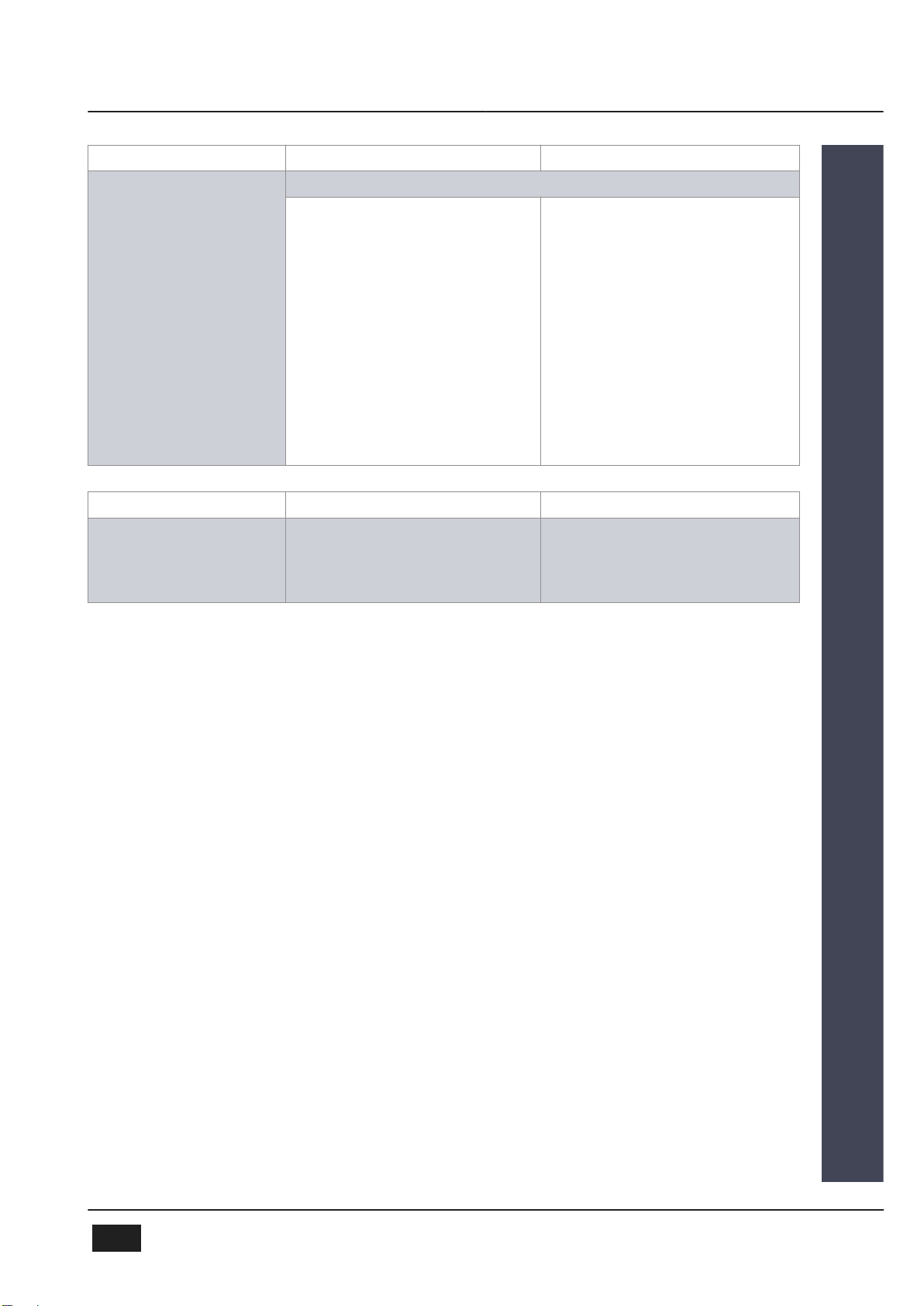

1000

1500

2000

2500

3000

3500

4000

20 30 40 50 60 70 80 90 100

pscav in mbar

Engine load in %MCR

TCA55-21004V on 6S46MC-C

S pe c ific a tio n TC A5 5-21 00 4V, VT A c lo s ing

S pe c ific a tio n TC A5 5-21 00 4V, VT A ope n

S ta nd ard s p ec ific ation T C A55 -20 027 w ith fixed

noz z le ring

Max. a llo w ab le ps c a v

S am e s p ec ific ation as T C A55-210 04V but w ith

fixe d n oz z le ring

A ux. B lowe r switc h po int

with V TA = 2 7% Lo ad

A ux. B lowe r switc h po int

without VTA = 3 2% L oa d

pscav Scavenge air pressure

MCR Maximum Continuous Rating

Figure 2: Increased scavenge air pressure with TCA55-21V on 6S46MC-C TIER I

MAN 2-stroke diesel engine 6S46MC-C with TCA55-21V turbocharger

The diagram Increased scavenge air pressure with TCA55-21V on 6S46MC-

C illustrates the mode of operation of the VTA on the 6S46MC-C engine.

The upper green line shows the scavenge air pressure that is set when the

VTA is closed towards partial load (“VTA closing”). In contrast, the scavenge

air pressures for the VTA test specification TCA55-21004V with the nozzle

ring remaining open for partial load (“VTA open” – ▲ dark line, bottom) and

the initial specification TCA55-20027 with rigid nozzle ring are also shown (■

light points).

