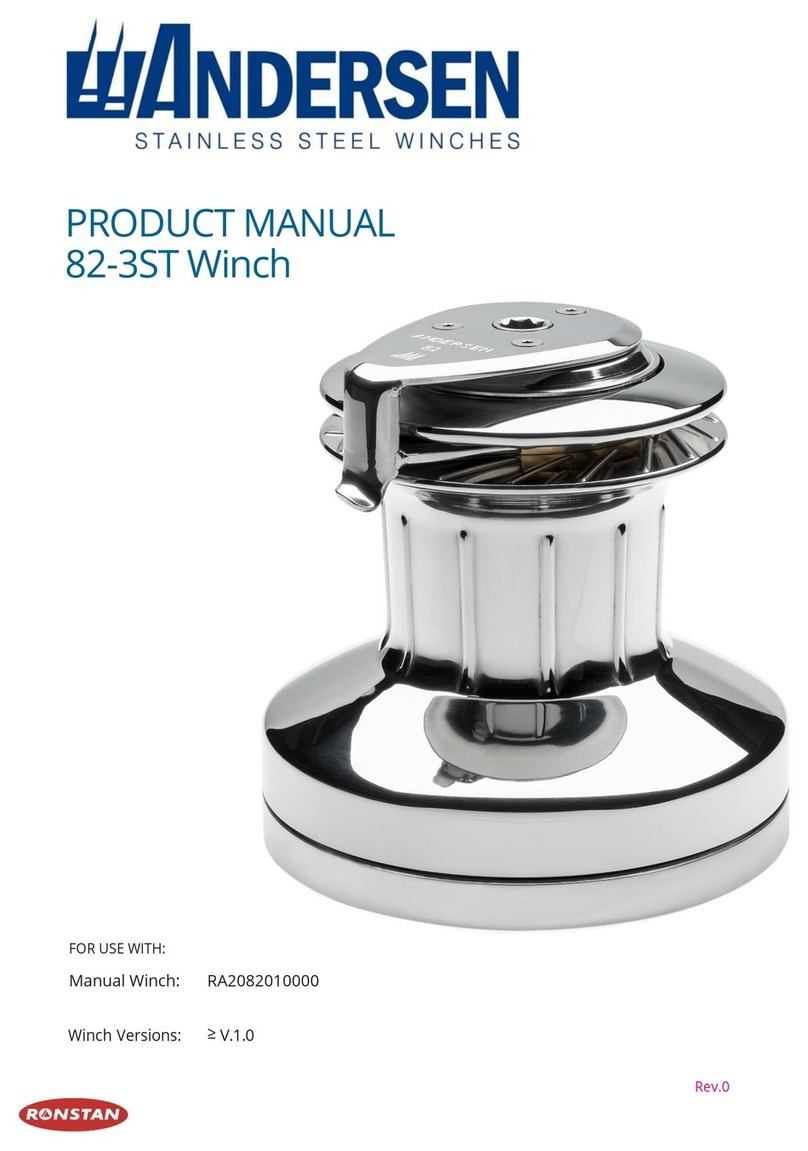

Enthuze ENT4401P User manual

SAVE THESE INSTRUCTIONS

2,000-Lb. 12 Volt DC Electric ATV Winch

Owner’s Manual

WARNING: Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other basic

safety precautions may result in serious personal injury.

Item # ENT4401P

Page 2 of 20

Thank you very much for choosing Enthuze Automotive Products!

For future reference, please complete the owner’s record below:

Serial Number/Lot Date Code: __________________________

Purchase Date: ______________________________________

Save the receipt, warranty, and this manual. It is important that

you read the entire manual to become familiar with this product

before you begin using it.

This electric winch is designed for certain applications only.

Enthuze is not responsible for issues arising from modification or

improper use of this product such as an application for which it

was not designed. We strongly recommend that this product not

be modified and/or used for any application other than that for

which it was designed.

For technical questions, please contact our customer support.

Enthuze Automotive Products

Website: www.enthuze.ca

Page 3 of 20

Table of Contents

Intended Use......................................................................................................4

Technical Specifications .....................................................................................4

Important Safety Information ............................................................................5

Specific Operation Warnings ..............................................................................7

Assembly Instructions .......................................................................................8

Before Each Use ...............................................................................................11

Operating Instructions .....................................................................................11

After Each Use..................................................................................................14

Maintenance.....................................................................................................15

Troubleshooting ...............................................................................................15

Parts List..........................................................................................................17

Replacement Parts ...........................................................................................18

Limited Warranty .............................................................................................19

Page 4 of 20

Intended Use

The Enthuze 2000-Lb. 12 Volt DC Electric ATV Winch has a permanent magnet motor

which draws less current, making it ideal for ATV use. The Differential Planetary gear

system allows for fast line speed while the automatic load-holding brake provides

maximum safety. It has free spooling for a fast line-out, a roller fairlead with nylon

bushings and an aircraft-grade wire rope.

