enVerid HLR 100M Technical Document

HLR®200M

Installation, Operation and Maintenance Guide

Version 1.3, 2023 All rights reserved.

enVerid Systems Inc.

21 Southwest Park, Westwood, MA 02090

617-795-4000

HLR 200M Installation and Application Guide Contents

enVerid Systems Inc. Page 2 of 83 Version: 1.3

Contents

Contents ................................................................................................... 2

Acronyms & Abbreviations .................................................................... 4

Safety ........................................................................................................ 5

HLR 200M Module Overview.................................................................. 6

HLR 200M Module Components ...................................................................................6

Component Descriptions ...............................................................................................9

Indoor Air Quality (IAQ) Inlet Sensor (Optional).........................................................10

Air Inlet Sensor Installation ............................................................................................. 12

Installation Procedure ...................................................................................................... 13

Module Dimensions and Weights ...............................................................................18

Maintenance and Service Clearance Requirements .................................................20

Installation............................................................................................. 21

HLR 200M Module Installation ....................................................................................21

Installation Requirements............................................................................................22

Ductwork Connections .................................................................................................24

Duct Insulation..............................................................................................................27

HLR 200M Module Power ............................................................................................27

Accessing the Control Panel ........................................................................................29

Installing Sorbent Cartridges .......................................................................................30

Initial Unit Startup.........................................................................................................36

Pre-Startup Checklist............................................................................ 37

Wiring Diagrams.................................................................................... 38

Controller Connections ........................................................................ 40

HLR Controller Inputs...................................................................................................40

HLR Controller Outputs................................................................................................41

Software Alarms and Limit Setpoints ................................................ 42

Software Alarm Points..................................................................................................42

Operation Limit Setpoints............................................................................................42

HLR 200M Startup & Configuration Guide ......................................... 44

Interfacing with the HLR Controller ............................................................................44

Default Controller GUI Login .......................................................................................45

HLR 200M Installation and Application Guide Contents

enVerid Systems Inc. Page 3 of 83 Version: 1.3

Model Selection.............................................................................................................46

Hardware Configuration ..............................................................................................47

SYLK™ Actuator Settings .................................................................................................. 47

Commissioning Procedure ..........................................................................................48

Setting Controller Time Clock ......................................................................................... 49

Commissioning Test Steps...........................................................................................50

Additional Configurations ............................................................................................51

Reports...........................................................................................................................52

Network Configuration.................................................................................................54

Setting the HLR 200R Controller’s IP address.............................................................. 54

Configuring BACnet IP ...................................................................................................... 55

Configuring BACnet MSTP ............................................................................................... 58

HLR Control Point Configuration.................................................................................... 59

MODBUS Settings .........................................................................................................62

TCP/IP Settings ................................................................................................................... 63

Services................................................................................................... 65

Alarms & Warnings .......................................................................................................66

History Services.............................................................................................................67

Scheduling .....................................................................................................................70

User Management ........................................................................................................74

Control Sequence .................................................................................. 76

Idle Mode.......................................................................................................................76

Scrubbing Mode............................................................................................................76

Regeneration Mode ......................................................................................................77

Operator Override Mode .............................................................................................79

Alarms & Warnings .......................................................................................................80

Safeties ..........................................................................................................................80

Default History Points ..................................................................................................81

Service and Warranty ........................................................................... 82

Scheduled Service.........................................................................................................82

Warranty Summary ......................................................................................................82

Warranty .............................................................................................................................. 82

Coverage.............................................................................................................................. 82

HLR 200M Installation and Application Guide Acronyms & Abbreviations

enVerid Systems Inc. Page 4 of 83 Version: 1.3

Acronyms & Abbreviations

Acronym/Abbreviation

Description

BACnet

Building Automation and Control Networks

BMS

Building Monitoring System

CO

2

Carbon Dioxide

DC

Direct Current

GUI

Graphical User Interface

HLR

HVAC Load Reduction

HVAC

Heating, Ventilation, and Air Conditioning

IAQ

Indoor Air Quality

IOM

Installation/Operation/Maintenance

LOTO

Lockout/Tagout

MERV

Minimum Efficiency Reporting Values

Modbus RTU

Modbus Remote Terminal Unit

MPN

Manufacturer Part Number

MSTP

Master – Slave Token Passing

NDIR sensor

Non-dispersive infra-red technology sensor

NEC

National Electrical Code

NEMA

National Electrical Manufacturers Association

OSHA

Occupational Safety and Health Administration

RH

Relative Humidity

TVOC

Total Volatile Organic Compounds

VOCs

Volatile Organic Compounds

HLR 200M Installation and Application Guide Safety

enVerid Systems Inc. Page 5 of 83 Version: 1.3

Safety

Read this manual in its entirety prior to performing any work on the HLR 200M module.