Since, for this engine, no device is offered for varying the start of injection, an

increase in the ignition pressure at partial load can only be achieved by

means of the scavenge air pressure. If a specification with a smaller rigid

nozzle ring were to be selected, a reduction of the maximum available power

VTA on 2-stroke diesel

engine

1 Adjustable turbine nozzle ring (VTA) 1.2 Application Examples

2013-12-04 - de

1MAN Diesel & Turbo

8 (38) EN-US

would be required in order not to exceed the maximum value for the ignition

pressure in the load range of approx. 80-100% MCR. This can be avoided

by opening the VTA from 75% MCR onwards.

MCR Maximum Continuous Rating

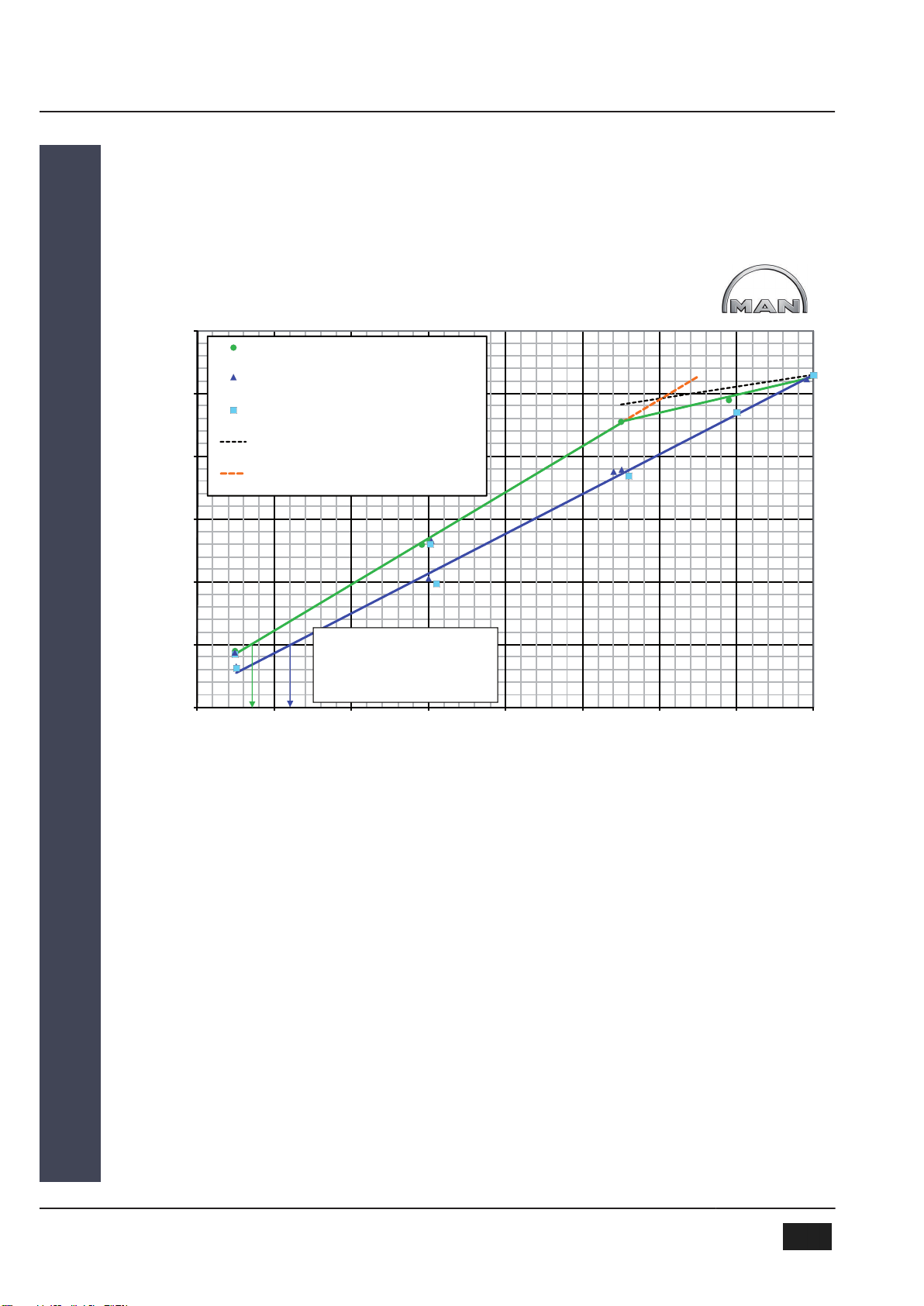

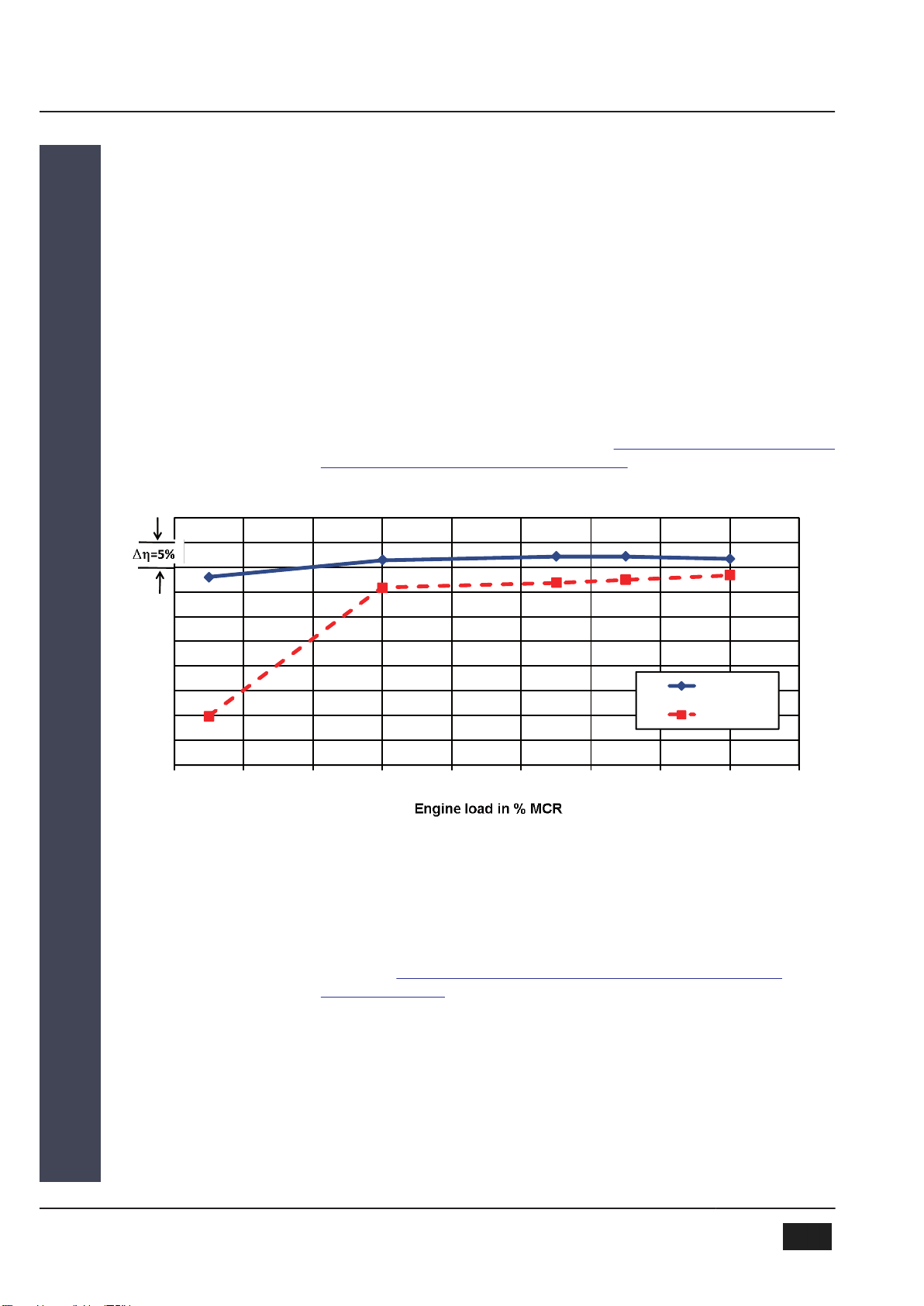

Figure 3: Turbocharger efficiencies with TCA55-21V on 6S46MC-C engine

In the diagram Turbocharger efficiencies with TCA55-21V on 6S46MC-C

engine, the efficiency characteristic of the VTA rating is plotted with the exist-

ing specification optimized for full load. With a closing nozzle ring, a marked

increase in the efficiency can be seen below 85% MCR.

In this case, the margin to the required efficiency rating has been used for

extreme optimization of the partial load performance. The difference between

the specification with and without VTA is thus extremely positive at partial

load and negative at full load – but still meeting all requirements.

Increased

turbocharger efficiency

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.2 Application Examples

MAN Diesel & Turbo 1

EN-US 9 (38)