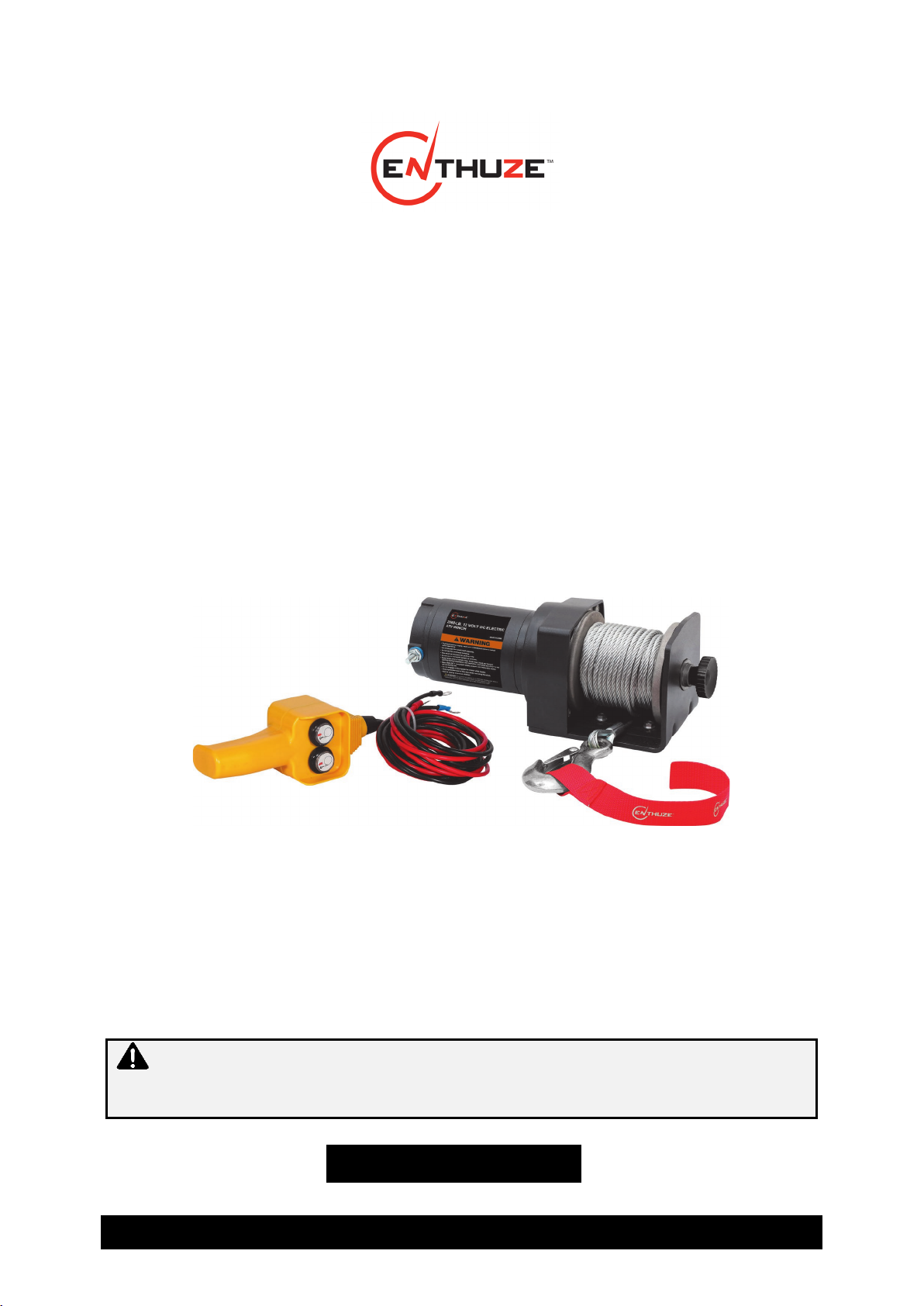

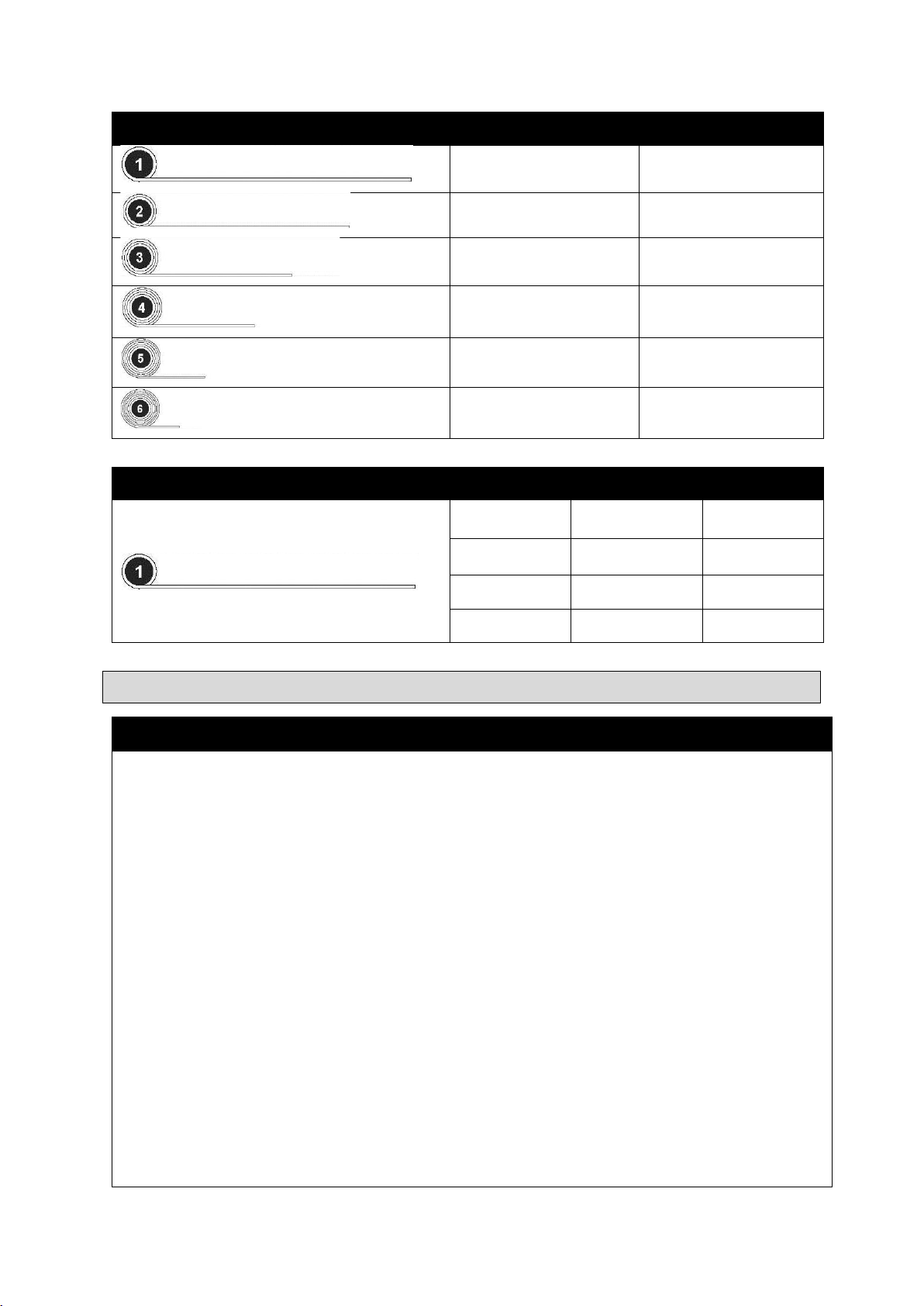

Technical Specifications

Property Specification

Rated Single Line Pull 2,000lb (907kg)

Application Utility/Shop/ATV

Motor 12V DC 1.1 HP Permanent Magnet

Power In & Power Out Yes

Duty Cycle Rating 5% (45 Seconds at Max Rated Load; 14 minutes, 15 seconds rest)

Wired Remote

Controller

Wired, 10ft (3.04m) Long

Gear Train

Differential Planetary

Gear Ratio 153:1

Free Spool Pull and Turn

Brake Automatic Load Holding Dynamic

Drum Diameter 1.24" X 2.83" (31.5mm x 72 mm)

Hook 1/4" Clevis, with Spring-Loaded Safety Latch

Fairlead Roller with Nylon Bushings

Wire Rope Size /Type

5/32" x 50' (4.0mmX15.2m)

7X19 Galvanized Steel

Aircraft-Grade Wire Rope

Battery 12V DC Minimum 12Ah

Battery Cables 10 Gauge,6' (1.83m) long

Motor Cables 10 Gauge, 4' (1.23m) long

Mounting Bolt Pattern 3.15’’ (80mm)

Mounting Hardware Winch: 2xG8, M8-1.25X35mm (0.05” X 1.38’’ )

Overload Protection In-line Circuit Breaker

Sound Rating 85 db

Overall Dimensions

(L X D X H)

11.1"×4.6"×4.2” (282mm×117mm×106mm)

Weight 13.2lb (5.98 kg)

IP Rating IP 65 - Winch and Controls (resistant to water jets)

Page 5 of 20

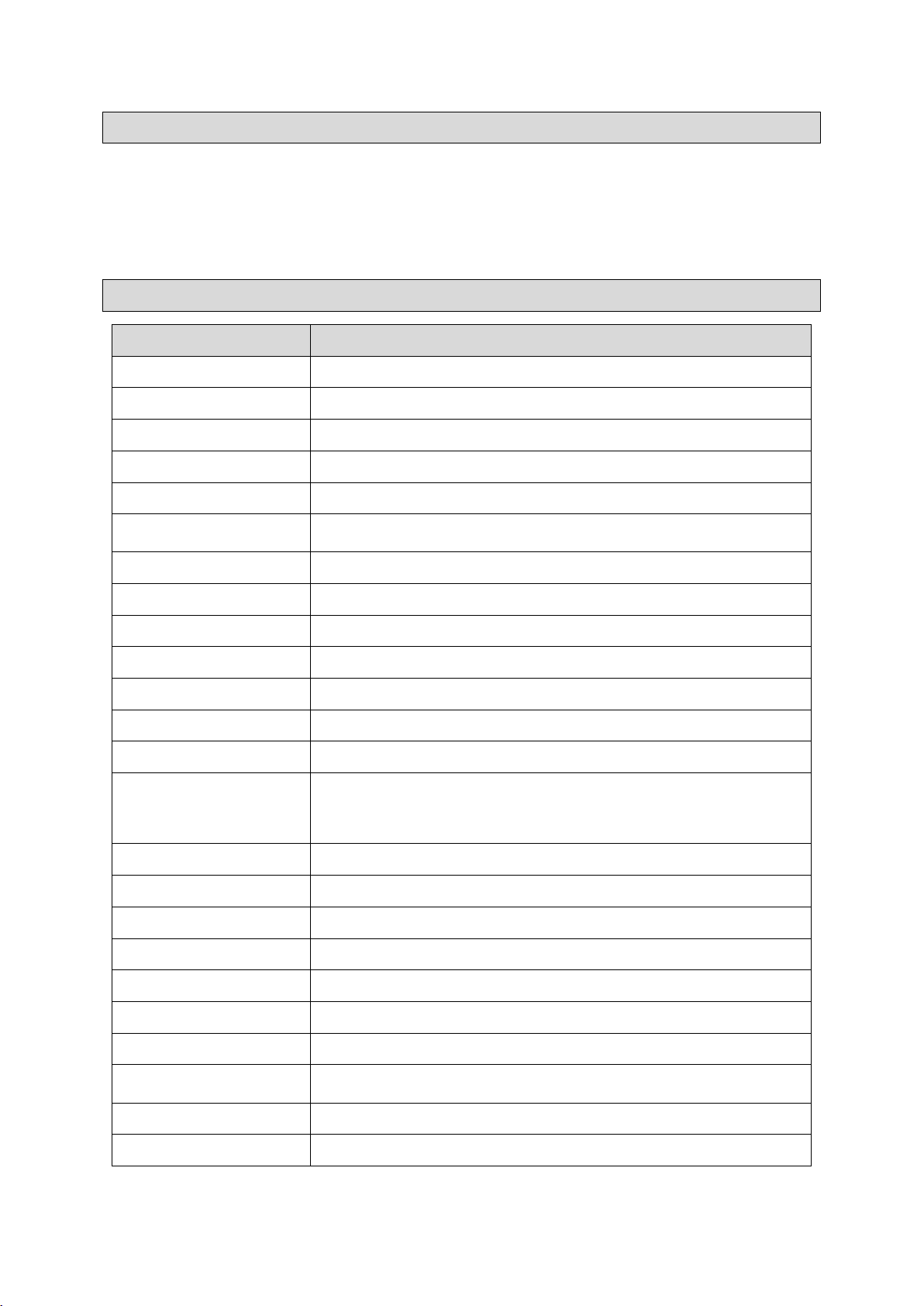

Layer Rated Line pull Rope Length/ Layer

2000lb (907kg) 6’ (1.8m)

1636lb (742kg) 13.3’ (4.0m)

1384lb (628kg) 21.9’ (6.7m)

1200lb (544kg) 31.8’ (9.7m)

1058lb (480kg) 43.1’ (13.1m)

947lb (430kg) 50’ (15.2m)

First Layer of Wire Rope Performance

Line Pull

lb (kg)

Line Speed

fpm (m/min)

Amp Draw

(DC12V)

0 (0) 13.3 (4.1) 10

1000 (454) 8.3 (2.5) 55

2000 (907) 4.1 (1.2) 106

Important Safety Information

⚠

WARNING

•Read and understand all instructions. Failure to follow all instructions may result in

fire, serious injury and/or DEATH.