Follow the recommendations provided in this manual to ensure personal safety, proper

installation and operation, optimal performance, and maximum module life.

WARNING! Personnel untrained to work with electrical equipment may be seriously

injured or killed if allowed to work on the HLR 200M module. Do not attempt

to perform any electrical work without proper personal protection

equipment.

•Do not alter, puncture, or cut into the casing of the HLR module at any location

without prior written approval from enVerid Systems Inc.

•All work performed on the HLR 200M module must comply with local and state

codes, federal regulations, the construction documents, and this manual.

•Only authorized, trained, and certified personnel should perform or supervise any

work on the HLR 200M module.

•Only qualified licensed electricians should perform any electrical work exterior to

the HLR 200M module.

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 6 of 83 Version: 1.3

HLR 200M Module Overview

HLR 200M Module Components

The HLR 200M module will be installed in a vertical orientation as shown.

Each HLR 200M module is a self-contained cabinet pre-assembled with the components

shown below.

Figure 1: HLR 200M Component Location and Description (External View)

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 7 of 83 Version: 1.3

Note: You can swap the function of the outlets between Clean Air and Exhaust Air.

This configuration is changed during the commissioning step and can be

found under Sylk Actuator Settings. This requires the commissioning settings

labeled “additional settings” and actuator addresses to be modified.

A

Clean air outlet damper and actuator*

B

Exhaust air outlet damper and actuator*

C

Main power conduit

D

Field wiring conduit

E

Return air inlet damper and actuator (Adsorption Mode)

F

Control panel

G

Regeneration inlet, damper and actuator (Regeneration Mode)

H

Fan/heater service door

I

Cartridge/internal damper access door

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 8 of 83 Version: 1.3

Figure 2: HLR 200M Component Location and Description (Internal View)

A

Sorbent cartridges

B

Internal damper (Regeneration Mode)

C

Sorbent cartridge bank

D

Heater and flame arrestor

E

Fan

F

Lower access door

G

Upper access door

H

Sorbent cartridge bank cover

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 9 of 83 Version: 1.3

Component Descriptions

•HLR Module Cabinet: The cabinet is made of a single-wall, galvanized steel

construction with powder-coated paint.

•Sorbent Cartridge Bank: The sorbent cartridge bank houses 12 sorbent cartridges that

capture contaminants of concern (VOCs, aldehydes, carbon dioxide, and other

inorganics).

•Heater: System integrated electric resistance heater that raises the internal

temperature of the HLR module to initiate release of captured contaminants during

regeneration mode

•Fans: Integrated Direct Current (DC), brushless fans control airflow through the HLR

200M module during the adsorption and regeneration modes

•Control Panel: Protected electrical component enclosure that houses the controller,

power supply, and communications hardware

•Indoor Air Inlet: Motorized damper assembly that routes indoor air into the HLR

module during adsorption

•Indoor Air Sensor (optional): Measures the incoming air temperature, relative

humidity, total volatile organic compounds (TVOC), and CO2concentration

•Indoor Air Inlet (Regeneration): Motorized damper assembly that routes indoor air

into the HLR module during regeneration mode

•Clean Air Outlet: Motorized damper assembly that routes clean air from the HLR

module to the return airstream

•Exhaust Outlet: Motorized damper assembly that manages the release of

contaminants to the outdoors during regeneration mode

•Internal Damper: Motorized damper assembly used during regeneration mode

•Internal Temperature Sensor: Provides temperature feedback for regeneration

heater control

•Main Power Pathway: External power connection port with 3/4" conduit adapter

•Differential Pressure Sensor: Sensor that measures the pressure drop across the

sorbent cartridge bank to monitor proper airflow

•Actuator: Controls the opening and closing of the damper. Each damper has an

actuator

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 10 of 83 Version: 1.3

Indoor Air Quality (IAQ) Inlet Sensor (Optional)

Figure 3:

The HLR 200M Inlet Sensor (KFTM-LQ-CO2-MODBUS) measures carbon dioxide (CO2), total

volatile organic compounds (TVOC), temperature, and humidity in the return air from areas

served by the HLR module. The Inlet Sensor is a high-quality, maintenance-free, digital

sensor with both automatic and manual calibration capabilities. It measures CO2levels

between 350 ppm and 5000 ppm and reports TVOC with a 0% to 100% range.

