entegris GateKeeper User manual

MICROCONTAMINATION CONTROL |MANUAL

GateKeeper®GPU

Ozone Gas Purifiers

Installation and operation manual

1

GATEKEEPER GPU OZONE GAS PURIFIERS

Installation and Operation Manual | Entegris, Inc.

TABLE OF CONTENTS

—

Overview ............................................................................ 2

Safety .................................................................................. 2

Installation Procedures ................................................... 3

Site Preparation .............................................................. 3

Installation ....................................................................... 3

Before Startup ................................................................ 3

Flowing Ozone Gas ...................................................... 3

Decommissioning Procedure When Heated ......... 4

Managing Replacement and Purifier Lifetime ........... 4

Disposal .............................................................................. 4

Troubleshooting Guide ................................................... 5

Mechanical Specifications ............................................. 6

GPU Options ..................................................................... 6

Limited Warranty ............................................................... 7

For More Information ...................................................... 7

Terms and Conditions of Sale ........................................ 7

2

GATEKEEPER GPU OZONE GAS PURIFIERS

Installation and Operation Manual | Entegris, Inc.

OVERVIEW

—

These instructions provide clear guidelines on

proper operation and maintenance of GateKeeper®

GPU Ozone Purifiers. Read this manual carefully as

there are important safety and product performance

topics that are discussed. Failure to follow these

instructions may result in damage to the product

or an unsafe condition.

SAFETY

—

Read Carefully

NOTE: Completely read this manual before

installation and operation.

DANGER! High-pressure fluids are dangerous.

Any accidental release of pressure can propel

objects at high speed and may cause damage

to equipment or injure personnel. Ensure that

proper safety precautions are taken in order to

prevent and/or mitigate hazardous conditions.

Ensure the area is well-ventilated to prevent

asphyxiation.

DANGER! USE THIS PURIFIER WITH APPROVED

GASES ONLY. If this product is exposed to

an incompatible gas, an exothermic or other

adverse reaction may occur. It is the user’s

responsibility to install all safety equipment

to prevent and mitigate the eects of such

a condition.

WARNING! Always pressurize and depressurize

a purifier slowly in order to prevent damage

to the filter membrane.

CAUTION! Never use purifiers with multiple

process gases. If this is required, contact

Entegris to ensure safe operation.

CAUTION! DO NOT exceed the maximum

flow rate for the purifier. See the

Mechanical

Specifications

section (page 6).

CAUTION! DO NOT exceed the maximum

or minimum operating temperatures. See

the Mechanical Specifications table in the

Mechanical Specifications

section (page 6).

CAUTION! DO NOT leave the purifier uncapped

for more than 60 seconds.

GATEKEEPER GPU OZONE GAS PURIFIERS

3Installation and Operation Manual | Entegris, Inc.

INSTALLATION PROCEDURES

—

SITE PREPARATION

CAUTION!! Use stainless steel gaskets for fitting

connection. The use of other gaskets may cause

abnormal heat generation of the purifier.

1. Modify the gas line prior to purifier installation using

a qualified high-purity mechanical contractor.

2. Purge the lines upstream of the purifier to remove

any atmospheric contaminants.

3. Do not remove the fittings until indicated in this

instruction manual.

4. Minimize exposure to atmosphere when loosening

or removing the sealing fittings.

5. Use the proper installation tools and unplated

stainless steel face seal gasket. If possible, avoid

using adjustable wrenches, as they often damage

fittings.

6. Please note, never reuse face seal gaskets.

INSTALLATION

CAUTION! Take care not to contaminate the

purifier wetted parts with any foreign substances

during installation. The contamination may cause

abnormal heat generation of the purifier.

1. Verify that the gas line has the proper clearance

dimensions for the purifier and adjust if needed,

and all face seals are undamaged.

2. Orient the purifier in the gas line with the flow

arrow pointing in the direction of the gas flow.

3. Prepare two new stainless steel face seal gaskets

before removing purifier caps. Be sure to work

quickly, completing the next five steps without

interruption. This will minimize the purifiers

exposure to atmosphere.

4. Inspect inlet and outlet face seals for damage.

5. Insert a new metal seal gasket for the outlet and

hand tighten the connection.

6. Insert a new metal seal gasket for the inlet and

hand tighten the connection.

NOTE: Take care to not rotate the purifier body. This

may damage the sealing surface, which could lead to

a leak.

7. Using the proper wrenches, tighten the inlet and

then the outlet connections an additional ⁄ of a

turn (45°) past finger tight to seal the connection.

The purifier must be held stationary while turning

the mating fitting. Do not over tighten as this may

cause damage to the fittings.