•The warnings, cautions and instructions in this manual cannot cover all possible

conditions or situations that could occur. Exercise common sense and caution when

using this electric winch. Always be aware of the environment and ensure that the

electric winch is used in a safe and responsible manner.

•Do not allow anyone to operate or assemble the electric winch until they have read

this manual and have developed a thorough understanding of how it works.

•Do not modify this electric winch in any way. Unauthorized modification may impair

the function and/or safety and could affect the life of the electric winch. There are

specific applications for which the electric winch was designed.

•Use the right tool for the job. DO NOT attempt to force small equipment to do the

work of larger industrial equipment. There are certain applications for which this

electric winch was designed. The tool will be safer and do the job better at the

capacity for which it was intended. DO NOT use this equipment for a purpose for

which it was not intended.

•Industrial or commercial applications must follow OSHA requirements.

Page 6 of 20

⚠

WARNING

WORK AREA SAFETY

•Inspect the work area before each use. Keep work area clean, dry, free of clutter and

well-lit. Cluttered, wet or dark work areas can result in injury. Using the electric

winch in confined work areas may put you dangerously close to other cutting tools

and rotating parts.

•Keep children and bystanders away from the work area while operating the tool. Do

not allow children to handle the electric winch.

⚠

WARNING

PERSONAL SAFETY

•Stay alert, watch what you are doing and use common sense when operating the

electric winch. Do not use the electric winch while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating the tool may

result in serious personal injury.

•Dress properly. Do not wear loose clothing, dangling objects or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts. Air vents on the tool often cover moving parts and

should be avoided.

•Wear the proper personal protective equipment when necessary. Use ANSI Z87.1

compliant safety goggles (not safety glasses) with side shields, or when needed, a

face shield. Use a dust mask in dusty work conditions. Also use non-skid safety

shoes, hardhat, gloves, dust collection systems and hearing protection when

appropriate. This applies to all persons in the work area.

•Do not overreach. Always keep proper footing and balance.

⚠

CAUTION

ELECTRIC WINCH USE AND CARE

•Inspect before every use, do not use if damaged or parts loose. Examine the winch

for structural cracks, bends, damage, frayed or kinked rope, and any other conditions

that may affect the safe operate of the winch. Do not use the winch even if minor

damage appears. A kink permanently weakens the rope. Even after it is straightened

out, kinked rope can fail suddenly and must not be used.

•Do not force the electric winch. Products are safer and do a better job when used in

the manner for which they are designed. Plan your work and use the correct product

for the job.

•Store the winch in a dry, secure place out of the reach of children when it is not in

use. Inspect the tool for good working condition prior to storage and before re-use.

•Use only accessories that are recommended by the manufacturer for use with your

electric winch. Accessories that may be suitable for one product may create a risk of

injury when used with another tool. Never use an accessory that has a lower

operating speed or operating pressure than the tool itself.

Page 7 of 20

Specific Operation Warnings

⚠

WARNING

GENERAL SAFETY

•To prevent injury or property damage, read and understand all instructions before

operating winch.

•Wear ANSI Z87.1 compliant safety goggles and heavy duty leather work gloves

during operation.

•Do not exceed the rated load capacity. Be aware of dynamic loading! Sudden load

movement may briefly create excess load, causing product failure.

INSTALLATION SAFETY

•Choose a mounting location that can support the winch and rated load capacity.

•Do not weld mounting bolts.

•Use supplied power cords and rope listed in manual only. Do not use thinner/longer

cables or link multiple cables together.

•Keep hands clear of winch rope, hook loop, hook and fairlead opening during

installation, operation, and when spooling in or out.

•Wrap the rope under 500 lbs. of tension before use. Otherwise, the rope may bind

during operation.

•Do not route electrical cables near sharp edges or parts that will move or become

hot.

•Work in a well-ventilated area. Explosive hydrogen gas can accumulate and explode

when ignited by a spark or open flame.

•Only connect to a clean, corrosion-free battery.

•Remove all jewelry and metallic objects before working near battery.

WINCHING SAFETY

•Inspect winch rope, hook, and slings before operating winch. Frayed, kinked or

damaged winch rope must be replaced immediately. Damaged components must be

replaced before operation.

•Do not maintain power to the winch if the motor stalls. Verify the load is within the

rated capacity for the wire rope layer. Make sure the battery is fully charged. Use

double line rigging whenever possible.

•Do not engage or disengage clutch while under load.

•Always ensure hook latch is closed and not supporting load.

•Never apply load to hook tip or latch. Apply load only to the center of hook.

•Never use a hook that has been bent, warped or twisted.

•Keep clear of fairlead when operating. Do not try to guide rope.

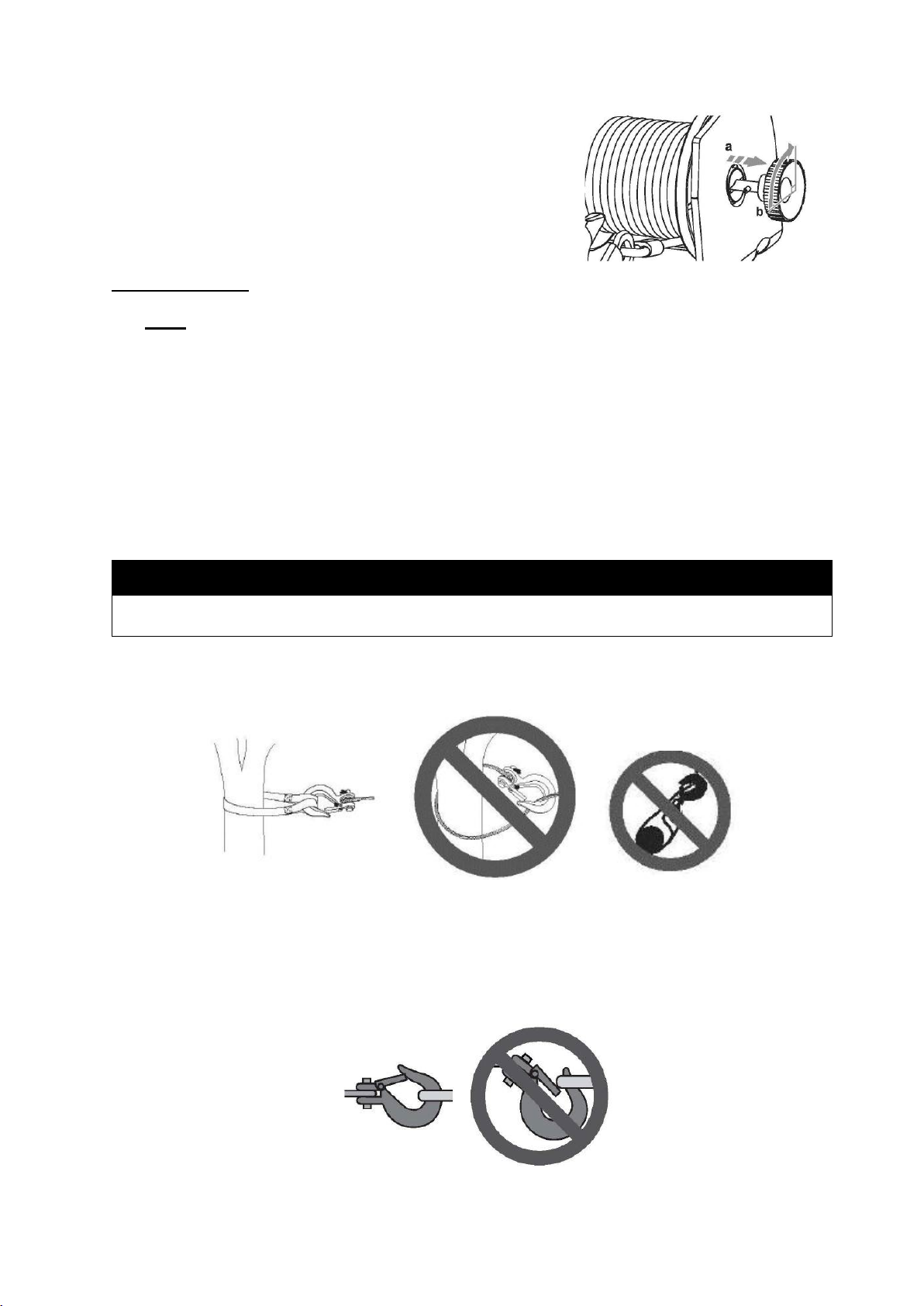

•Do not place any fingers through the hook. Fingers may be caught and get pulled

into the fairlead or drum. Use the included strap to hold the hook instead.