Figure 4: Inlet Sensor (Optional)

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 11 of 83 Version: 1.3

Data Points Total volatile organic compounds (TVOC), carbon dioxide

(CO2), temperature, and relative humidity

Temperature (°C)

-30°F to 175°F (-35°C to 80°C)

Humidity (% RH)

0% to 100% RH

Measuring range,

CO

2

350 ppm to 5000 ppm

Measuring

accuracy, CO2

Typically ± 30 ppm ± 3% of measured value

Sensor, CO2Optical NDIR sensor (non-dispersive infra-red technology) with

automatic and manual calibration

Measuring range,

VOC

0% to 100% air quality; referred to calibrating gas; multi-range

switching VOC sensitivity low, medium, high

Measuring

accuracy, VOC

±20% of final value (referred to calibrating gas)

Sensor, VOC

VOC sensor (metal oxide) with automatic calibration

Response time

< 2 minutes

Service life

> 60 months (under normal load conditions)

Housing

dimensions

5.0” x 3.5” x 2.0” (126 mm x 90 mm x 50 mm)

Long-term

stability

< 2 % in 15 years

Protection class

III (according to EN 60 730)

Protection type

IP 65 (according to EN 60 529) - housing only

Standards CE conformity, EMC according to EN 61 326, EMC Directive

2014/30/EU

For full specifications, visit:AERASGARD® KFTM-LQ-CO2-Modbus Technical Specification Sheet

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 12 of 83 Version: 1.3

Air Inlet Sensor Installation

Tools Required

1 Philips screwdriver

2 Small flathead screwdriver

3 Wire strippers

Components Required

Item Quantity

1 KCO2-Modbus Sensor (Air quality

sensor)

MPN: KFTM-LQ-CO2-MODBUS

1

2 Industrial USB to RS485

Converter

MPN: B081MB6PN2

1

3 Allied Wire & Cable 4 Conductor

Wire (22AWG)

MPN: 8126

10 ft

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 13 of 83 Version: 1.3

Installation Procedure

Note: If the installation is using BACnet MS/T: the BACnet connection will occupy

the RS485 input, typically used by the Modbus IAQ sensor. The Indoor Air

Quality Sensor will be integrated directly to the BMS via Modbus. Mount the

sensor to the return air duct of the applicable zone and configure the

settings using the documentation provided from the sensor manufacturer.

1. Run the 4-conductor wire from the sensor to the electronics box through the field

wire conduit (top right of HLR when looking at the electronics box).

Note: If a cable longer than the supplied 10 foot length is required, ensure RS-485

wiring standards and applicable local codes are followed when selecting

and installing cable.

2. Strip back 12 inches of the gray jacket of the wire inside electronics box.

3. Twist the green and white wires together.

4. Connect the green and white wires to the USB-to-RS485 converter.

5. Strip the ends of the green and white wires.

6. Connect the white wire to B on the screw terminal. Connect the green wire to A on

the screw terminal.

Figure 5:

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 14 of 83 Version: 1.3

7. Plug the USB-to-RS485 converter into CIPer30 above pin 19 on the CIPer30.

Figure 6:

8. Connect the red and black wires to power distribution blocks in positions labeled

Sensor + and Sensor –.

Figure 7:

Note: The red and black terminal blocks function as a 24VDC bus. Any open

terminals (Red+, Black-) on this bus will provide 24VDC power to the sensor.

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 15 of 83 Version: 1.3

9. Run the cable through a grommet into the sensor housing.

Figure 8:

10. Remove the four screws securing the face of the sensor body and remove the face.

11. Strip the wires and connect them to the screw terminals inside the sensor body as

follows:

•White: B

•Green: A

•Black: GND

•Red: V+

Figure 9:

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 16 of 83 Version: 1.3

12. Reinstall the face of the enclosure and secure using the four screws.

Confirm that the Modbus address and settings are correct as shown in the

following graphic. These are not the factory default settings. For details, see

MODBUS Settings.

Figure 10:

13. Confirm that the DIP switches inside the sensor match the settings in the CIPer30.

For additional details, see the Modbus Settings section. The default settings in the

HLR software are as shown in the following graphic.

Figure 11:

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 17 of 83 Version: 1.3

14. If everything is configured correctly, you should see the sensor information (like that

shown in the following graphic) displayed on the home screen of the HLR CIPer30

software.

Figure 12:

15. Install the sensor to the return air duct of the zone being served by the HLR, or to

the return air inlet duct of the HLR. Use sheet metal screws to mount the sensor.

The sensor should be installed so that the probe is inside the air stream with the

flow direction illustration on the sensor cover matching the return air flow direction.