8. Perform the leak test according to procedure that is

defined at site.

BEFORE STARTUP

Ensure the purifier has been leak checked and

installed as recommended. Also ensure the purifier

is being operated within its operating limits, such as

temperature and pressure.

FLOWING OZONE GAS

CAUTION! Monitor the purifier surface tem-

perature when starting service in ozone gas.

If the purifier is contaminated with any foreign

substances during installation, the purifier may

experience abnormal heat generation.

1. Flow a minimum of 20 liters of ozone gas in the

purifier inlet through the outlet for a minimum of

five minutes.

2. Ensure the purifier surface temperature is lower

than 40°C (104°F) while ozone gas is flowing. If

the surface temperature exceeds 40°C (104°F),

immediately turn o ozone gas flow and remove

the purifier according to the following decommis-

sioning procedure.

3. Purifier is now ready for use.

4

GATEKEEPER GPU OZONE GAS PURIFIERS

Installation and Operation Manual | Entegris, Inc.

DECOMMISSIONING PROCEDURE WHEN HEATED

When the purifier generates heat, decommission

the purifier immediately following this procedure.

1. Turn o ozone gas flow.

2. Purge the purifier with a minimum of 20 liters of

inert gas for a minimum of 10 minutes.

3. Ensure the surface temperature goes down to a

safe temperature for handling.

4. Remove the purifier according to the procedure

defined at the operating site.

5. Cap the purifier tightly with metal caps.

CAUTION! DO NOT REUSE the decommissioned

purifier.

MANAGING REPLACEMENT AND PURIFIER LIFETIME

—

Since the series does not have an end-of-life

indicator, it is recommended that they be put on a

Preventative Maintenance (PM) cycle based on the

estimated lifetime.

In order to determine the purifier’s lifetime, please

visit www.entegris.com or contact your local Entegris

oce for assistance.

DISPOSAL

—

All purifiers should be purged with an inert gas

before disposal.

CAUTION! When the purifier is serviced in ozone

gas that is produced by an ozone generator using

nitrogen as a dopant, nitric acid may accumulate

in the purifier.

GATEKEEPER GPU OZONE GAS PURIFIERS

5Installation and Operation Manual | Entegris, Inc.

TROUBLESHOOTING GUIDE

—

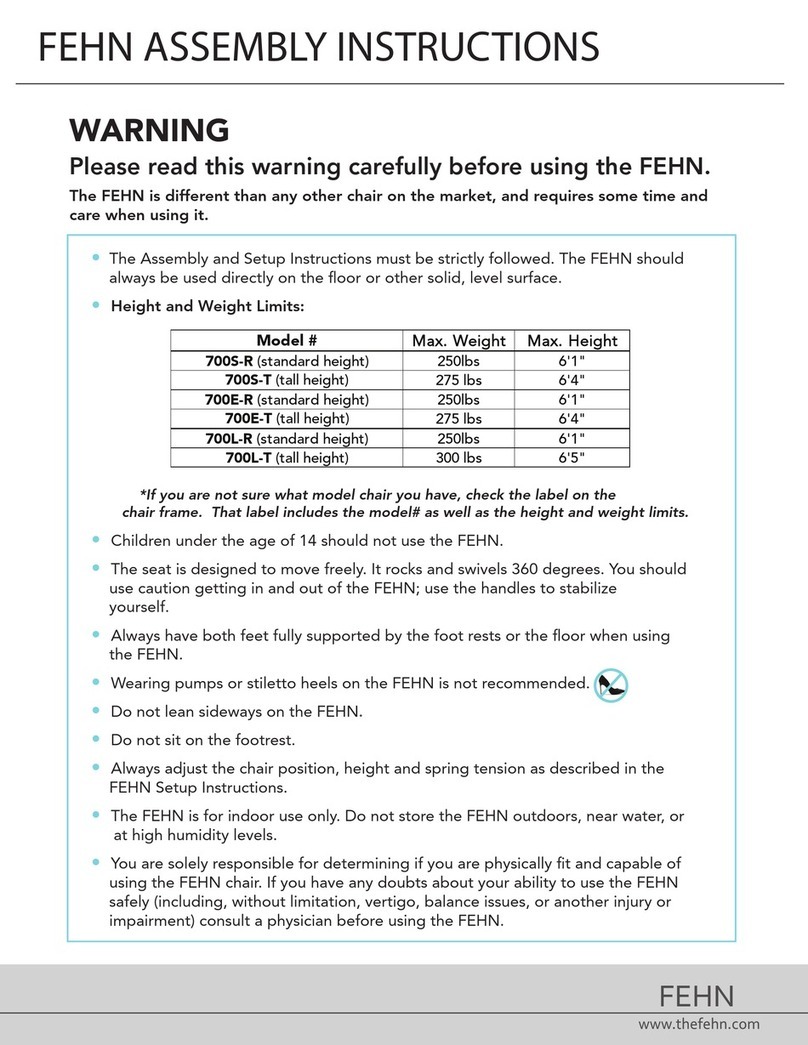

SYMPTOM POSSIBLE CAUSE SOLUTION

The purifier generates

abnormal heat.

