Envirco CC1-10 User manual

www.envirco.com

Operation Manual

Control Console Operation Manual Rev 0400809.doc

ENVIRCO

Control Console

Models: CC1-10 (Part No. 63971-001)

CC1-25 (Part No. 63971-002)

CC1-50 (Part No. 63971-003)

ENVIRCO Control Console

Operation Manual

Page 2

TABLE OF CONTENTS

TITLE PAGE

1.0. SAFETY PRECAUTIONS............................................................................................................................ 3

2.0. OVERVIEW .................................................................................................................................................. 4

2.1. CONTROL CONSOLE MODELS............................................................................................................. 4

2.2. MAIN FUNCTIONS............................................................................................................................... 4

2.3. FEATURES......................................................................................................................................... 4

2.4. BENEFITS .......................................................................................................................................... 4

3.0. SPECIFICATIONS........................................................................................................................................ 5

3.1. ELECTRICAL SPECIFICATIONS............................................................................................................. 5

3.2. ELEVATION AND DIMENSIONS ............................................................................................................. 5

4.0. INSTALLATION ........................................................................................................................................... 6

4.1. NETWORK WIRING ............................................................................................................................. 6

4.2. CONTROL CONSOLE INSTALLATION TEMPLATE..................................................................................... 7

5.0. CONTROL CONSOLE OPERATION........................................................................................................... 8

5.1. FRONT PANEL FEATURES................................................................................................................... 8

5.2. POWER ON........................................................................................................................................ 8

5.3. STANDBY MONITOR MODE ................................................................................................................. 9

5.4. USER MONITOR MODE ..................................................................................................................... 10

5.5. USER ADJUST MODE........................................................................................................................ 10

5.6. OPTION MENU ................................................................................................................................. 11

5.7. ACCESS LEVELS .............................................................................................................................. 12

6.0. LIMITED WARRANTY ............................................................................................................................... 13

ENVIRCO Control Console

Operation Manual

Page 3

1.0. Safety Precautions

Please read and save the following important safety information regarding the

VOR-12 Surgery Isolator prior to unit operation.

To reduce the risk of fire, electrical shock or injury to persons, observe the following:

• Installation work and electrical wiring for the Control Console and other clean system

equipment must be done by a qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

• When cutting or drilling into a wall or ceiling, do not damage electrical wiring or other hidden

utilities.

• Service to the Control Console cannot be performed in the field. Returned equipment still

under warranty to Envirco.

• Before trying to remove the Control Console from the clean system it controls, switch power

off for the entire clean system at service panel and lock service panel to prevent power from

being switched on accidentally, and follow proper procedures as necessary.

• Use this unit only in the manner intended by the manufacturer. If you have questions,

please contact:

ENVIRCO CORPORATION FEDDERS INTERNATIONAL

Envirco Office Headquarters

5601 Balloon Fiesta Parkway N.E. No. 268 Xi Zang Road (M)

Albuquerque, New Mexico 87113 Haungpu District, Shanghai 200001

U.S.A. PRC

Tel : (505) 345-3561 Tel : (86) 512 6258 7180

Fax : (505) 345-8875 Fax : (86) 512 6258 0035

TRION LTD. FEDDERS INTERNATIONAL, INC.

The Cavendish Centre DP Computers Building

Winnall Close 128 Joo Seng Road #05-01

Winchester, Hampshire, SO23 0LB, UK Singapore 368356

Tel : 44 1962 840465 Tel : 65 286 0995

Fax : 44 1962 828619 Fax : 65 286 0859

Email: info@trion.co.uk Email: infoAsia@envirco.com

ENVIRCO Control Console

Operation Manual

Page 4

2.0. Overview

The Envirco Control Console combines intelligent speed control with industry standard

MODBUS®networking. The versatile design allows control of an array of MAC 10 XL installed

Envirco Phase Controllers or “Smart” MAC 10 units linked to an Envirco DC Controller.

The console combines a user interface with MODBUS master capability so no additional

networking components are needed and no MODBUS knowledge is necessary to install a

network. Once the console has automatically scanned the network, only a few simple

configuration selections are required.

