Envirco MAC 10 e3 Manual

02/05/03

*** READ AND SAVE THESE INSTRUCTIONS ***

MAC 10âe3FAN FILTER MODULE

INSTALLATION AND SERVICE MANUAL

STANDARD and RSR MODELS

Mac 10âis a registered Trademark of the

Envirco Corporation, Albuquerque, New Mexico, U.S.A.

US Patent 4,560,395 Other patents issued and pending in foreign countries

MAC 10 e3SERVICE MANUAL

PAGE 1 02/05/03

READ AND SAVE THESE INSTRUCTIONS

WARNING !

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING :

A. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

C. If this unit is to be installed over a tub or shower, it must be marked as appropriate for the application.

D. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer :

ENVIRCO CORPORATION

5601 Balloon Fiesta Parkway NE

Albuquerque, New Mexico 87113, U.S.A.

Tel : (800) 545-6598

Fax : (505) 345-8875

ENVIRCO CORPORATION

Eastern Regional Office

1185 Mt. Aetna Rd.

Hagerstown, Maryland 21740, U.S.A.

Tel : (800) 645-1610

Fax : (301) 714-4784

E. Before servicing or cleaning unit, switch power off at service panel and lock service panel to prevent power from

being switched on accidentally.

MAC 10 e3SERVICE MANUAL

PAGE 2 02/05/03

Table of Contents

Title Page

I. INSTALLATION 3

II. SERVICE : CLEANING THE MAC 10 e3PREFILTER 4

III. SERVICE : REMOVAL AND REPLACEMENT OF THE HEPA FILTER5

IV. SERVICE : REMOVAL AND REPLACEMENT OF THE ROOM SIDE

REPLACEABLE FILTER (RSR) 6

V. SERVICE : REMOVAL AND INSTALLATION OF THE MOTOR 7

VI. SERVICE : REMOVAL AND INSTALLATION OF THE OPTIONAL

FLUORESCENT TUBES 9

VII. ON/OFF SWITCH-SPEED/AIRFLOW ADJUSTMENTS 10

VIII. TROUBLE SHOOTING 12

IX. MAC 10 e3WIRING DIAGRAMS 13

X. MAC 10 e3REPLACEMENT PARTS LIST 15

XI. WARRANTY 16

XII. TESTING 17

MAC 10 e3SERVICE MANUAL

PAGE 3 02/05/03

I. INSTALLATION

Note : The MAC 10 e3Filter Unit is completely assembled at the factory with the exception of the optional

¼”(0.64 cm)-20 eyebolts, which can be used when hanging the unit from an overhead structure.

Step 1. Carefully remove the unit from the shipping carton and inspect for any damage that may have occurred during

transportation.(see Figure 1)

Step 2. Wipe down plastic bag and move unit into clean room.

Step 3. If using rigidly supported grid (usually 2” or wider), raise unit through ceiling and lower onto the gasketed grid.

If using a flexible grid (typically supported with wires) the unit must be secured to an overhead structure with

eyebolts, s-hooks and chain. A roll of high density gasket has been provided for use with ungasketed grids.

Step 4. Have an electrician wire the unit to the appropriate voltage (115V, 220V, 277V AC), according to the wiring

diagram in section IX and local electric codes. To install permanent power, remove the two screws that hold

the 2x4 j-box cover in place. Secure the electrical cable to the j- box. Connect L1 (black conductor) to the

black lead located in the j-box. Connect L2 (white conductor) to the common. Connect the ground (green

conductor) to the ground screw provided in the j-box, use an uninsulated lug for the connection. When the

permanent connection has been made, replace the j-box cover and reinstall the two screws. If optional power

cord was purchased, plug unit into a grounded receptacle.

Figure 1

MAC 10 e3SERVICE MANUAL

PAGE 4 02/05/03

II. SERVICE : Changing the MAC 10 e3Prefilter

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

Note : To keep the filter in top operating condition, replacing the pleated prefilter is

recommended every six months.

Step 1. To gain access to the prefilter, remove the ceiling panel next to the unit, if applicable.