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 18 of 83 Version: 1.3

Module Dimensions and Weights

Figure 13: 200M Module Dimensions

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 19 of 83 Version: 1.3

Table 1: Dimensions and Weights

HLR 200M Dimensions (Including Dampers and Door Handles)

Height 72” / 1,828mm

Width

48” / 1,219mm

Depth 27” / 686mm

Weights lbs/kgs

Module Shipping Weight

505 lb / 229 kg

Filter Shipping Weight 200 lb / 91 kg

Installation (Module Only)

393 lb / 178 kg

Operating (With Filters) 593 lb / 269 kg

HLR 200M Installation and Application Guide HLR 200M Module Overview

enVerid Systems Inc. Page 20 of 83 Version: 1.3

Maintenance and Service Clearance Requirements

The area around the HLR 200M module should be kept clear for maintenance and service.

The following diagrams show the clearances to be maintained for proper operation and

installation, as well as the clearances required for servicing the module.

CAUTION: Keep the area in front of the control panel and electrical access panel clear

of obstructions as required by the local electrical code.

Figure 14: HLR 200M Minimum Clearances

Other manuals for HLR 100M

1

Table of contents

Popular Control Unit manuals by other brands

DMX4ALL

DMX4ALL PixxRangeExtender 12V manual

Moxa Technologies

Moxa Technologies MiiNePort E Series Quick installation guide

Smartgen

Smartgen HGM6100N-RM user manual

Tranquil Ease

Tranquil Ease HC-2H operating instructions

Integra

Integra 201-33 instruction sheet

Bürkert

Bürkert Type 2000 operating instructions

Deif

Deif Multi-line 2 General guidelines for commissioning

Sony

Sony HDCU-950 Operation manual

SMD

SMD 4.2DIN manual

ALCO CONTROLS

ALCO CONTROLS 110RB Series operating instructions

VAT

VAT 590 Series Installation, operating, & maintenance instructions

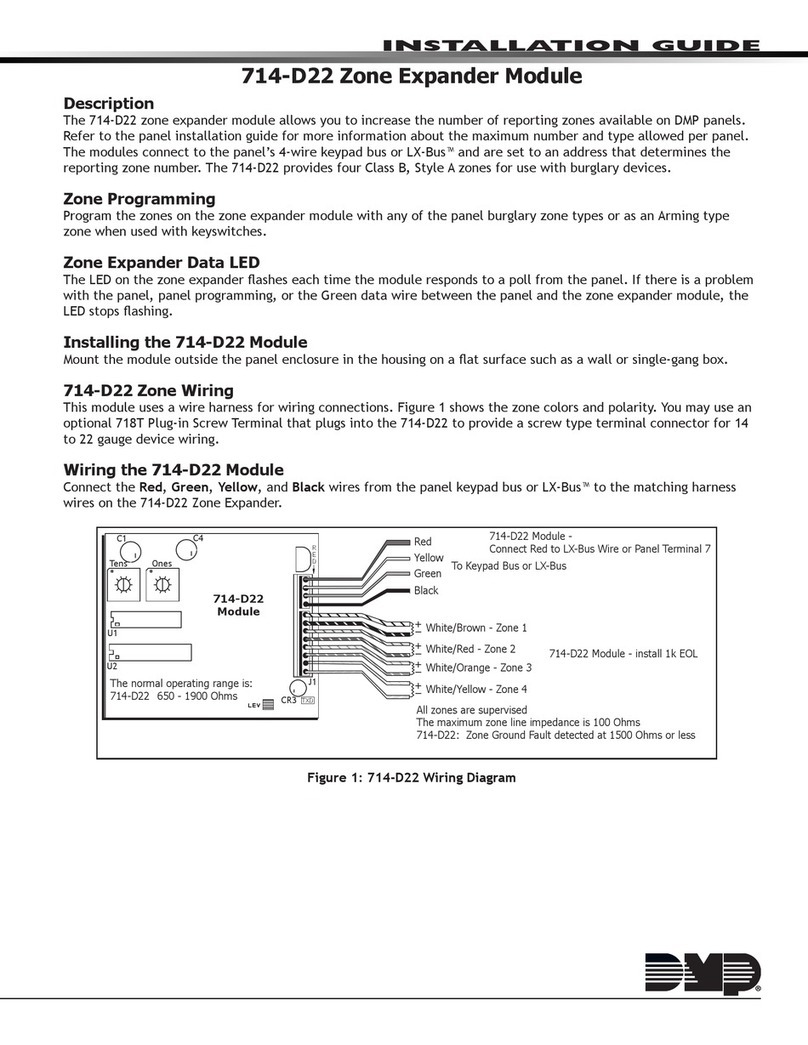

DMP Electronics

DMP Electronics 714-D22 installation guide