2.1. Control Console Models

Envirco CC1-Series Control Console

Model No. Addresses No. of MAC 10 XL FFUs No. of “Smart” MAC 10 Units

CC1-10 10 up to 80 up to 10

CC1-25 25 up to 200 up to 25

CC1-50 50 up to 400 up to 50

2.2. Main Functions

• Individual address speed adjustment

• Global address speed adjustment

• Global address set-back speed adjustment

2.3. Features

• 7-Seginent LED Control Console Display

• Dual rotary dials for easy option selection and system adjustments

• “Set Speed Memory” resets to last setting under power loss

• Global standby feature

• Pre-programmed user access levels and pass-codes to prevent tampering or

accidental system changes

2.4. Benefits

• Quick and easy system air balancing of Envirco Fan Filter Units

• Global standby feature for energy savings

• Simple set-up and wall-mount Control Console installation

• No installer configuration required

ENVIRCO Control Console

Operation Manual

3.0. Specifications

3.1. Electrical Specifications

Supply Voltage: 6-12 Vdc

Typical Supply Current: 90 mA

Network Transceivers: 2-wire, 1/8 unit load type

Operating Temperature: 0-40° Celsius (32-104°F)

DC Power Connector: 2.1 mm DC power jack

MODBUS network: RJ45 socket

3.2. Elevation and Dimensions

Page 5

ENVIRCO Control Console

Operation Manual

Page 6

4.0. Installation

The Envirco Control Systems are engineered for easy installation. However testing either

before permanent installation or as the system is installed is strongly recommended.

The Control Console can be wall installed in the cleanroom or at a remote location, however,

the maximum recommended distance from the beginning to the end of the daisy chain should

not exceed 800 linear feet.

4.1. Network Wiring

Note: Cabling shall be provided and installed by others. Network cable requirements

should be specified based on:

A network is constructed by simply daisy-chaining MAC 10 XL installed Envirco Phase

Controllers or “Smart” MAC 10 installed DC Controllers from the Control Console.

Specific network wiring information can be found in the Envirco MAC 10 XL Control

System or MAC 10 DC Control System operation manuals.

Network cable requirements should be specified based on:

• Distance between nodes

• Total network length

• Noisy electrical environment

• Environmental conditions

• Mechanical issues

Once the Control Console has been connected to at least one phase controlled MAC 10

XL or “Smart” MAC 10 installed DC Controller, power can be applied. The Control

Console will automatically scan the network.

Each Phase Controller or DC Controlled “Smart” MAC 10 FFU should be given a unique

address within the Control Console’s available address range (determined by model

number.) The addresses do not need to be contiguous, but contiguous addressing will

make operator functions easier.

ENVIRCO Control Console

Operation Manual

4.2. Control Console Installation Template

Page 7

ENVIRCO Control Console

Operation Manual

5.0. Control Console Operation

5.1. Front Panel Features

• Rotate to Select Unit or

Option Menu.

•

Push to enter Option Menu

Selected Address

Status of Selected Unit

Speed of Selected Unit • Rotate to Adjust Speed or

O

p

tion Settin

g

s

5.2. Power On

At power-on, the Control Console displays a series of parameters including model

number on the three LED displays for about one second. The Control Console then

cycles all segments in display to confirm that the display is functional. Once display

cycling is complete, the Control Console then scans all addresses valid for that model

(10, 25 or 50.)

If no MAC 10 XL installed Envirco Phase Controllers or “Smart” MAC 10 units linked to

an Envirco DC Controller is detected, the Control Console repeats the scan sequence

until at least one unit is found.

Scan Address

Number of Units found No Effect

No Effect

Figure 1: Front Panel Functions During Power-On

Page 8

ENVIRCO Control Console

Operation Manual

5.3. Standby Monitor Mode

The Control Console immediately enters standby monitor mode at the conclusion of

power-on scanning. The Control Console remains in standby monitor mode until one of

the two dials are rotated. If the dials are not adjusted for a period of 30 seconds, the

Control Console will revert to standby monitor mode.

In standby monitor mode, the Control Console repeatedly polls all units detected during

power-on scanning. Unused motor addresses are skipped, but the highest address

must be within range of the Control Console model settings (10, 25 or 50.)