Step 2. Lift and remove the prefilter off the prefilter frame.(see Figure 2)

Step 3. Reassemble by reversing the above steps.

Figure 2

MAC 10 e3SERVICE MANUAL

PAGE 5 02/05/03

III. SERVICE : Removal and Replacement of the HEPA/ULPA Filter (Standard Unit)

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

Step 1. Remove unit from ceiling.

Step 2. Remove the screws holding the HEPA/ULPA filter to the lid assembly.

Step 3. Lift the lid assembly off the HEPA/ULPA filter (see Figure 3). Discard the used filter as per requirements of the

applicable regulations.

Note : Before replacing with a new HEPA/ULPA filter, carefully inspect the new filter for any visible damage. Also

inspect the gasket in the “tee” bar to insure a tight seal. Replace as necessary.

Step 4. Replace with the new HEPA/ULPA filter and assemble by reversing the above steps.

Figure 3

MAC 10 e3SERVICE MANUAL

PAGE 6 02/05/03

IV. SERVICE : Removal and Installation of the Room Side Replaceable Filter

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

Step 1. Remove the diffuser screen by shifting it to one side and lowering it out of the housing.

Step 2. While supporting the filter, remove the six screws and clips and lower the filter.(see Figure 4)

Note : Before replacing with a new filter, carefully inspect the new filter for any visible damage.

Step 3. Replace with the new HEPA filter and assemble by reversing the above steps.

Note : Tighten filter clip bolts as necessary to insure no bypass leakage. DO NOT over tighten.

Figure 4

MAC 10 e3SERVICE MANUAL

PAGE 7 02/05/03

V. SERVICE : Removal and Installation of the Motor

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

WARNING !

Electrical service should be performed by licensed electricians or authorized ENVIRCO service technicians.

Step 1. To gain access to the motor/blower, remove the ceiling panel next to the unit, if applicable.

Step 2. Remove the prefilter off the prefilter frame.(see Figure 5)

Step 3. Remove the four screws from the electrical cover and tilt the electrical cover open..

Figure 5

MAC 10 e3SERVICE MANUAL

PAGE 8 02/05/03

Step 4. Make note of all wire locations for reinstallation later.

Step 5. Disconnect the brown, black and white wires from the capacitor.

Step 6. Disconnect the motor wiring from the speed control and the green/ yellow ground wire from the ground screw.

Step 7. Remove the six screws to free the motor/blower assembly from the lid assembly.(see Figure 6)

Step 8. Using a 10mm socket remove the four M6 bolts which hold the bottom motor plate from the standoffs. Again

using a 10mm socket remove the four M6 bolts from the motor.

Step 9. Replace with the new motor/blower and reassemble by reversing the above steps. Set the spacing between the

venturi ring and the blower wheel at 0.06”(0.15 cm) clearance. When reinstalling the M6 bolts through the

grommets into the bottom of the motor tighten the bolts using the lowest torque setting. Visually inspect the

blower wheel to assure the wheel is parallel to the bottom motor plate. Adjust the motor bolts to even the

wheel if necessary.

Figure 6

MAC 10 e3SERVICE MANUAL

PAGE 9 02/05/03

VI. SERVICE : Removal and Installation of the Optional Fluorescent Lamps

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

Note : Accessibility to the fluorescent tubes is gained from the room side.

Step 1. To remove the fluorescent tubes, pull down on the two clips and swing down the light diffuser.

Step 2. Carefully remove the fluorescent tubes out of the fixture.(see Figure 7)

Step 3. To install the new fluorescent tubes, reverse the above steps.

Figure 7

MAC 10 e3SERVICE MANUAL

PAGE 10 02/05/03

VII. ON/OFF Switch - Speed Control/Airflow Adjustment

All MAC 10 e3units are equipped with a two-position rocker switch and a speed control switch, which are located on the

side of the electrical box on top of the unit.

Electrical power to the fan may be disconnected by moving the toggle switch to the “O” position.

WARNING !

Disconnect the unit from the electrical power source before attempting any service.

Units are furnished speed controls which enable adjustment of airflow at any setting within the

recommended performance range. The speed control knob is located on side of the electrical box.