•Stay out of the direct line that the rope is pulling. If it slips or breaks, it will create a

whiplash effect. Utilize a winch dampener to help absorb the force released if the

rope breaks.

Page 8 of 20

•Do not use for overhead hoisting. This winch is intended to be used for pulling only.

•Use a spotter to assist you with safe operation of the winch. Make sure the spotter

is out of the way of the vehicle and the rope before activating the winch.

•Do not use the hand crank, if equipped, to assist the winch.

•Do not use vehicle to pull on the rope and assist the winch.

•Do not use to transport people or animals.

•Disconnect battery cables before working near the rope, drum, fairlead or load to

prevent accidental starting.

•Keep rope straight to avoid kinking the rope.

•Keep children and bystanders away while operating.

•Hook onto the object using a pulling point, tow strap or chain. Do not wrap the rope

around the object and hook onto the rope itself.

•Do not use a recovery strap while winching.

•Secure the load after moving. Do not lock the mechanism.

•Keep at least 5 full turns of rope on the drum.

•Keep clear of the rope, hook, and load while winching. Do not step over the rope or

apply pressure to the rope under tension. The rope might break and cause personal

injury.

•If the rope begins to get entangled, stop the winch immediately and release the

rope using the switch.

•Only winch with the winching vehicle’s transmission placed in neutral. Winching with

a vehicle’s transmission in gear or park may damage the transmission. A vehicle’s

transmission is not designed to handle this type of load.

•Do not operate the winch on extreme slopes. Do not exceed 45° from center line of

vehicle for a roller fairlead. For a Hawse fairlead, the angle should be as close to

vehicle center line as possible.

•People with pacemakers should consult their physicians before use. Electromagnetic

fields near a heart pacemaker could cause pacemaker interference or pacemaker

failure.

•Remove all obstacles before operation.

•Always use supplied hook strap whenever spooling winch rope in or out, during

installation and during operation.

•Always take time to use appropriate rigging techniques for winch pull.

Assembly Instructions

⚠

WARNING

Read the entire Important Safety Information section at the beginning of this manual,

including all text under subheadings, before setting up or using this electric winch.

Page 9 of 20

Mounting the Winch

1. The mounting plate must be rated to at

least

the winch’s

capacity.

2.

Align the winch perpendicular to the center line of

the

vehicle at the desired

location and

mark the

locations

of the winch base holes. Compare the

dimensions

of the marked holes.

3. Before drilling, verify that the

installation

surface has no hidden components

or

structural pieces that will be

damaged.

Note: This winch can generate extreme

force

s

.

Select

a location that can

withstand the rated capacity

without

damage or weakening. Steel reinforcement

plates

may

be needed or a certified welder may need to weld

on

additional

bracing, depending on the mounting

location.

4. Drill holes appropriate for the

hardware

at the marked

locations.

5. Install the winch using

hardware

described

under the

specifications table.

Mounting the Solenoid Assembly

1. Mount the solenoid box in proper location so that:

a) The winch components are close enough to each other to allow wires to be

routed properly.

b) The vehicle component operation is not interfered with.

c) The vehicle components are not damaged by drilling or driving screws.

d) The winch components will not be damaged by stresses caused by vehicle

operation.

2. Mark the location where the screw holes will be.

3. Verify that the installation surface has no hidden components or structural pieces

that will be damaged before drilling.

Page 10 of 20

4. Drill pilot holes for the mounting screws.

5. Secure in place with mounting screws.

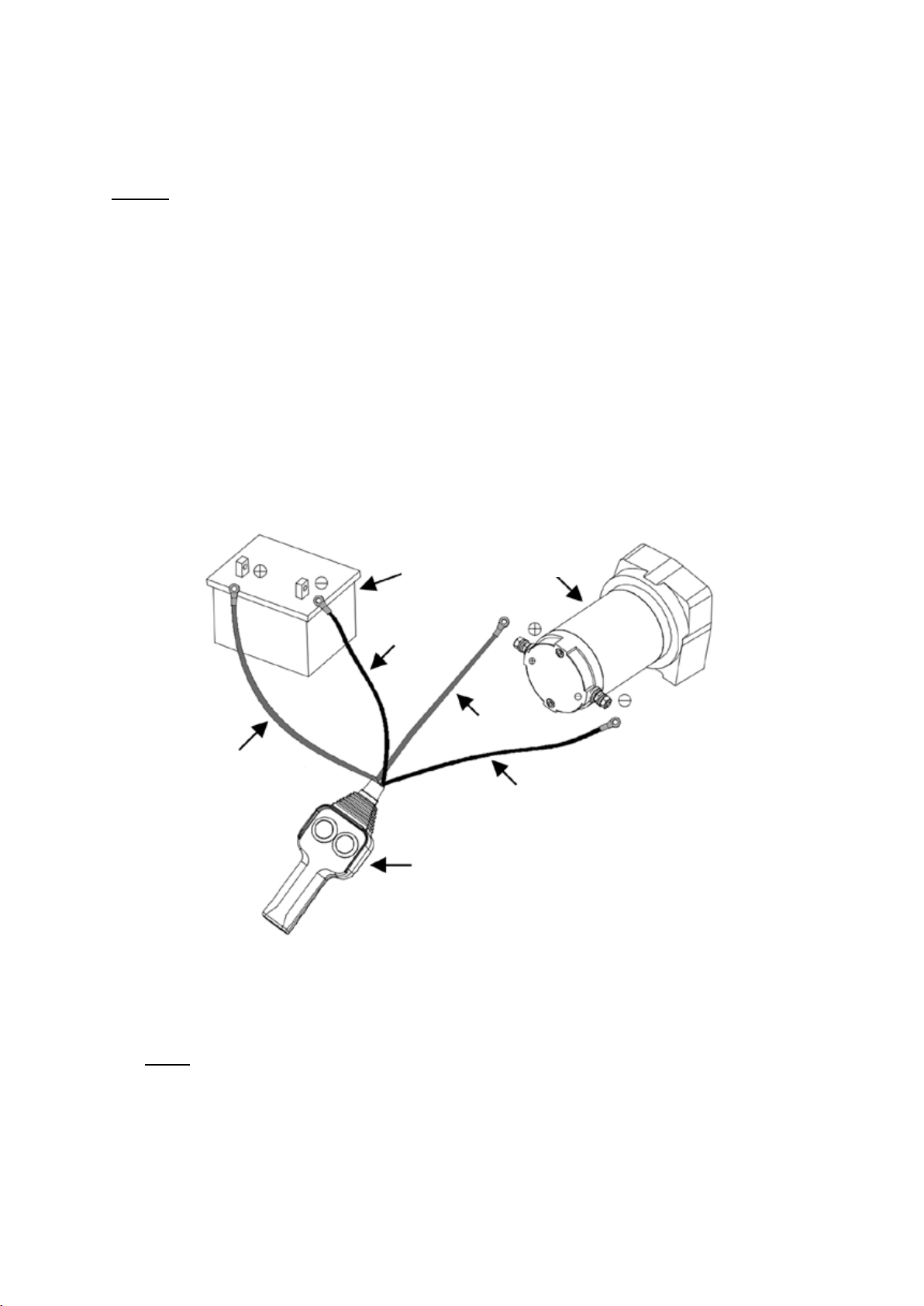

Wiring

To prevent serious injury from explosion (sparking at the battery connection), disconnect

the battery cables before making other wiring connections.

To prevent serious injury from leaking battery acid, do not use a dirty, corroded or

leaking battery. Only use a 12V automotive (or equivalent) battery, in good condition.