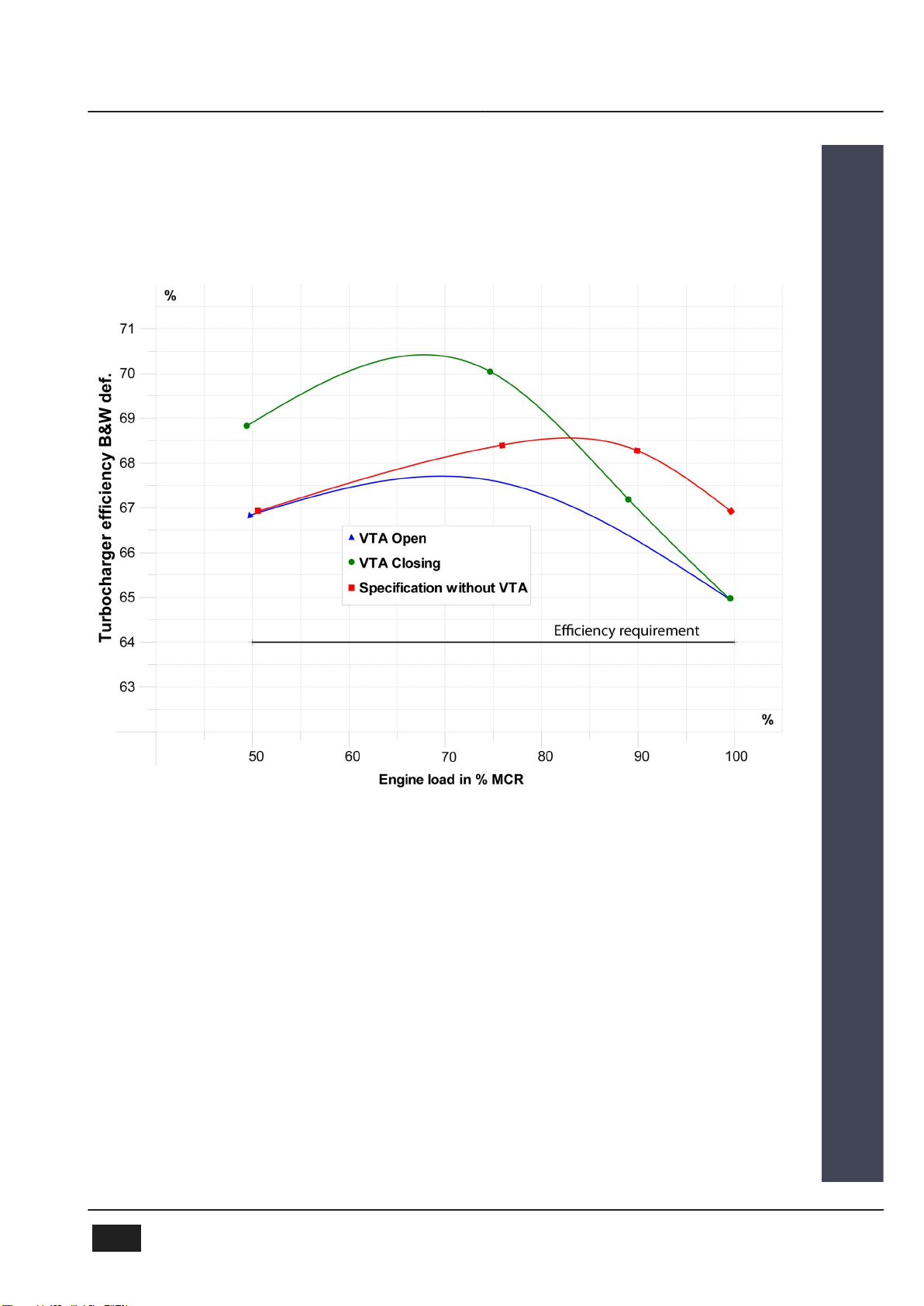

Gas-powered operation of the 7L51/60DF dual-fuel engine with

TCA55-41V turbocharger

For stable, knock-free combustion, gas-powered engines require a limited

gas/air ratio, which is achieved by regulating the charge pressure. If the load

drops below 50%, a significant reduction of the charge pressure is required.

Furthermore, a control reserve must be provided for load applications and

high intake temperatures in the load range of 50-100% MCR. For a rigid

geometry, this can be achieved by means of blow-off during operation at

normal conditions or partial load with significant charging efficiency losses, or

efficiently by opening the VTA position. Moreover, an open VTA position at

partial load allows a more efficiency-optimized setting than a rigid turbine

nozzle ring.

The resulting increase in charging efficiency with VTA compared with the

bypass concept is illustrated in the diagram Improvement of the charging effi-

ciency with TCA55-41V on 7L51/60DF engine.

2 0 3 0 4 0 5 0 6 0 7 0 8 0 9 0 1 0 0 11 0

Charging efficiency in %

V TA

B yp as s

MCR Maximum Continuous Rating

Figure 4: Improvement of the charging efficiency with a TCA55-41V on an 7L51/60DF engine

For a gas-powered engine operated predominantly in the load range of 50 –

100%, this results in a potential improvement of approx. 0.5 percentage

points in the thermal efficiency of the engine.

See Figure Improvement of the thermal efficiency with TCA55-41V on

7L51/60DF engine.

Fuel saving for 4-stroke gas-

powered engine

Increased

charging efficiency

Thermal efficiency

1 Adjustable turbine nozzle ring (VTA) 1.2 Application Examples

2013-12-04 - de

1MAN Diesel & Turbo

10 (38) EN-US

4 0 5 0 6 0 7 0 8 0 9 0 1 0 0 11 0

Engine thermal efficiency in %

Engine load in % MCR

V TA

B yp as s

∆η=1%

MCR Maximum Continuous Rating

Figure 5: Improvement of the thermal efficiency with a TCA55-41V on an 7L51/60DF engine