Address

Page 9

Figure 2: Standby Monitor Mode Front Panel Functions

The Control Console polls each Phase Controller or “Smart” MAC 10 FFU while

displaying status information on each unit for about 2 seconds. The following

information is displayed:

A. MODBUS Address of unit monitored (Top LED)

B. Pressure Switch Status

• “PG” for Pressure Good

• “PF” for Pressure Fault

• If Pressure Switches are not enabled, the display will be blank

• If the Control Console is in Low Speed Mode, then “LO” will be displayed instead

of the pressure switch status

C. Set Speed or Blank Display (Center LED)

• Displays Set speed in percent

• This value is read from MODBUS register 2.

Note: If no response is received, the middle and lower LED shall display “—“

Set Speed

Any rotation to exit standby

monitor mode

Pressure Switch Status

ENVIRCO Control Console

Operation Manual

5.4. User Monitor Mode

If any dial activity is detected, the Control Console leaves standby monitor mode and

enters user monitor mode. In this mode, any unit can be selected by rotating the Select

dial.

Figure 3: User Monitor Mode Front Panel Functions

Note: If the Select dial is moved past the valid address range, the select display shows

"OP". Pushing the Select dial enters the Option Menu.

Page 10

5.5. User Adjust Mode

This mode is identical to User Monitor mode, except that the set speed of any motor can

be adjusted.

Address

Set Speed No Effect

Rotate to select address.

Press to lock selection.

Pressure Switch Status

Address

Set Speed 2. Adjust Set Speed

Up or Down.

1. Rotate to select address.

Pressure Switch Status

Figure 4: User Adjust Mode Front Panel Functions

If the Select dial is moved below the valid address range, the select display shows "OP".

The current access level is also displayed. Pushing the Select dial enters the Option

Menu.

The Control Console writes the set speed as a percentage of the maximum speed (0-

99%). If power fails, each Digital Speed Controller will run at the most recent speed

selected.

ENVIRCO Control Console

Operation Manual

5.6. Option Menu

The option menu allows a user to perform the following functions:

A. Change the access level by entering pass-codes (A1…A3)

B. Select High Speed (normal) or Low Speed (global set back)

C. Adjust the Low Speed set back

D. Select whether pressure switches are present or not

E. Set the speed for every node simultaneously

1. Rotate Select dial to display

“OP” on top LED.

2. Press Select dial to enter option

menu.

1. Rotate Select dial to display

desired option in the center LED.

2. Push Select dial again to exit

option menu.

Figure 5: Option Menu Navigation

5.6.1. Access Levels

• Use the Select Dial to display the new access level requested.

• Press the Select Dial

• If the new level has fewer privileges, then no pass-code is needed. The

bottom LED will scroll through its seven LED segments to confirm the change

• If a pass-code is needed, enter the two-number code on the Adjust Dial.

Press the Adjust Dial to lock in the code.

• If the pass-code is correct, the bottom LED will scroll through its seven LED

segments

5.6.2. Selecting High or Low Speed (HL)

• This action requires access levels A1-A3

• Rotate the Select dial to display “HL” in the center LED and press Select dial

to lock in this option.

• Rotate the Adjust dial to select "HI" or "'LO"

• If “HI” is selected the units shall run at their individually set speeds

• If “LO” is selected, each unit will be set back by a global amount (see

adjusting Low Speed below)

• If Low Speed is selected, this setting will remain in effect until High Speed is

selected or the power is cycled.

Page 11

ENVIRCO Control Console

Operation Manual

Page 12

5.6.3. Adjusting Low Speed Set Back (LS)

• This action requires access levels A1-A2

• Use the Select dial to display the “LS” menu option

• Rotate the Adjust dial to vary the set-back percentage (0-99%)

5.6.4. Selecting Pressure Switch (Pr)

• The Pressure switch option should be enabled if Phase Controlled units have

a pressure switch installed

• Rotate the Adjust dial to select:

A. “NC”: Normally closed (the switch opens if there is a pressure fault.)

B. “NO”: Normally open (the switch closes if there is a pressure fault.)

C. “__”: No pressure switch

5.6.5. Global Speed Set (All)

• This is available only when operating at Access Level 1.

• Rotate the Adjust dial to set the desired speed.

• Press the Adjust dial to set every node to that speed

5.7. Access Levels

To restrict access to functions other than monitoring, the Control Console implements

access levels. Level A1 carries the greatest privileges.