1. Plan a route for the wiring from the planned winch location to the battery. This route

must be secure and out of the way of moving parts, road debris, or any possibility of

being damaged by operation or maintenance of the vehicle. For example, you may

wish to route the wires under the vehicle, attaching it to the frame using suitable

fasteners. Do not attach the wires to the exhaust system, drive shaft, emergency

brake cable, fuel line, or any other components which may damage the wiring

through heat or motion, or create a fire hazard.

2.

If you drill through the bumper or any part of the body to route the wires, be sure to

install a rubber grommet in the hole to prevent fraying the wires.

3. Route the cables from the solenoid to the battery and from the solenoid to the

winch, following the precautions discussed above. See the following picture.

Wiring Connection

4. Attach the short wires from the remote to the terminals on the motor.

5. Attach the red battery cable directly to the positive terminal on the battery.

6. Attach the black battery cable directly to the negative terminal of the battery.

Note: The attachment of the motor cables determines the operation

of the remote's button. After the unit is mounted and powered,

check the direction of the Power In and Power Out on the remote

button. If you wish to change the direction on the remote,

disconnect the battery cables from the battery, switch the motor

cable connections on the motor assembly, then reconnect the

battery cables.

Black

Black

Red

Red

Battery

Tethered Remote

Motor

Page 11 of 20

Preparing the Wire Rope

1. The wire rope must be properly coiled under tension to be able to support a load

without damage.

2. Uncoil the wire rope, except for 5 full wraps.

3. Recoil the rope back into the winch under at least 500 lb. of tension.

Before Each Use

⚠

WARNING

•Inspect the winch rope, hook, and slings before operating the winch. Frayed, kinked

or damaged winch ropes must be replaced immediately. Damaged components

must be replaced before operation.

•Wrap the rope under 500 lbs. of tension before use. Otherwise, the rope may bind

during operation.

•Work in a well-ventilated area. Explosive hydrogen gas can accumulate and explode

when ignited by a spark or open flame.

•Remove all jewelry and metallic objects before working near batteries.

Operating Instructions

⚠

WARNING

•Read the entire Important Safety Information section at the beginning of this

manual, including all text under subheadings, before setting up or using this winch.

•The instructions that follow are basic guidelines only and cannot cover all situations

encountered during use. The operator and assistants must carefully plan usage to

prevent accidents.

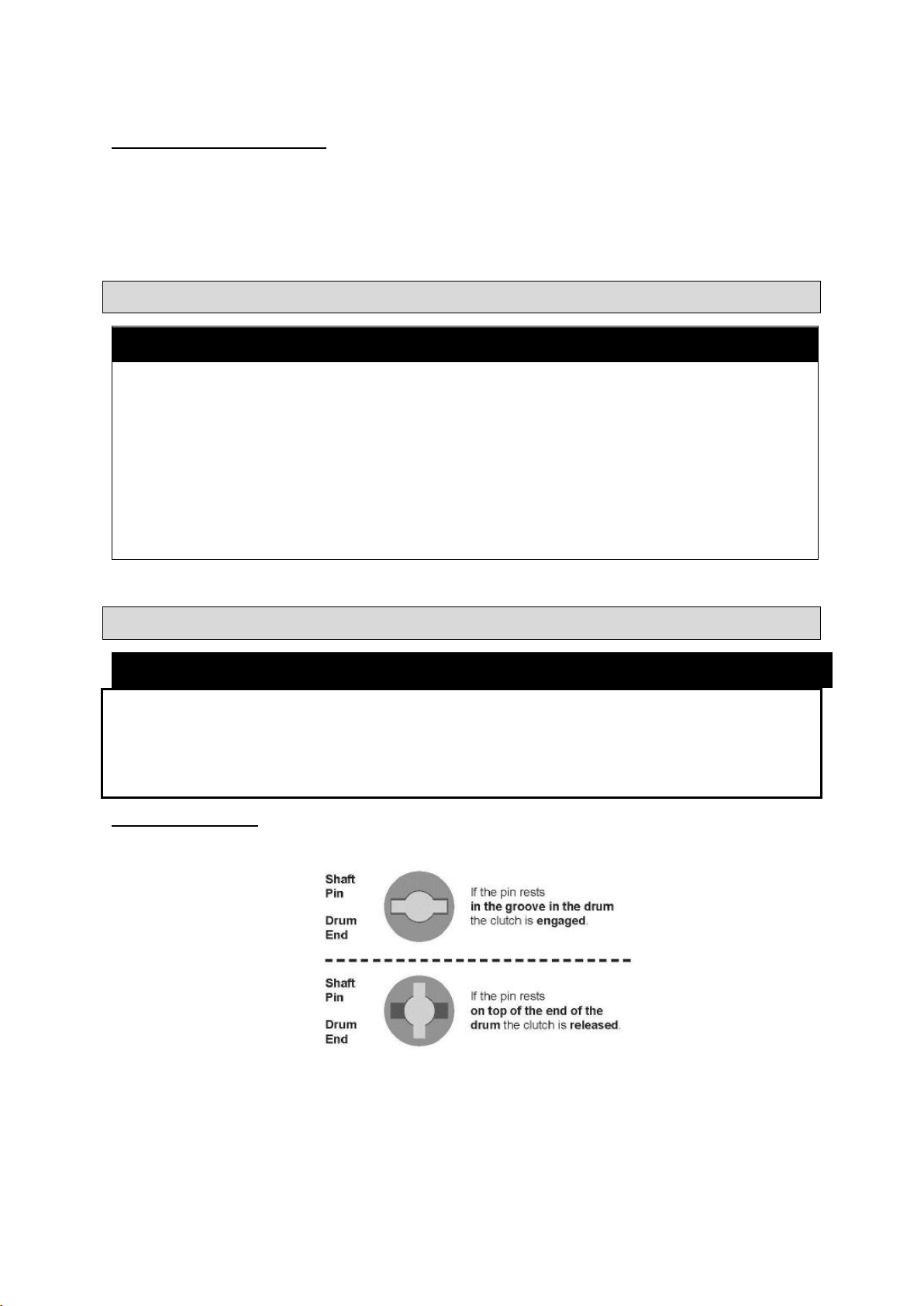

Clutch Operation

1. The position of the pin in the shaft determines whether the clutch is engaged or not.

Page 12 of 20

2. To change clutch position:

a) Pull clutch knob out

b) Turn it 90°while it is pulled out, then release it.

Basic Operation

Note: If a winch is to be used to pull a vehicle, it should optimally be rated to a

single line pull at least twice the vehicle’s weight.

1. Examine the rope. Do not use the winch if the rope is frayed, kinked, or damaged.

2. Fully charge the vehicle’s battery.

3. Check the winch's electrical connections. All connections must be tight and clean.

4. Put the vehicle's transmission in ‘neutral’.

5. If the vehicle (where the winch is mounted) is not supposed to be moved, engage

the emergency brake and block the wheels using wheel chocks (sold separately).

6. To pull out the rope, move the clutch control to the released position (same as photo

in Step 2 on Page 11), slide the loop of the hook strap over the hook, then pull on

the hook strap to pull out the rope.

7. Hook onto the object using a pulling point, tow strap, tree strap or chain. See the

following picture.

Do not wrap the rope around the object and hook onto the rope itself. This can damage

the object being pulled, and kink or fray the rope.

8. The attachment point must be centered in loop of the hook and the hook’s safety

clasp must be fully closed. See the following picture.

⚠

WARNING

Leave at least five full turns of rope on the drum.

Page 13 of 20

9. Do not use a recovery strap while winching. They are designed to stretch and can

suddenly whip back towards the operator during a winching operation.

10. Place a heavy rag or carpet (sold separately) over the rope span, 6 feet from the

hook, to help absorb the force released if the rope breaks.

11. Move the clutch control to the engaged position. See the instruction for your winch

model under clutch operation.

⚠

WARNING

Do not allow anyone to stand near the rope, or in-line with the rope behind the winch

while it is under power. If the rope should slip or break, it can suddenly whip back

towards the winch, causing a hazard for anyone in the area. Stand to the side while

winching.

12. Operate the wired remote controller briefly to ensure the controls work properly. If

operation is reversed, the power cables may be connected backwards. Correct any

such issue before use.

13. When it is safe to do so, use the power switch on the wired remote controller to

retract the rope, and winch the item as desired. To prevent damage, do not power

the hook all the way into the fairlead.

14. Do not operate the winch at extreme angles. Do not exceed the angles shown below

for a roller fairlead. For a Hawse fairlead, the angle should be as close to straight as

possible.

15. If the object to be pulled must be pulled at an angle in relation to the winch, use a

pulley (sold separately) and an anchor point directly in front of the winch (see

illustration) to keep the rope pulled straight.