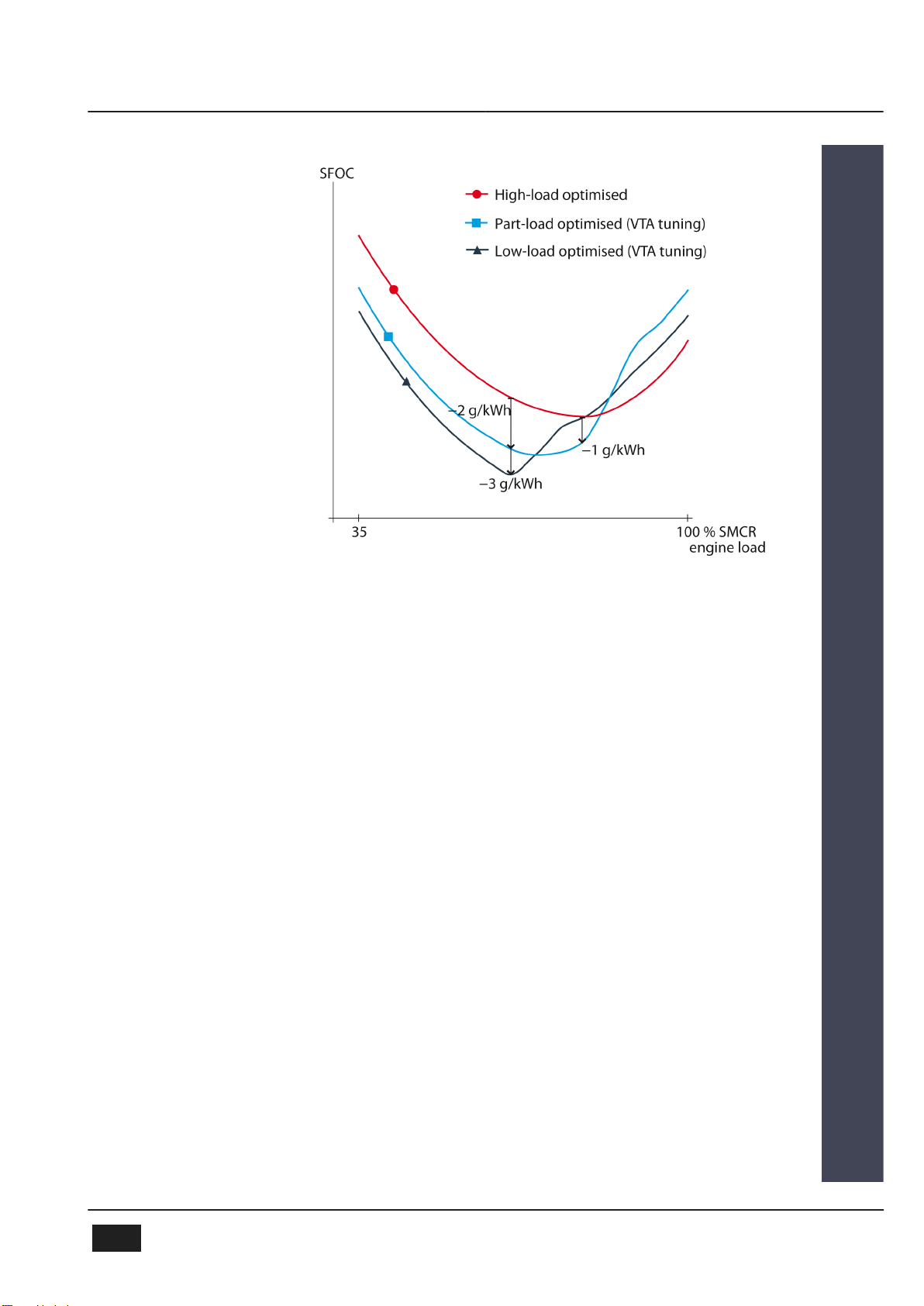

1.3 Low-speed propulsion engines from MAN B&W

The following tables summarize the fuel-saving potential existing for

MAN B&W engines. All SFOC values refer to the SFOC for a load of 100%

for a standard L1 engine.

SFOC-optimized load range Tuning method SFOC change [g/kWh]

35% 50% 65% 80% 100%

High load (85-100%) Standard L1 engine 3.5 -1 -3.5 -3.5 0

Partial load (50-85%) VTA 0.5 -4 -6.5 -4.5 0.5

Low load (25-70%) VTA -1.5 -6 -8.5 -3.5 0.5

Standard L1 engine – turbocharger without adjustable turbine nozzle ring

VTA – turbocharger with adjustable turbine nozzle ring

Table 8: Optimization potential – ME/ME-C Tier II engines, SMCR = L1

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.3 Low-speed propulsion engines from MAN B&W

MAN Diesel & Turbo 1

EN-US 11 (38)

Figure 6: Reduction of the specific fuel consumption SFOC of ME/ME-C engines by

means of VTA

SFOC-optimized load range Tuning method SFOC change [g/kWh]

35% 50% 65% 80% 100%

High load (85-100%) Standard L1 engine 4 0 -2.5 -3 0

Partial load (50-85%) VTA 2 -2 -4.5 -4 2

Low load (25-70%) VTA 1 -3 -5.5 -3 1

Standard L1 engine – turbocharger without adjustable turbine nozzle ring

VTA – turbocharger with adjustable turbine nozzle ring

Table 9: Optimization potential – MC/MC-C/ME-B Tier II engines, SMCR = L1

1 Adjustable turbine nozzle ring (VTA) 1.3 Low-speed propulsion engines from MAN B&W

2013-12-04 - de

1MAN Diesel & Turbo

12 (38) EN-US

Figure 7: Reduction of the specific fuel consumption SFOC of MC/MC-C/ME-B

engines by means of VTA

For a specific L1 engine, the SFOC profile can be taken directly from the

tables above. For example, an S70ME-C8.2 at a load of 65% and with an L1

SFOC of 169 g/kWh, optimized for partial load with VTA tuning, has a con-

sumption of 169 - 6.5 g/kWh = 162.5 g/kWh.

The tuning methods specified above are also available for derated engines

with various SMCRs. The load-dependent standard SFOC profile is different

for a derated engine; the difference specified above between the individual

tuning methods and the standard engine is the same, however.

For engines with turbochargers featuring conventional efficiency, optimization

is only possible at high load.

The specified methods and options are explained below.