For 115v and 220v Units

Airflow/speed is adjusted by rotating the knob (see Figure 8):

Clockwise àLowers the speed

Counter-Clockwise àIncreases the speed

Fully rotating the speed control knob to the left or counter-clockwise will turn the unit off.

Note : When turning the unit “ON” from the “OFF” position of the speed control, the fan is at the highest speed.

Turning the speed control knob clockwise will lower the airflow.

For 277v Units

Airflow/speed is adjusted by rotating the knob:

Clockwise àIncreases the speed

Counter-Clockwise àLowers the speed

Fully rotating the speed control knob to the left or counter-clockwise will turn the unit off.

Note : When turning the unit “ON” from the “OFF” position of the speed control, the fan is at the lowest speed. Turning

the speed control knob clockwise will increase airflow.

Figure 8

(115v and 220v only)

MAC 10 e3SERVICE MANUAL

PAGE 11 02/05/03

VIII. Trouble Shooting :

Low Air Velocity

Step 1. Verify proper rotation, motor/blower rotates clockwise (CW). If unit is rotating counter clockwise (CCW),

verify that the capacitor has the black and wire wires on the same connector and the brown is on it’s own

connector. If the unit continues to rotate contact the factory.

Step 2. Check prefilter media; replace as necessary.

Step 3. Adjust variable speed control for higher blower output.

Step 4. Check power supply for proper voltage, amperage and distribution frequency.

Step 5. Replace HEPA/ULPA filter if the air velocity remains low.

High Air Velocity

Step 1. Adjust variable speed control for lower blower output.

Non-Laminar Flow and/or Excessive Contamination

Step 1. Insure that no large obstructions are upstream of airflow pattern.

Step 2. Determine that no other air-moving devices are operating in or around clean room which disrupt room’s airflow

pattern.

Step 3. Check air velocity and if low, conduct the “Low Air Velocity” procedure outlined above.

Step 4. Conduct smoke and photometer test on HEPA/ULPA filter. Seal or replace HEPA/ULPA filter as necessary.