Page 14 of 20

⚠

WARNING

Stop the winch and release tension on the rope before moving the rag or carpet placed

on it.

16. Do not continue use of the winch until the battery is completely run down. Stop

before it reaches that point.

17. When possible, keep the engine running while using this winch to continually

recharge the battery and prevent the battery from being drained so much that the

vehicle cannot start. However, you should use extreme caution when working

around a running vehicle and ONLY operate a vehicle in an outdoor area.

Note: Do not use the winch in a constant duty application; it is designed for

INTERMITTENT USE ONLY. Keep the duration of the pulling job as short as possible. If

the motor becomes very hot to touch, stop and let it cool down for several minutes. Do

not pull for more than one minute at or near the rated load. Do not maintain power to

the winch if the motor stalls. Double-line rigging will help prevent overloading and should

be used whenever practical.

18. When finished pulling the load, reverse the direction of the winch just enough to

release tension on the rope so that you can unfasten the hook from the load and reel

in the rope.

19. Disconnect the wired remote controller (if equipped) after use.

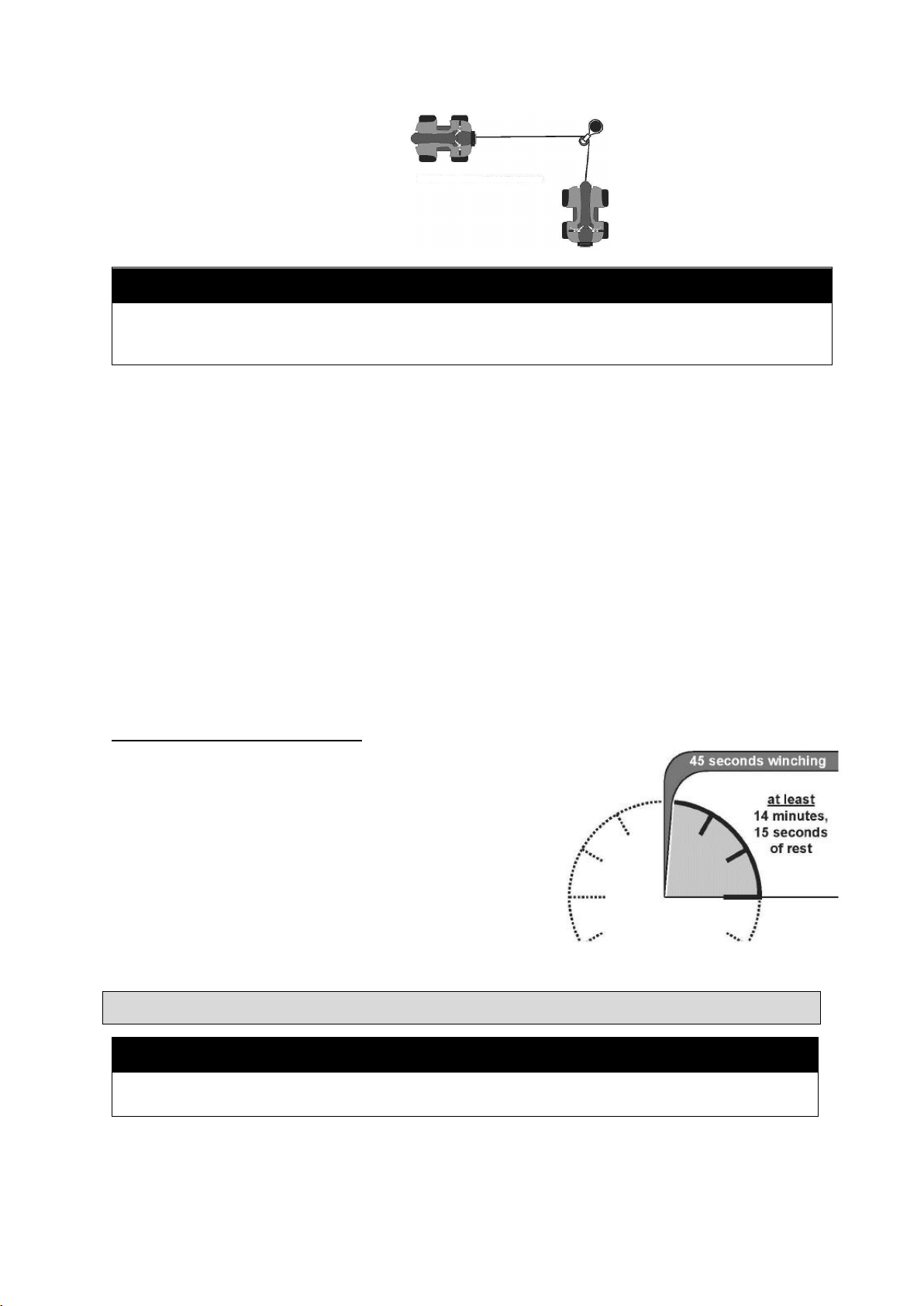

Duty Cycle (Duration of Use)

Avoid damage to the winch by not winching for more

than the prescribed duty cycle time.

The duty cycle defines the amount of time, within a

15-minute period, during which a winch can operate at

its maximum capacity without overheating. For

example, this winch with a 5% duty cycle at its

maximum load must be allowed to rest for at least 14

minutes, 15 seconds after every 45 seconds of

continuous operation. Failure to carefully observe duty

cycle limitations can easily over-stress a winch and

contribute to premature winch failure.

After Each Use

⚠

WARNING

Wipe external surfaces of the winch with a clean cloth.

Page 15 of 20

Maintenance

⚠

WARNING

•To prevent serious injury from accidental operation, disconnect the battery cables

before performing any inspection, maintenance or cleaning procedures

•To prevent serious injury from winch failure, do not use damaged equipment. If an

abnormal noise or vibration occurs, have the problem corrected before further use.

•Lubricate the wire rope occasionally with a light oil.

•The winch‘s internal mechanism is permanently lubricated. Do not open the

housing. However, if the winch is submerged, it should be opened, dried, and re-

lubricated by a qualified technician as soon as possible to prevent corrosion.

Troubleshooting

⚠

WARNING

•Follow all safety precautions whenever diagnosing or servicing the tool.

•Disconnect power supply before service.

Use the table below to troubleshoot problems before contacting service personnel. If the

problem continues after troubleshooting, contact us at info@enthuze.ca for assistance.

Failure Possible Cause Corrective Action

Motor

overheats 1. Incorrect power cords

2. Winch is running too long

1. Use only supplied power cords

2. Allow winch to cool down

periodically

Motor does

not turn

on

1. Remote battery is dead

2. Loose battery cable

connections

3. Vehicle battery needs charging

4. Solenoid is malfunctioning

5. Remote damaged.

6. Defective motor

7. Water has entered motor

8. Internal damage or wear

1. Replace remote battery

2. Tighten nuts on all cable connections

3. Fully charge battery

4. Tap solenoid to loosen

contacts. Apply

12

volts to

coil terminals directly. A

clicking indicates proper

activation

5. Replace remote

6. Check for voltage at armature

port with switch pressed. If

voltage is present, replace

motor

7. Allow to drain and dry. Run

in short bursts without

load until completely dry

8. Have technician service winch

Motor runs

but rope Clutch not engaged

Move the clutch handle to the engaged

position. If problem persists, a qualified

technician needs to check and repair.