2013-12-04 - de

1 Adjustable turbine nozzle ring (VTA) 1.3 Low-speed propulsion engines from MAN B&W

MAN Diesel & Turbo 1

EN-US 13 (38)

2 Overview of series

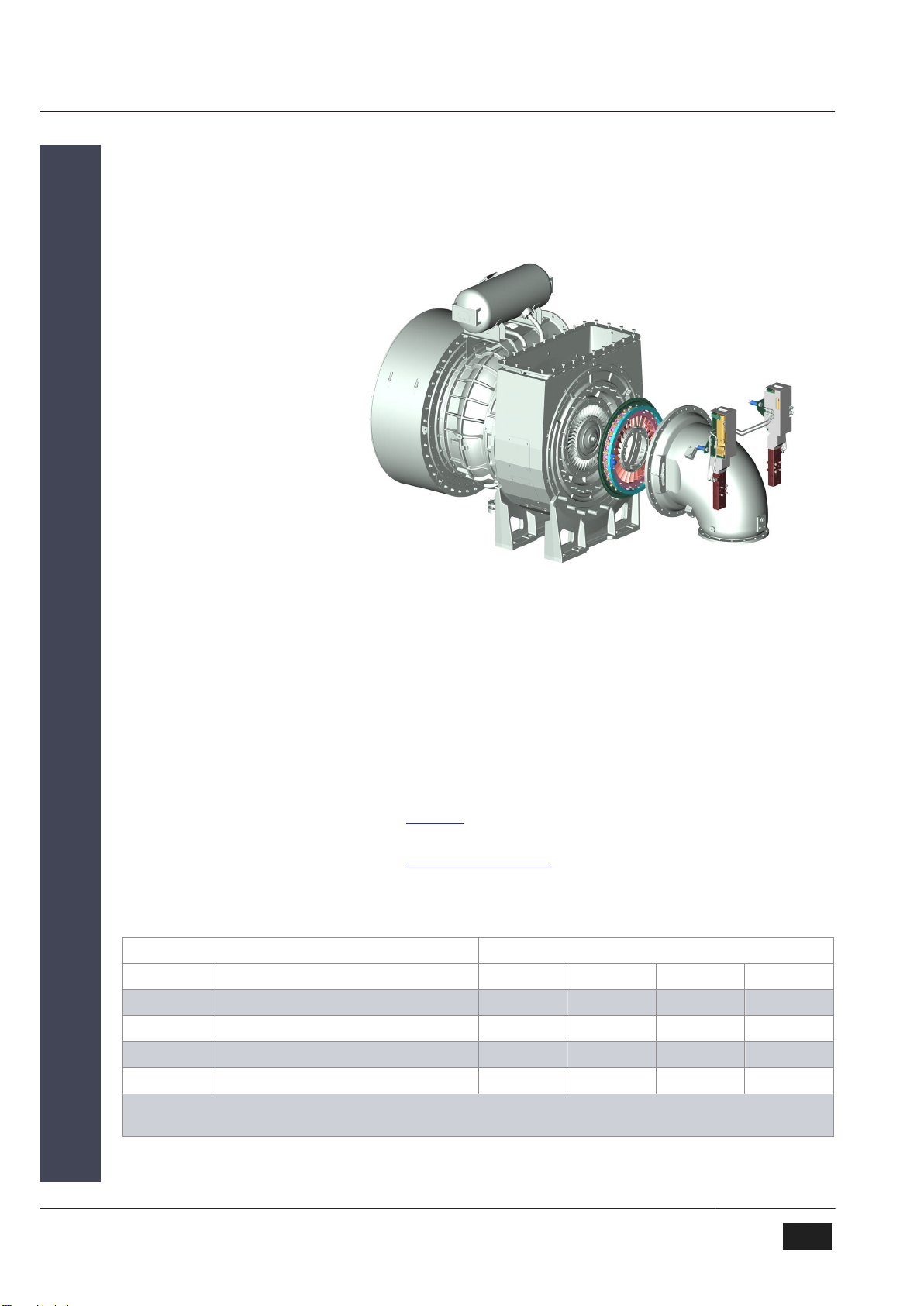

2.1 VTA on TCA turbocharger

Figure 8: TCA turbocharger with adjustable turbine nozzle ring

2.2 Dimensions

The dimensions of the turbocharger are not changed by using an adjustable

turbine nozzle ring.

Overall dimensions for TCA turbocharger:

See Project Guide “TCA Turbochargers”.

Depending on the engine plant, an additional control cabinet or switch box is

required to house the VTA controller for the adjustable turbine nozzle ring.

Description of the required components for the VTA controller:

See chapter Systems / VTA control.

Dimensions and installation of the required control cabinets:

See chapter Engine room planning.

2.3 Weights

Subassembly Turbocharger

Number Designation TCA55 TCA66 TCA77 TCA88

510 Adjustable turbine nozzle ring 78 kg 131 kg 220 kg 361 kg

511 Adjustment device 40 kg 40 kg 56 kg 56 kg

549 Sealing air pipe 2 kg 2 kg 3 kg 3 kg

–m+1) 100 kg 110 kg 140 kg 190 kg

1) m+ = weight increase of a TCA turbocharger with VTA compared with a TCA turbocharger of the same size with-

out VTA

Table 10: Weights of individual VTA components

Overall dimensions

Control cabinet

2 Overview of series 2.3 Weights

2013-12-04 - de

2MAN Diesel & Turbo

14 (38) EN-US

TIP The VTA can generally be implemented in all TCA turbocharger

types and sizes.

To obtain weight specifications for VTA components of TCA turbochargers

that are not listed here, please contact our Technical Sales department.

e-mail: [email protected]

2.4 Casing Positions

Use of the adjustable turbine nozzle ring does not restrict the rotatability of

individual casings on TCA turbochargers.

TIP Possible casing positions for TCA turbochargers:

See Project Guide “TCA Turbochargers”.

The adjustment device for the turbine nozzle ring is fastened to the gas

admission casing and cannot be rotated separately.

The servomotors of the adjustment device generally point in the direction of

the exhaust gas pipe – see Figure 90° gas admission casing with VTA adjust-

ment device.