Access Level Pass-Code Description

A1 12 88 Operator can adjust configuration settings.

A2 25 75 Operator can use all functions for monitoring and control.

A3 49 51 Operator can monitor and adjust High/Low settings.

A4 N/A Operator can only monitor status of the network.

Table 1: Access Levels and Codes

ENVIRCO Control Console

Operation Manual

Page 13

6.0. Limited Warranty

Envirco Corporation (“Envirco”) warrants the equipment will be free of defects in materials and

workmanship under normal use for a period of one (1) year. The HEPA filter shall only be

warranted against loading for a period of one (1) year when operated in clean room conditions.

Envirco’s sole obligation under this warranty is to repair or replace any parts of the equipment

which are defective for a period of one (1) year from the invoice date, provided that the repair or

replacement is actually performed within the one (1) year period from the invoice date. The

buyer agrees to assume any incidental expenses including, but not limited to, the cost of

transporting the defective equipment to Envirco’s repair facility. The buyer’s sole remedy under

this limited warranty is the repair or replacement of any defective part of the equipment.

ENVIRCO DISCLAIMS ANY IMPLIED WARRANTIES INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT

SHALL ENVIRCO BE LIABLE FOR PUNITIVE, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THIS SALE, INCLUDING, BUT NOT LIMITED TO DAMAGE

TO A PERSONS OR PROPERTY, LOSS OF USE, LOSS OF TIME, INCONVENIENCE,

EQUIPMENT RENTAL, LOSS OF EARNINGS OR PROFIT OR ANY OTHER COMMERCIAL

LOSS. THIS WARRANTY EXCLUDES CERTAIN EXPENDABLE ITEMS SUCH AS

PREFILTERS, ETC. ENVIRCO EXPRESSLY DISCLAIMS AND EXCLUDES FROM THE

WARRANTY ANY RESPONSIBILITY FOR EQUIPMENT FAILURES AND/OR DEFECTS

ATTRIBUTABLE TO IMPROPER MAINTENANCE, ABUSE, ACCIDENT OR MODIFICATION

OF EQUIPMENT (SUCH AS APPLICATION OF AN ADJUSTABLE FREQUENCY DRIVE).

5601 Balloon Fiesta Parkway N.E. •Albuquerque •New Mexico •87113 •USA

505.345.3561 •800.545.6598 •Fax: 505.345.8875

www.envirco.com

This manual suits for next models

2

Table of contents

Other Envirco Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson 91 Installation and maintenance instructions

Coolmay

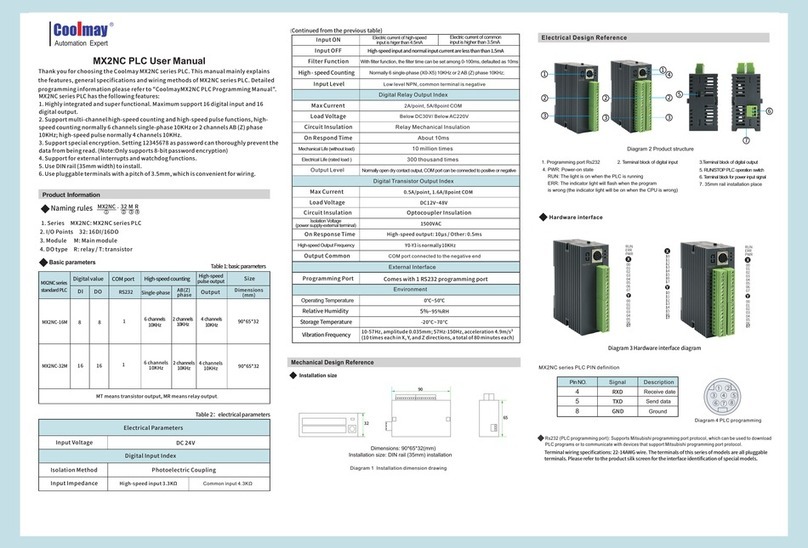

Coolmay MX2NC PLC user manual

Dieffematic

Dieffematic PROXMINI quick start guide

BERMAD

BERMAD C80 Installation, operation & maintenance manual

Funkwerk

Funkwerk TRT800RT Operation and installation

Avalue Technology

Avalue Technology EBM-BDW user manual