Page 16 of 20

drum does

not turn

Motor runs

slowly or

without

normal

power

1 Insufficient current or voltage

2. Loose or corroded

battery cable connections

3. Incorrect power cords

1. Battery weak, recharge it. Run

winch with vehicle motor running

2. Clean, tighten, or replace

3. Use only supplied power cords

Motor runs

in one

direction

only

1. Defective or stuck solenoid

2. Remote damaged

1. Tap solenoid to loosen contacts

Repair or replace solenoid

2. Replace remote

Page 17 of 20

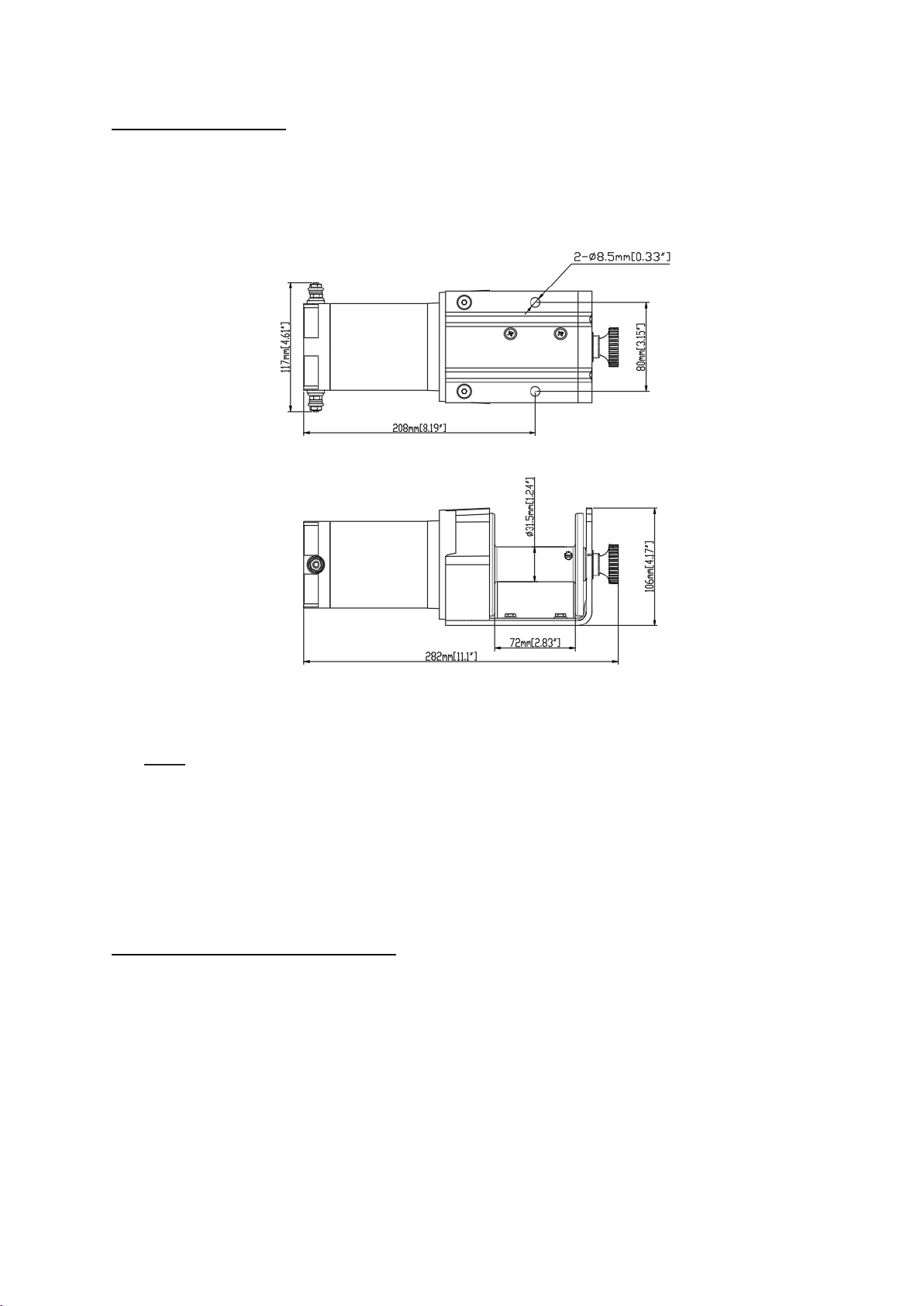

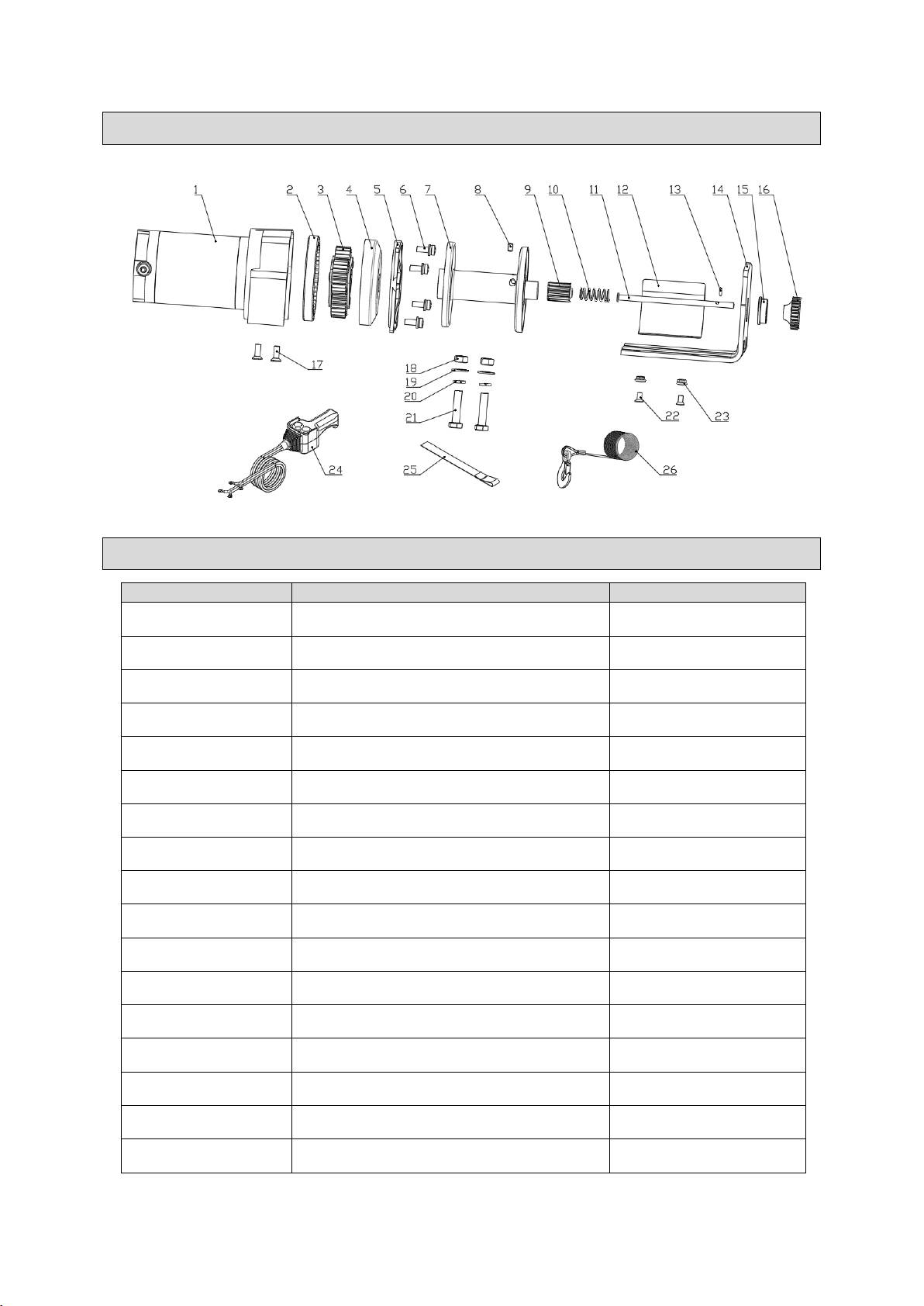

Parts Diagram

Parts List

Part Number

Description

Quantity

1

Motor

1

2

Gear Ring

1

3

Planetary Gear Assembly

1

4

Rotator Gear

1

5

Drum Support Plate

1

6

Pan Head Screw M6x16

4

7

Drum Assembly

1

8

Screw M5x8

1

9

Spline

1

10

Spring

1

11

Clutch Assembly

1

12

Tension Plate

1

13

Pin 2.5 x 12

1

14

Baseplate

1

15

Bushing

1

16

Clutch Knob

1

17

Hex Socket Screw M6x 16

2

Page 18 of 20

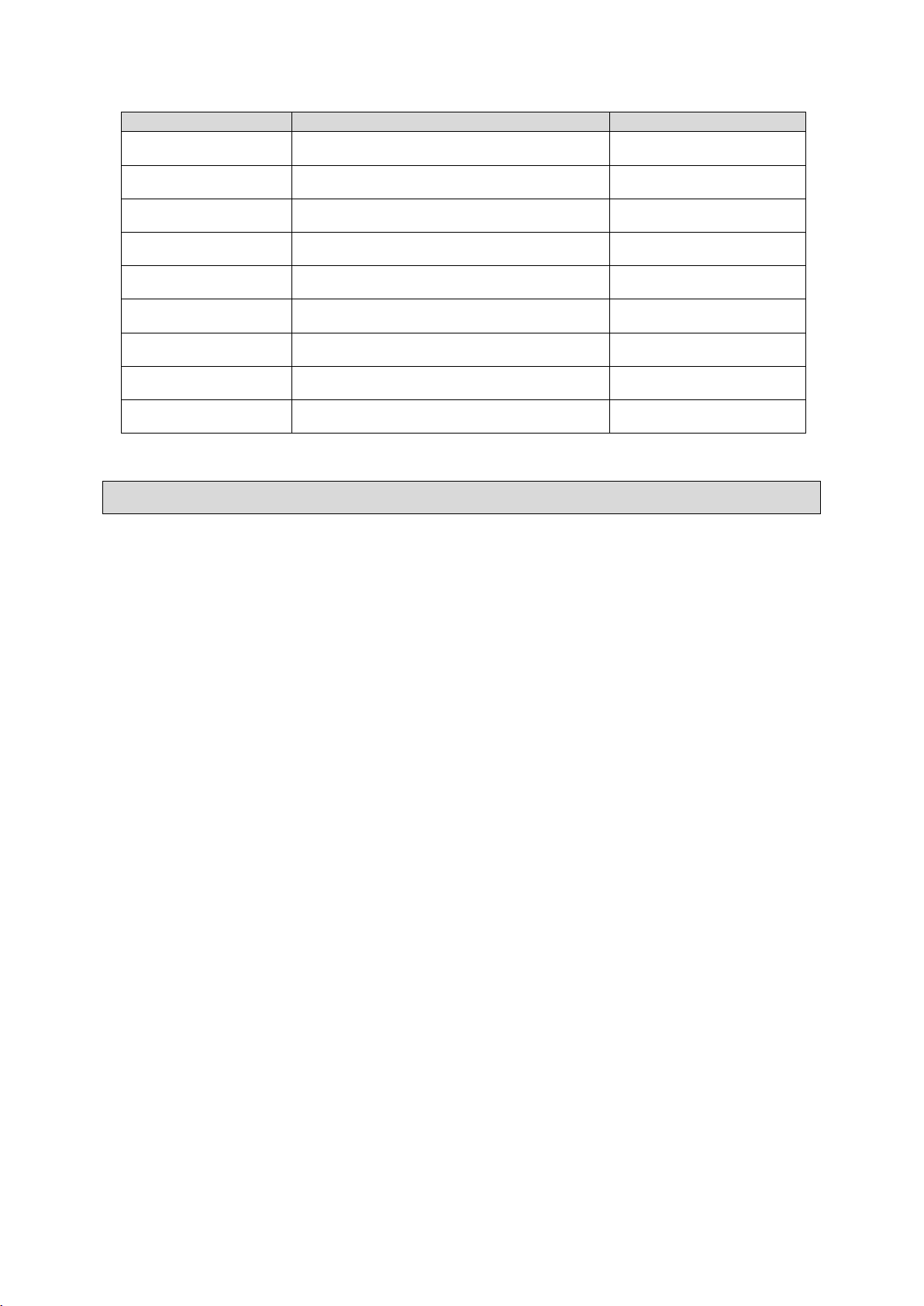

Part Number

Description

Quantity

18

Nut M8

2

19

Flat gasket M8

2

20

Spring washer M8

2

21

Hexagon bolt M8 x 35

2

22

Screw M5 x 12

2

23

Hex Flange Nut M5

2

24

Wired Remote Controller

1

25

Red Strap

1

26

Cable Assembly

1

Replacement Parts

•For replacement parts and technical questions, please call Customer Service at

info@enthuze.ca

•Not all product components are available for replacement. The illustrations provided

are a convenient reference to the location and position of parts in the assembly

sequence.

•When ordering parts, the following information will be required: item description,

item model number, item serial number/item lot date code, and the replacement part

number.

•The distributor reserves the rights to make design changes and improvements to

product lines and manuals without notice.

Page 19 of 20

Limited Warranty

Enthuze Automotive Products (“Us” or “We”) warrants to the original purchaser only

("You'' or “Your”) that the Enthuze product purchased will be free from material defects

in both materials and workmanship, normal wear and tear excepted, for a period of one

year from date of purchase. The foregoing warranty is valid only if the installation and

use of the product is strictly in accordance with product instructions. There are no other

warranties, express or implied, including the warranty of merchantability or fitness for a

particular purpose. If the product does not comply with this limited warranty, Your sole