501.000 Gas-admission casing E Exhaust-gas inlet

510.000 Variable turbine area

511.000 Adjusting device

Figure 9: 90° gas-admission casing with VTA adjusting device

Installation position

of adjustment device

2013-12-04 - de

2 Overview of series 2.4 Casing Positions

MAN Diesel & Turbo 2

EN-US 15 (38)

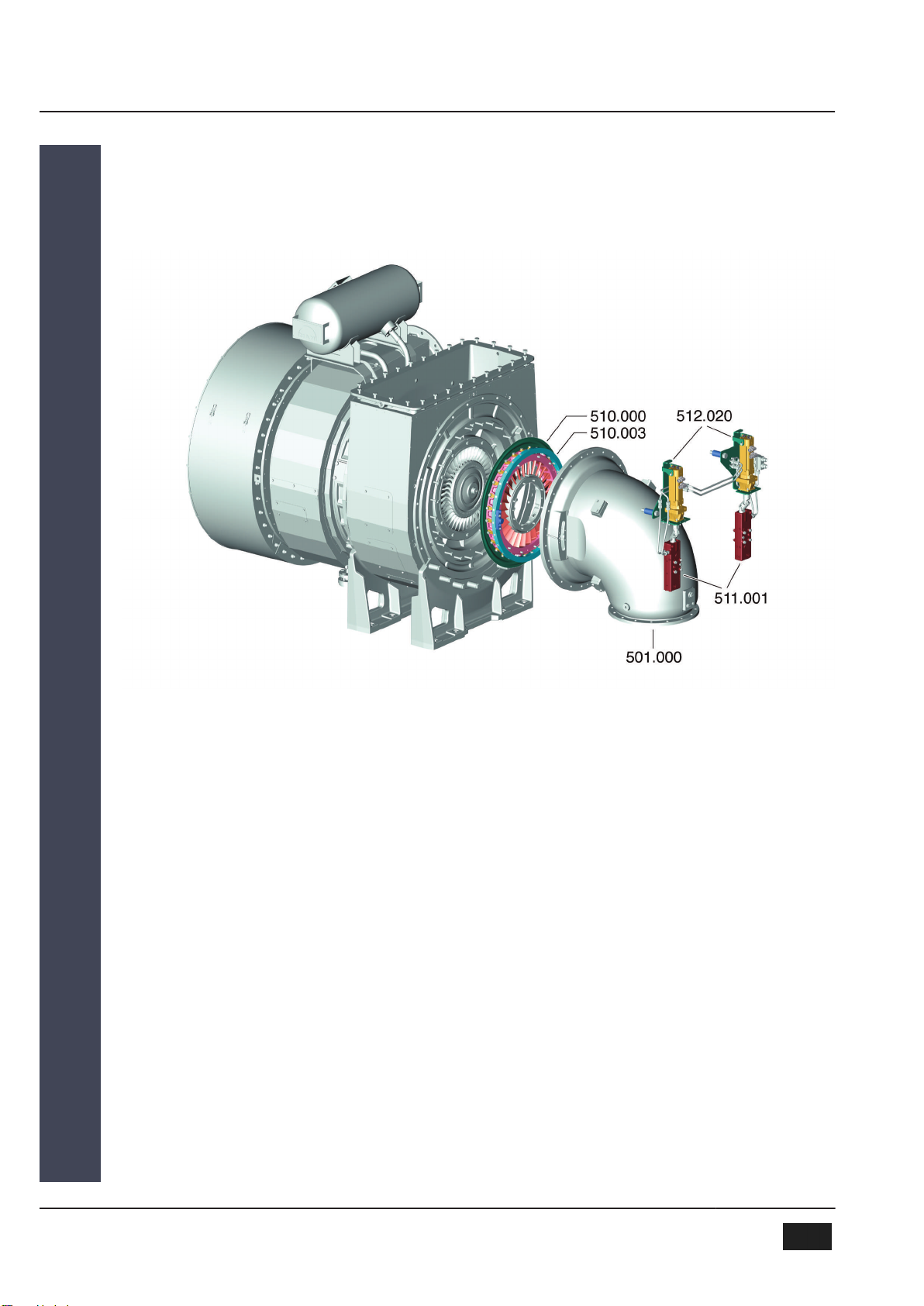

3 Design

3.1 Characteristics of the Assemblies

501.000 Gas admission casing

510.000 Adjustable turbine nozzle ring

510.003 Setting ring

511.001 Spindle drive

512.020 Servomotor

Figure 10: TCA turbocharger with adjustable turbine nozzle ring (VTA)

Adjustable Turbine Nozzle Ring

The cast turbine guide vanes of the adjustable turbine nozzle ring (510.000)

have the same profile as the fixed nozzle ring in order to benefit from the

advantages of low vibration and good flow characteristics.

Adjustment Device

The principal components of the adjustment device are the two spindle

drives (511.001) which are responsible for converting the rotational motion of

the servomotors (512.020) to a linear motion for adjustment of the VTA.

Subassembly 510

Subassembly 511

3 Design 3.1 Characteristics of the Assemblies

2013-12-04 - de

3MAN Diesel & Turbo

16 (38) EN-US

3.2 Operation Method of the Adjusting Device

The adjustable turbine nozzle ring is driven by two servomotors mounted on

the adjustment device. The motor speed is reduced and the torque

increased by means of a planetary gear unit. A Cardan joint transfers the tor-

que from the servomotor to the spindle drive. There is one spindle drive for

each servomotor.

In each spindle drive is a shaft with axial needle bearings. This shaft rotates

as the torque is applied. The rotational motion of the spindle shaft is con-

verted into a translational motion by means of a slotted nut.