Ozone reactive substances are

captured in the purifier.

Turn o the ozone gas flow and replace the

purifier with a new purifier.

Outlet metal concentration

does not meet specified

performance.

Downstream parts generate metals

after purification.

Install the purifier near the use point to avoid

metal generation by downstream parts.

Purifier flow rate is too high. Verify that the maximum flow rate is not

exceeded.

Outlet purity level

degrades with time.

Purifier has exceeded its useful life. Replace the purifier with a new purifier.

Ozone concentration

declines after purification.

The inertness of the purifier is degraded

by ozone reactive substances captured

in the purifier, or by the accumulation

of impurities in the purifier.

Replace the purifier with a new purifier.

6

GATEKEEPER GPU OZONE GAS PURIFIERS

Installation and Operation Manual | Entegris, Inc.

MECHANICAL SPECIFICATIONS

—

Materials of construction Filter membrane PTFE

Purification media Porous inorganic material

Housing 316L stainless steel

Surface finish, internal Ra <0.17 µm (electropolished)

Retention Volatile metals Cr and Mn

Volatile metal removal eciency >99% for Cr

Particles >99.9999999% for particles ≥0.003 µm

Connection ⁄" gasket seal

Gas Ozone (O₃) <300 g/Nmconcentration

Inlet metal level Cr: <1 ppm

Recommended flow rate 5 to 25 slm

Operating conditions Maximum operating pressure:

20 kPa (2.9 psi)

Operating temperature:

20° to 30°C (68° to 86°F)

Please consult Entegris Account Managers for flow rate and O₃ gas concentration exceeding specifications.

GPU OPTIONS

—

Part number Description

GPUS200TOZ04R11CA For vacuum conditions

GPUS200TOZ04R12CA For pressurized conditions

129 Concord Road

Billerica, MA 01821

USA

Tel +1 952 556 4181

Fax +1 952 556 8022

Toll Free 800 394 4083

Corporate Headquarters Customer Service

LIMITED WARRANTY

Entegris' products are subject to the Entegris, Inc. General Limited Warranty. To view and print this information,

visit entegris.com and select the Legal & Trademark Notices link in the footer. Entegris does not warrant any

failure in the case of customers using unapproved foreign components.

FOR MORE INFORMATION

Please call your Regional Customer Service Center today to learn what Entegris can do for you.

Visit entegris.com and select the Contact Us link to find the customer service center nearest you.

TERMS AND CONDITIONS OF SALE

All purchases are subject to Entegris’ Terms and Conditions of Sale. To view and print this information,

visit entegris.com and select the Terms & Conditions link in the footer.

www.entegris.com

Installation and Operation Manual.

Entegris®, the Entegris Rings Design®, and other product names are trademarks of Entegris, Inc. as listed

on entegris.com/trademarks. All third-party product names, logos, and company names are trademarks or

registered trademarks of their respective owners. Use of them does not imply any aliation, sponsorship,

or endorsement by the trademark owner.

©2019 Entegris, Inc. |All rights reserved. |Printed in the USA |4503-10756ENT-0819

Table of contents

Other entegris Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ITALVIBRAS GIORGIO SILINGARDI

ITALVIBRAS GIORGIO SILINGARDI MVCC Series Technical handbook

Delta Regis

Delta Regis DRFF-300R user manual

HBM Machines

HBM Machines HBM 250 instruction manual

COREMO OCMEA

COREMO OCMEA A3-3N User and maintenance manual

A.B.S.

A.B.S. Flexilo SPRING Assembly-, Operating-, and Filling Instructions

XCMG

XCMG XDN450 Operation manual

ESE

ESE HD-266/SD Operation and maintenance manual

EVAPCO

EVAPCO EAFWD Additional Installation, Operation and Maintenance Instructions

bonitron

bonitron M3484 Customer Reference Manual

Mayer

Mayer TM 1610F operating instructions

HBM

HBM HLCM Series Mounting instructions

Simplex

Simplex VSH SUPER Technical information installation instructions