and exclusive remedy is that We will, at our sole option and within a commercially

reasonable time, either replace the product or product component without charge to You

or refund the purchase price (less shipping). This limited warranty is not transferable.

Limitations on the Warranty

This limited warranty does not cover: (a) normal wear and tear; (b) damage through

abuse, neglect, misuse, or as a result of any accident or in any other manner; (c)

damage from misapplication, overloading, or improper installation; (d) improper

maintenance and repair; and (e) product alteration in any manner by anyone other than

Us, with the sole exception of alterations made pursuant to product instructions and in a

workmanlike manner.

Obligations of Purchaser

You must retain Your product purchase receipt to verify date of purchase and that You

are the original purchaser. To make a warranty claim, contact info@enthuze.ca,

identify the product by make and model number, and follow the claim instructions that

will be provided. The product and the purchase receipt must be provided to Us in order

to process Your warranty claim. Any returned product that is replaced or refunded by Us

becomes our property. You will be responsible for return shipping costs or costs related

to Your return visit to a retail store.

Remedy Limits

Product replacement or a refund of the purchase price is Your sole remedy under this

limited warranty or any other warranty related to the product. We shall not be liable for:

service or labor charges or damage to Your property incurred in removing or replacing

the product; any damages, including, without limitation, damages to tangible personal

property or personal injury, related to Your improper use, installation, or maintenance of

the product or product component; or any indirect, incidental or consequential damages

of any kind for any reason.

Assumption of Risk

You acknowledge and agree that any use of the product for any purpose other than the

specified use(s) stated in the product instructions is at Your own risk.

Table of contents

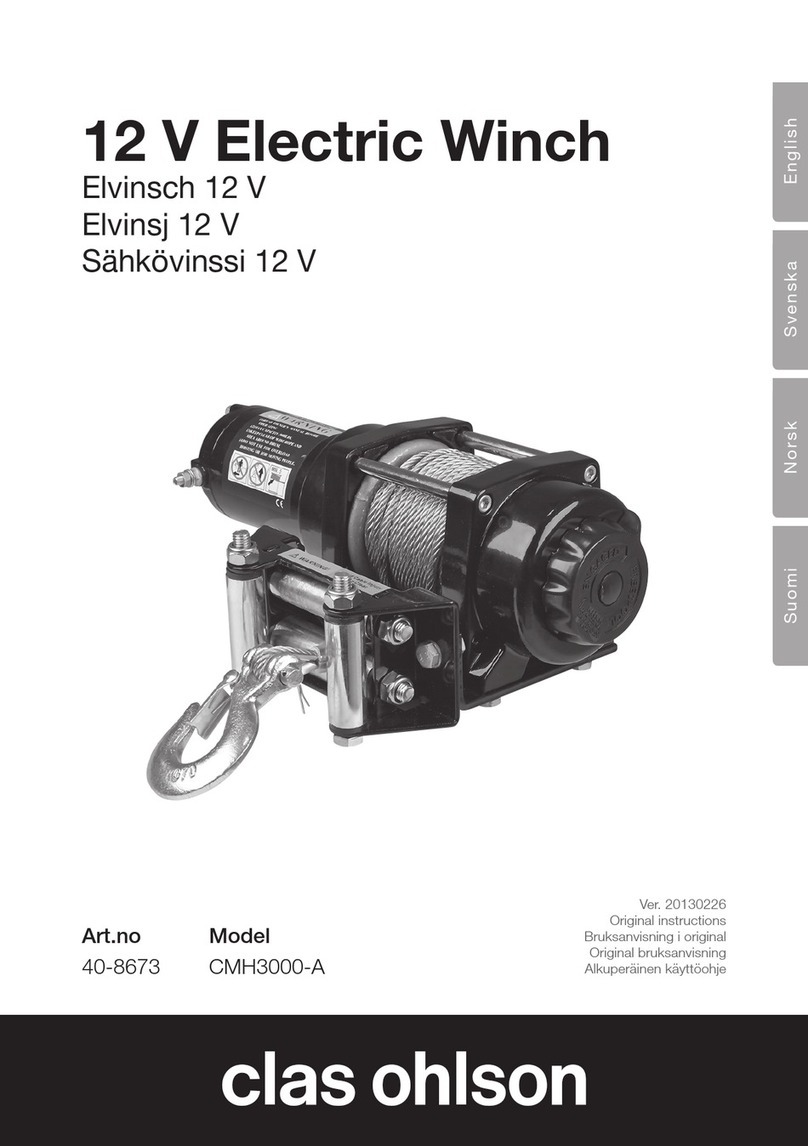

Popular Winch manuals by other brands

Clas Ohlson

Clas Ohlson CMH3000-A Original instructions

Champion Power Equipment

Champion Power Equipment SUP2500 Assembly & operating instructions

Kolpin Outdoors

Kolpin Outdoors POLARIS SPORTSMAN Assembly & owners manual

ROCK

ROCK RP2000 Series manual

haacon

haacon 4190 Operating and maintenance manual

Warrior Winches

Warrior Winches S12000 Assembly & operating instructions