MAC 10 e3SERVICE MANUAL

PAGE 12 02/05/03

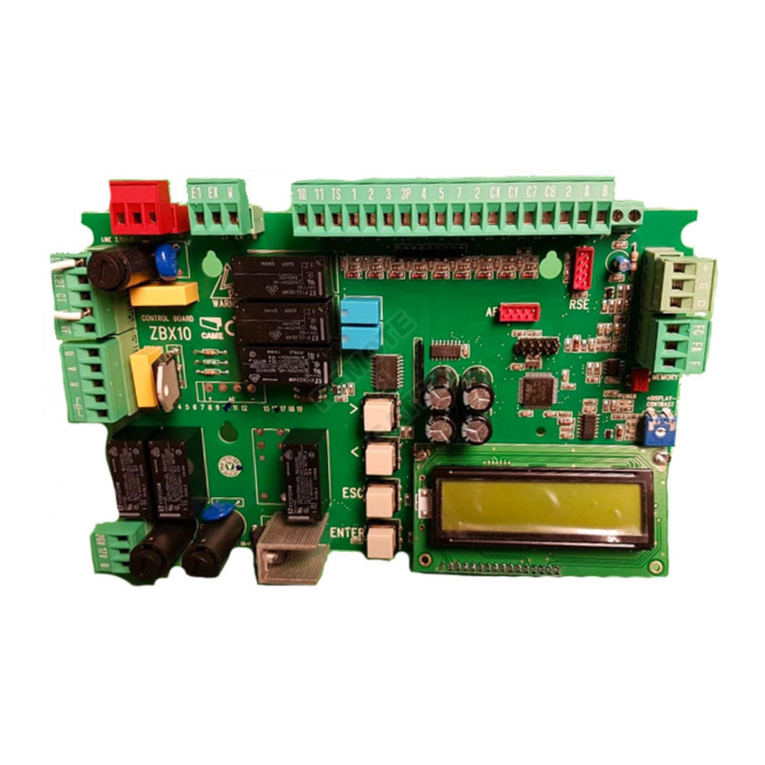

IX. MAC 10 e3 Wiring Diagrams

Figure 10

Wiring Diagrams

MAC 10 e3SERVICE MANUAL

PAGE 13 02/05/03

IX. MAC 10 e3 Wiring Diagrams (continued)

Figure 11

MAC 10 e3SERVICE MANUAL

PAGE 14 02/05/03

X. MAC 10 e3 Replacement Parts List :

Description Quantity ENVIRCO part number

per unit 115V 220V 277V

______________________________________________________________________________

Prefilter 18.25 x 18.25 x 1 1 63527 63527 63527

Motor/Blower 1 63432 63433 63434

Capacitor 1 94505 61409 63164

On / Off Switch 1 63518 63518 63518

Speed Control 1 63011 63015 63016

HEPA filter(STANDARD) :

2’ x 4’ 1 69495-001 69495-001 69495-001

ULPA filter(Option) :

2’ x 4’ 1 69495-002 69495-002 69495-002

HEPA filter(RSR Option) :

2’ x 4’ 1 69391-001 69391-001 69391-001

Optional Accessories :

Power cord

Fluorescent lighting

Ionizing bar

12”(30.48 cm) diameter A/C intake collar

208-240 V, 50-60 HZ motor

277 V, 60 HZ motor

Gel seal filter(RSR unit only)

ULPA filter(Standard and RSR)

Replacement parts are available through your authorized ENVIRCO representative. If you cannot locate a representative

in your area, contact Customer Service at :

ENVIRCO CORPORATION

5601 Balloon Fiesta Pkwy, NE

Albuquerque, NM 87113, U.S.A.

Tel : (505) 798-4403

Fax : (505) 345-8875

MAC 10 e3SERVICE MANUAL

PAGE 15 02/05/03

XI. LIMITED WARRANTY

ENVIRCO CORPORATION (“ENVIRCO”) warrants the equipment will be free of defects in materials and

workmanship under normal use for a period of three(3) years. The HEPA filter shall only be warranted against loading

for a period of two(2) years when operated in clean room conditions. ENVIRCO’s sole obligation under this warranty is

to repair or replace any parts of the equipment which are defective for a period of three(3) years from the invoice date,

provided that the repair or replacement is actually performed within the three(3) year period from the invoice date. The

buyer agrees to assume any incidental expenses including but not limited to the cost of transporting the defective

equipment to ENVIRCO’s repair facility. The buyer’s sole remedy under this limited warranty is the repair or

replacement of any defective part of the equipment. ENVIRCO DISCLAIMS ANY IMPLIED WARRANTIES

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. In no

event shall ENVIRCO be liable for punitive, incidental, or consequential damages arising out of this sale, including, but

not limited to damage to persons or property, loss of use, loss of time, inconvenience, equipment rental, loss of earnings

or profit or any other commercial loss. This warranty excludes certain expendable items such as light tubes, prefilters,

etc. ENVIRCO expressly disclaims and excludes from this warranty any responsibility for equipment failures and/or

defects attributable to improper maintenance, abuse, accident or modification of the equipment (such as application of

an adjustable frequency drive).

MAC 10 e3SERVICE MANUAL

PAGE 16 02/05/03

XII. TESTING

Each MAC 10 e3filter unit is thoroughly tested at the factory before shipment. However,

because of the “rigors” of shipping, ENVIRCO encourages its re-test after installation.

ENVIRCO recommends that the customer contact an independent organization, with

technicians trained and experienced in performance evaluation and maintenance of clean

air equipment.

Some of the testing procedures performed on the MAC 10 e3include aerosol challenge

of HEPA filters to assure specified performance, along with air velocity measurement and

adjustment tests.

For more information on testing procedures, contact :

ENVIRCO CORPORATION

5601 Balloon Fiesta Parkway NE

Albuquerque, New Mexico 87113, U.S.A.

Tel : (800) 545-6598

Fax : (505) 345-8875

ENVIRCO CORPORATION

Eastern Regional Office

1185 Mt. Aetna Rd.

Hagerstown, Maryland 21740, U.S.A.

Tel : (800) 645-1610

Fax : (301) 714-4784

Table of contents

Other Envirco Control Unit manuals