The motion of the nuts of both spindle drives is transferred to the carriers

fastened to the setting ring, thereby inducing a rotational motion of the set-

ting ring.

There are setting levers evenly distributed around the circumference – one

setting lever per turbine guide vane – mounted in the setting ring. The setting

levers are positively connected to the turbine guide vanes, which are

mounted in the outer guide ring. The torque imparted by the setting ring to

the levers induces a rotational motion of the turbine guide vanes.

NOTE For the adjustment of the turbine nozzle ring, the two servomo-

tors, operated in parallel, must be rotated in opposite directions.

Servomotors

(512.020)

Spindle drive

(511.001)

Setting ring

(510.003)

Adjustable

turbine guide vanes

2013-12-04 - de

3 Design 3.2 Operation Method of the Adjusting Device

MAN Diesel & Turbo 3

EN-US 17 (38)

4 Systems

4.1 VTA Control (VCS)

Various controller variants are available in order to be able to cover all appli-

cations.

Detailed list of the components required for this:

See chapter Scope of supply / Scope of supply of VTA and equipment.

VTA Variable Turbine Area

VCS VTA Control System

MPC Multi Purpose Controller

MOP Main Operating Panel

SACS Scavenging Air Control Software

ECS Engine Control System

For this application, parameters including the following are required for

adjustment of the VTA:

▪Filling of fuel index transmitter or regulator

▪Scavenge air pressure

These parameters are processed in the Multi-purpose controller (MPC) of the

VTA control system (VCS). The MPC supplies the VTA control system with

signals for adjusting the VTA.

The following parameters are output:

▪Slow Down

▪Warnings for the safety system

Explanation of terms

VTA on MC/MC-C

two-stroke engine

4 Systems 4.1 VTA Control (VCS)

2013-12-04 - de

4MAN Diesel & Turbo

18 (38) EN-US

Table of contents

Popular Industrial Equipment manuals by other brands

Magnaflux

Magnaflux Universal WE TOUCH with TCODE operating manual

ITEM

ITEM LRE 8 D25 ZU 80 R50 Notes on Use and Installation

Essemtec

Essemtec Fox Maintenance manual

Graziadio & C.

Graziadio & C. K Series Assembly instructions

Irontite Products

Irontite Products Kwik-Way SVS II Deluxe Instruction manual and parts list

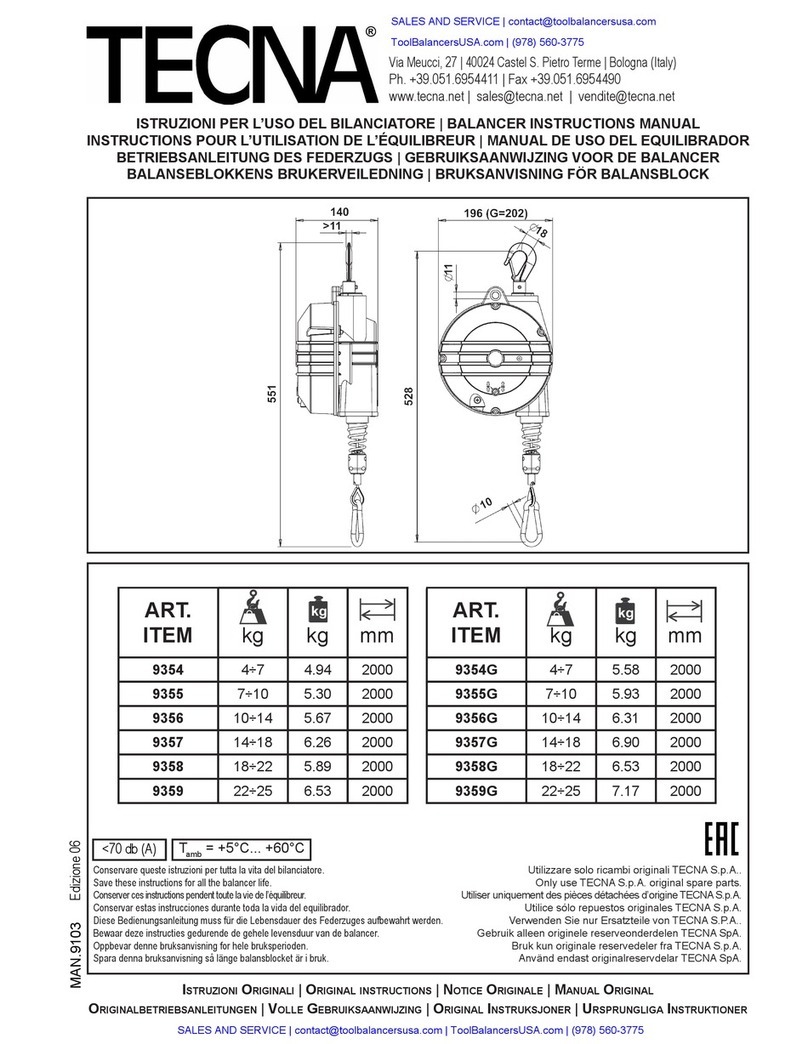

TECNA

TECNA 9354G instruction manual

Full Spectrum Laser

Full Spectrum Laser MUSE MOPA user manual

HYTROL

HYTROL 190-NSP Series Installation and maintenance manual

Miller

Miller INTELLIMATIC SS-12M owner's manual

ABB

ABB HT603383 Operation manual

Jäger

Jäger Chopper 6500 H manual

FLENDER

FLENDER B H 23 28 Series Assembly and operating instructions